Energy-storage heating and warming fiber and preparation method thereof

A thermal fiber and fiber technology, applied in the fiber field, can solve the problems of large difference in heating performance, poor heat absorption efficiency, limited heat, etc., and achieve the effects of improving human immunity, improving comfort, and good temperature response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: A preparation method of an energy-storing heat-retaining fiber:

[0026] (1) Preparation of inorganic exothermic particle modified polymer fiber-forming polymer

[0027] 99.9 parts of PET and 0.1 part of 1000-mesh zirconium carbide powder were uniformly mixed and dried. Under the condition of 250°C, twin-screw blending and granulation was carried out to prepare inorganic heating particle modified polymer fiber-forming material slices.

[0028] (2) Preparation of energy-storing heat-generating fiber:

[0029] Using conventional polyester staple fiber production equipment and a special spinneret for hollow fibers to produce hollow fibers with a single-hole circular cross-section, 100 pieces of the prepared inorganic heating particle-modified polymer fiber-forming material slices are dried, melt-spun, and bundled. , drafting, shaping, cutting, and packaging, and the spinning temperature is 290 ° C, that is, the energy-storing heat-generating thermal fiber is pr...

Embodiment 2

[0043] Example 2: A preparation method of an energy-storing heat-generating fiber:

[0044] (1) Preparation of inorganic exothermic particle modified polymer fiber-forming polymer

[0045] Mix 99.8 parts of PBT with 0.1 part of 1000-mesh zirconium carbide powder and 0.1 part of 2000-mesh far-infrared ceramic powder and dry them. Under the condition of 235°C, they are blended and granulated by twin-screw to prepare modified inorganic heat-emitting particles. High molecular fiber-forming polymer chips.

[0046] (2) Preparation of energy-storing heat-generating fiber:

[0047] Dry, melt-spin, bundle, draw, shape, cut, and package 100 parts of the prepared inorganic heat-generating particle-modified polymer fiber-forming polymer chips. The spinning temperature is 260°C, and the energy-storing, heating-warming product is prepared. fiber.

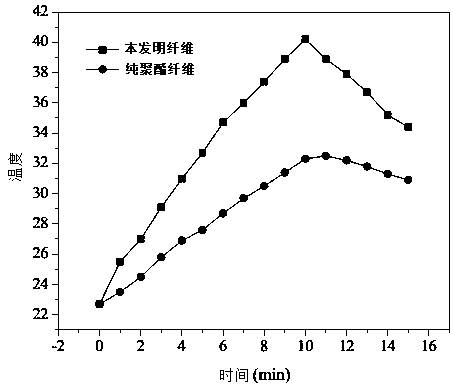

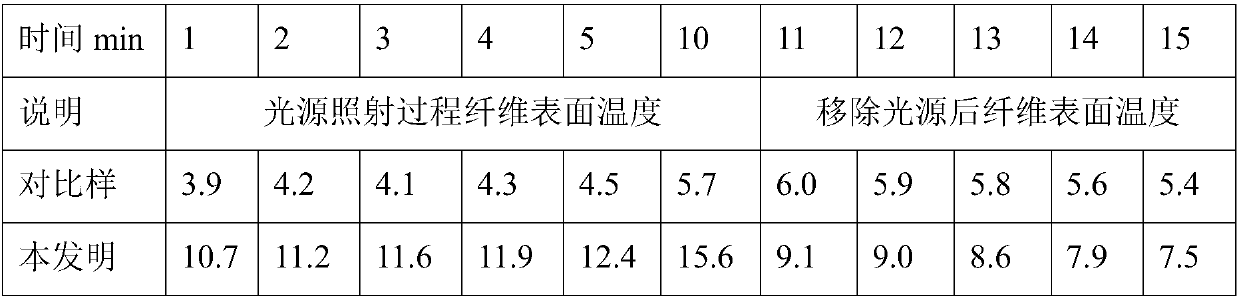

[0048] Carry out the performance test to the prepared energy-storage heat-generating warm-keeping fiber, compare it with pure polyester stapl...

Embodiment 3

[0053] Example 3: A preparation method of an energy-storing heat-generating fiber:

[0054] (1) Preparation of inorganic exothermic particle modified polymer fiber-forming polymer

[0055] Mix 80 parts of PA66 with 5 parts of 3000-mesh silicon carbide powder and 15 parts of 1000-mesh zirconium carbide powder and dry them. Under the condition of 240℃, they are blended and granulated by twin-screw to prepare inorganic heat-emitting particles. Molecular fiber-forming material masterbatch.

[0056] (2) Preparation of energy-storing heat-generating fiber:

[0057] Mix and dry 10 parts of prepared inorganic heat-generating particle-modified polymer fiber-forming material slices and 90 parts of conventional polymer fiber-forming material, melt spinning, clustering, drafting, shaping, cutting, packaging, and the spinning temperature is 290 ℃, that is, the energy-storing heat-generating thermal fiber is prepared.

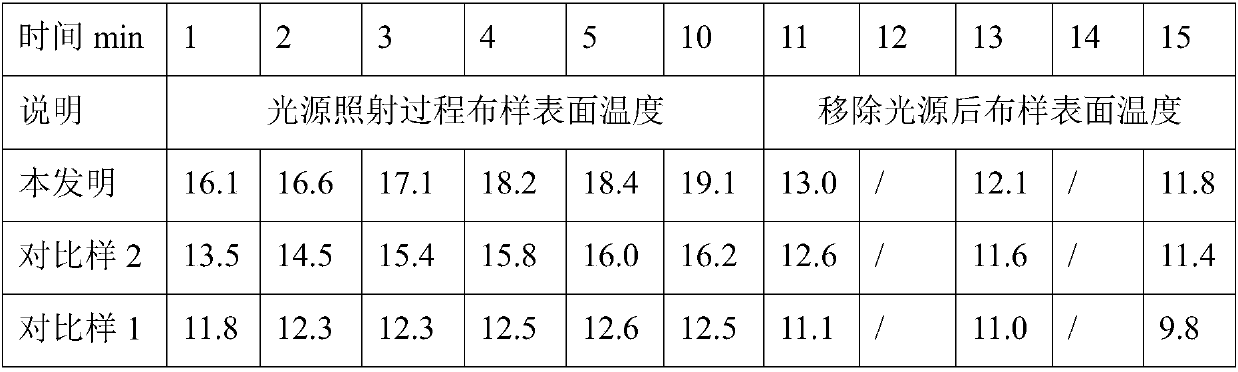

[0058] Since the human body radiates far-infrared heat with a wavele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com