Valve element assembling structure for double-valve element EGR valve

A technology of EGR valve and double spool, applied in the direction of charging system, engine components, exhaust gas recirculation, etc., can solve the problems of low work efficiency, complicated process, high cost, etc., to improve production quality, simplify process, and reduce production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with specific embodiments.

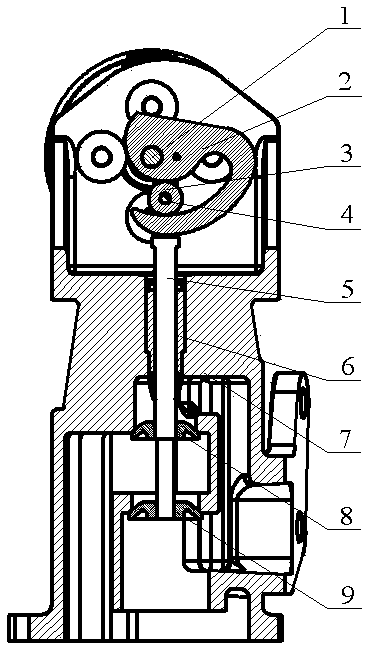

[0014] A kind of spool assembly structure of double spool EGR valve, its structure is as follows figure 1 As shown, it includes a motor 1, a drive plate 2, a center rod 5, a valve body assembly 7, a small spool 8 and a large spool 9. The motor 1 is set on the electric EGR valve, the central rod 5 is inserted inside the valve body assembly 7, and the middle and lower parts of the central rod 5 are respectively provided with a small valve core 8 and a large valve core 9, a small valve core 8 and a large valve core. The core 9 cooperates with the sealing port of the valve seat to improve the sealing performance of the EGR valve. The drive plate 2 is arranged in the valve seat above the center rod 5. The drive plate 2 is a cam structure. One end of the drive plate 2 connects with the motor 1 through the rotating shaft. The other end of the drive plate 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com