Battery box, battery pack and vehicle

A battery box and box technology, which is applied to large-sized batteries/battery packs, small-sized batteries/battery packs, battery pack components, etc. The improvement of energy density and the incompatibility with the lightweight of automobiles can meet the requirements of power performance and cruising range, reduce the types and quantities, and prevent excessive deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

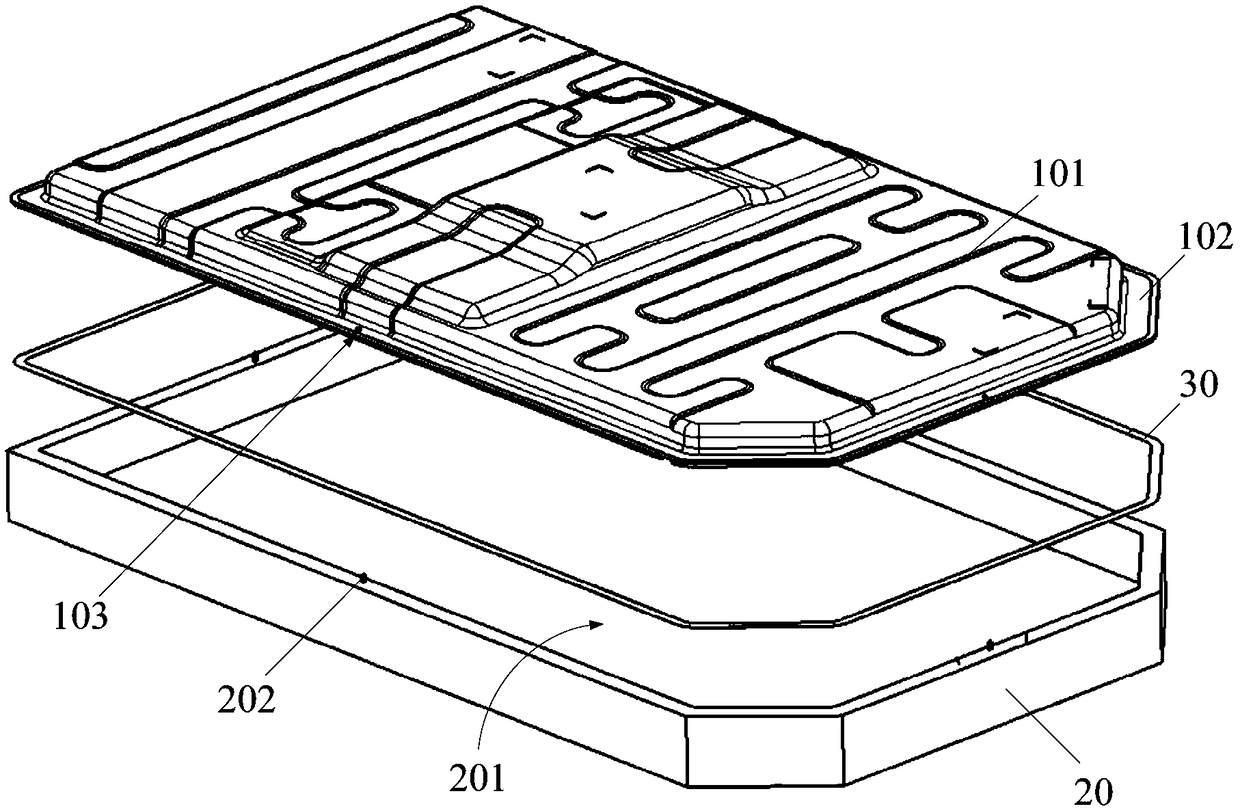

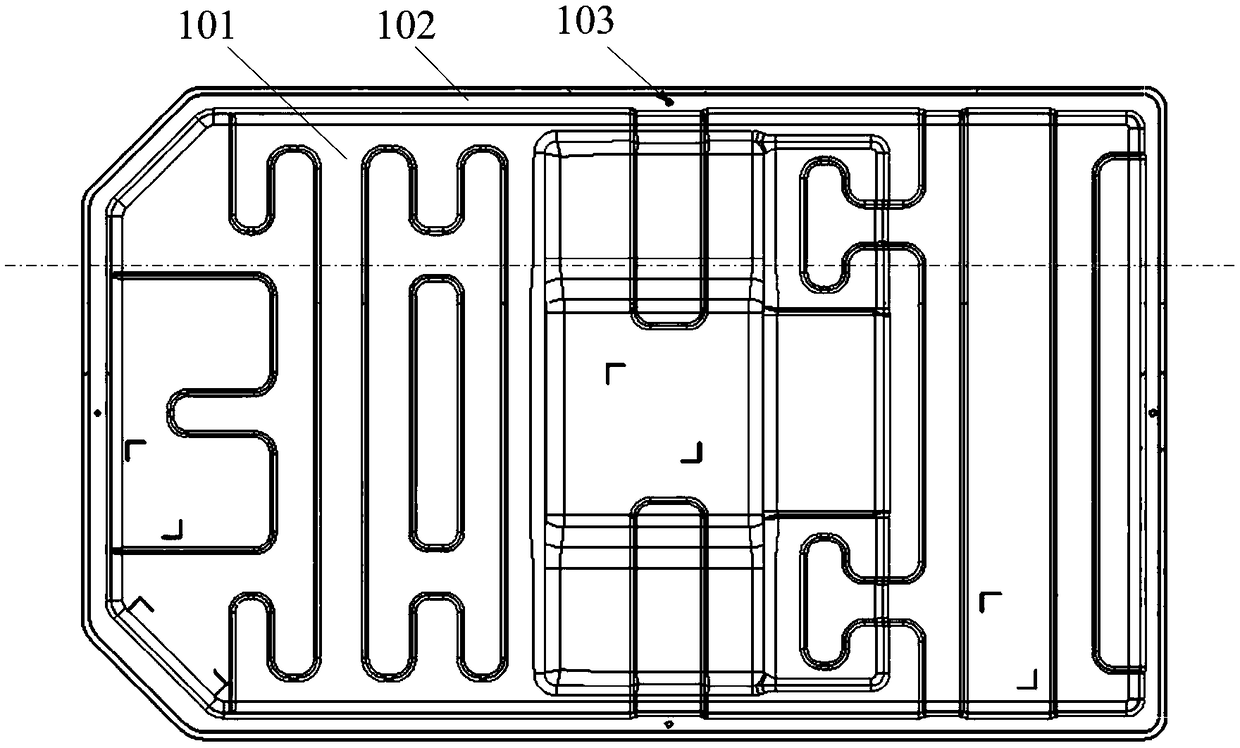

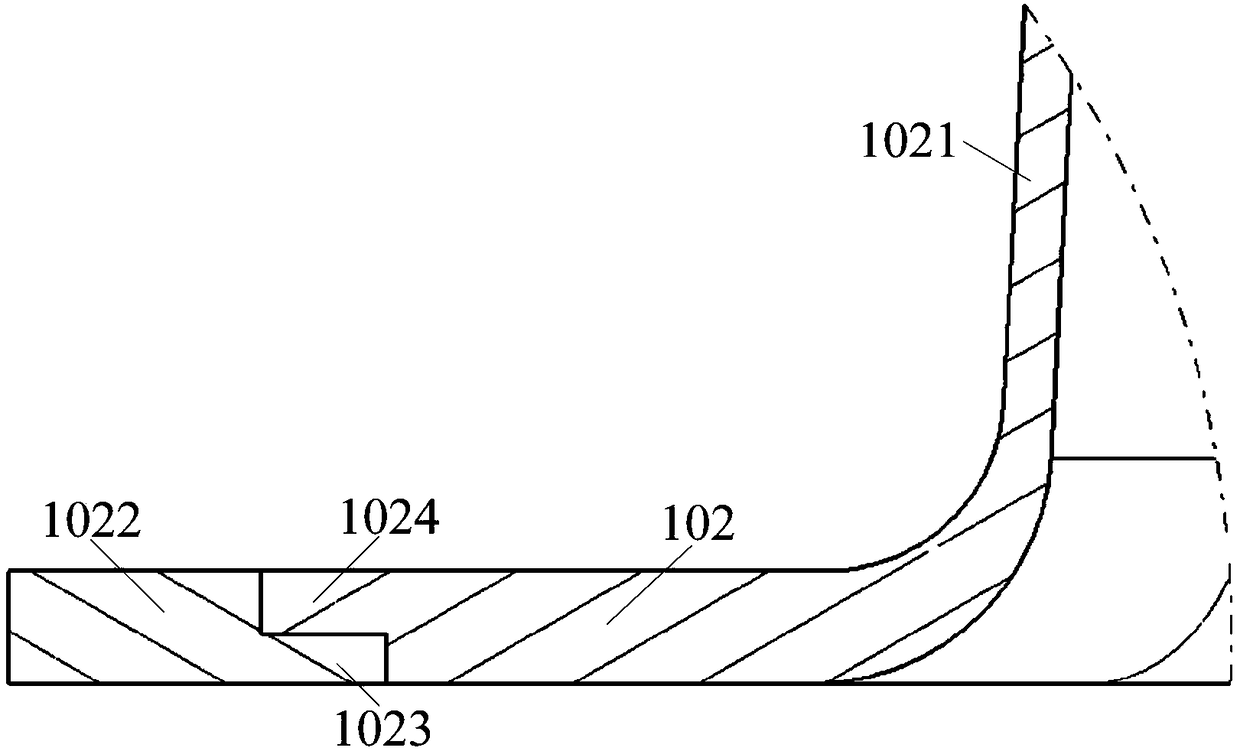

[0075] The cover body 101 has a cover edge 102, and the edge of the cover edge 102 is formed as the outer edge of the cover body 101, such as Figure 3 to Figure 6 As shown, the cover edge 102 is tightly connected to the flange surface.

[0076] The cover body 101 has a cover edge 102, the edge of the cover edge 102 is formed as the outer edge of the cover body 101, and the sealing member 1022 is connected with the outer edge of the cover edge 102, as Figure 3 to Figure 6 As shown, and the cover edge 102 is tightly connected with the flange surface, it not only realizes the fast connection between the box cover 10 and the box body 20, but also plays a good supporting role for the seal 1022, which can effectively prevent the seal 1022 from excessively deformation, to ensure that the sealing member 1022 fits stably with the flange surface, thereby improving the sealing reliability.

[0077] Further, one of the cover edge 102 and the flange surface is provided with a plurality ...

Embodiment 2

[0091] The difference from Embodiment 1 is that: the first overlapping portion 1023 is on the top, and the second overlapping portion 1024 is on the bottom. The principle is basically the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0093] The difference from Embodiment 1 or Embodiment 2 is that: there are multiple first overlapping portions 1023; or, there are multiple second overlapping portions 1024, such as Figure 5 shown.

[0094] The number of the first overlapping portion 1023 is multiple, that is, the sealing member 1022 is provided with a plurality of first overlapping portions 1023 protruding toward the cover body 101, and the plurality of first overlapping portions 1023 are all connected to the second overlapping portion 1024. (can be one or more) fit together, which further increases the contact area between the sealing member 1022 and the cover body 101, thereby further improving the connection strength between the sealing member 1022 and the cover body 101, and further improving the use of the box cover 10 reliability.

[0095] Similarly, the number of the second overlapping portions 1024 is multiple, that is, the cover body 101 is provided with a plurality of second overlapping portions 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com