Simulative analysis method for hot riveting process of automobile thrust rod

A technology of process simulation and analysis method, which is applied in the field of simulation analysis of automobile thrust rod hot riveting process, can solve the problems of unfavorable product development cycle and development cost, long batch production and finalization cycle, high cost of trial production test, etc., to reduce the number of process trial production , shorten the trial production cycle, improve the effect of trial production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

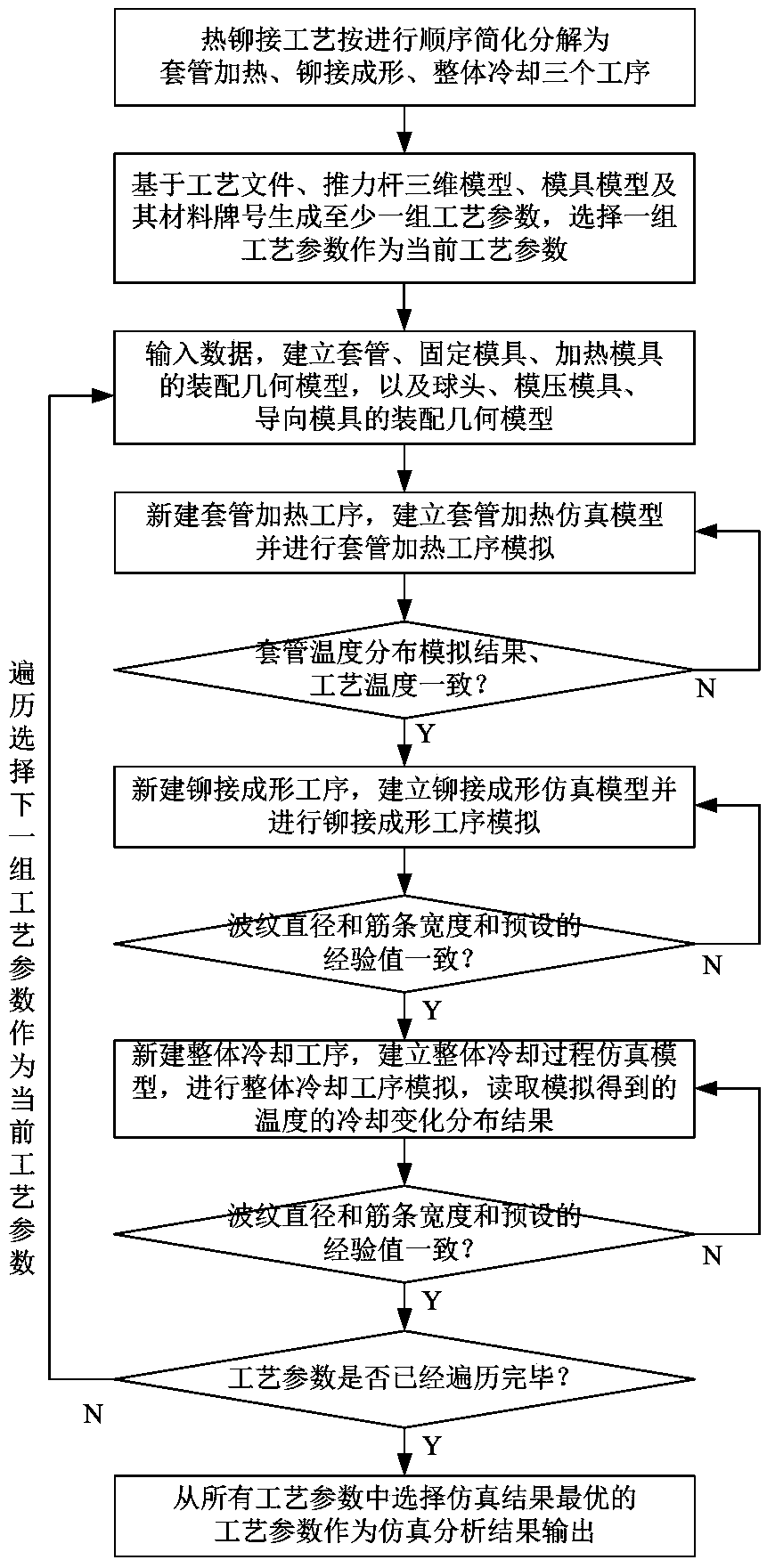

[0030] like figure 1 As shown, the implementation steps of the simulation analysis method for the hot riveting process of the automobile thrust rod in this embodiment include:

[0031] 1) The automotive thrust rod thermal riveting process used to thermally rivet the sleeve and ball head into an automotive thrust rod is simplified and decomposed into three processes: sleeve heating, riveting forming, and overall cooling, based on process documents, three-dimensional thrust rod The model, the mold model and its material grade generate at least one set of process parameters, and select a set of process parameters as the current process parameters.

[0032]2) Obtain the input data including the process file corresponding to the current process parameters, the three-dimensional model of the thrust rod, the mold model and its material grade, and establish the assembly geometric model of the sleeve, the fixed mold, and the heating mold. The fixed mold is used in the In the casing he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com