Fabrication method of trench Schottky device

A manufacturing method and groove technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of high cost of anode injection process, high requirements of anode injection process, increase of manufacturing cost of trench Schottky devices, etc. problem, to achieve the effect of reducing process cost, high removal efficiency and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

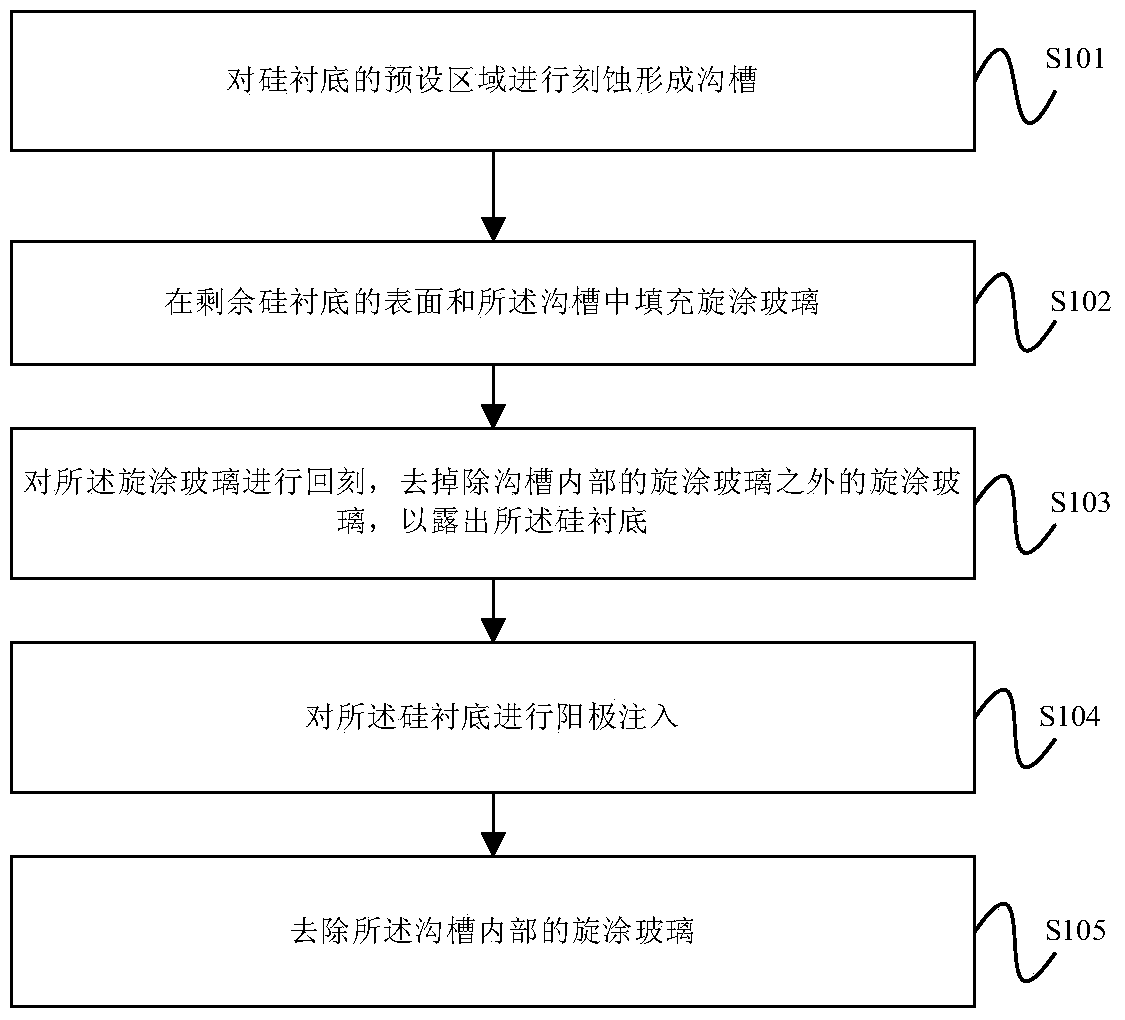

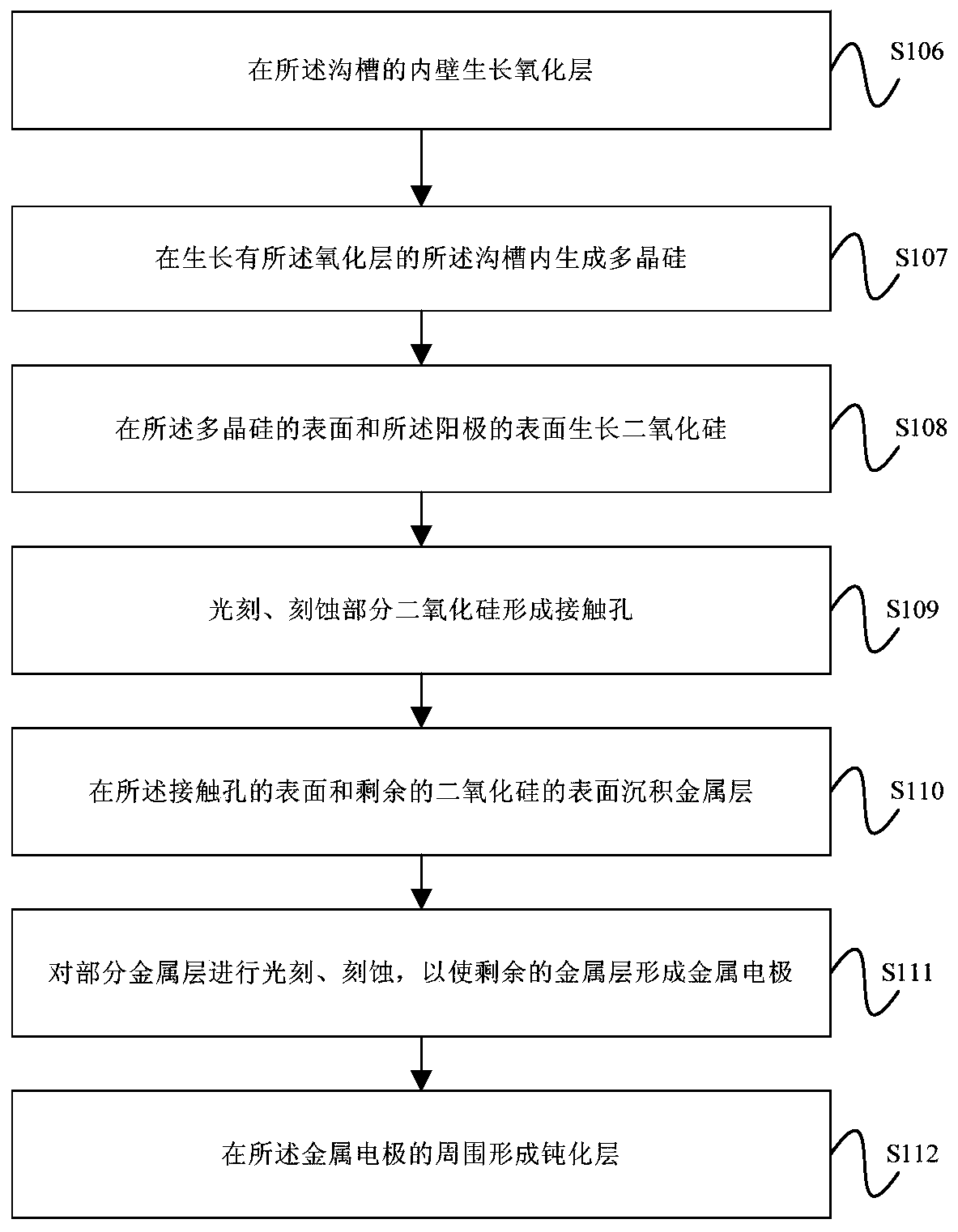

[0029] Figure 1A A flowchart of a method for fabricating a trench Schottky device provided by an embodiment of the present invention. In order to describe the method in this embodiment clearly and systematically, Figure 2-Figure 7 A schematic cross-sectional view of a trench Schottky device during the implementation of the method of the embodiment of the present invention, as shown in Figure 1A As shown, the method includes:

[0030] Step S101, etching a preset region of the silicon substrate to form a trench;

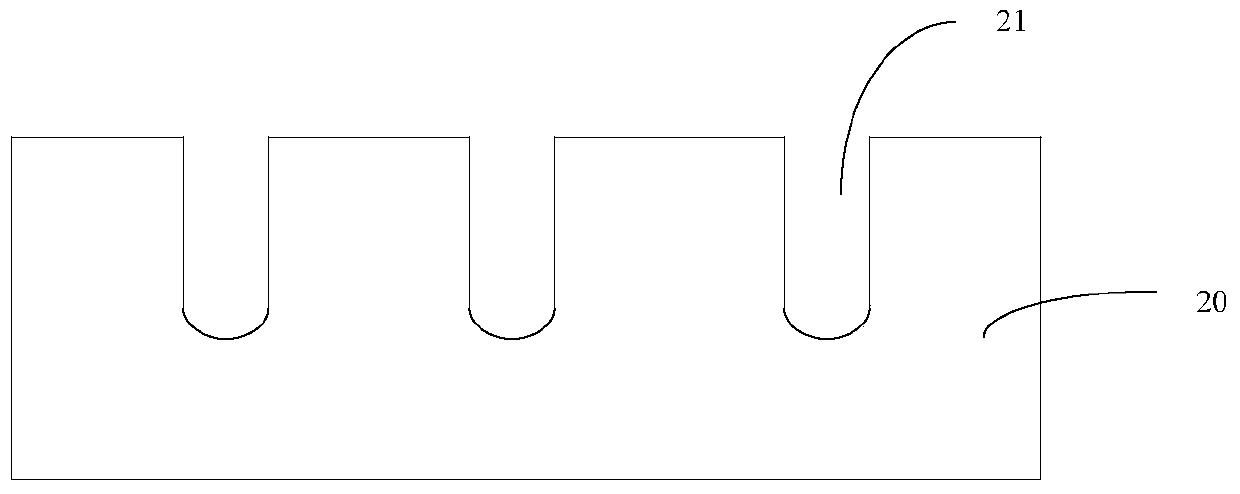

[0031] Coat photoresist on the surface of the silicon substrate, and form grooves by exposing, developing, and etching part of the photoresist. This embodiment does not limit the number of grooves, and the number of optional grooves is as follows Figure 1A 3 shown. The schematic cross-sectional view of the trench Schottky device after performing step S101 is as follows: figure 2 As shown, wherein, the silicon substrate is indicated by 20, and the trench is indic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com