Rocking green tea processing technology

A processing technology and technology of green tea, which is applied in the field of tea beverages, can solve the problems of dark soup, increased tea aroma substances, short aroma, etc., achieve strong floral and fruity aromas, maintain a complete shape, and improve permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

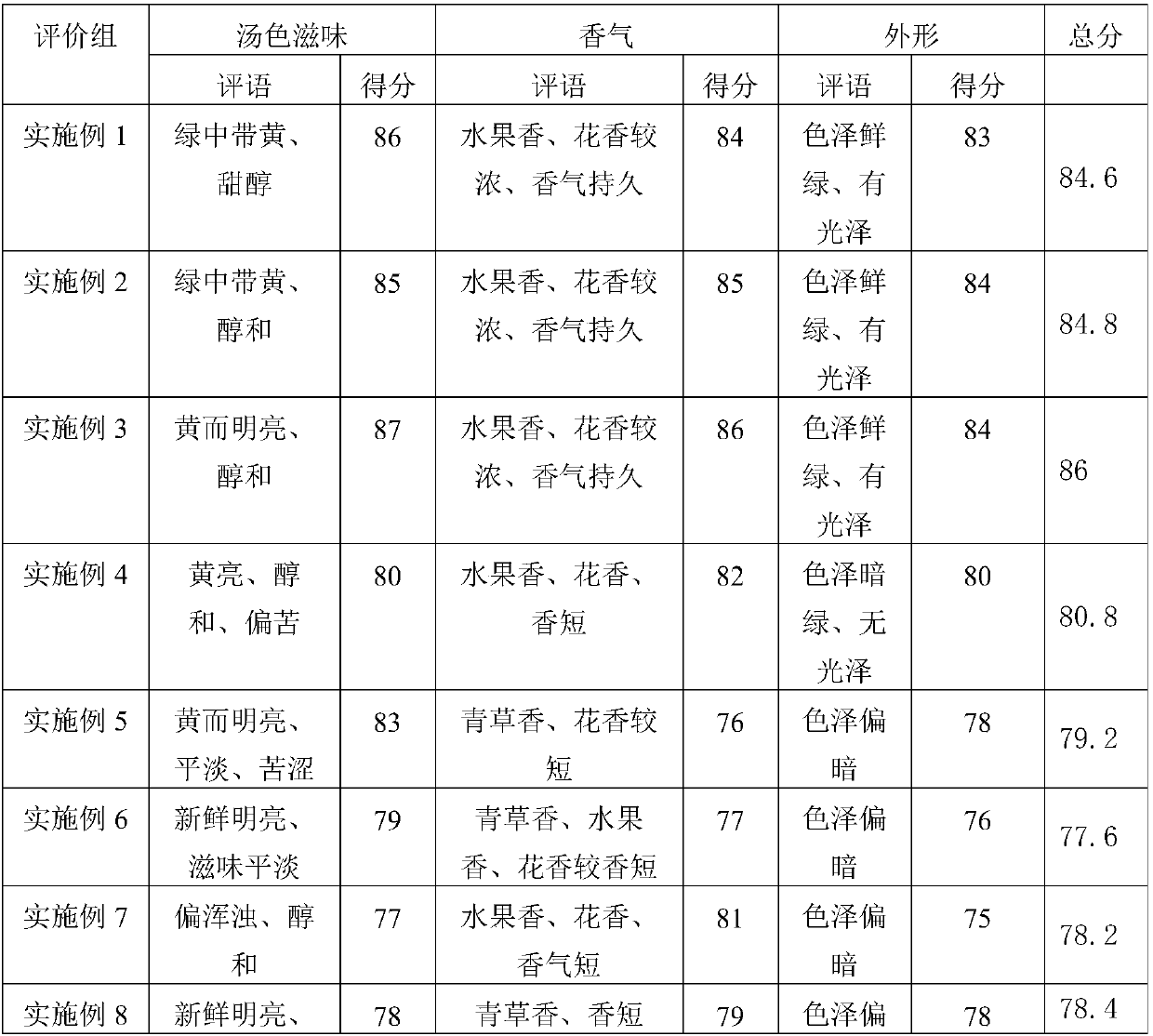

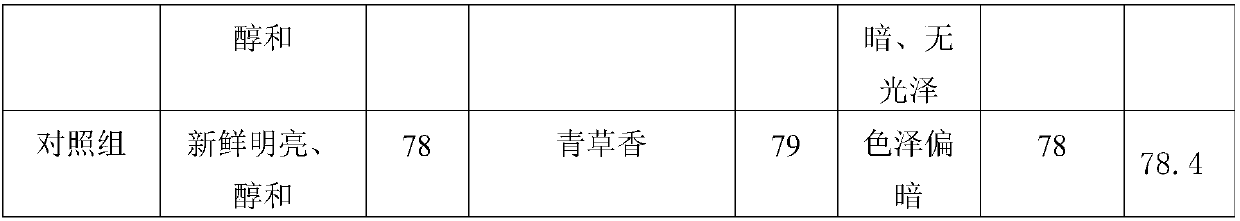

Examples

Embodiment 1

[0033] A processing technology for shaking green tea, comprising the following steps:

[0034] 1) Material preparation: take fresh leaves with one bud and one leaf or one bud and two leaves as raw materials and wash them for later use;

[0035] 2) Sun drying; the tea leaves are dried at 16:30-17:30, the thickness of the tea leaves is 10cm, and the tea leaves are turned twice during the period;

[0036] 3) withering: the tea leaves obtained in step 2) are spread out on the withering tank, the thickness is 8cm, the hot air temperature is 26°C, and the tea leaves are blown until the moisture content of the tea leaves is 70%;

[0037] 4) shaking green: step 3) the tea leaves and additives obtained are shaken green according to the mass ratio of 37.5:3.6;

[0038] 5) deenzyming: the tealeaves of step 4) gained, under the vacuum degree of 500Pa, the microwave power of 41.5KW decapitation 1.5min, obtain decapitation leaf;

[0039] 6) Kneading: knead the green leaves after drying to...

Embodiment 2

[0057] A processing technology for shaking green tea, comprising the following steps:

[0058] 1) Material preparation: take fresh leaves with one bud and one leaf or one bud and two leaves as raw materials and wash them for later use;

[0059] 2) Sun drying; the tea leaves are sun dried at 16:30-17:30, the thickness of the tea leaves is 12cm, and the tea leaves are turned twice during the period;

[0060] 3) withering: the tea leaves obtained in step 2) are spread on the withering tank, the thickness is 10cm, the hot air temperature is 27°C, and the tea leaves are blown until the moisture content of the tea leaves is 72%;

[0061] 4) shake green: step 3) gained tealeaves and additive are carried out shake green according to mass ratio 38.5:3.9;

[0062] 5) deenzyming: with the tealeaves of step 4) gained, under the microwave power that vacuum degree is 550Pa, 42.0KW, decapitate 1.8min, obtain decapitation leaf;

[0063] 6) Kneading: knead after drying the green leaves to 27...

Embodiment 3

[0081] A processing technology for shaking green tea, comprising the following steps:

[0082] 1) Material preparation: take fresh leaves with one bud and one leaf or one bud and two leaves as raw materials and wash them for later use;

[0083] 2) Sun drying; drying the tea leaves at 16:30-17:30, spreading the tea leaves to a thickness of 14cm, and turning the tea leaves 3 times during the period;

[0084] 3) Withering: the tea leaves obtained in step 2) are spread on the withering tank, the thickness is 12cm, the hot air temperature is 28°C, and the tea leaves are blown until the moisture content of the tea leaves is 75%;

[0085] 4) shake green: step 3) gained tea leaves and additive are carried out shake green according to mass ratio 40.7:4.3;

[0086] 5) deenzyming: with the tealeaves of step 4) gained, under vacuum degree is 580Pa, the microwave power of 42.6KW completes 2.2min, obtains decapitated leaves;

[0087] 6) Kneading: knead the leaves after drying to 30°C, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com