Pellets Food Forming Equipment

A food forming and food technology, which is applied in the field of pellet food equipment, can solve problems such as unfavorable processing and production, consuming manpower and man-hours, and achieves the effects of reducing processing costs, increasing production capacity, and reducing processing error rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

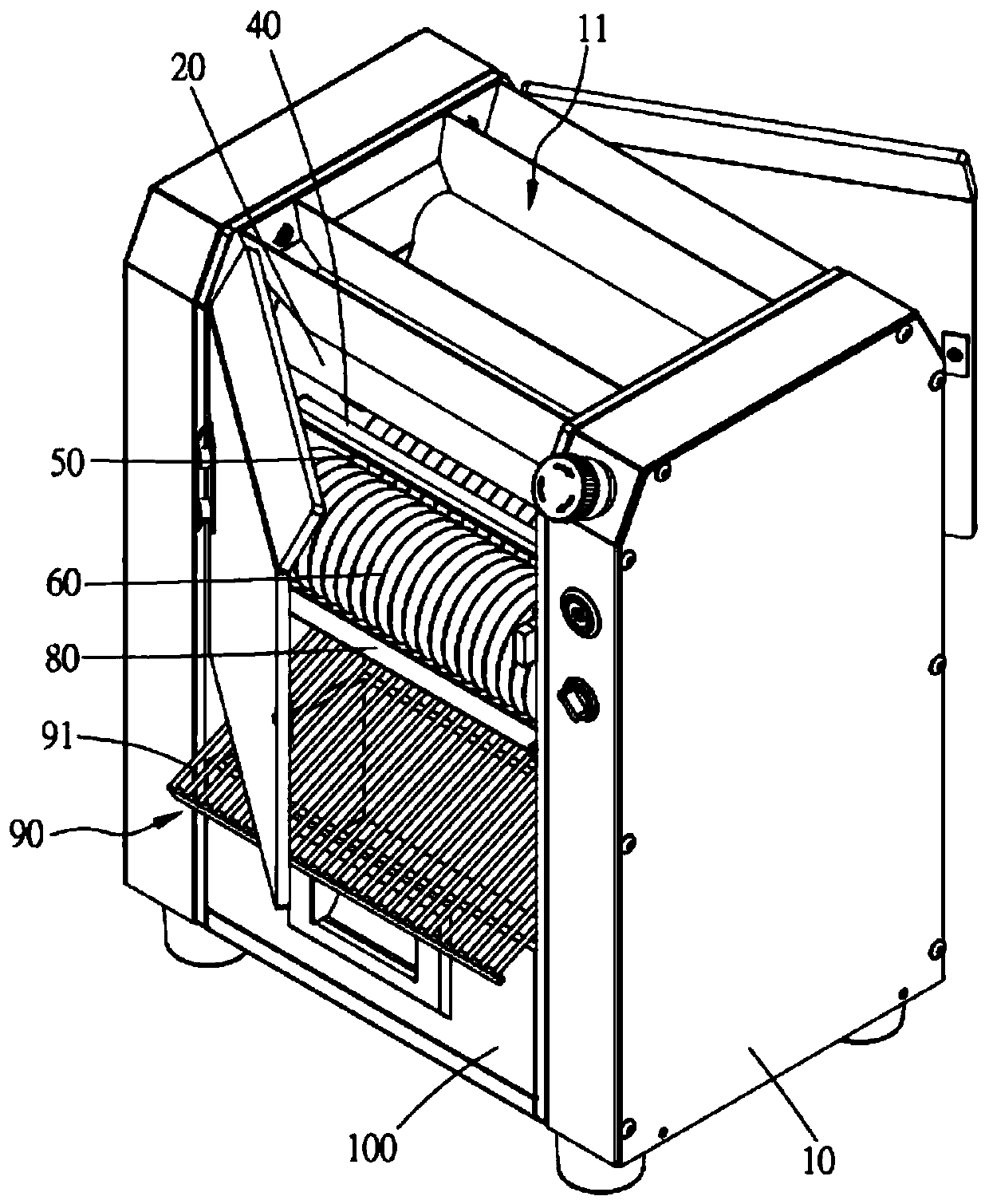

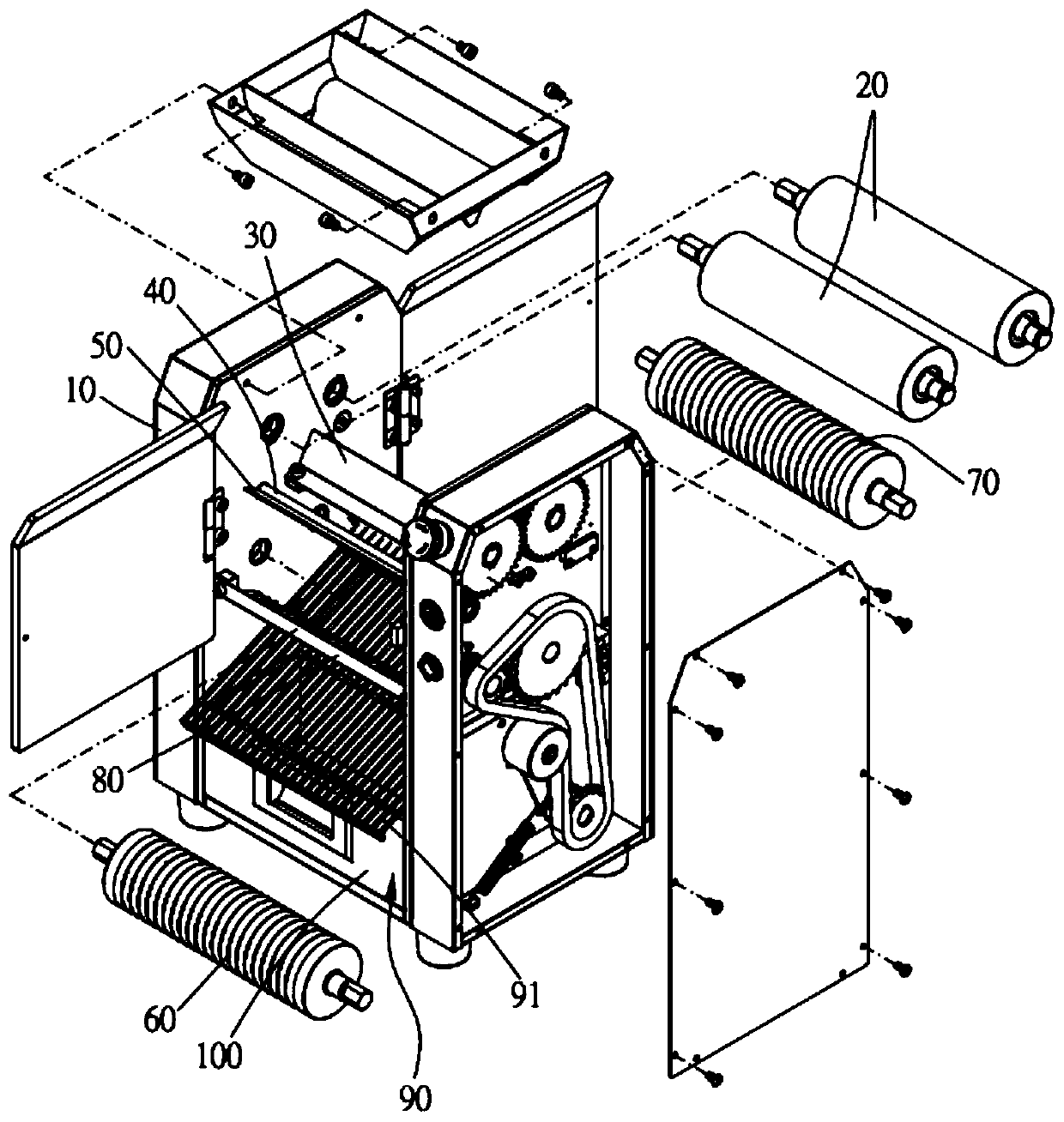

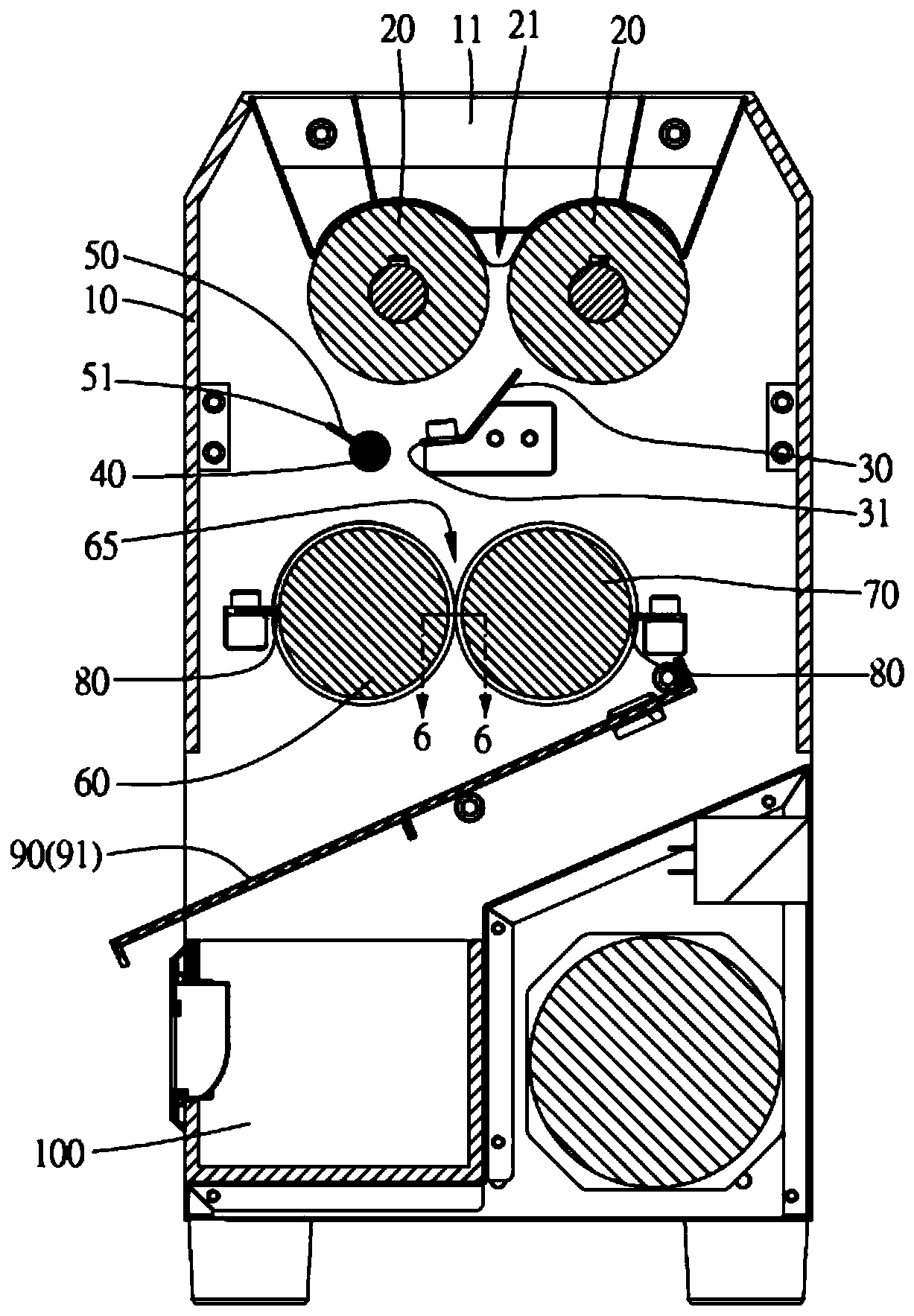

[0019] Please refer to Figs. 1 to 3, what is depicted is a preferred embodiment of the pill-shaped food forming equipment of the present invention, which comprises a housing 10, a pair of sheet-pressing rollers 20, a guide piece 30, a cutter roll 40, a cutter 50, a first pelletizing roller 60 and a second pelletizing roller 70. Wherein, the tableting roller 20, the knife roller 40, the cutting knife 50 and the first and second pelletizing rollers 60, 70 are all parallel to each other.

[0020] There are side plates on the left and right sides of the housing 10, and the front and rear sides are generally open. The top of the housing 10 has a tank 11, and the upper and lower sides of the housing 11 are open, preferably funnel-shaped. The outer casings on the left and right sides of the housing 10 can be provided with power and transmission mechanisms to drive the tablet roller 30, the cutter roller 40, the first pelletizing roller 60 and the second pelletizing roller 70 to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com