Jacking and quick-removing device for centering test of aircraft nose landing gear and its application method

A technology of nose landing gear and landing gear, which is applied in the direction of aircraft component testing, etc. It can solve the problem that the centering time of the nose landing gear has not been truly and effectively verified, the centering test of the nose landing gear does not meet the design requirements, and the measurement of the time of the nose landing gear Extending and other issues to achieve the effect of improving authenticity and reliability, convenient implementation, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

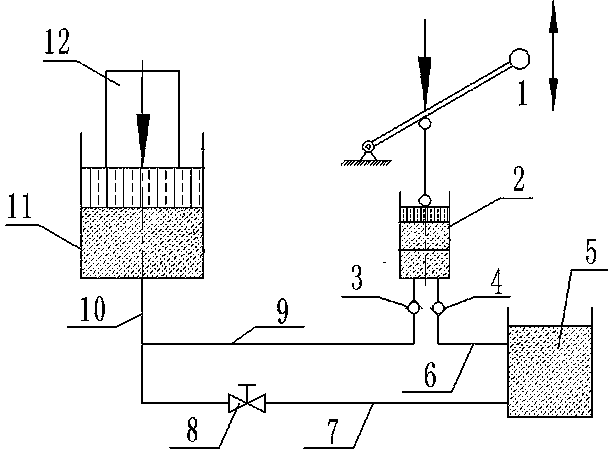

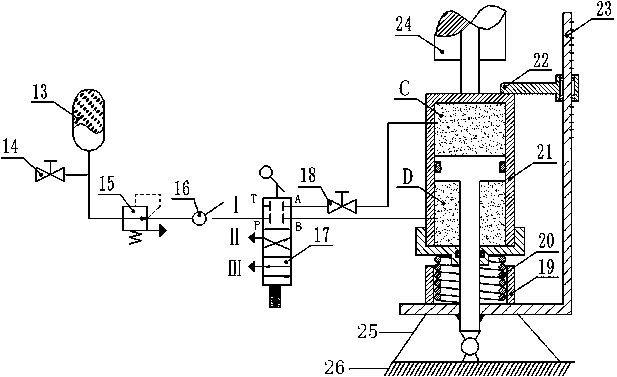

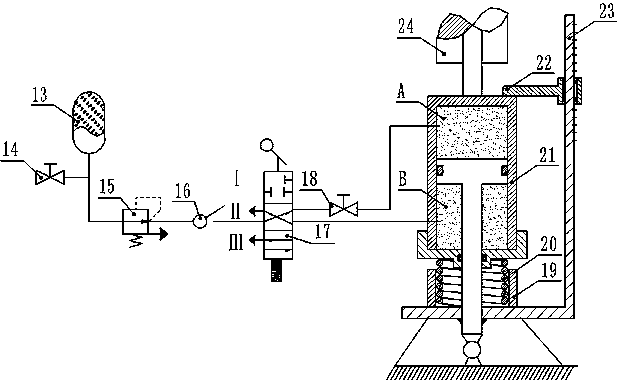

[0024] Such as figure 2 - Figure 4 As shown, a kind of jacking and quick-removal device used for the centering test of the aircraft front landing gear of the present invention includes a cylinder 21, which is installed on the working platform 25 upside down through the buffer spring 20, and the piston rod of the cylinder 21 The protruding end passes through the buffer spring 20, and the working platform 25 is fixedly connected with the working level 26. The top of the cylinder 21 is used to butt against the front landing gear. The buffer spring 20 at the bottom of the cylinder 21 is arranged on the reference platform of a stroke scale 23, and the horizontal mark 22 of the stroke scale 23 is freely lapped on the top of the cylinder 21, and moves on the stroke scale as the cylinder 21 moves up and down. Slide on the vertical pole of chi 23, like this, the moving distance of horizontal pole 22 is equal to the moving distance of cylinder 21 relative to vertical pole. The rodl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com