Nonel detonator automatic assembly line and assembly method

A technology of automatic assembly and detonator, which is applied to detonators, offensive equipment, etc., can solve the problems of automatic processing of basic detonators, automatic assembly of detonators, and inability to realize automatic processing of detonators, so as to improve safety and save assembly. cost, the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

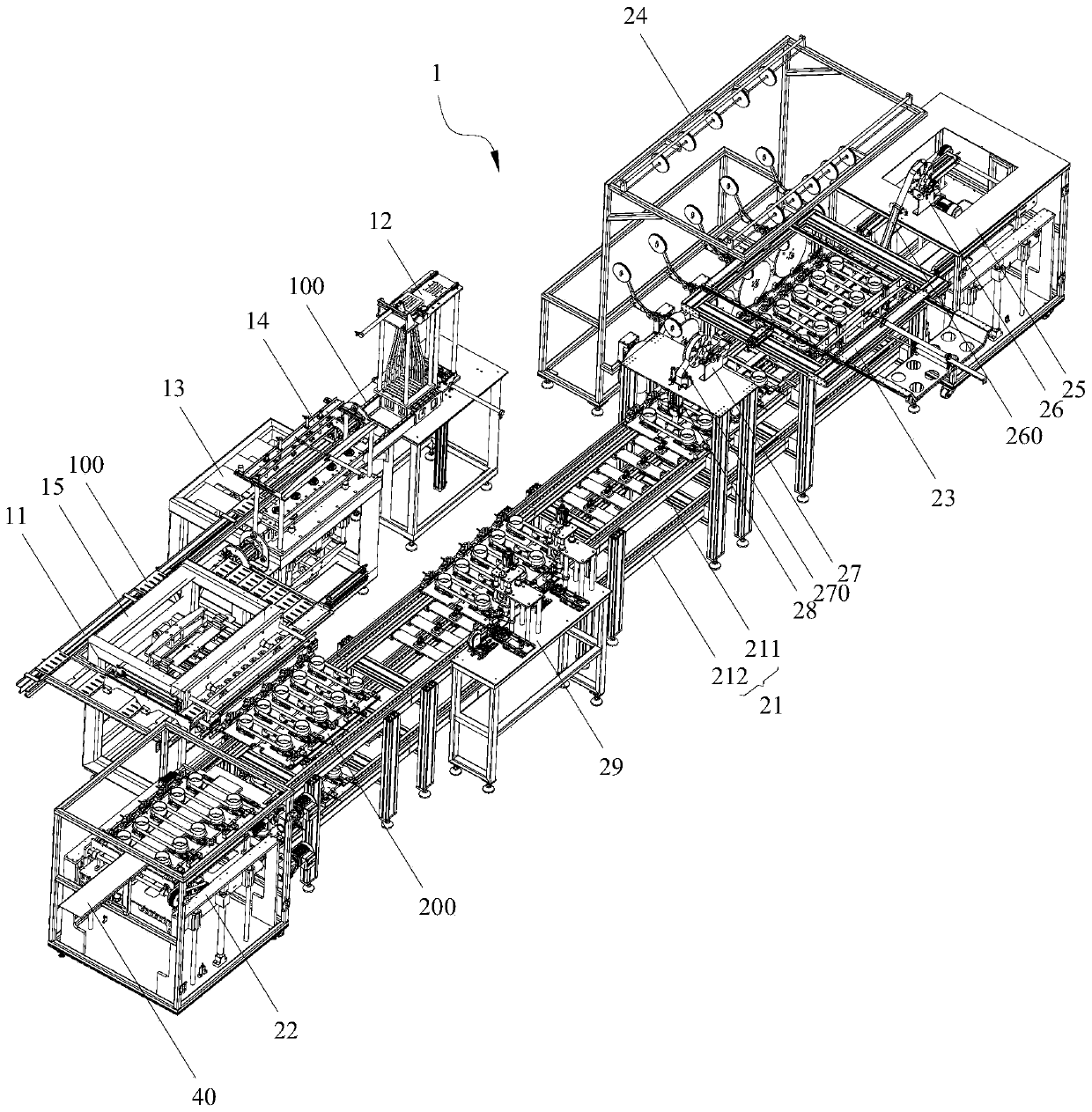

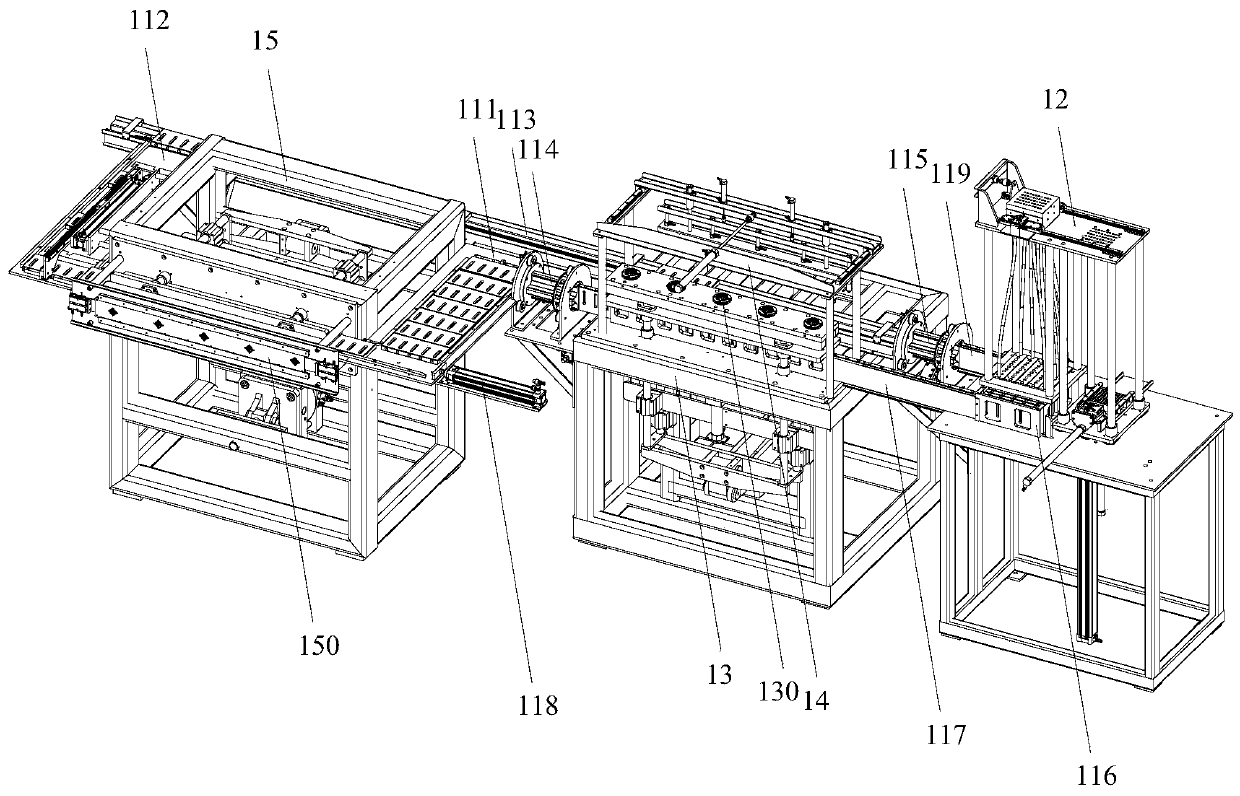

[0057] see figure 1 and image 3 , the nonel detonator automatic assembly line 1 includes a first transmission device 11, a second transmission device 21, a mold transfer device 12, a waist clamping device 13, a rubber plug assembly device 14, a material sorting device (not shown), a card Mouth device 15, coding device (not shown), first lifting device 22, winding device 23, pay-off device 24, second lifting device 25, first film feeding device 26, second film feeding device 27, hot cutting Device 28 and heat-sealing labeling device 29, wherein, the first conveying device 11 is used for conveying detonator carrier 100; The second conveying device 21 is positioned at the side of first conveying device 11, is used for conveying nonel wrapping platform 200, The rotary mold device 12 is connected to one end of the first transmission device 11, and is used to arrange and place the basic detonators 2 loaded with delay elements (not shown) in the detonator carrier 100; The rotary m...

Embodiment 2

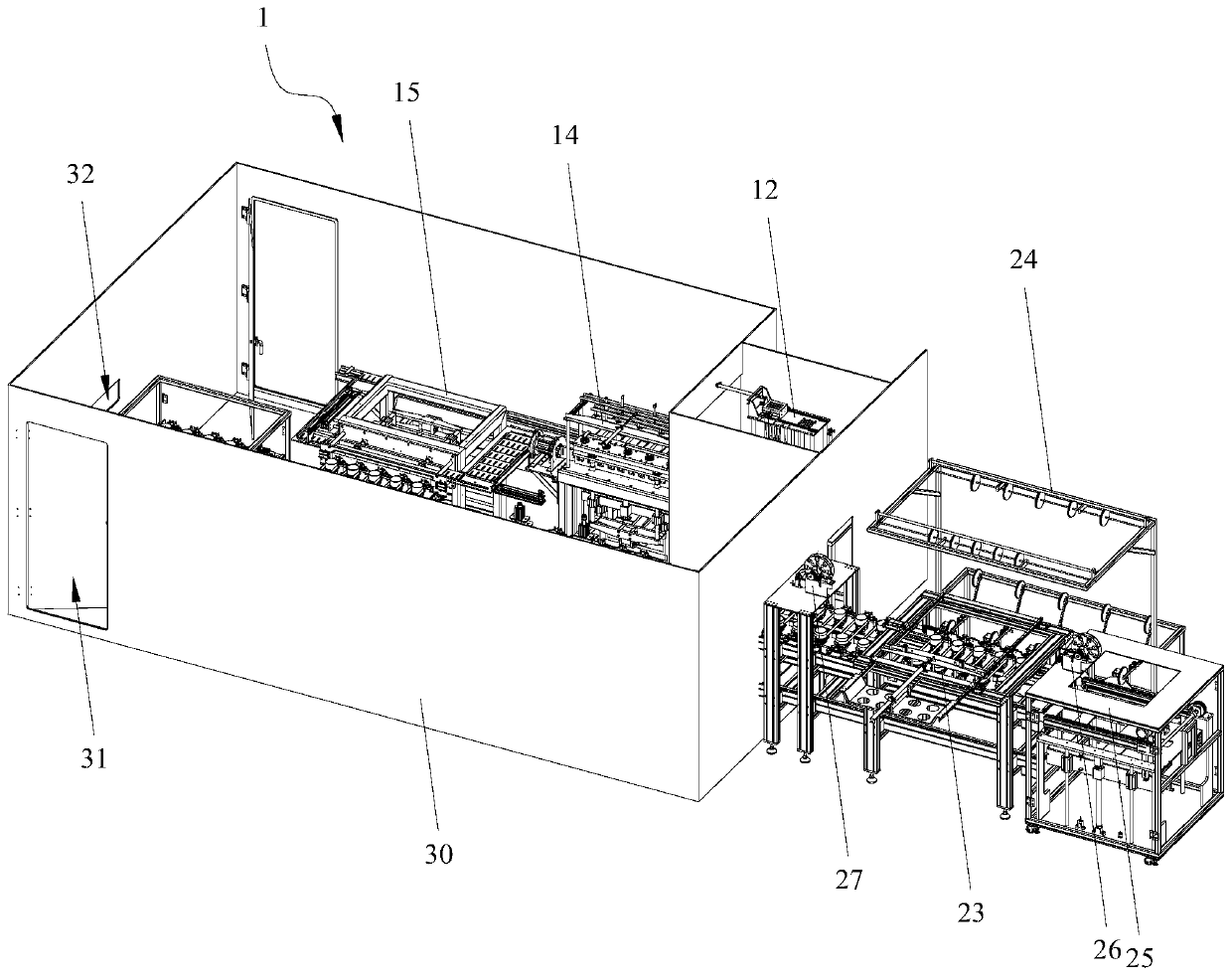

[0082] see figure 2 , the nonel detonator automatic assembly line provided by the embodiment of the present invention is basically the same as the nonel detonator automatic assembly line disclosed in Embodiment 1, the difference is that the nonel detonator automatic assembly line 1 also includes a protection room 30, The protection room 30 is used to enclose the basic detonator processing area and the nonel detonator assembly area, thereby improving the safety of the basic detonator processing and nonel detonator assembly processes. Specifically, the first conveying device 11, the rotary mold device 12, the waist clamping device 13, the rubber plug assembly device 14, the material sorting device, the coding device, the bayonet device 15, the first lifting device 22, and the heat-sealing and labeling device 29 are evenly distributed in the protection room 30 , and one end of the second transmission device 21 protrudes into the protection room 30 . It can be understood that: t...

Embodiment 3

[0084] see Figure 8 The nonel detonator automatic assembly method provided by the embodiment of the present invention is basically the same as the nonel detonator automatic assembly method disclosed in Embodiment 1, the difference is that step S30 is an intermediate step connecting step S126 and step S20, and belongs to Nonel processing part. Specifically, in step S30, the fourth conveyor belt 211 sends the detonating tube winding platform 200 completed in step S126 to a position opposite to the heat-sealing labeling device 29, and then the heat-sealing labeling device 29 wraps one end of the detonating tube 3 Carry out thermocompression sealing, and label 5 is cut off from label roll, sticks on the sealing end of detonator tube 3, completes detonator tube processing; Then enter step S20, in step S20, the 4th conveyor belt 211 will be finished The detonating tube winding platform 200 in step S30 is sent to the position opposite to the bayonet device 15, and then the bayonet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com