Polyvinyl chloride resin light guide material and light guide fiber

A polyvinyl chloride resin and light-guiding material technology, applied in the direction of optical waveguide light guide, cladding optical fiber, etc., can solve the problems of unable to meet the communication requirements and general light-guiding performance, and achieve good visual light-guiding effect and elongation at break The effect of high rate and moderate hardness

Inactive Publication Date: 2018-01-19

东莞市宏昱新材料有限公司

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the light guiding performance of traditional optical fibers is average, which cannot meet the rapid development of communication needs.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 4

[0029] The product obtained in this embodiment 2 is tested for performance, and Table 2 is the result of the performance test.

[0030] Table 2

[0031]

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

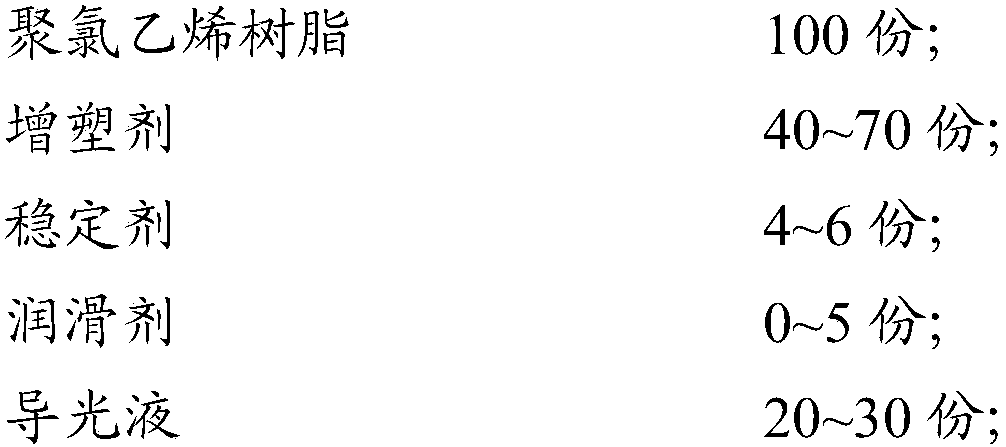

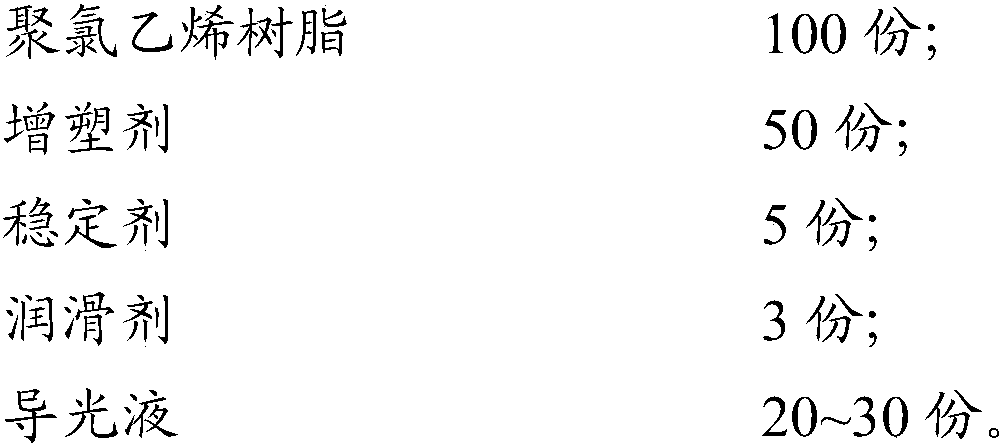

The invention belongs to the field of preparation of light guide fiber, and in particular relates to a polyvinyl chloride resin light guide material and light guide fiber. The polyvinyl chloride resinlight guide material provided by the invention comprises 100 parts of polyvinyl chloride resin, 40 to 70 parts of a plasticizer, 4 to 6 parts of a stabilizer, 0 to 5 parts of a lubricating agent and20 to 30 parts of light guide liquid. The light guide fiber prepared by the formula has high light guide property, high elongation at break and moderate hardness, and meets the use requirements of special environments in the aspect of comprehensive performance.

Description

technical field [0001] The invention belongs to the field of optical fiber preparation, and in particular relates to a polyvinyl chloride resin light-guiding material and an optical fiber. Background technique [0002] Optical fiber is a transparent glass fiber filament with a diameter of only about 1 to 100 μm. It is composed of two layers, the inner core and the jacket. The refractive index of the inner core is greater than that of the jacket. The light enters from one end, and is emitted from the other end after multiple total reflections at the interface between the inner core and the jacket. At present, the light guiding performance of traditional optical fibers is average, which cannot meet the high-speed development of communication needs. Contents of the invention [0003] In view of this, the purpose of the present invention is to provide a polyvinyl chloride resin light-guiding material, which is applied to the preparation of optical fibers. Its specific techni...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/06C08L23/06C08K5/151C08K5/098G02B6/02

Inventor 肖和伟

Owner 东莞市宏昱新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com