Suspension arm rotary shaft device of hot braising tank

A technology of a rotating shaft device and a boom, which is applied in the field of hot stuffy tanks, and can solve problems such as tank lids that are easy to sink, and achieve the effects of avoiding sinking, simple structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a further detailed description of a boom shaft device for a hot stuffy tank according to the present invention through specific embodiments.

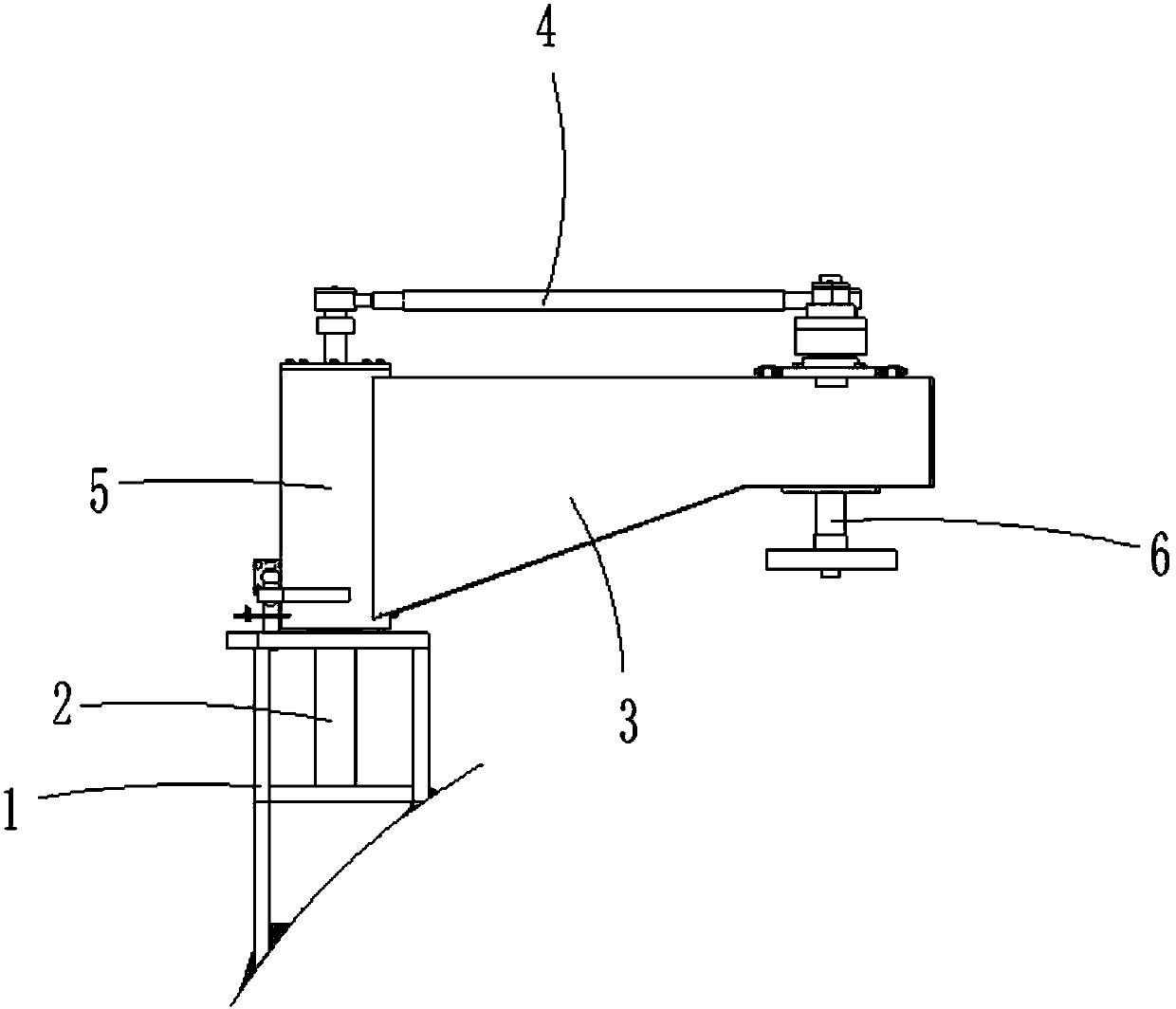

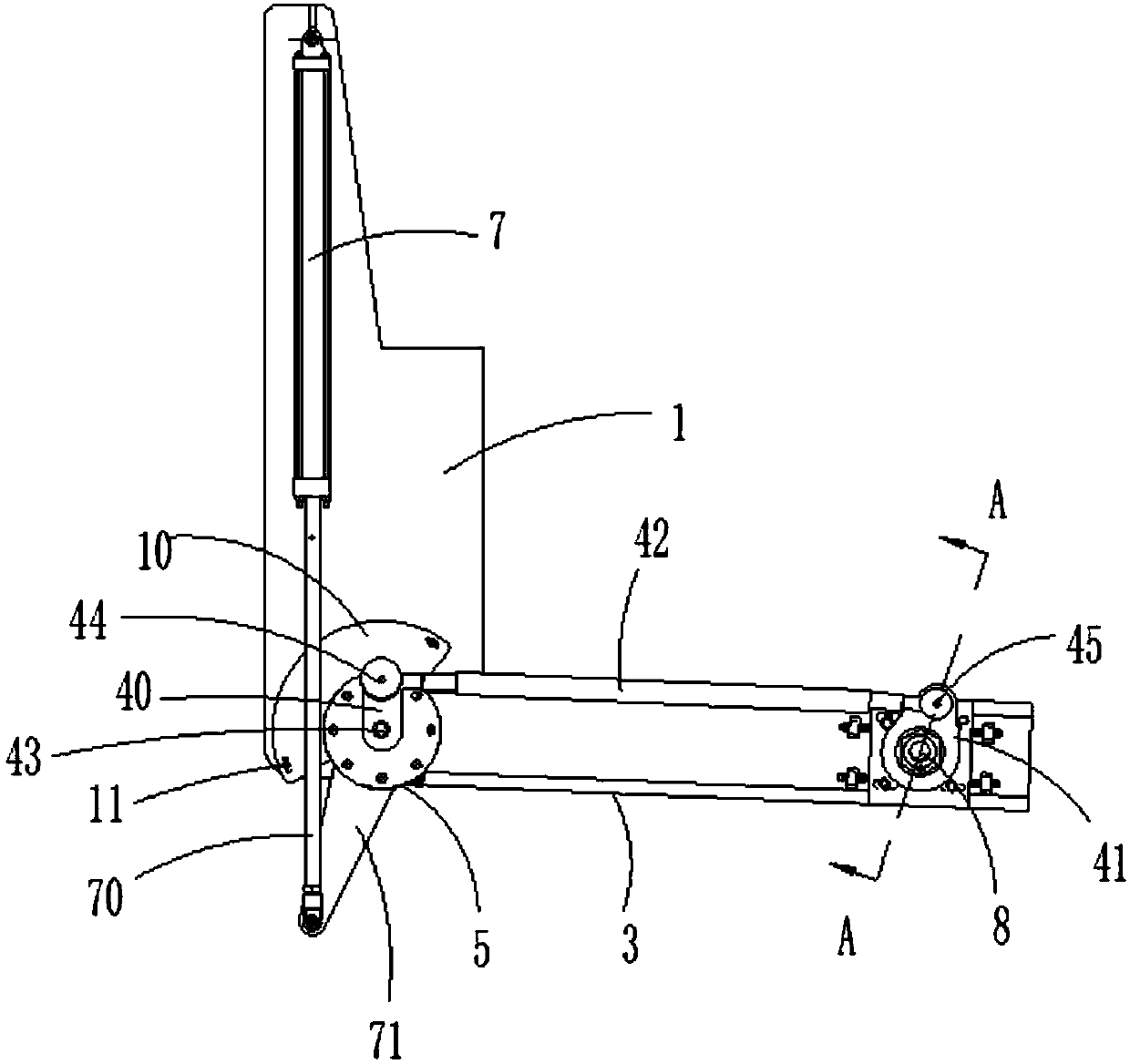

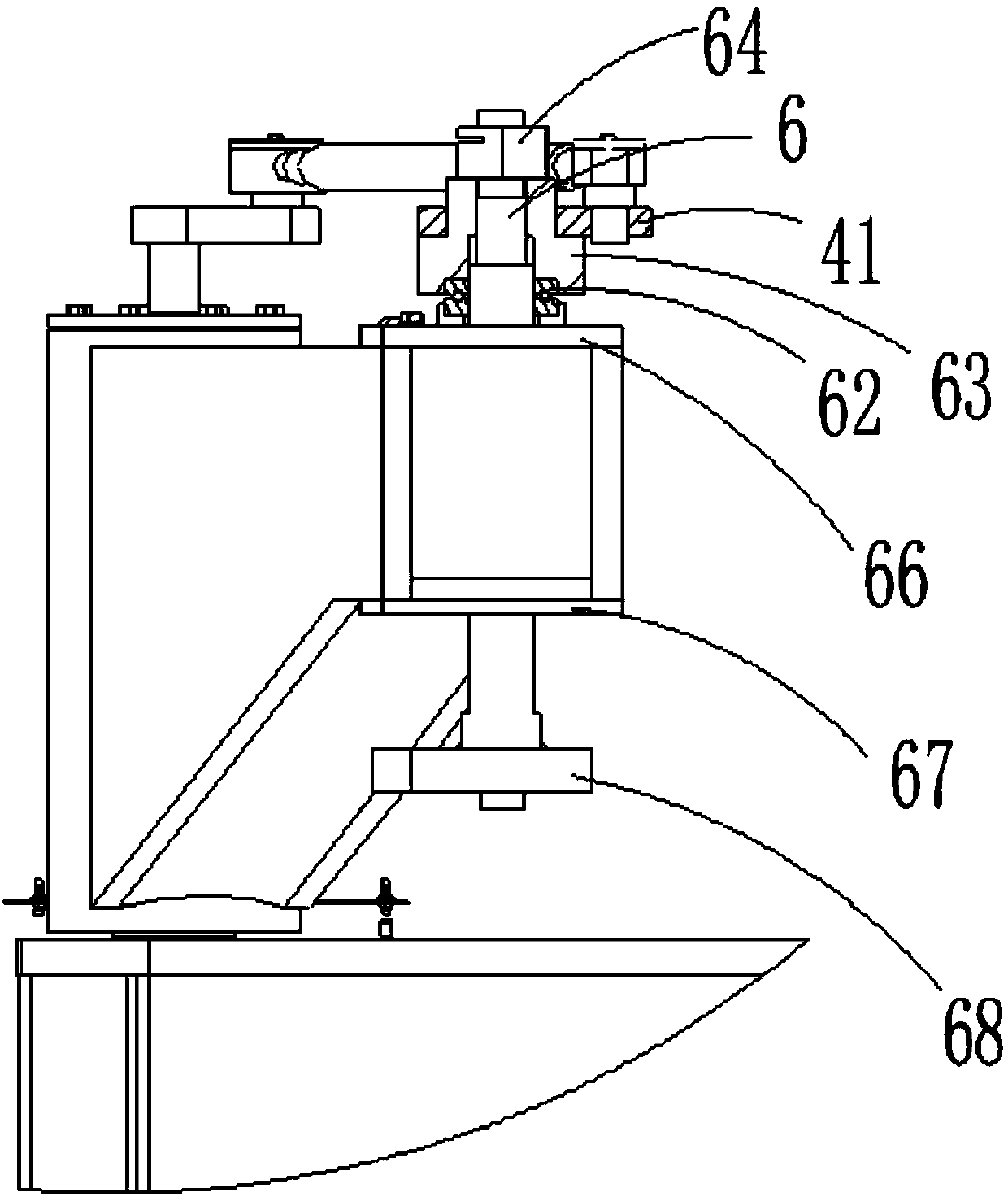

[0024] Such as figure 1 and figure 2 As shown, a boom shaft device for a hot stuffy tank includes: a boom mounting seat 1 arranged on a hot stuffy tank cylinder, a boom 3 mounted on the boom mounting seat 1 through a boom support shaft 2 and The link mechanism 4 installed on the boom 3, the boom shaft mechanism 5 is arranged between the boom 3 and the boom support shaft 2, the can lid shaft fixedly connected with the can lid is installed in the boom 3 6. The boom mounting seat 1 is equipped with a hydraulic cylinder 7 for driving the boom shaft mechanism 5 to rotate, and the piston rod 70 of the hydraulic cylinder 7 is connected with the boom shaft mechanism 5 through a connecting piece 71. The mounting base 1 is provided with a proximity switch mounting plate 10, and the proximity switch mounting plate 10 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap