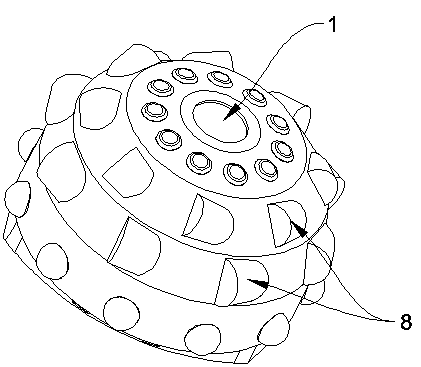

PDC tooth wheel and composite drill bit comprising PDC tooth wheels

A compound drill bit and cone technology, which is applied in the direction of drill bit, drilling equipment, earthwork drilling, etc., can solve the problem of increasing the vertical collision probability between the cutting layer of the PDC cutter and the rock formation, the unstable cutting depth of the PDC bit, and the ROP of the compound bit. Impact and other issues, to achieve the effect of reducing the longitudinal vibration amplitude, improving drilling efficiency and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0029] The difference from the PDC cone embodiment 1 is that the PDC composite sheet 8 adopts flat teeth, and the value range of the cutting layer chamfer R is 0.8~3.

Embodiment 3

[0031] The difference from PDC cone embodiment 1 lies in the number of auxiliary cones, which can be 0, 1, 2, or 3.

[0032] PDC cone embodiment 4

[0033] The difference from the embodiment of the PDC cone lies in the diameter of the PDC composite sheet 8, which ranges from 8 mm to 26 mm.

Embodiment 1

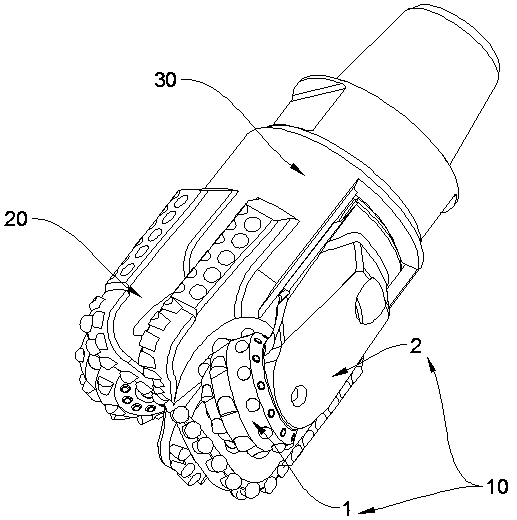

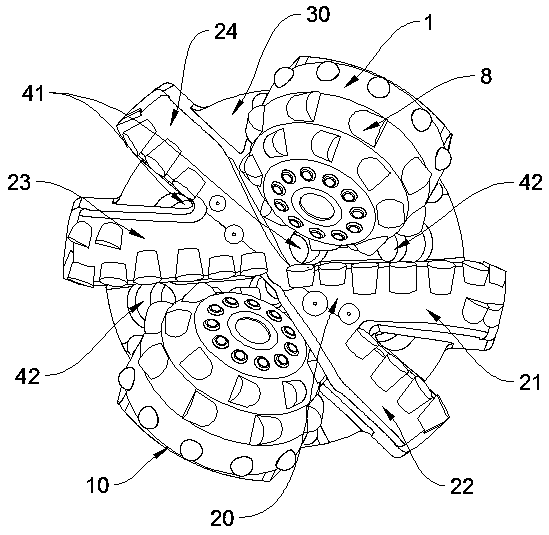

[0035] Such as figure 2 and image 3As shown, a compound drill bit is provided with a PDC cutter set 20 on the drill bit body 30, including four PDC cutting wings, which are the first main cutter wing 21, the first auxiliary cutter wing 22, the second main cutter wing 23 and the second auxiliary cutter wing. Blade 24. The bit body 30 between the first main blade 21 and the second auxiliary blade 24 and between the first auxiliary blade 22 and the second main blade 23 passes through the tooth palm 2 respectively. Two groups of above-mentioned PDC cones 10 are fixedly installed.

[0036] The PDC cutter set 20 is X-shaped, and the drill bit body 30 is provided with a type of water hole 41 near the intersection point of X for cleaning and cooling the PDC cutting wings.

[0037] The bit body 30 is provided with a second type of water hole 42 at the area between the first main blade 21 and the PDC cone 10, and at the area between the second main blade 23 and the PDC cone 10 , f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com