Double-chamber u-shaped furnace body system for shell solidification furnace

A technology of shell-condensing furnace and furnace body, which is applied in the field of double-chamber U-shaped furnace body system of shell-condensing furnace, which can solve the problems of low structural reliability and expandability, strong vibration of furnace body and electrode rod, and small modal frequency of centrifugal mechanism and other problems, to achieve the effect of safe, reliable and stable structure, large renovation space, and increased pouring height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

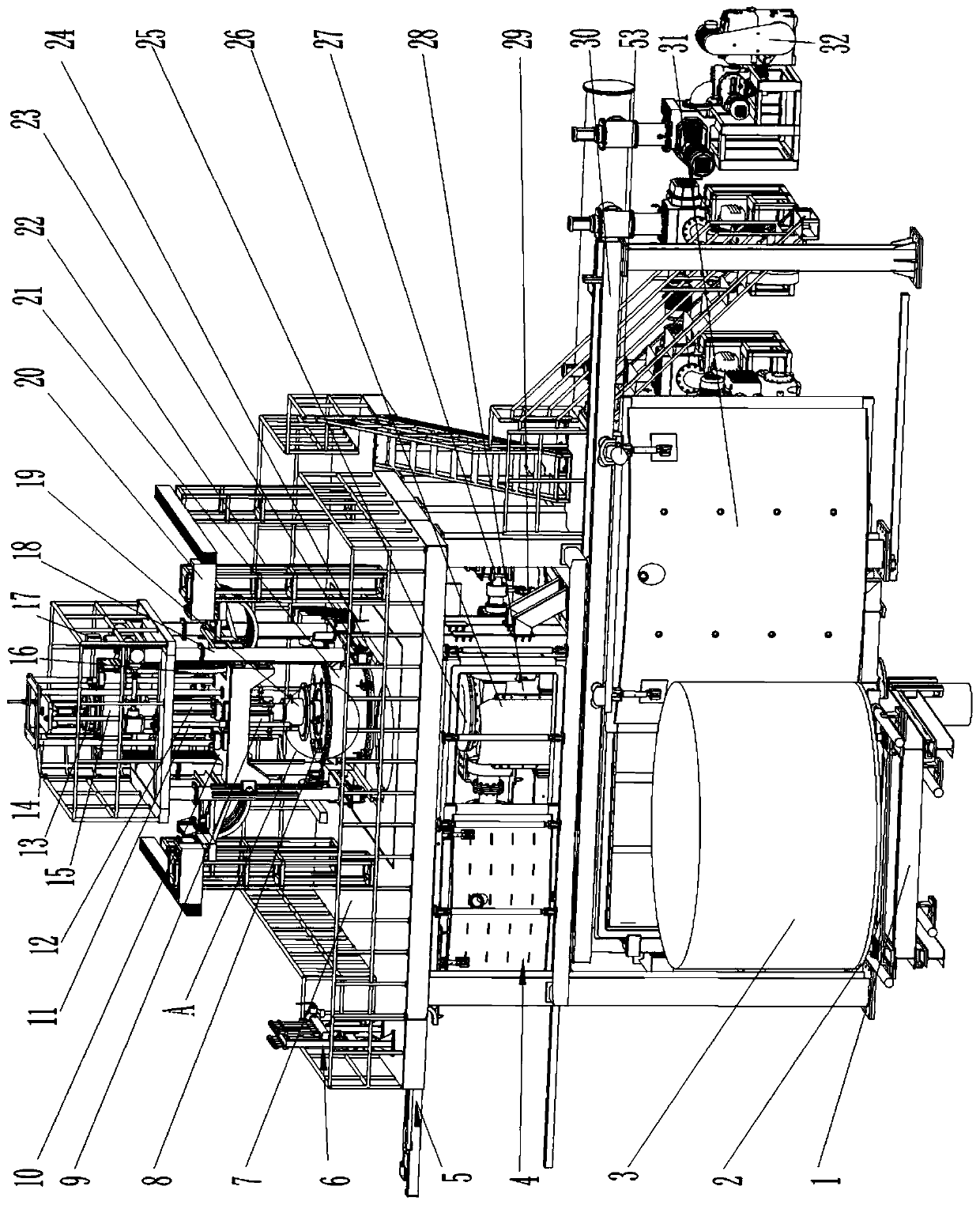

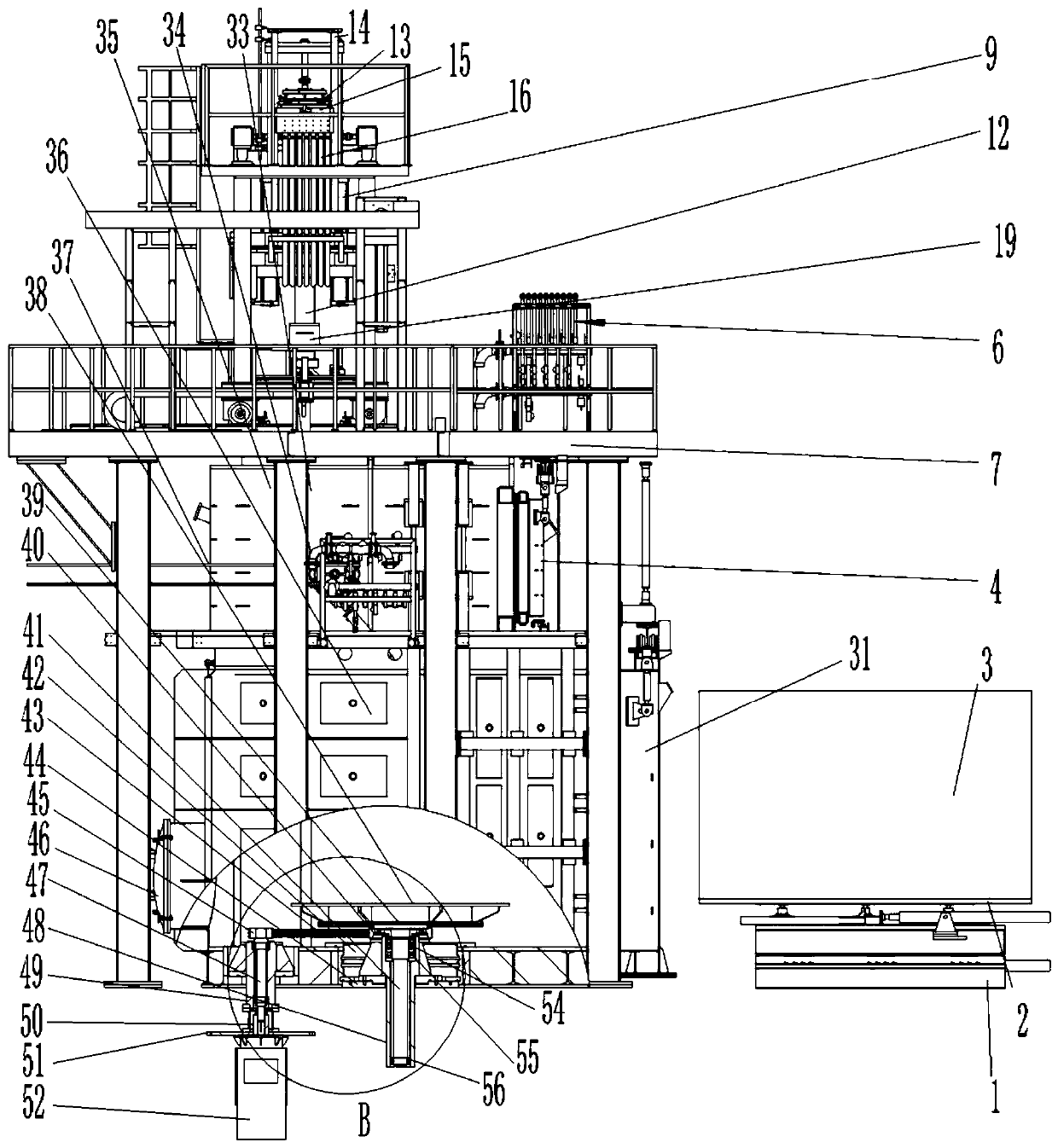

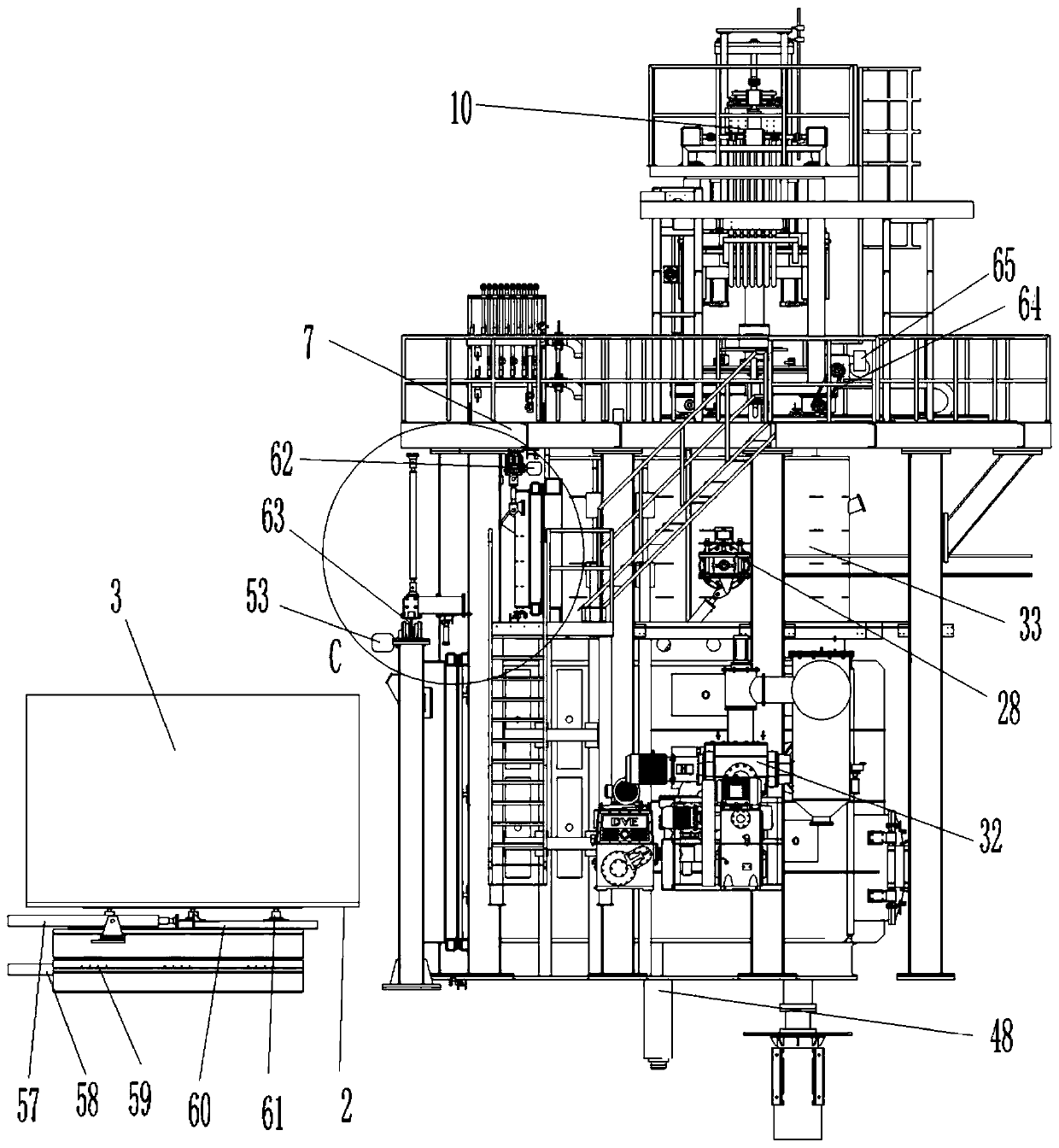

[0046] As shown in the figure, the dual-chamber U-shaped furnace body system of the condensing shell furnace of the present invention can be applied to the vacuum consumable electrode arc condensing shell furnace. The vacuum consumable electrode arc condensing shell furnace includes a furnace body system, an electrode transmission system, a crucible Turning system, centrifugal system, vacuum system, mold transmission trolley and platform, furnace body system and platform are integrally connected together;

[0047]The furnace body system includes an upper furnace body and a lower furnace body, the crucible turning system is arranged on the upper furnace body, the lower end of the upper furnace body is connected with the upper end of the lower furnace body, and the upper end of the upper furnace body is provided with an electrode chamber;

[0048] The electrode transmission system is movably arranged on the platform through the track; the electrode transmission system is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com