Method for testing solidification strength of water-containing oilstone interface of asphalt pavement

A technology of asphalt pavement and consolidation strength, which is applied in the direction of instruments, measuring devices, and mechanical devices, can solve the relationship between less water interface and quantitative interface water and asphalt interface consolidation strength. No more mature test methods and methods have been found. Test results and other issues, to achieve the effect of accurate and scientific test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

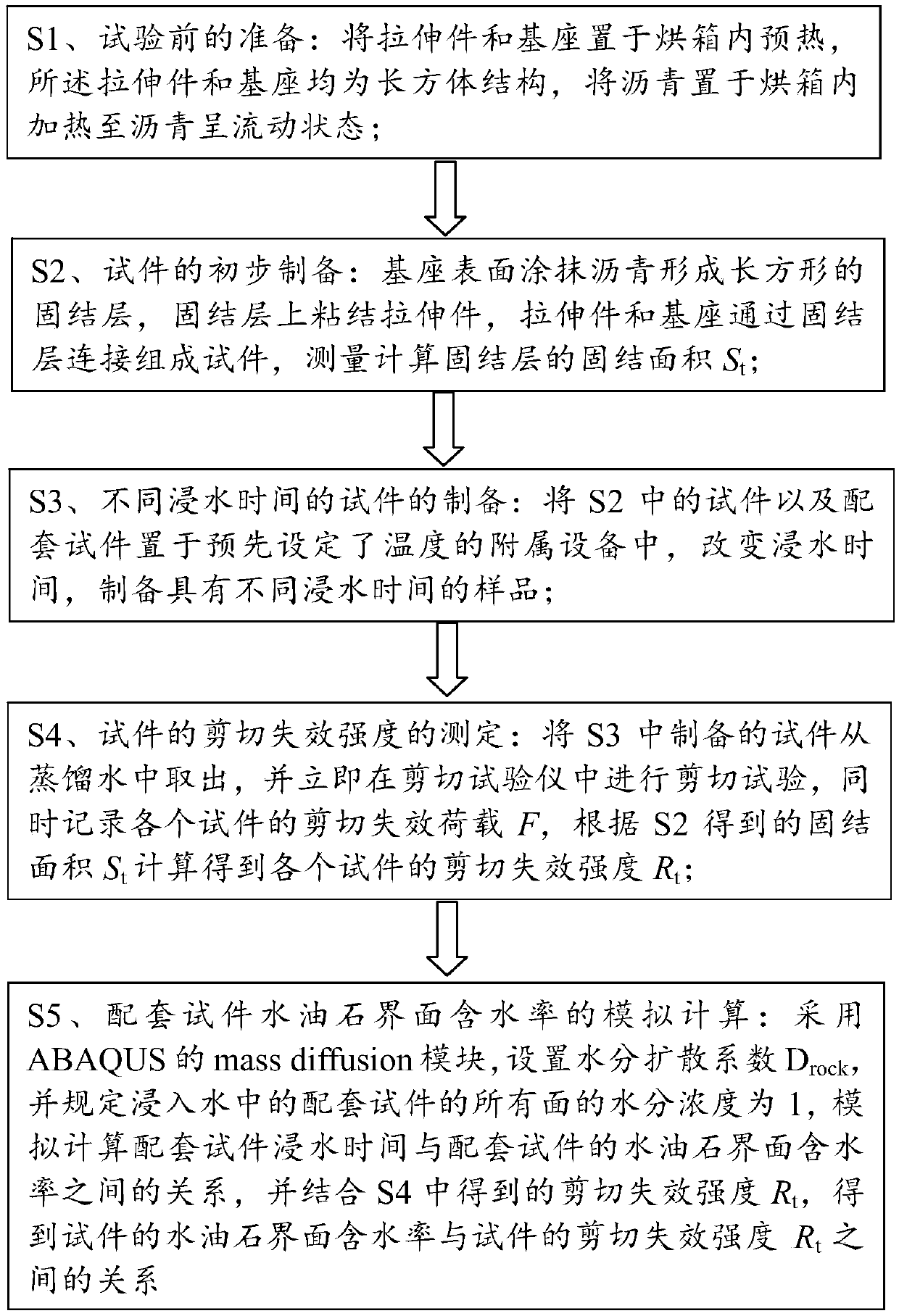

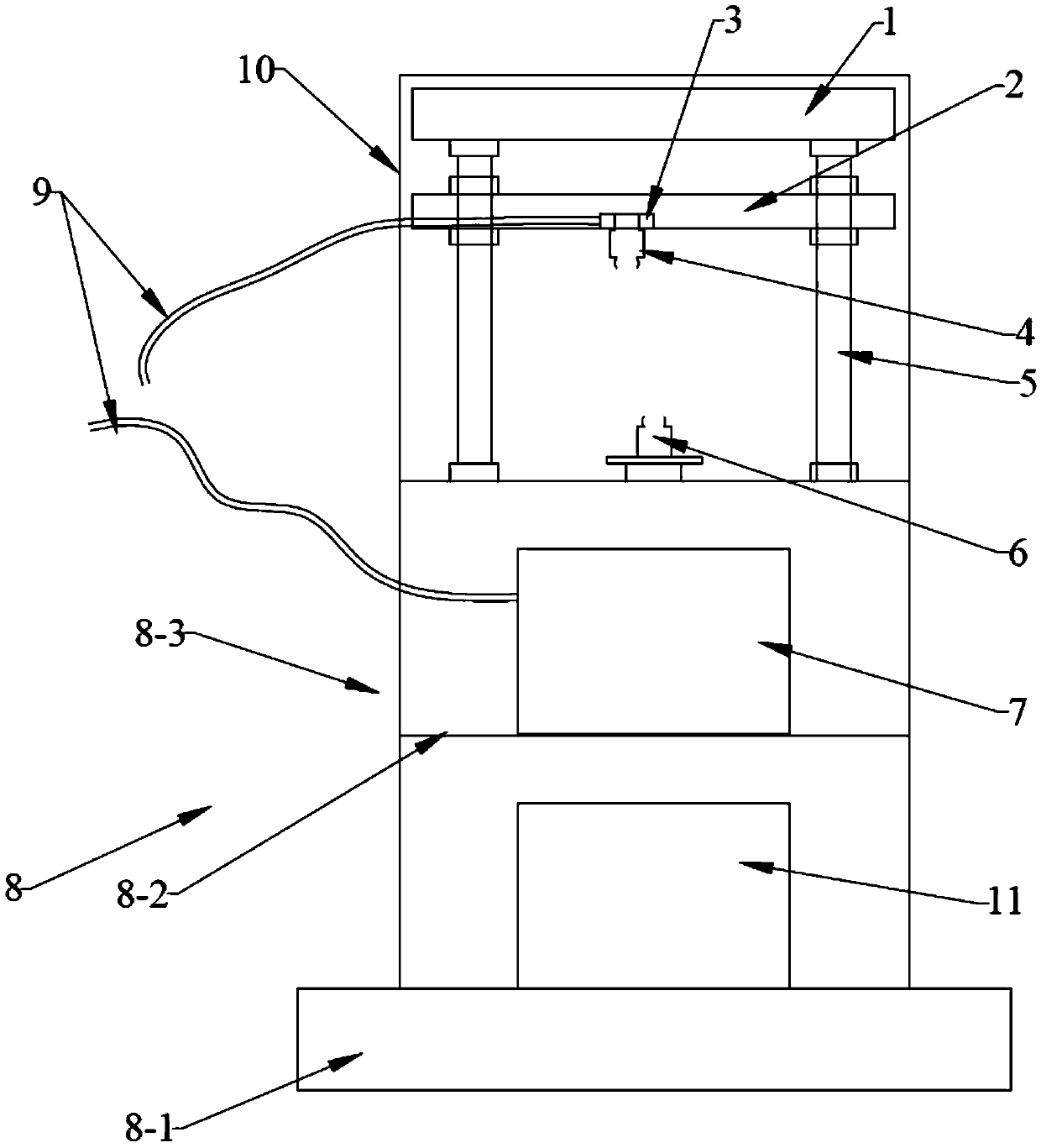

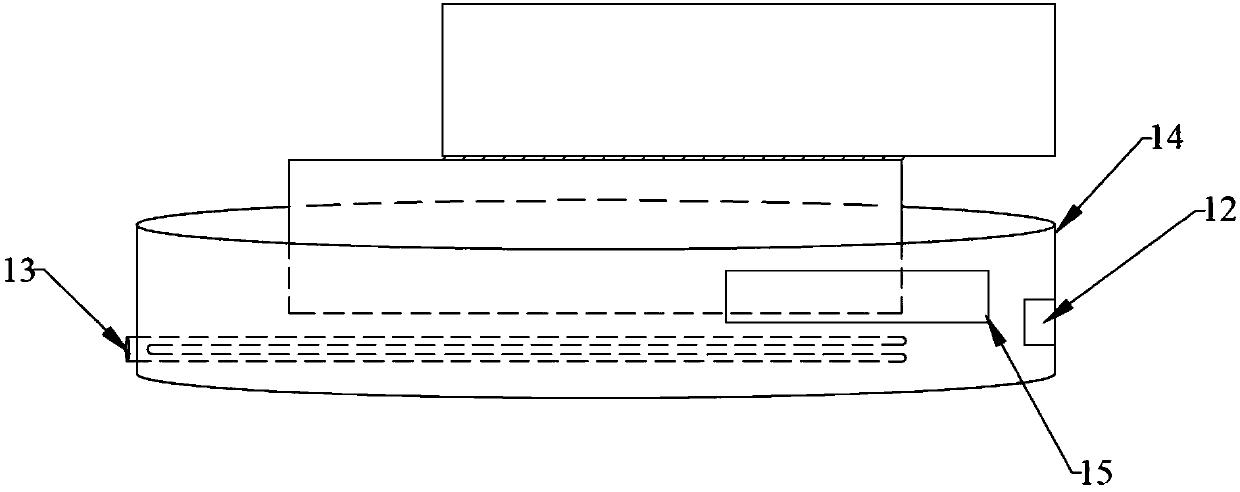

[0037] S3. Preparation of test pieces with different immersion times: place the test pieces prepared in S2 and the supporting test pieces in the auxiliary equipment with a preset temperature. The supporting test pieces include the base, asphalt consolidation layer and tensile The base of the test piece and the base of the supporting test piece are immersed in the distilled water of the auxiliary equipment, the immersion height of the base is less than the overall height of the base, and the immersion time of the base is changed to prepare test pieces with different immersion times Samples and supporting test piece samples with different immersion times;

[0038] S4. Determination of the shear failure strength of the test piece: The test piece samples prepared in S3 with different immersion times were immediately placed in the temperature-controlled test chamber of the asphalt pavement water-containing oil-stone interface consolidation strength shear tester at a preset temperatu...

Embodiment 1

[0063] S1. Preparations before the test: Preheat the tensile parts and the base in an oven. The tensile parts and the base are both rectangular parallelepiped structures. Heat in an oven at about 135°C until the asphalt is in a fluid state, where the base asphalt is represented by CA;

[0064]S2. Preliminary preparation of the test piece: smear asphalt on the surface of the base to form a rectangular consolidation layer, bond the tensile piece on the consolidation layer, connect the tensile piece and the base through the consolidation layer to form a test piece, measure and calculate the consolidation layer The consolidation area S t ; Both the stretched part and the base of this example are made of 40*40*10mm granite blocks. Firstly, the matrix asphalt CA is applied to the surface of the base with a side length of 40mm*40mm to form a rectangular consolidation layer. One side of the layer is completely coincident with one side of the surface of the base, and the smearing area...

Embodiment 2

[0071] S1. Preparation before the test: Preheat the tensile part and the base in an oven. The tensile part and the base are both rectangular parallelepiped structures. The black modified asphalt is heated in an oven at about 135°C until the asphalt is in a fluid state, and the silane silica modified asphalt is represented by SSA;

[0072] S2. Preliminary preparation of the test piece: smear asphalt on the surface of the base to form a rectangular consolidation layer, bond the tensile piece on the consolidation layer, connect the tensile piece and the base through the consolidation layer to form a test piece, measure and calculate the consolidation layer The consolidation area S t ; Both the stretched part and the base of this example use 40*40*10mm granite stones, first apply silane silica modified asphalt SSA to the surface of the base with a side length of 40mm*40mm to form a rectangular solid Consolidated layer, one side of the consolidated layer completely coincides with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com