A New Alloy Hot Cracking Tendency Prediction Method

A prediction method and alloy technology, applied in measuring devices, material thermal analysis, instruments, etc., can solve problems such as invariance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

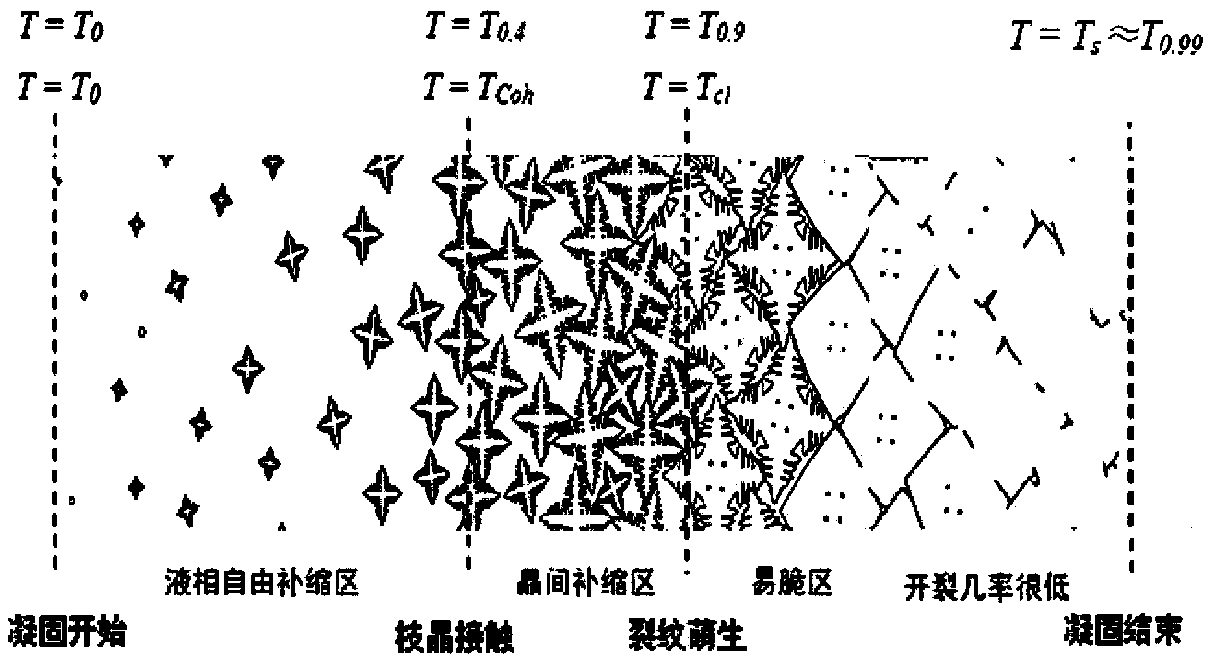

Problems solved by technology

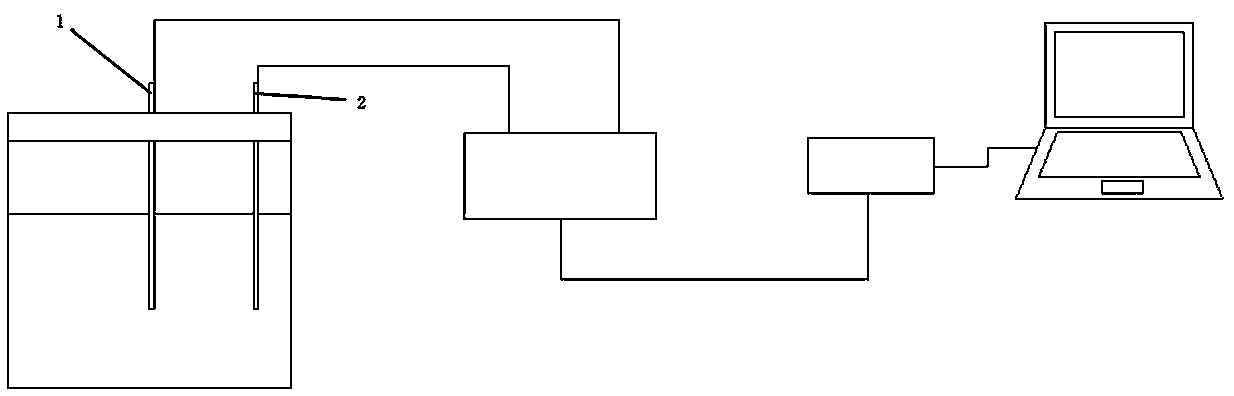

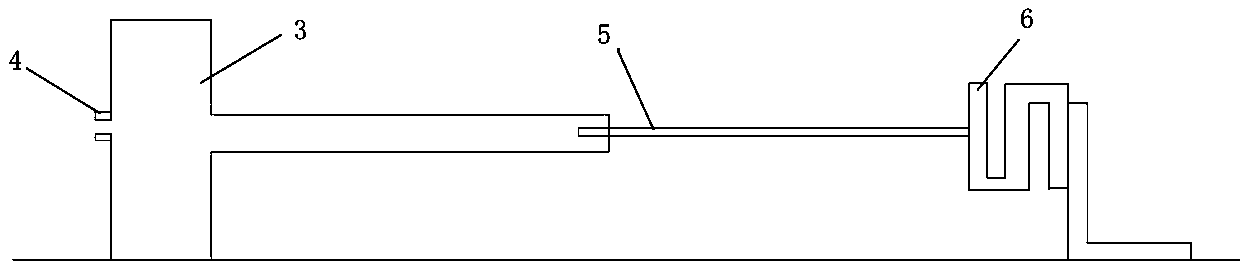

Method used

Image

Examples

Embodiment

[0045] The hot cracking tendency of Mg-6.5Zn-1Y-0.5Zr and Mg-6.5Zn-2Y-0.5Zr magnesium alloys was predicted by this method.

[0046] 1. In the Mg-6.5Zn-1Y-0.5Zr alloy, T coh =608.8°C, T hci =411.2°C, T s =365.7°C. That is, CSC(T)=(T hci -T s ) / (T coh -T hci )=0.23.

[0047] 2. In Mg-6.5Zn-2Y-0.5Zr alloy T coh =617.5°C, T hci =397.4°C, T s =330.9°C. That is, CSC(T)=(T hci -T s ) / (T coh -T hci ) = 0.30.

[0048] According to this method, it can be predicted that the hot cracking tendency of Mg-6.5Zn-2Y-0.5Zr alloy is greater than that of Mg-6.5Zn-2Y-0.5Zr alloy.

[0049] The molten paraffin infiltration method was used to measure the macroscopic hot crack volumes of the two alloys and to verify the accuracy of the method's predictions. The macroscopic crack volumes of the two alloys are as Figure 5 shown. Among them, the macroscopic crack volume of Mg-6.5Zn-1Y-0.5Zr alloy is 0.1076cm 3 , the macroscopic crack volume of Mg-6.5Zn-2Y-0.5Zr alloy is 0.1208cm 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com