Working medium for heat cycles and heat cycle system

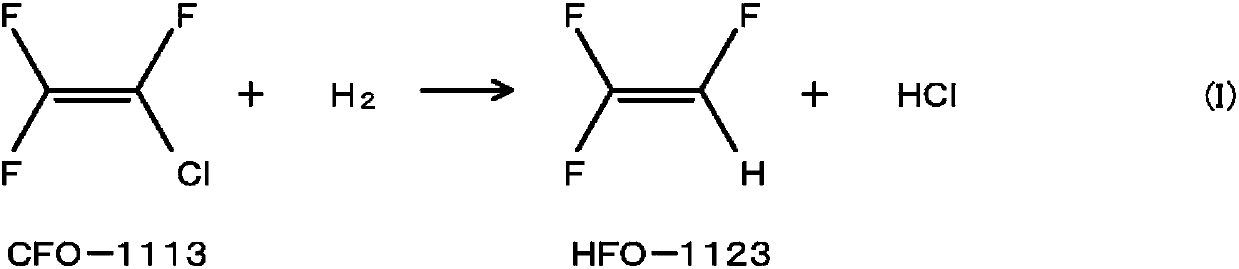

A technology of working medium and circulation system, which is applied in irreversible cycle compression machines, chemical industry, heat exchange materials, etc. It can solve the problems of HFO-1123's flammability, safety issues, and insufficient cycle performance of thermal cycle systems. , to achieve excellent cycle performance, high productivity, and little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0208] Hereinafter, the present invention will be described in detail through examples, but the present invention is not limited to the following description. Examples 1-3 are examples. In addition, the even numbers of Examples 4 to 65 are examples, and the odd numbers are comparative examples.

example 1~3

[0210] Four components, HFO-1123, HFC-134a, HFC-125, and HFO-1234yf, and HFO-1132a were mixed so that the ratio of each compound was as shown in Table 2, and a working medium of a 5-component system containing the above compounds was prepared. Then, these working media were mixed with air at a ratio of 10 to 90% by mass with respect to air, and the flammability at the time of mixing with air to reach an equilibrium state was evaluated in the following manner at intervals of 1% by mass.

[0211] [Flammability evaluation]

[0212] The flammability evaluation was carried out using the equipment specified in ASTM E-681.

[0213] After vacuum-exhausting the flask with an inner volume of 12 liters set in a thermostat controlled at a temperature of 25°C, the working medium adjusted to each concentration and air were sealed in the flask until it reached atmospheric pressure. Then, after performing discharge ignition for 0.4 seconds on the conditions of 15 kV and 30 mA in the gas phas...

example 4~65

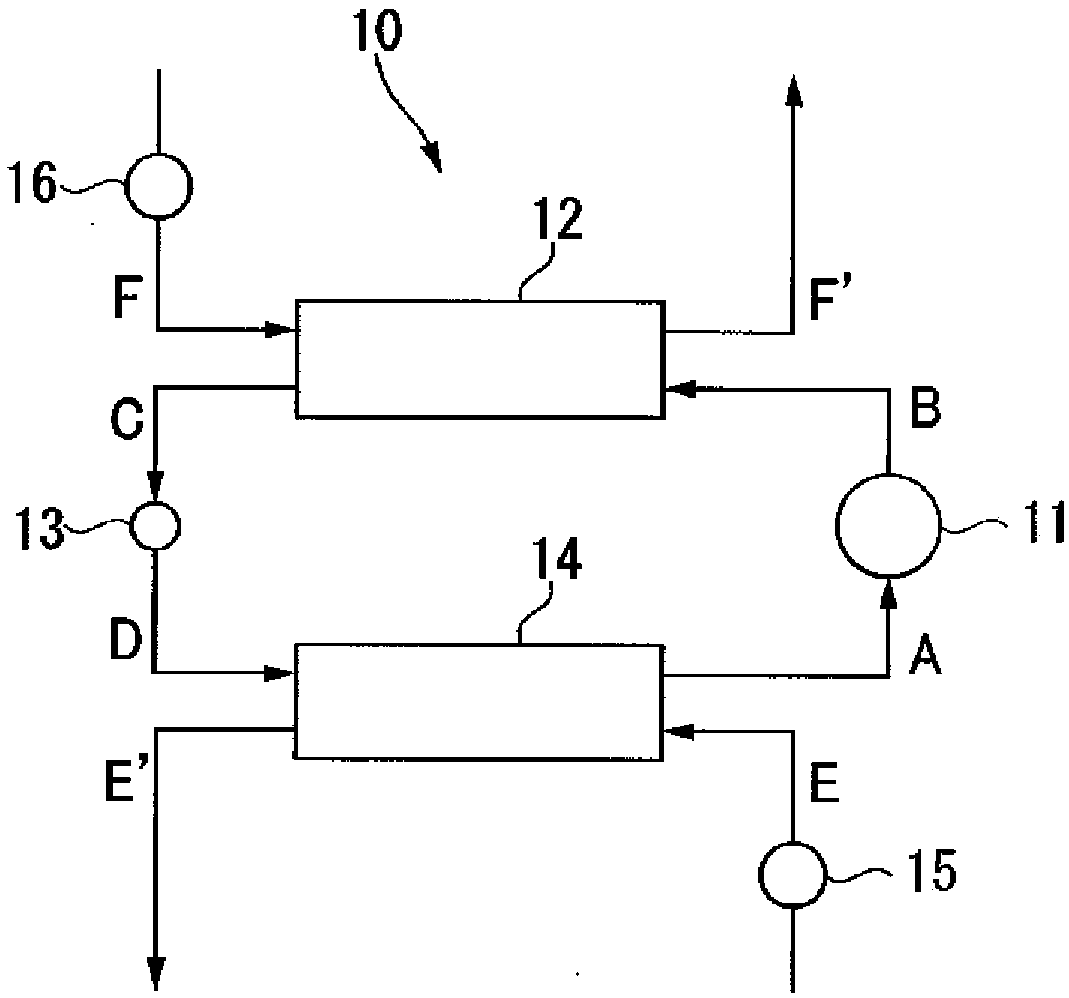

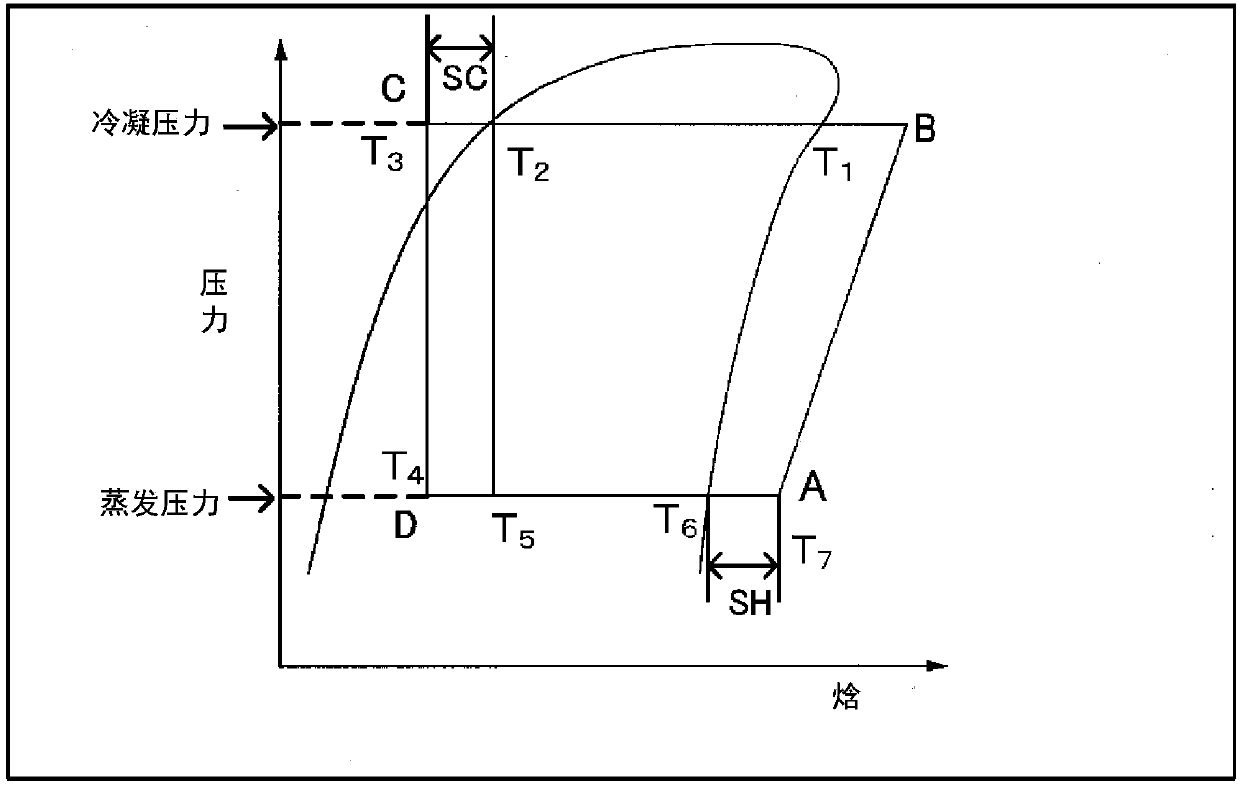

[0219] The following working media were prepared: containing HFO-1123, HFC-134a, HFC-125 and HFO-1234yf in the ratios shown in Table 3 and Table 4, and at the ratios shown in the same table relative to the total amount of the working media The ratio contains HFO-1132a. Then, the refrigeration cycle performance (hereinafter referred to as refrigeration capacity Q) was measured for these working media by the following method.

[0220] In addition, the refrigerating capacity Q refers to the capacity of refrigerating a loaded fluid, and the higher the Q, the more work can be realized in the same system. In other words, when the Q value is large, it means that the target performance can be obtained with a small amount of working medium, and the miniaturization of the system can be realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com