Horizontal type self-cleaning pressure-bearing solid-phase reaction kettle

A solid-phase reaction and self-cleaning technology, applied in chemical/physical/physicochemical fixed reactors, cleaning methods and tools, cleaning methods using tools, etc., can solve problems affecting heat transfer efficiency and easy adhesion of materials , to achieve the effects of improving heat exchange efficiency, increasing output, and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

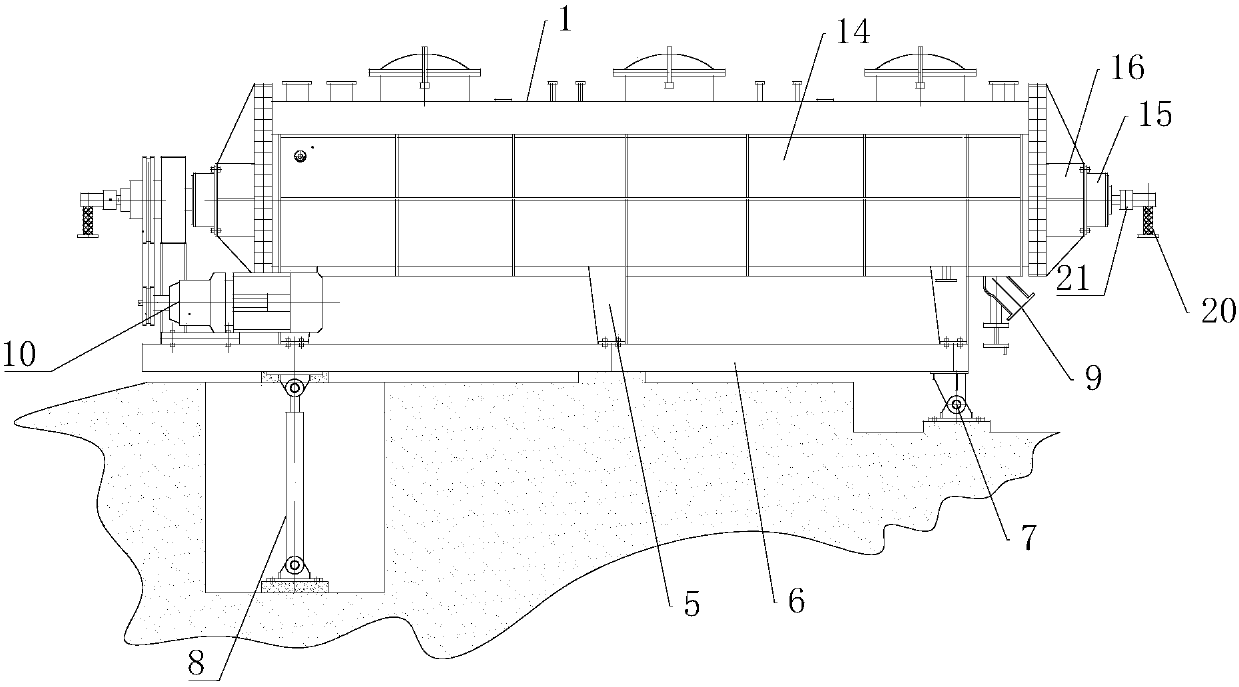

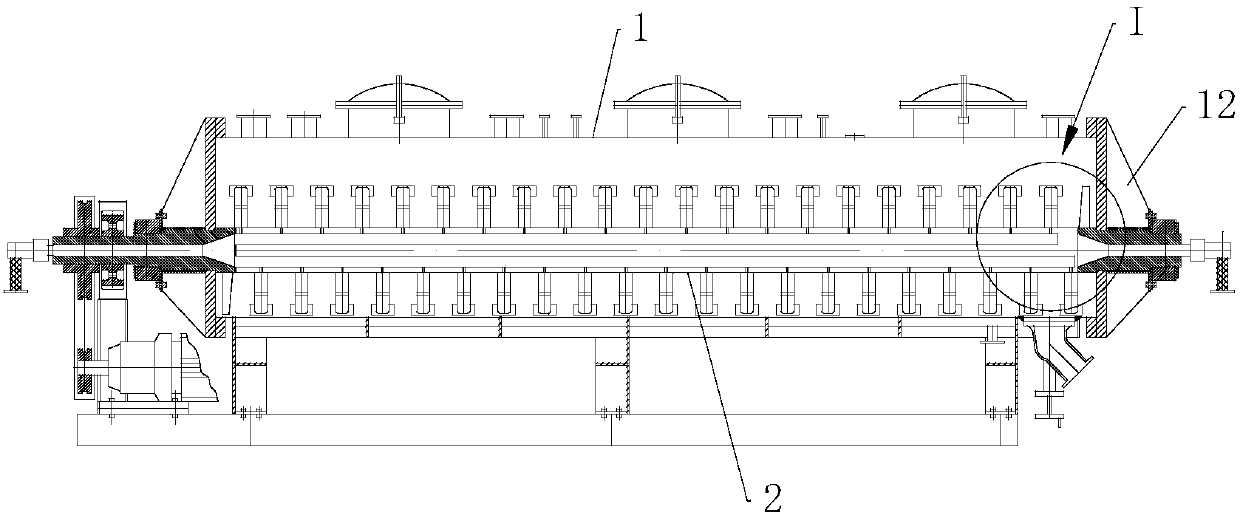

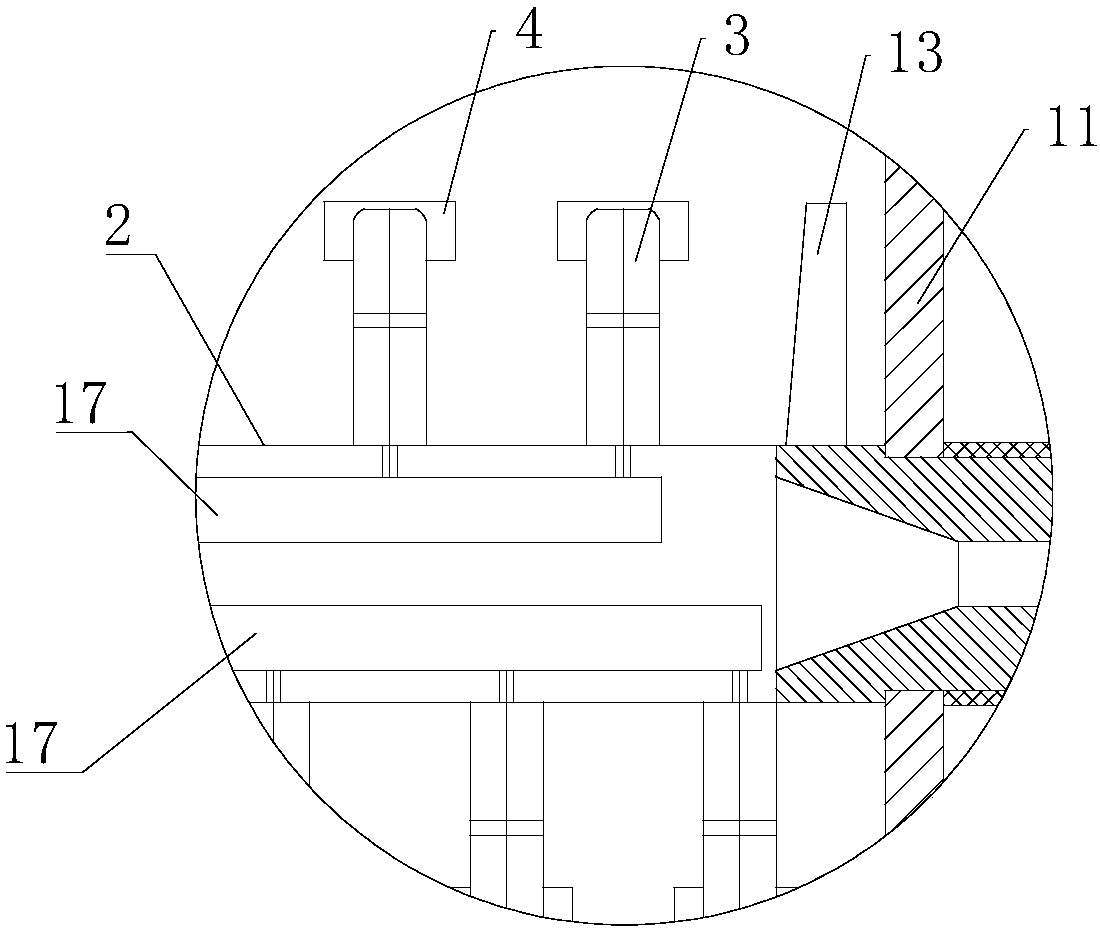

[0049] Such as figure 1 , figure 2 and image 3 As shown, it is an embodiment of the horizontal self-cleaning pressurized solid-phase reactor of the present invention, which includes a horizontally placed reactor cylinder 1, and at least two cylinders along its length are arranged in the reactor cylinder 1. A rotatable stirring shaft 2 extending in a direction, on which two rows of stirring blades 3 arranged symmetrically in the circumferential direction are fixed, the stirring blades 3 are fan-shaped, and the fan-shaped stirring blades 3 The plane where it is located is perpendicular to the stirring shaft 2. With this structure, the axial driving force of the side of the stirring blade 3 on the material is relatively weak. Therefore, after the material enters the reactor cylinder 1, it is mainly dispersed by gravity, and then it is stirred. Under the action of the shaft 2 and the stirring blade 3, it mainly moves radially and circumferentially. In this way, the material wi...

Embodiment 2

[0061] Such as Figure 6 As shown, it is a schematic cross-sectional view of Embodiment 2. The difference between this embodiment and Embodiment 1 is that the reactor cylinder 1 of this embodiment adopts a rectangular structure, and the number of stirring shafts inside it is 4, and the stirring shaft 2. The structure of the upper stirring paddles 3 is the same as that of the first embodiment, and they are all arranged at intervals. In this embodiment, corresponding parts need to be provided on the inner bottom surface of the reactor cylinder 1 to form an ω-shape matching the outer edge of the stirring paddle 3. At this time, the reactor cylinder 1 and the ω-shape have no overlap.

Embodiment 3

[0063] Such as Figure 7 As shown, it is a cross-sectional schematic diagram of Embodiment 3. The difference between this embodiment and Embodiment 1 is that the reactor cylinder 1 of this embodiment adopts an oblong structure, and the number of stirring shafts inside it is 4, and The structure of the stirring paddle 3 on the stirring shaft 2 and Figure 4 Similarly, it is a completely symmetrical structure, and the reactor cylinder 1 and the omega shape of this embodiment are also partially overlapping structures.

[0064] Moreover, in this embodiment, the stirring shaft 2 is arranged at the middle position in the vertical direction of the reactor cylinder body 1, and the gap between the upper edge of the stirring blade 3 and the top surface of the reactor cylinder body 1 is less than 5 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com