Electroplating wastewater treatment device

A technology for treating device and electroplating wastewater, which is applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the difficulty of resin regeneration, different pH value ranges, and it is difficult to discharge ions up to the standard standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

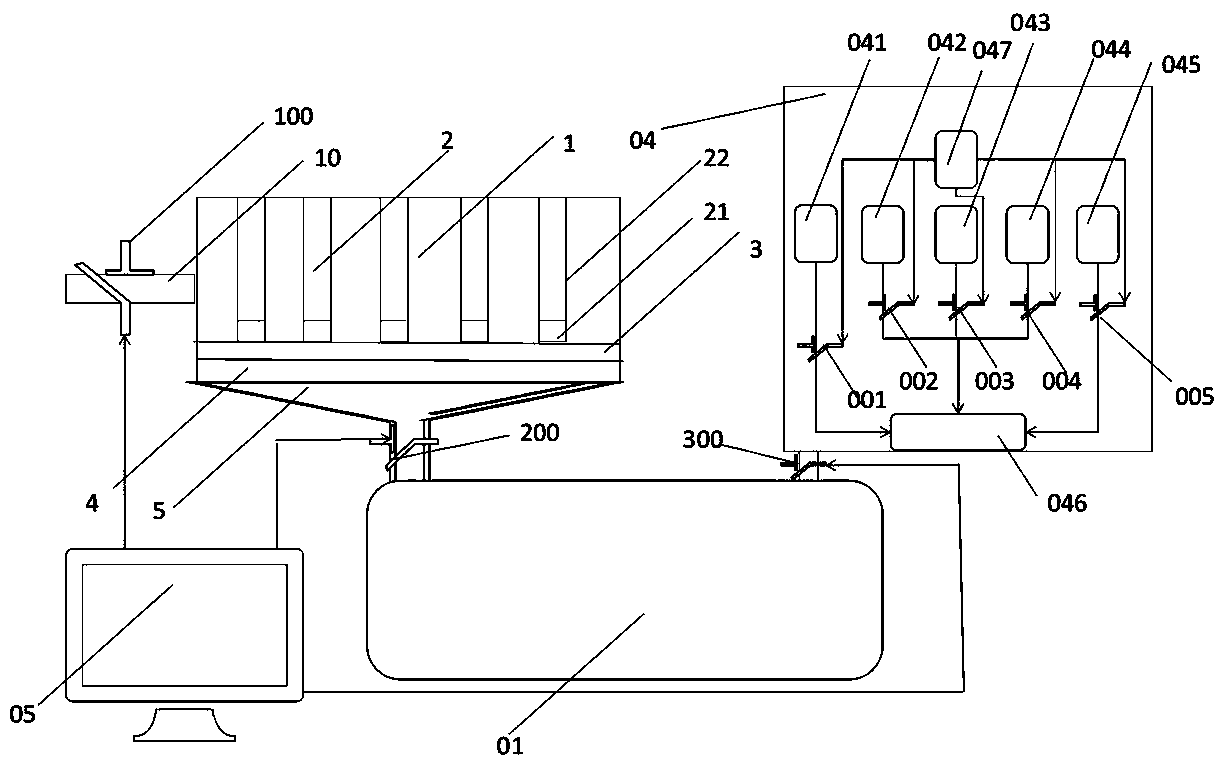

[0022] An electroplating wastewater treatment device, such as figure 1 shown, including:

[0023] It includes an adsorption pool 1 and a purification pool 01 communicating with the adsorption pool. A water inlet 10 is provided on the side wall of the adsorption pool 1. The water inlet 10 is communicated with the first control valve 100. The water inlet 10 is used for waste water Inflow; the bottom of the adsorption pool 1 is connected to a funnel-shaped pipeline 5 inlet, the shape of the funnel-shaped pipeline 5 inlet is consistent with the shape of the bottom of the adsorption pool 1, and the waste water flows out of the Adsorption pool 1, the outlet of the funnel-shaped pipeline 5 communicates with the inlet of the purification pool 01 through a second control valve 200, and the level of the adsorption pool 1 is higher than that of the purification pool 01;

[0024] The purification pond 01 is communicated with a purifying agent generating device 04 through the third contro...

Embodiment 2

[0035] An electroplating wastewater treatment device, such as figure 1 shown, including:

[0036] It includes an adsorption pool 1 and a purification pool 01 communicating with the adsorption pool. A water inlet 10 is provided on the side wall of the adsorption pool 1. The water inlet 10 is communicated with the first control valve 100. The water inlet 10 is used for waste water Inflow; the bottom of the adsorption pool 1 is connected to a funnel-shaped pipeline 5 inlet, the shape of the funnel-shaped pipeline 5 inlet is consistent with the shape of the bottom of the adsorption pool 1, and the waste water flows out of the Adsorption pool 1, the outlet of the funnel-shaped pipeline 5 communicates with the inlet of the purification pool 01 through a second control valve 200, and the level of the adsorption pool 1 is higher than that of the purification pool 01;

[0037] The purification pond 01 is communicated with a purifying agent generating device 04 through the third contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com