Furnace air-distribution structure inhibiting generating of carbon monoxide

A carbon monoxide and furnace technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of reducing waste incineration, reducing boiler load, increasing coal volume, etc., to prolong the residence time, improve the residence time, and ensure full combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

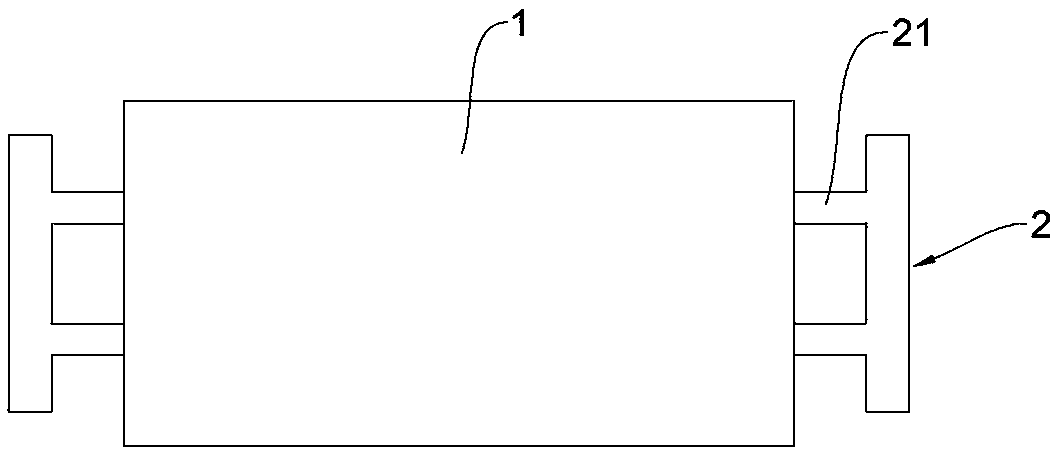

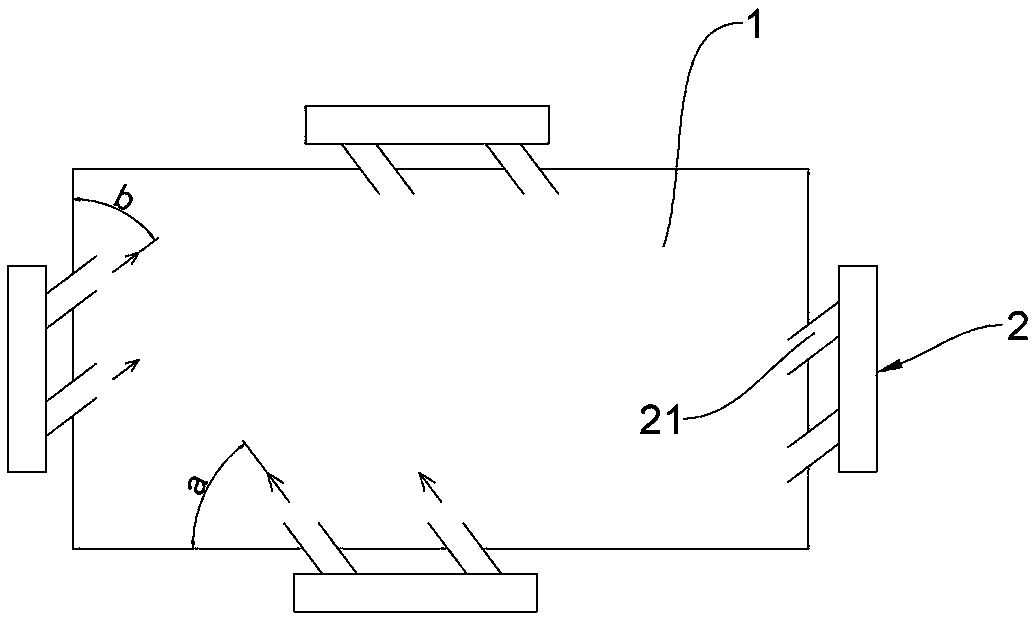

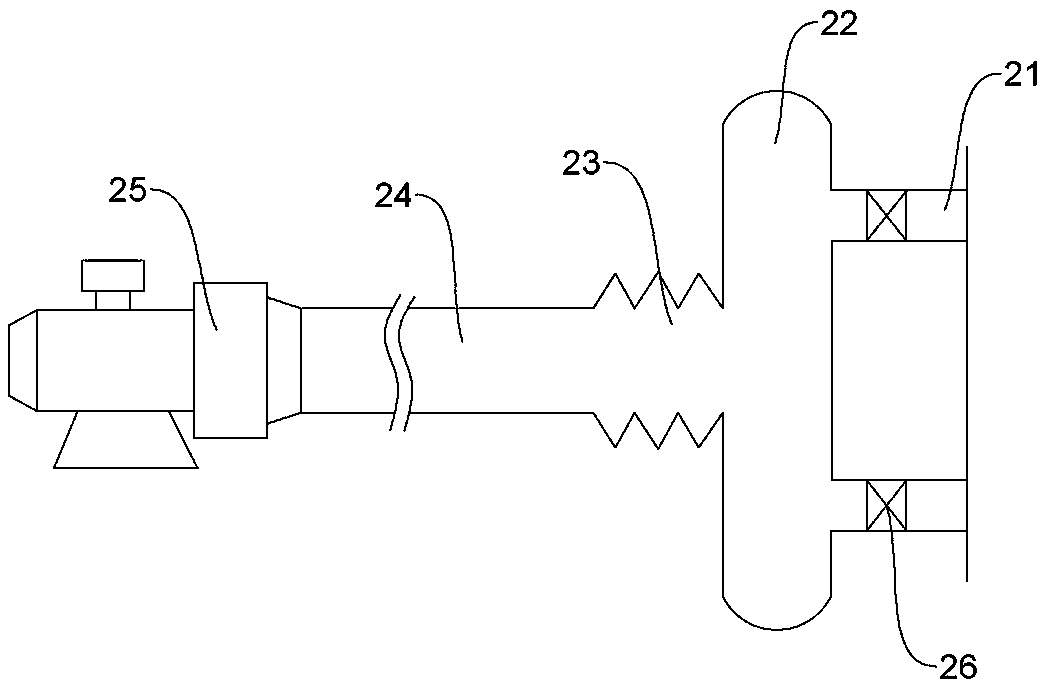

[0027] Example: such as Figure 2 to Figure 4 As shown, a furnace air distribution structure for suppressing the formation of carbon monoxide includes a furnace 1 and a secondary air device 2 that feeds into the furnace 1. The secondary air device 2 has at least three layers and is arranged up and down along the height direction of the furnace. The secondary air The number of devices 2 is generally three layers, and may also be four layers, and the distance between each layer is 1.2 meters to 1.5 meters. There are at least four sets of secondary air devices 2 in each layer, which are respectively arranged around the furnace, and the furnace 1 is a rectangular structure.

[0028] Such as figure 2 As shown, the secondary air device 2 includes an air inlet pipe, and the air inlet pipe is connected to the furnace 1, and the air inlet pipes in the secondary air device 2 on each floor are located at the same height. The blowing direction of the air inlet pipe is inclined to the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com