Sewage treatment equipment capable of separating sludge and use method

A kind of sewage treatment equipment and sludge technology, applied in the direction of water/sludge/sewage treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve the problem of blocked pipes and filter screens, easily damaged cutter heads, and difficult cleaning and other issues, to achieve the effect of energy saving, high degree of automation, and complete functional items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

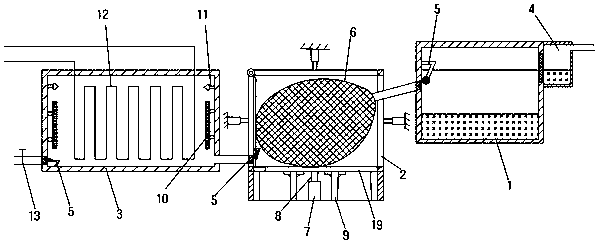

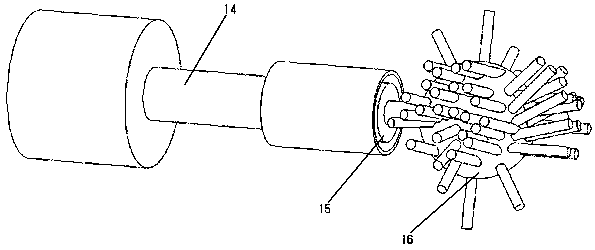

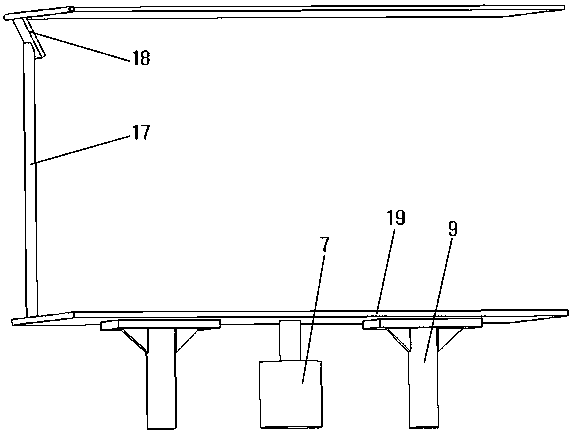

[0029] A sewage treatment equipment capable of separating sludge, including a sedimentation tank 1, a squeezing tank 2, a heat exchange tank 3 and a main control system; the inlet of the sedimentation tank 1 is provided with a primary filter 4, and the outlet is connected to the squeezing tank 2; the squeeze pool 2 is surrounded by six movable plate surfaces, and each surface is provided with a squeeze device 8; a filter bag 6 is arranged in the squeeze pool; the filter bag 6 is placed on the squeeze On the extrusion device 8 on the bottom surface of the pressure pool 2; the outlet of the extrusion pool 2 is connected to the heat exchange pool 3; the inside of the heat exchange pool 3 is provided with a coil pipe 12, and the wall of the pool is provided with an electric heater 10 and a high-pressure water gun 11 , the bottom outlet is provided with a solenoid valve 13; the sedimentation tank 1, extrusion tank 2 and heat exchange tank 3 are all arranged underground; the outlets ...

Embodiment 2

[0033] The second embodiment is basically the same in structure and principle as the first embodiment, except that the bottom of the squeeze pool 2 is provided with a support column 9 . When the filter bag 6 is not filled with sludge, the support column 9 assists the squeezing device 8 at the bottom 2 of the pool to support the filter bag 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com