Method used for preparing plurality of metal organic frameworks using hydrosolvent system

A metal-organic framework and water solvent technology, which is applied in the field of preparing various metal-organic frameworks in a water solvent system, can solve the problems of environmental damage, endanger the health of experimenters, increase costs and other problems, achieve cost reduction, simple and controllable preparation method, The effect of high universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

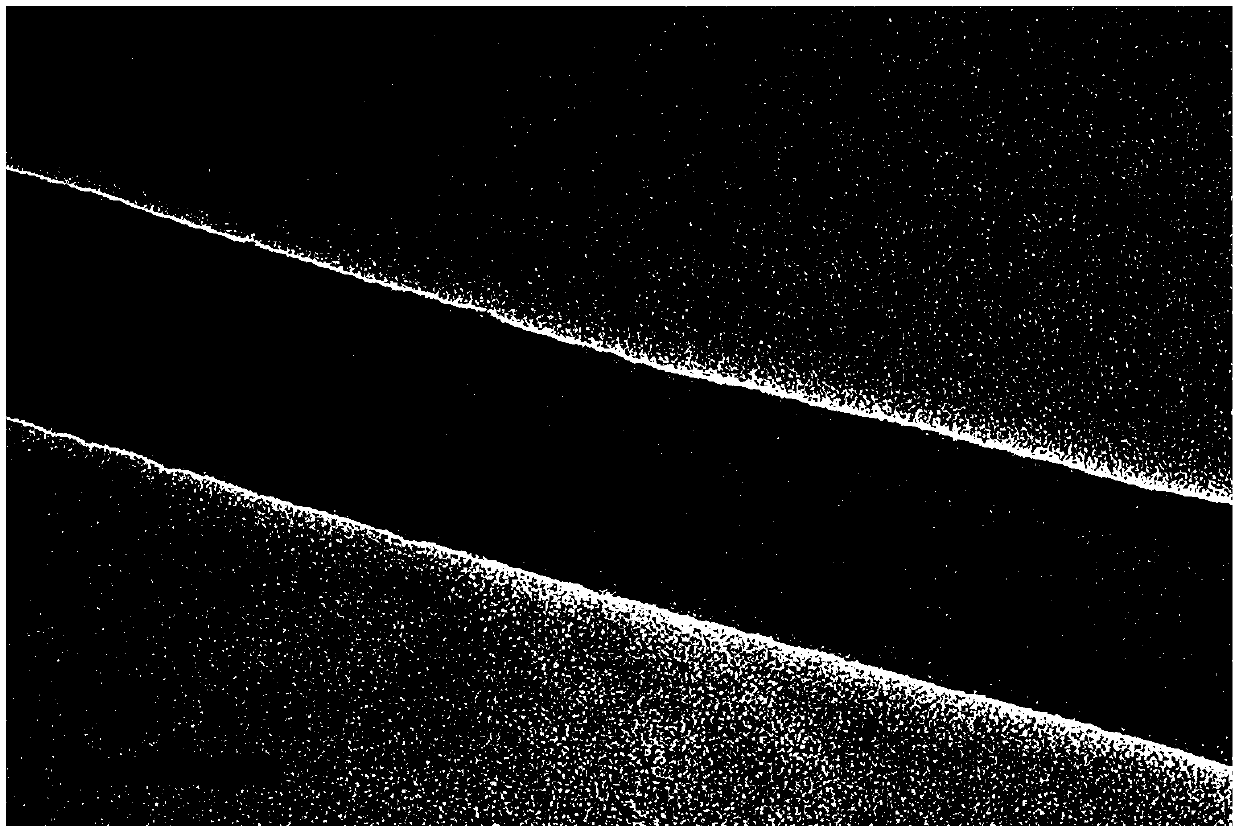

Image

Examples

preparation example Construction

[0028] (2) Preparation of metal-organic framework materials

[0029] Weigh 0.2441-1.7544g metal salt and dissolve it in 20-100ml deionized water, then add it into the aqueous solution in which trimesic acid is dissolved in step (1), heat and stir in an oil bath, wherein the oil bath heating temperature is 60-150 ℃, stirring time 10s-60min, then take it out, wash it with ethanol and deionized water alternately, and dry it in an oven to obtain the metal organic framework material.

[0030] The metal salts in the step (2) include manganese acetate, cerium nitrate, nickel acetate, cobalt acetate, copper nitrate and other metal salts.

Embodiment 1

[0033] (1) Dissolution of trimesic acid in water

[0034] Weigh 0.4286g of trimesic acid and add it to 50mL of deionized water, heat and stir in an oil bath at 80°C until all trimesic acid is dissolved in water;

[0035] (2) Preparation of Mn-BTC

[0036] Weigh 0.4951g of manganese acetate and dissolve it in 50mL of deionized water, then add it into the aqueous solution dissolved with trimesic acid, heat and stir at 80°C for 30min, then take it out and wash it alternately with ethanol and deionized water, and the centrifugal speed is 3500rpm, Centrifuge for 3 minutes, repeat 6 times, and dry in an oven at 80°C for 12 hours to obtain Mn-BTC.

Embodiment 2

[0038] (1) Dissolution of trimesic acid in water

[0039] Weigh 0.4286g of trimesic acid and add it to 50mL of deionized water, heat and stir in an oil bath at 80°C until all trimesic acid is dissolved in water;

[0040] (2) Preparation of Ce-BTC

[0041] Weigh 0.8772g of cerium nitrate and dissolve it in 50mL of deionized water, then add it into the aqueous solution dissolved with trimesic acid, heat and stir at 80°C for 20s, take it out and wash it with ethanol and deionized water alternately, and the centrifugal speed is 3500rpm. The time is 3 minutes, repeated 6 times, and oven-dried at 80° C. for 12 hours to obtain Ce-BTC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com