High-strength cable descending rope connector structure and machining method thereof

A joint structure and high-strength technology, applied in the field of cable drop, can solve the problems of occupying the operating space of cable drop personnel, the influence of cable drop operation, and the impact on service life, etc., and achieve the effect of compact structure, small loss of connection strength, and avoiding life reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings and embodiments.

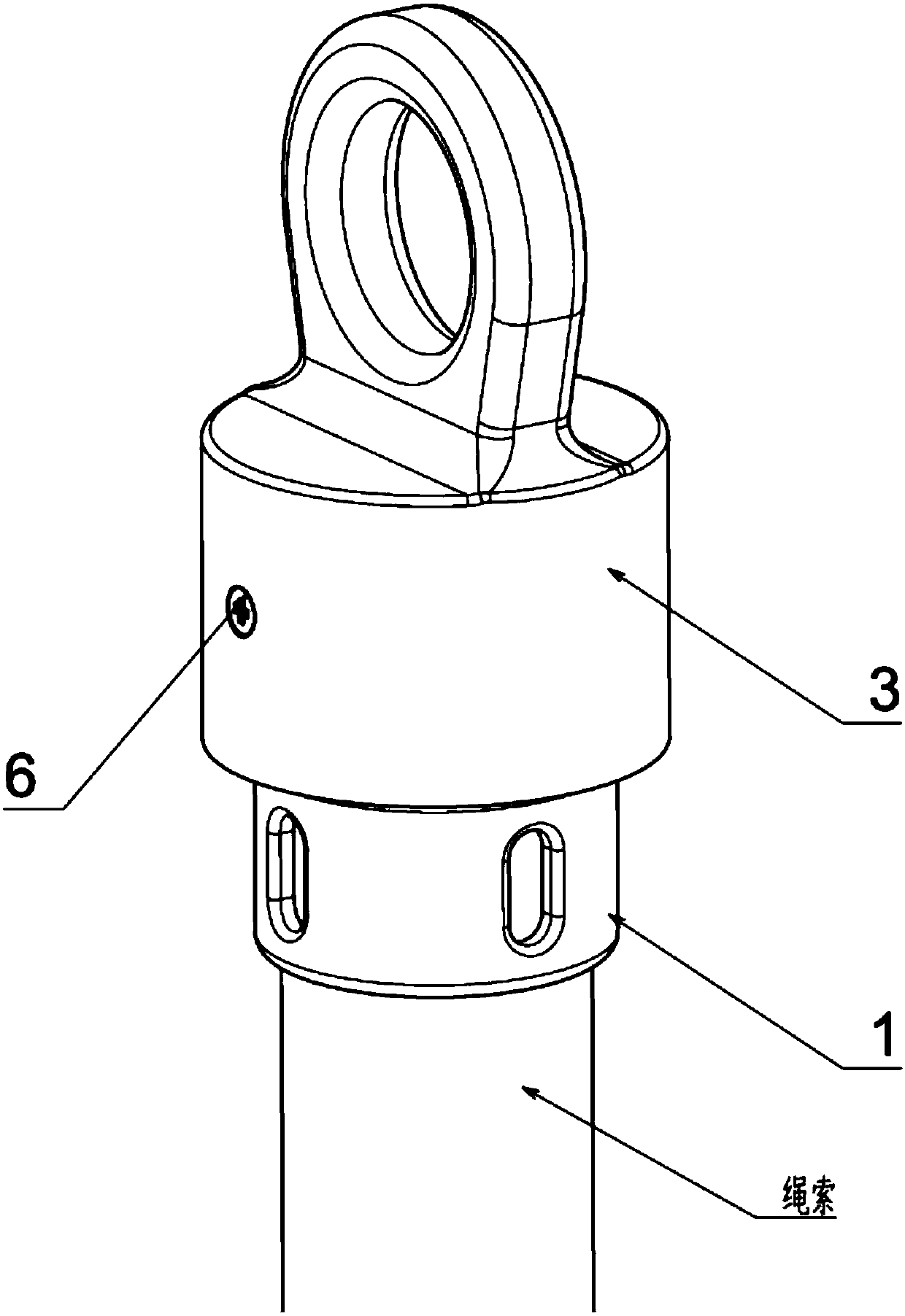

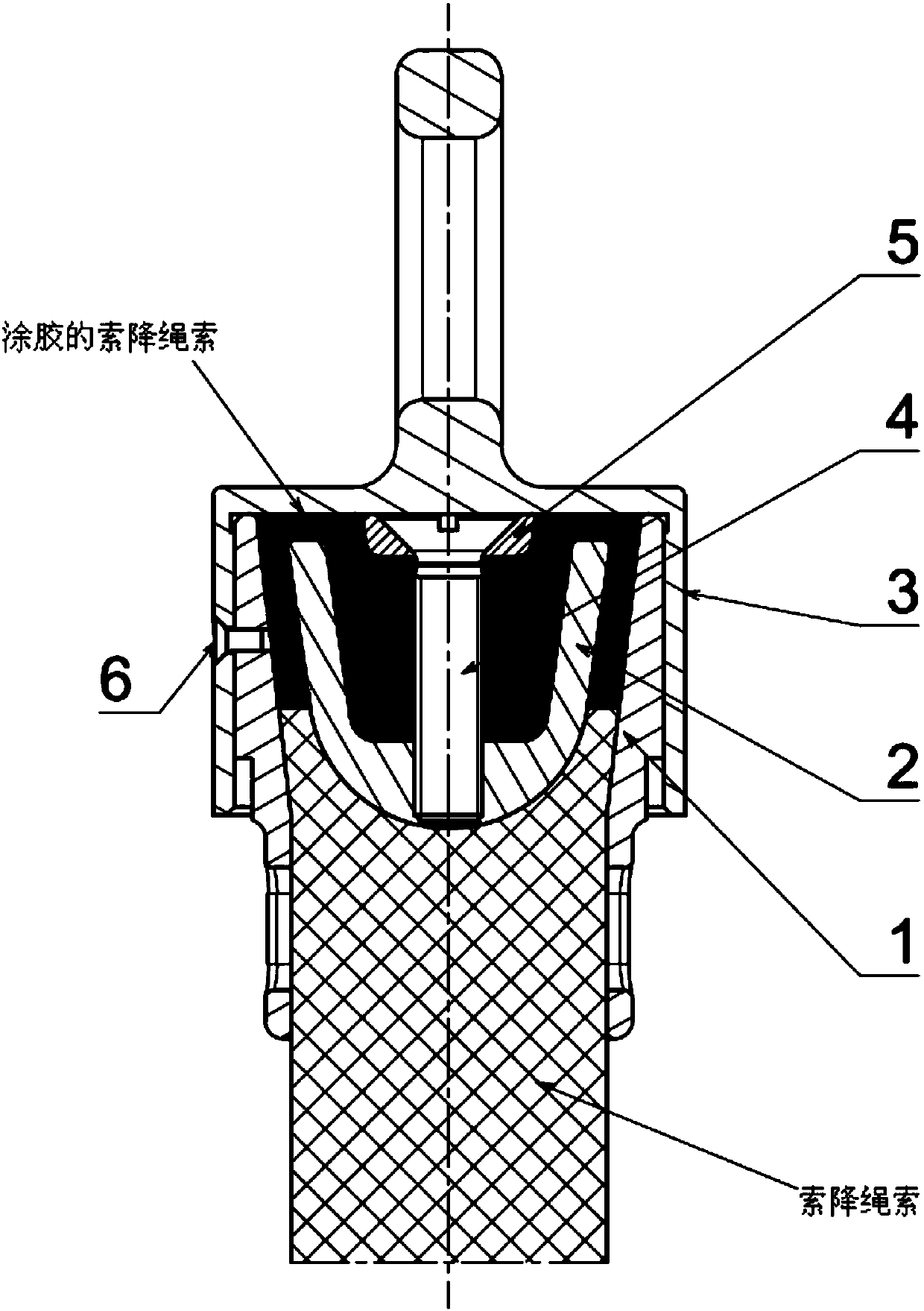

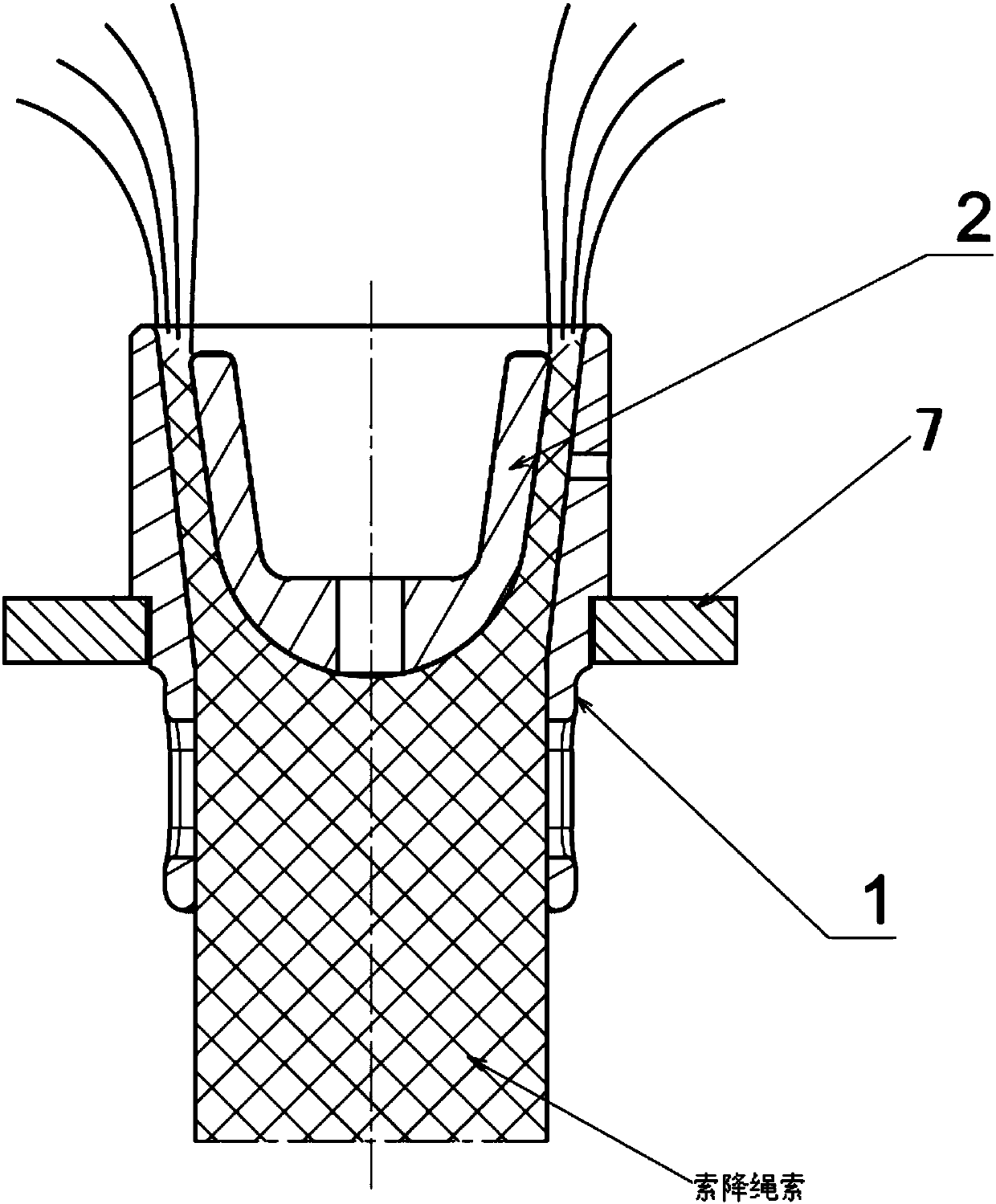

[0025] Such as figure 1 with figure 2 As shown, a high-strength cable-dropping rope joint structure includes an annular cylindrical connecting seat 1, a cable-dropping rope passing through the connecting seat 1 and being scattered at the end, and located in the center of the cable-falling rope breaking up in the connecting seat 1. A wedge with a cavity on the top 2, a pressure plate 5 located above the center of the inner cavity of the connecting seat 1, a screw 4 that passes through the pressure plate 5 and is connected to the wedge 2, and a hanging cover with a ring structure connected to the top of the connecting seat 1 3. The connecting seat 1, the wedge 2, the pressing plate 5 and the hanging cover 3 are all metal parts. The cable drop rope fiber extends from the wedge 2 and the connecting seat 1 and folds back into the cavity, the cavity and the wedge 2 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com