Composite insulating member, manufacturing method therefor, and electrical device comprising composite insulating member

A technology of insulating components and composite insulation, applied in the direction of insulated cables, insulated conductors, electrical components, etc., can solve the problems of reduced output of electrical devices, shortened life of electrical devices, restrictions on heat transfer performance, etc., to suppress excessive temperature rise, promote conductors. Excellent effect of inter-heat transfer and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0066] In this specification, even if it is a different embodiment, the same or similar reference numerals are given to the same or similar structures, and the description thereof will be replaced by the first description. A singular expression used in this specification includes a plural expression unless there is a clear difference in context.

[0067] The present invention relates to a composite insulation member having insulation performance and heat dissipation performance capable of promoting cooling of conductors, a method for manufacturing the composite insulation member, and an electrical device having the composite insulation member.

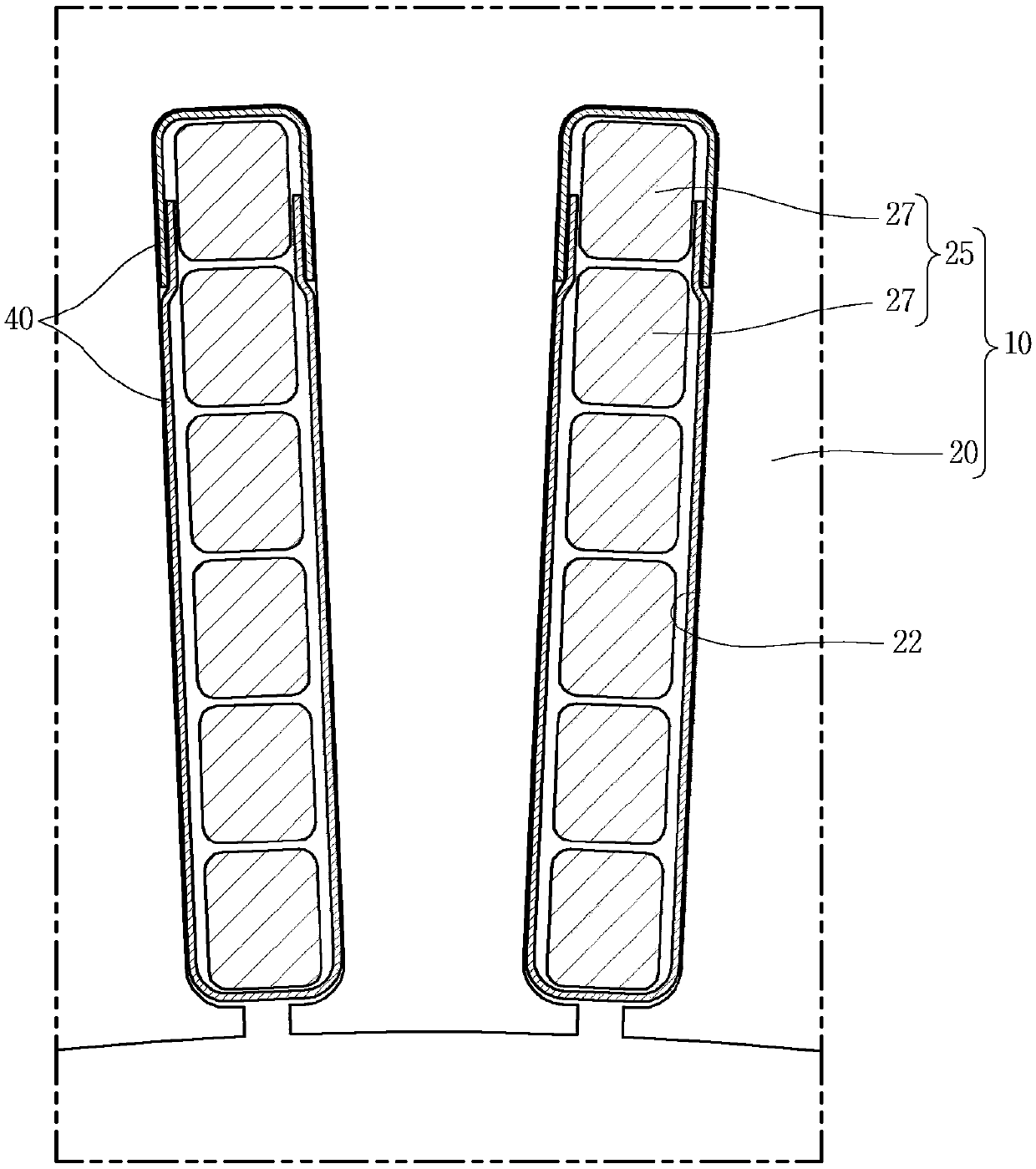

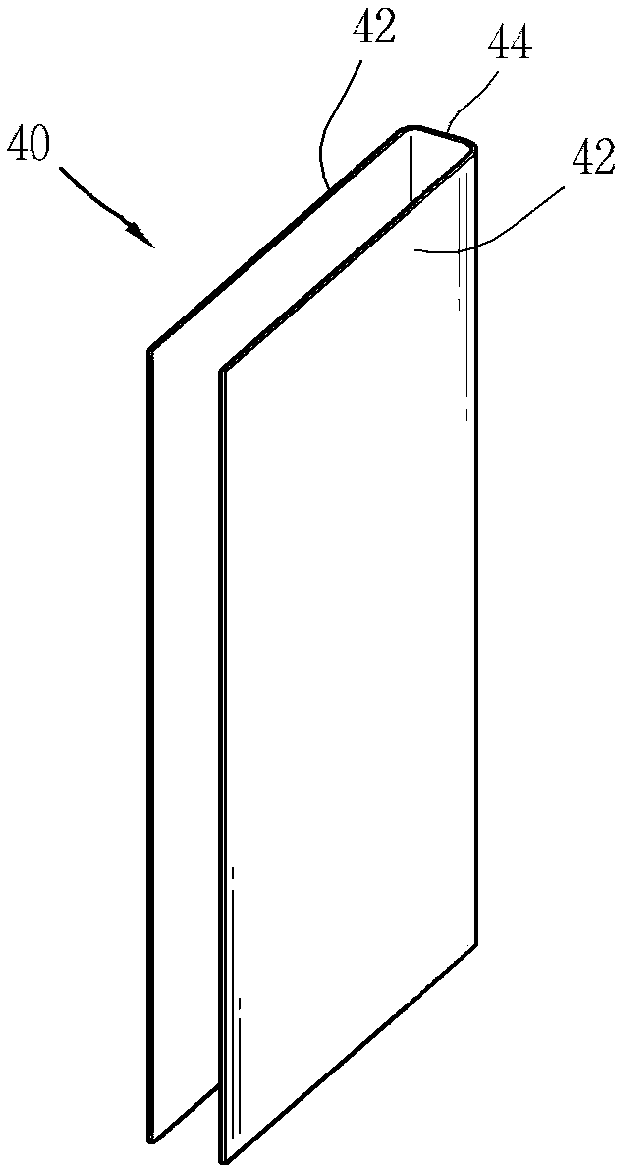

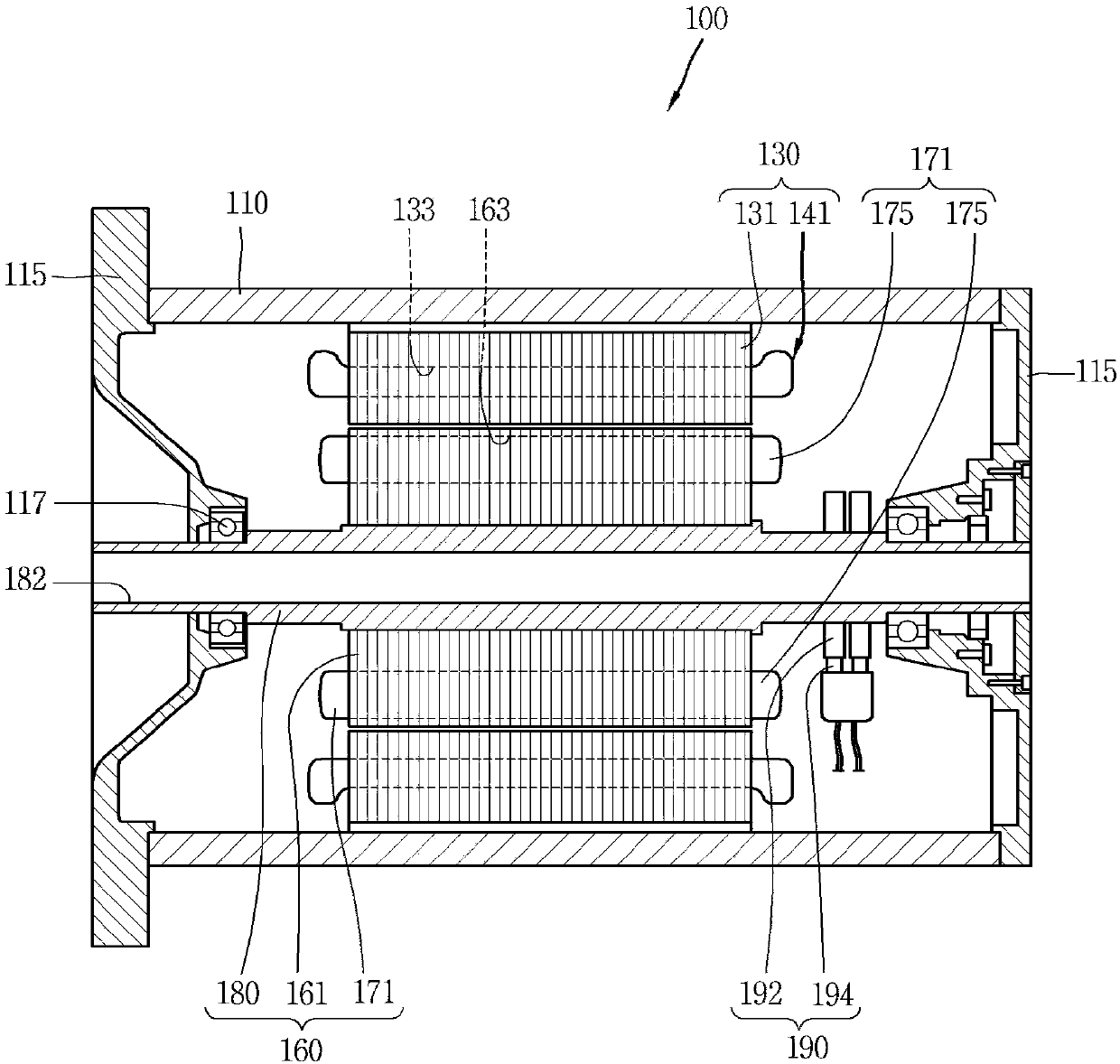

[0068] image 3 It is a cross-sectional view of an electrical device having a composite insulating member according to an embodiment of the present invention, Figure 4 yes image 3 An enlarged view of the main part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com