Patents

Literature

34results about "Contact cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

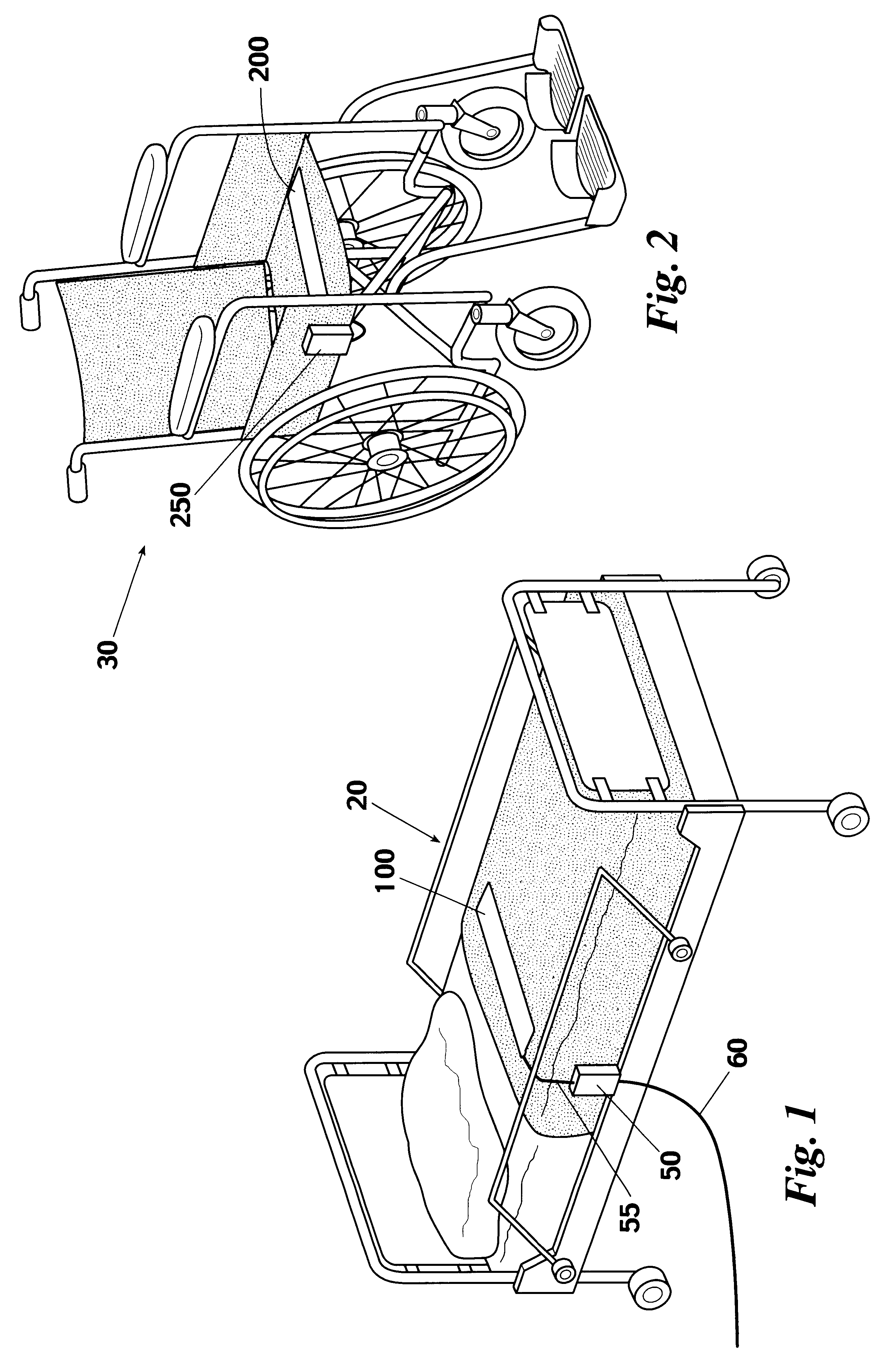

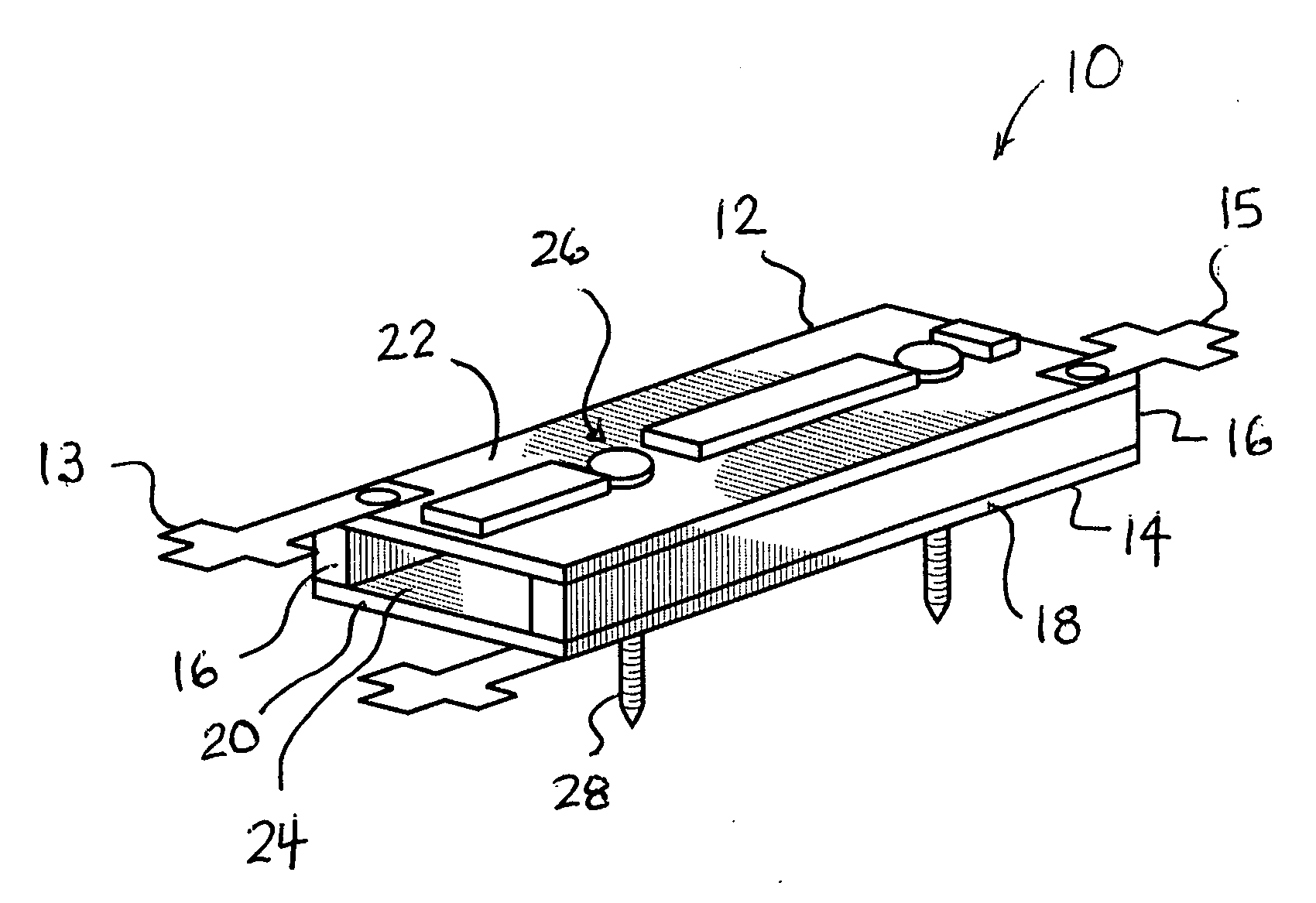

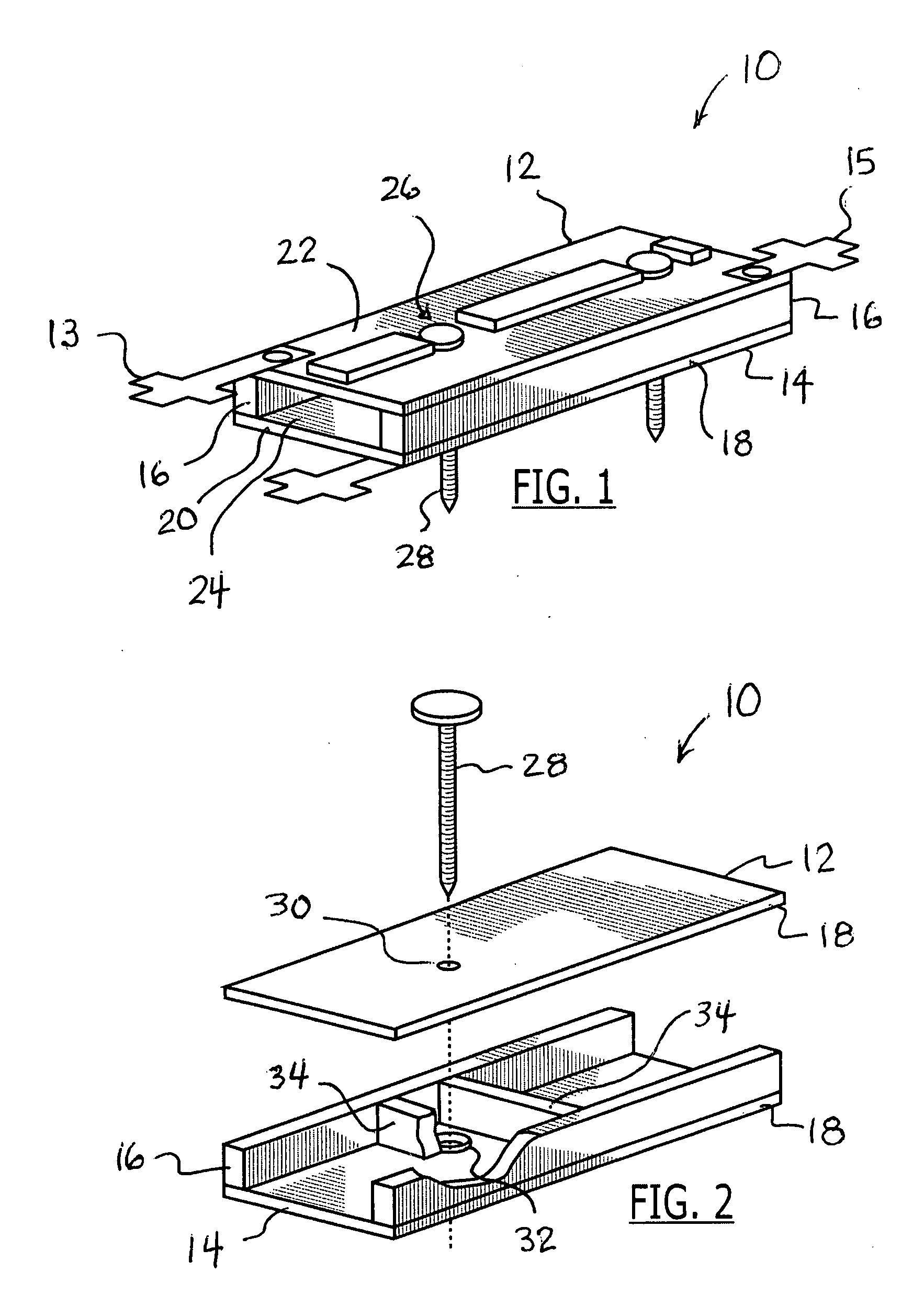

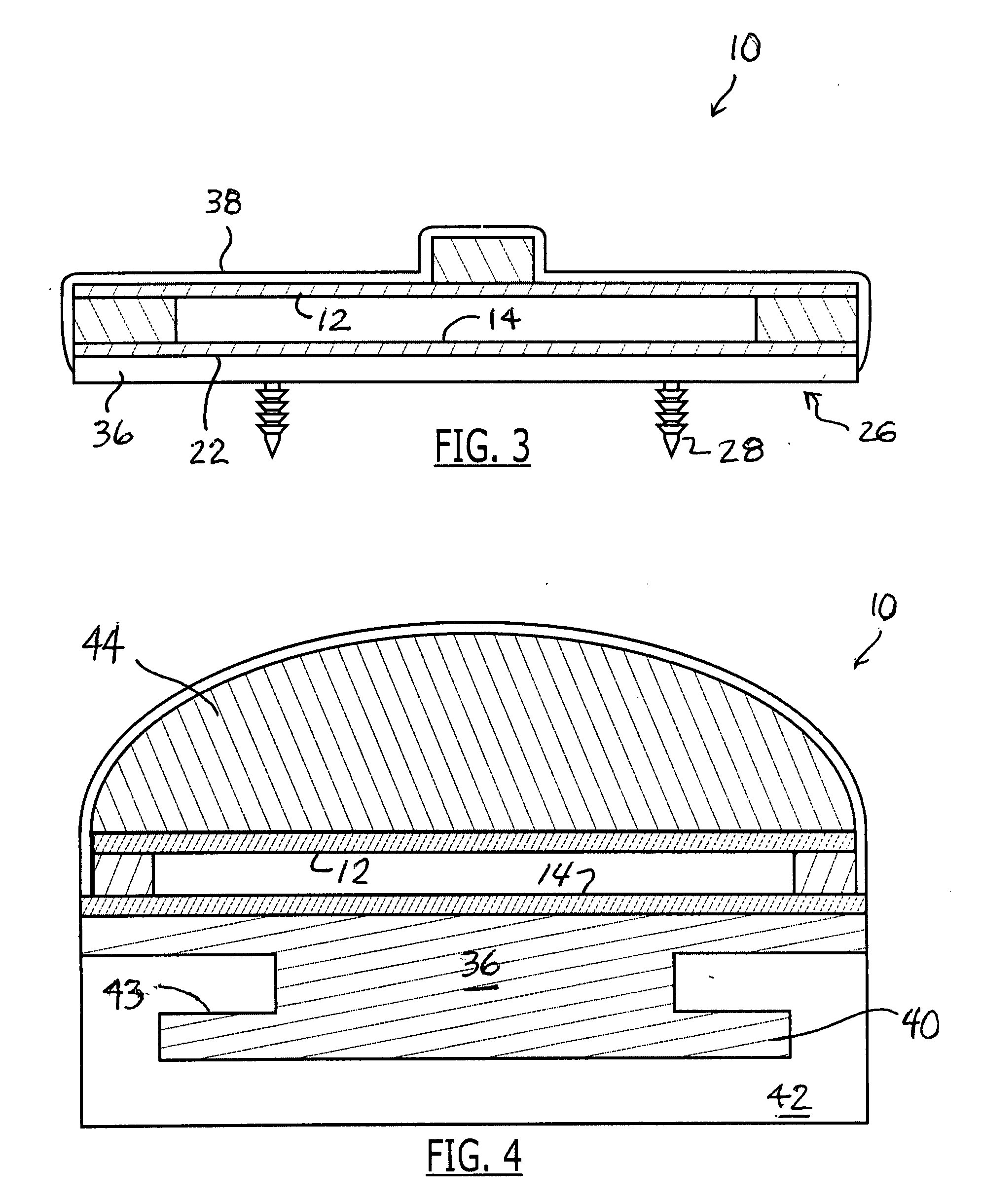

Binary switch apparatus and method for manufacturing same

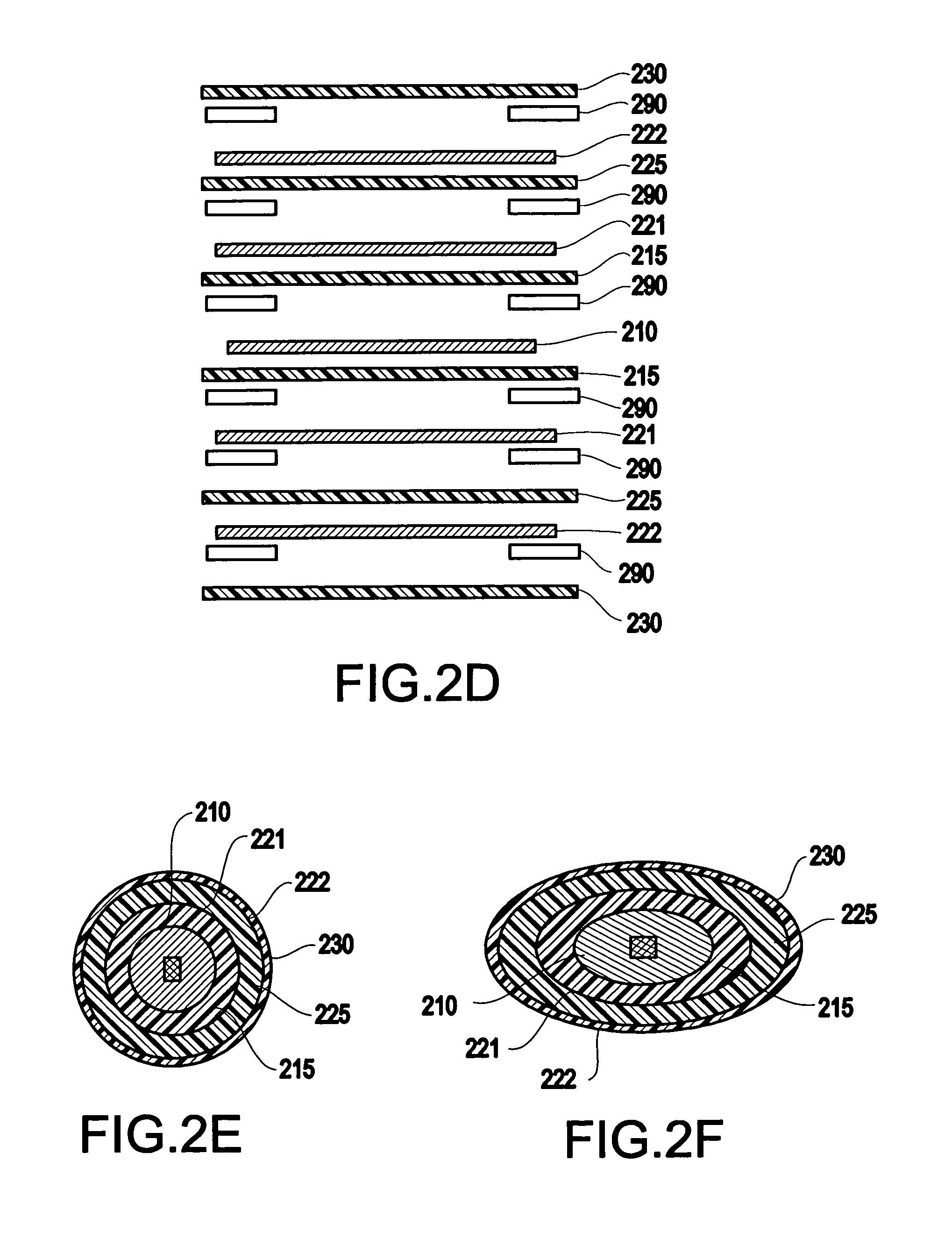

InactiveUS6696653B1Freedom of movementDetection of traffic movementContact operating partsPatient monitorMedical treatment

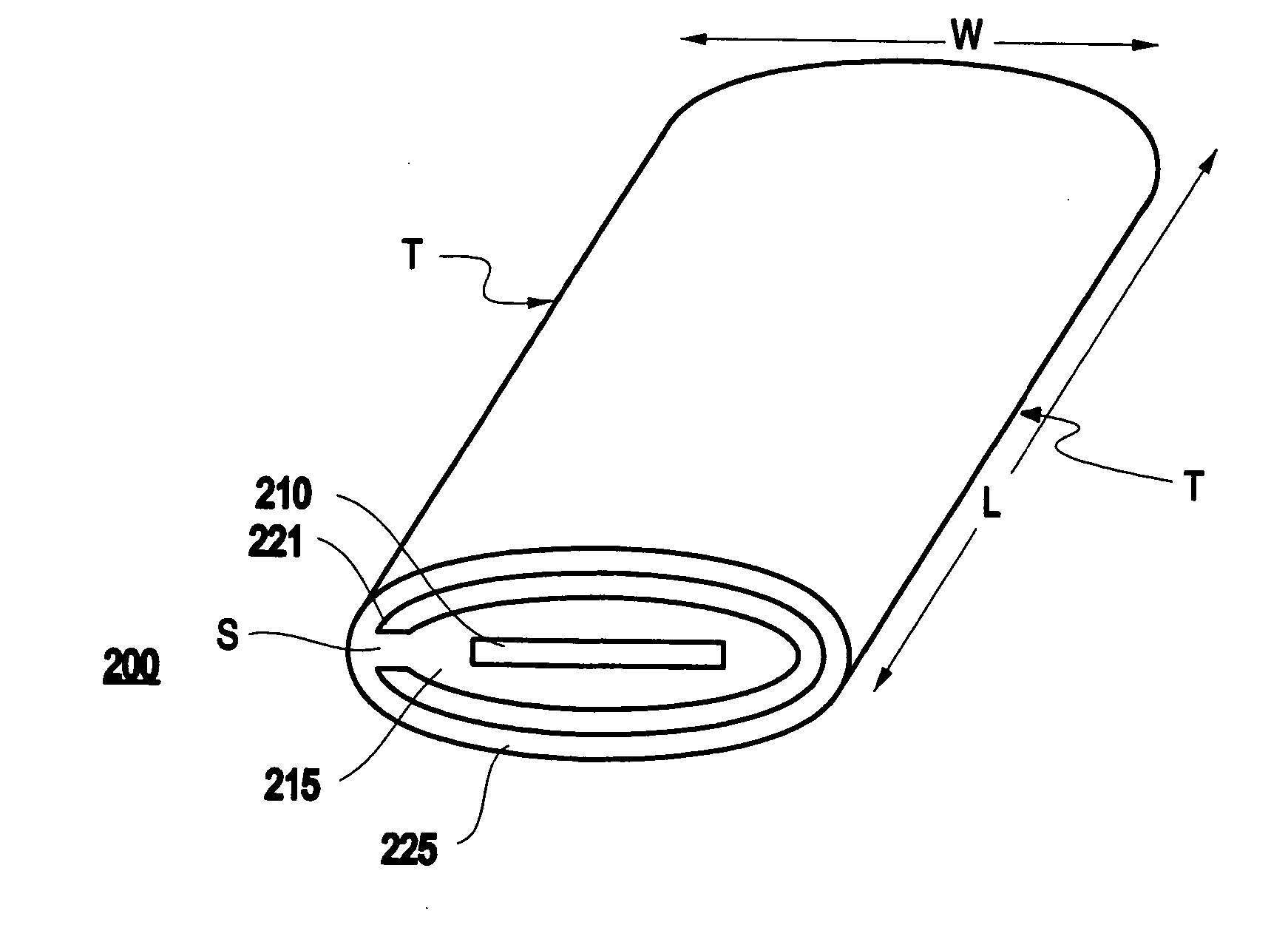

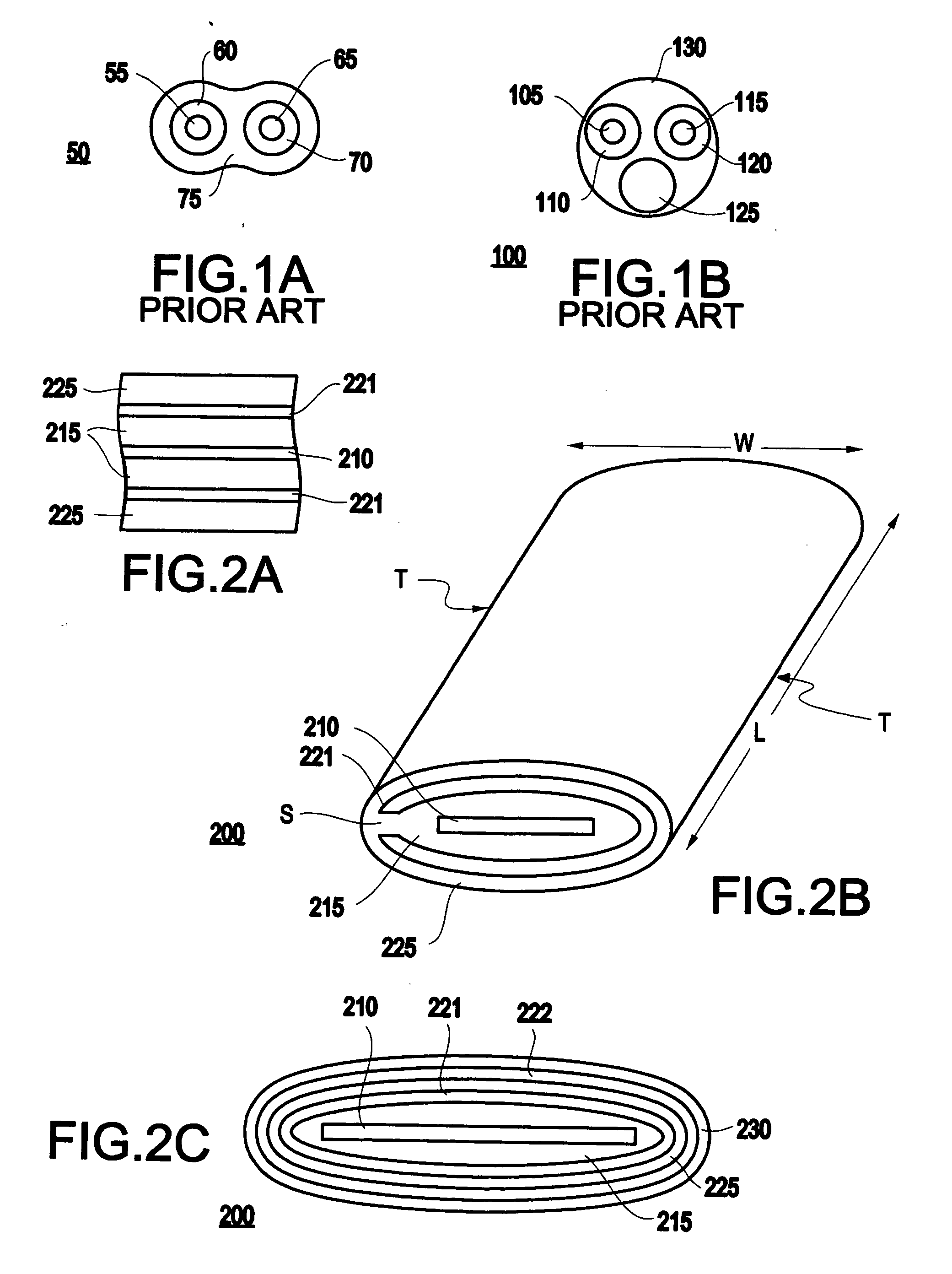

The present invention relates generally to binary switches for use in the medical monitoring field and to methods for manufacturing same. More particularly, the instant invention involves the construction, manufacture, and operation of pressure sensitive patient monitors of the sort commonly used in medical settings to detect when a patient has, for example, exited a chair or a bed. In accordance with a preferred embodiment of the instant invention, an apparatus for patient monitoring is disclosed herein that contains one or more therein which resiliently collapse in response to weight, thereby completing an electrical circuit and indicating a presence or absence of a patient on the mat. Other preferred embodiments include hermetically sealed mats and methods of manufacturing same.

Owner:BED CHECK

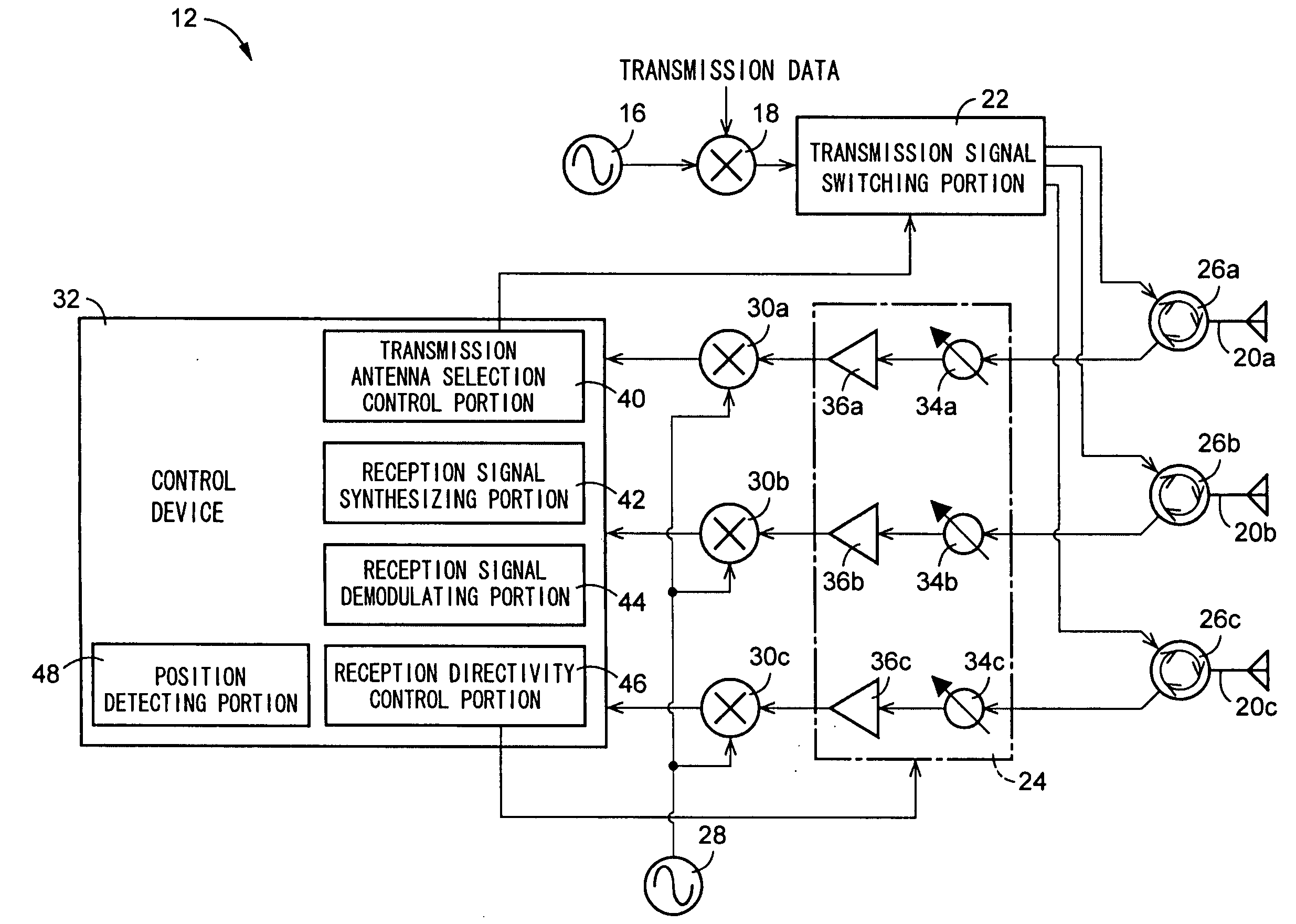

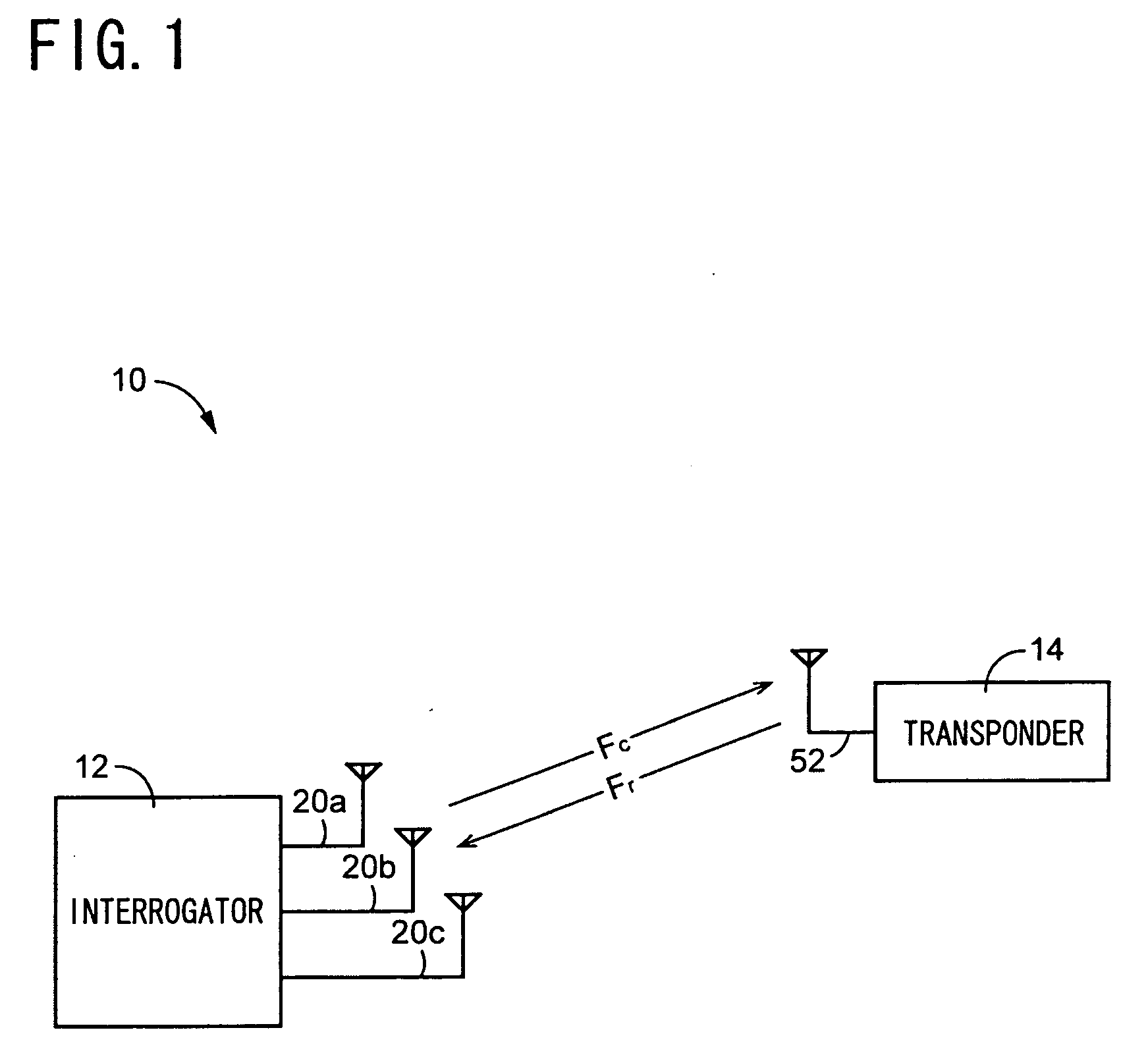

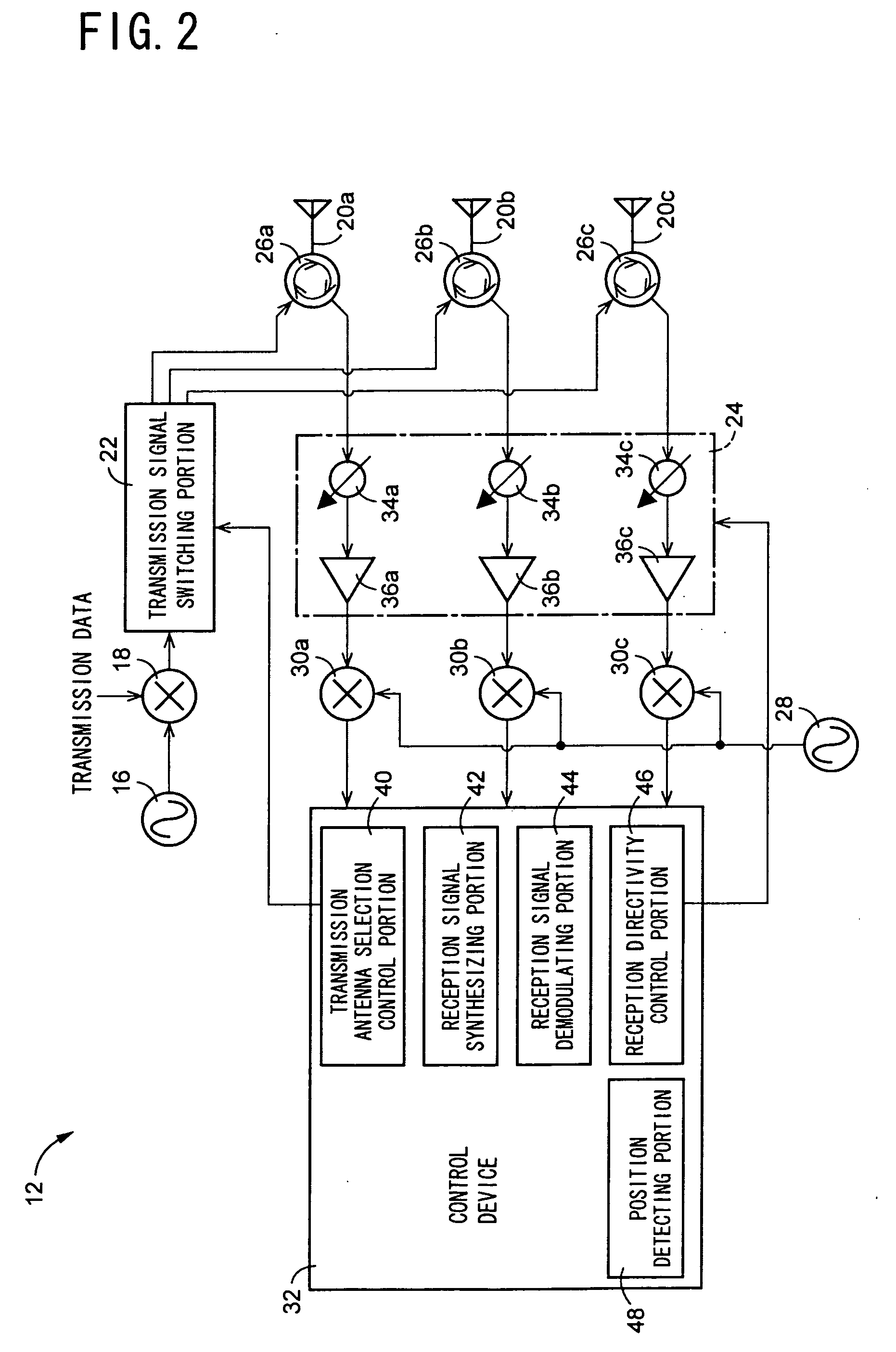

Radio tag communication apparatus

InactiveUS20070037529A1Wide spreadEasy constructionSpatial transmit diversityAntenna arraysEngineeringAntenna element

A radio tag communication apparatus having a broad communicable range and a simple arrangement, is provided. Since there are provided a transmission antenna selection control portion for selecting a single transmission-reception antenna element to transmit a transmission signal, from a plurality of transmission-reception antenna elements, and a reception signal synthesizing portion for synthesizing respective reception signals received by the plurality of transmission-reception antenna elements, with each other, a communicable range of the radio tag communication apparatus can be broadened by transmitting the transmission signal from a diversity antenna having a simple arrangement, and a reception sensitivity of the radio tag communication apparatus can be enhanced by synthesizing the reception signals received by the plurality of transmission-reception antenna elements, with each other.

Owner:BROTHER KOGYO KK

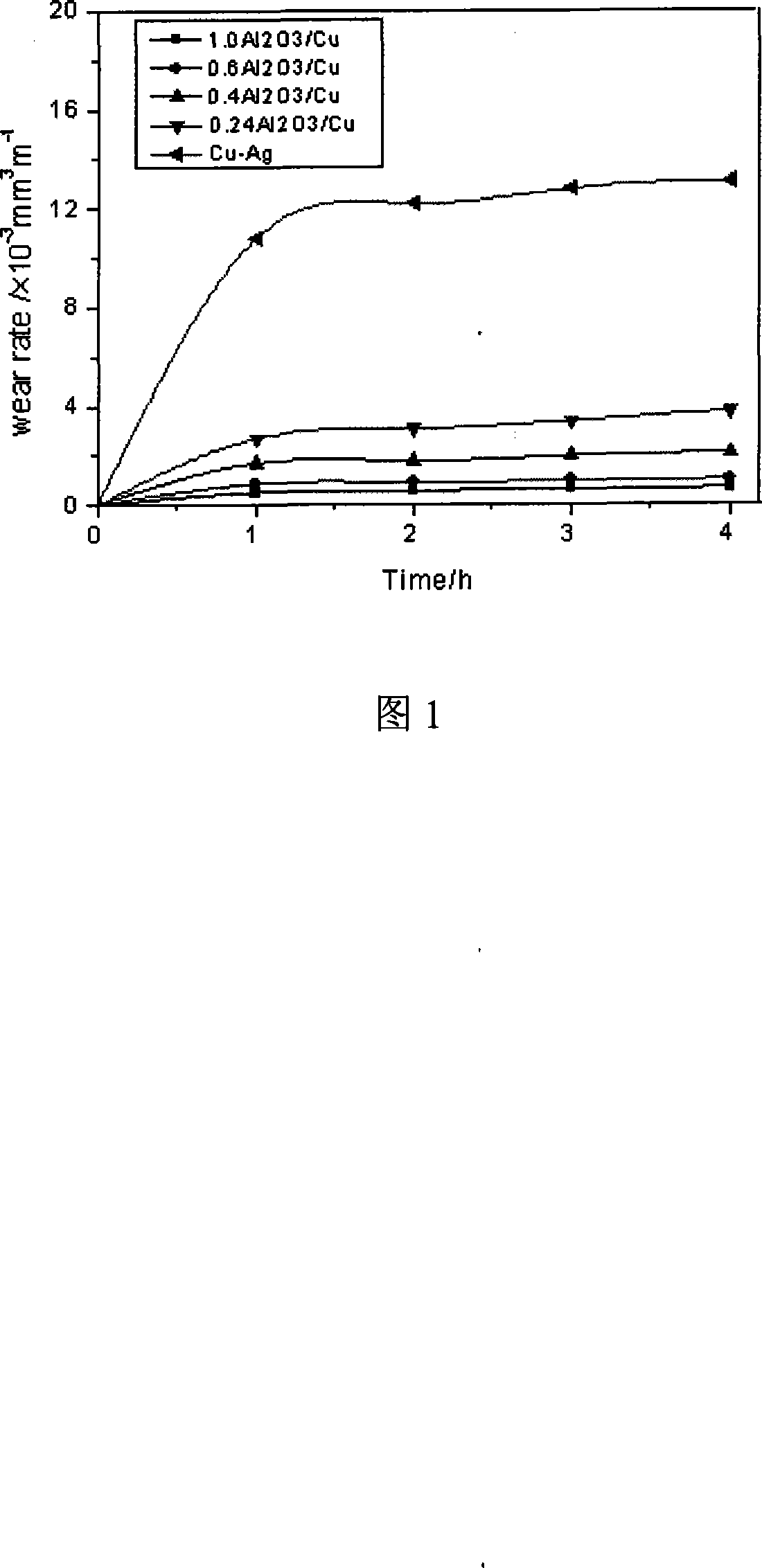

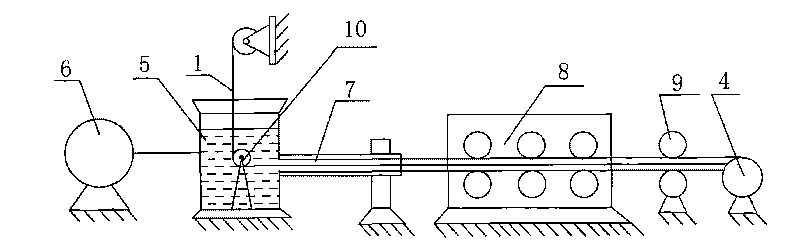

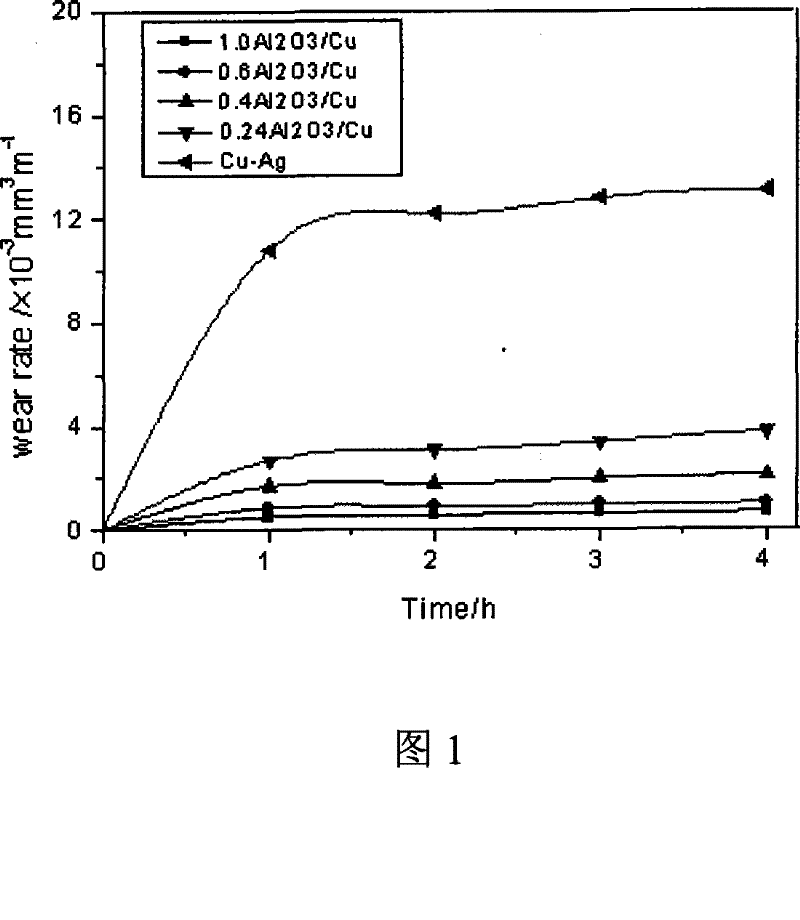

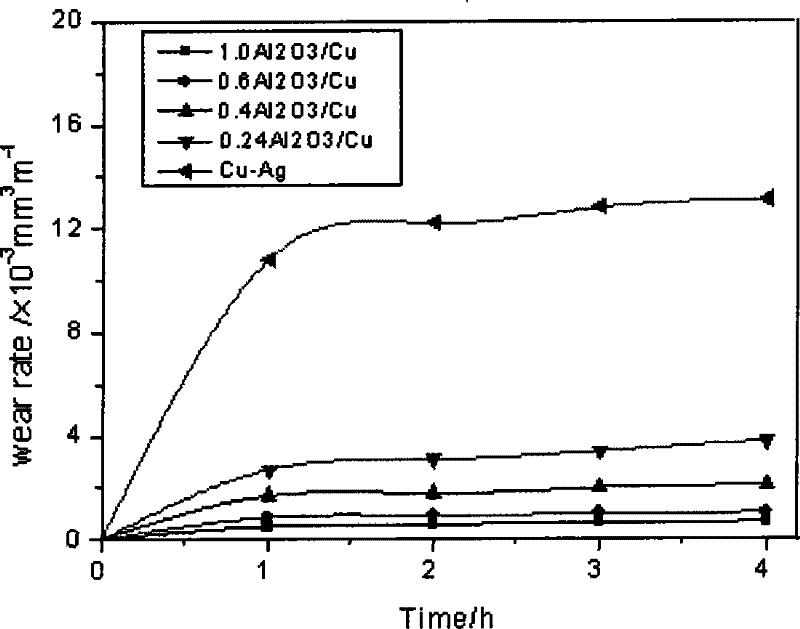

Copper alloy contact wire and method of producing the same

InactiveCN101178957AImprove wear resistanceImprove fatigue resistanceSingle bars/rods/wires/strips conductorsContact cablesReduction treatmentInternal oxidation

The invention provides copper alloy contact lines and a preparation method thereof, wherein, the method includes the following steps: (1) preparing master alloy powders of Cu-AI, in which 0.21-0.53wt% is the content of AI, and the rest is copper; (2) using the master alloy powders of Cu-AI obtained from step (1) to prepare an oxygen source of Al2O3-Cu2O, in which the weight ratio of Cu and AI keeps unchanged; (3) mixing the master alloy powders of Cu-AI obtained from step (1) and the oxygen source of Al2O3-Cu2O obtained in step (2), wherein, the weight ratio of the oxygen source of Al2O3-Cu2O in the mixture is 10-25wt%; (4) carrying out internal oxidation and reduction treatment for the mixture obtained in step (3), so as to obtain alloy powders of Cu-Al2O3, in which the content of Al2 O3 is 0.4-1.0wt%; (5) suppressing the alloy powders of Cu-Al2O3 obtained in step (4) into billets and then carrying out sintering treatment; (6) molding the suppressed and sintered billets obtained in step (5) into bars; (7) making the bars obtained in step (6) into contact lines with required section size by drawing. The copper alloy contact lines prepared by the method present good conductivity, high mechanical strength and softening temperature, good performance of friction and abrasion resistance.

Owner:DATANG LUOYANG SHOUYANGSHAN POWER PLANT

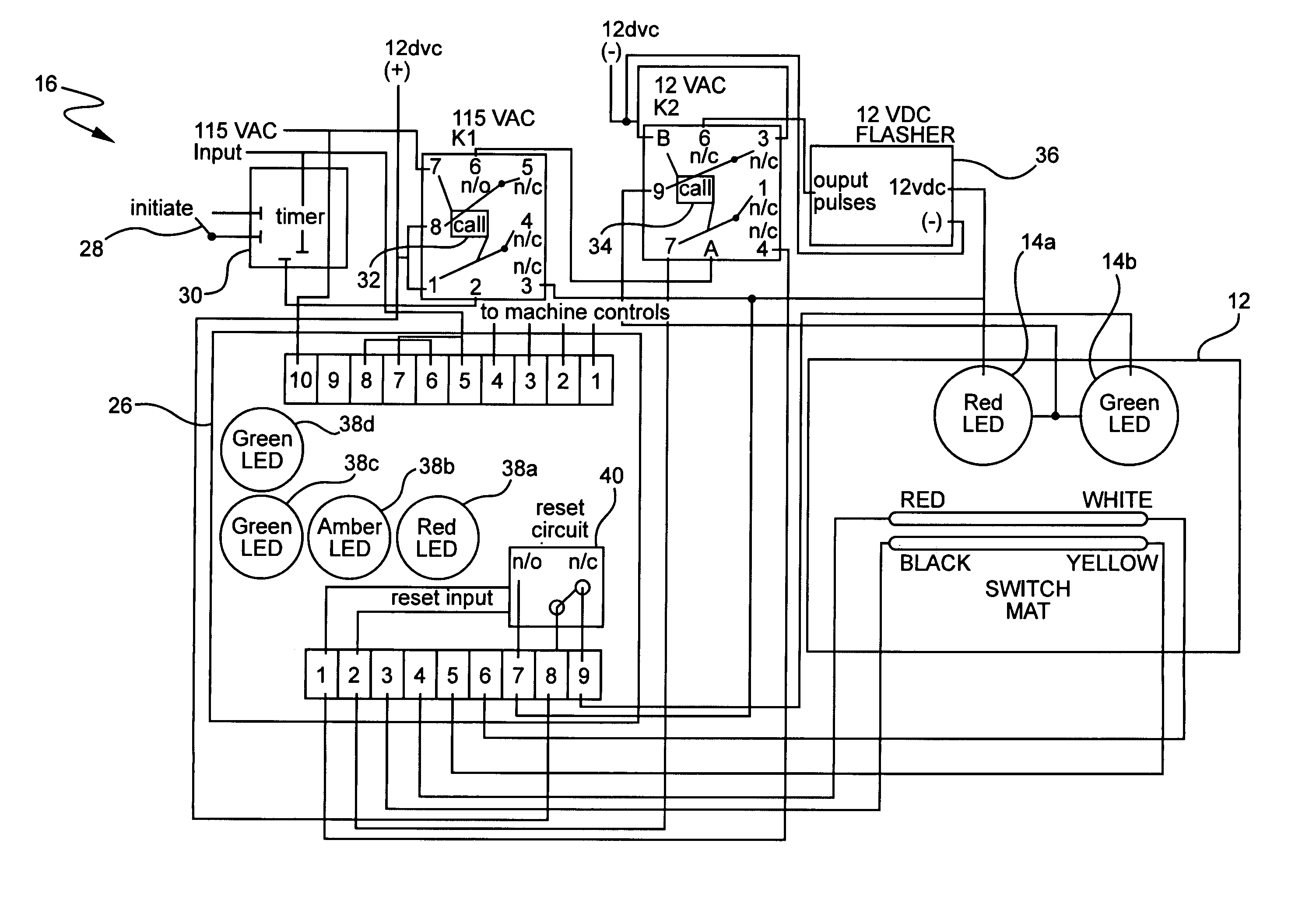

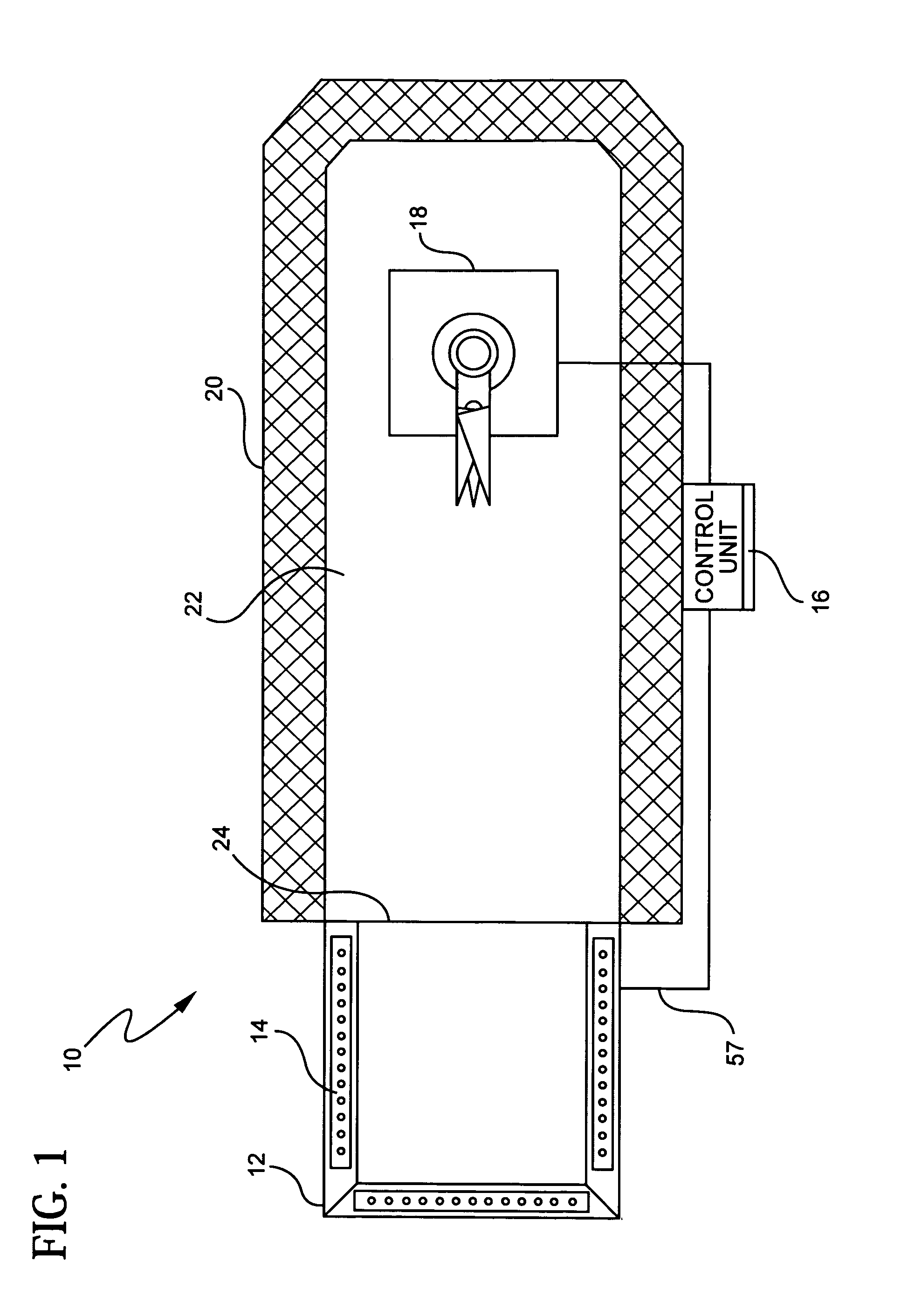

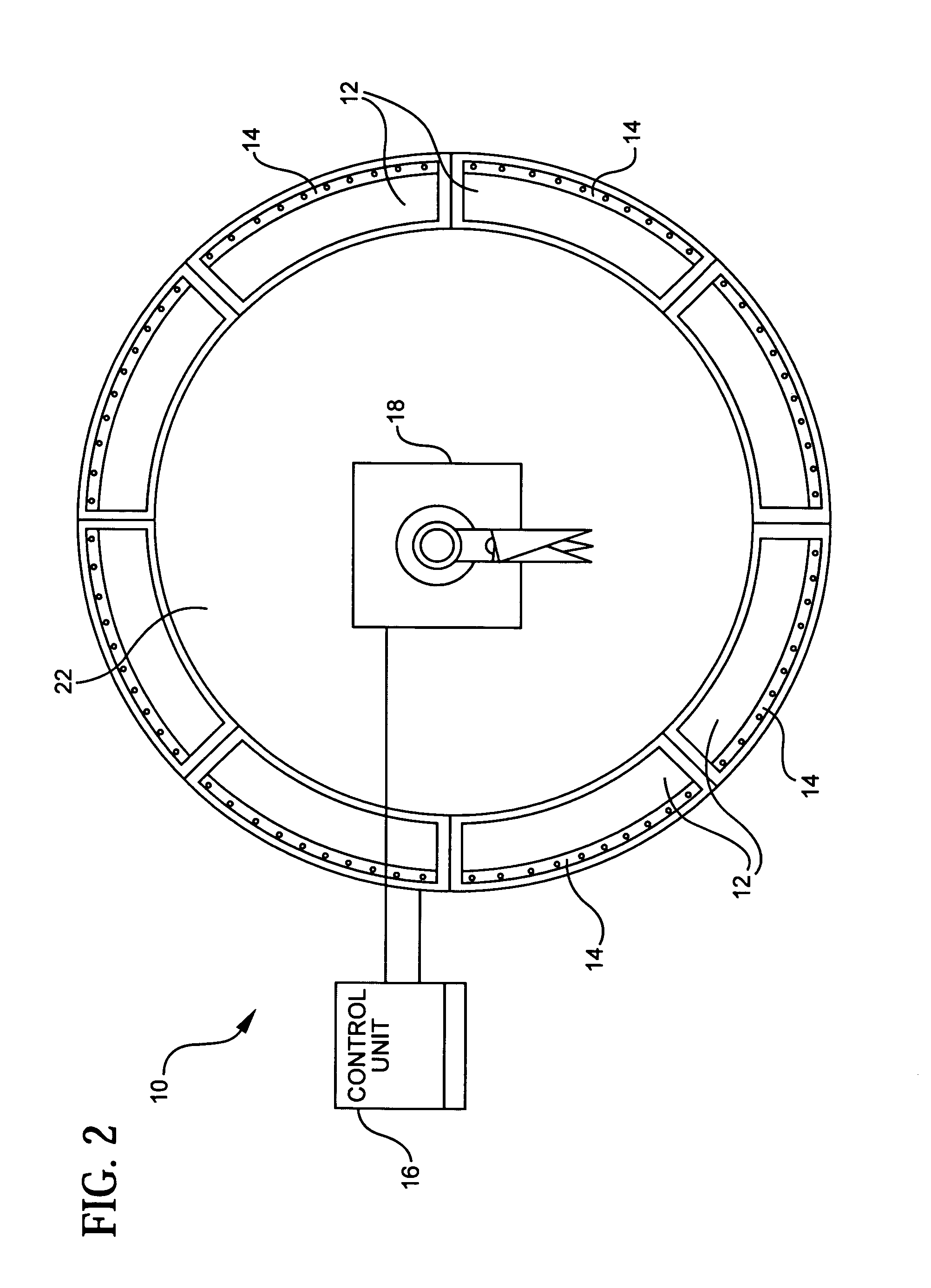

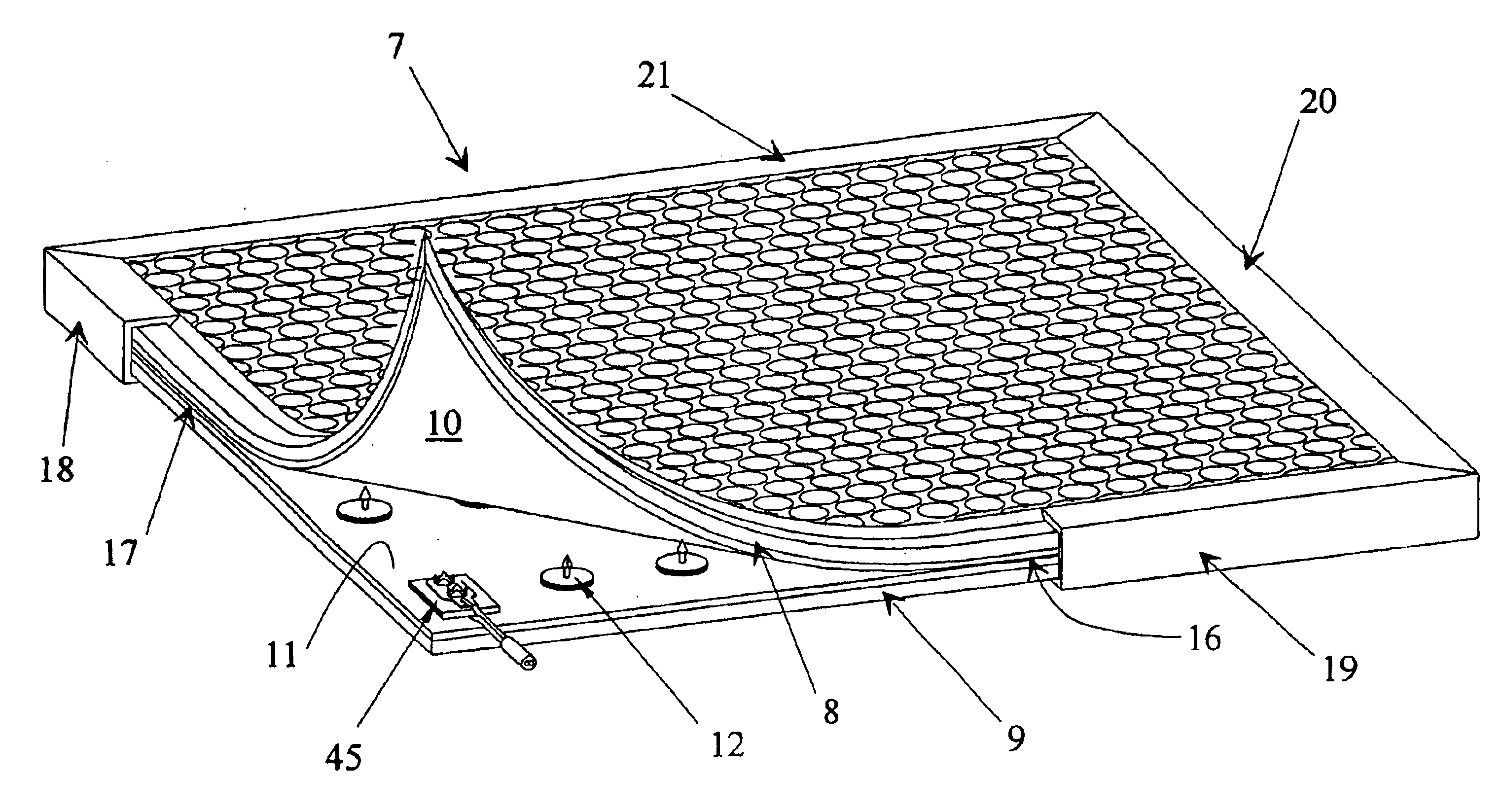

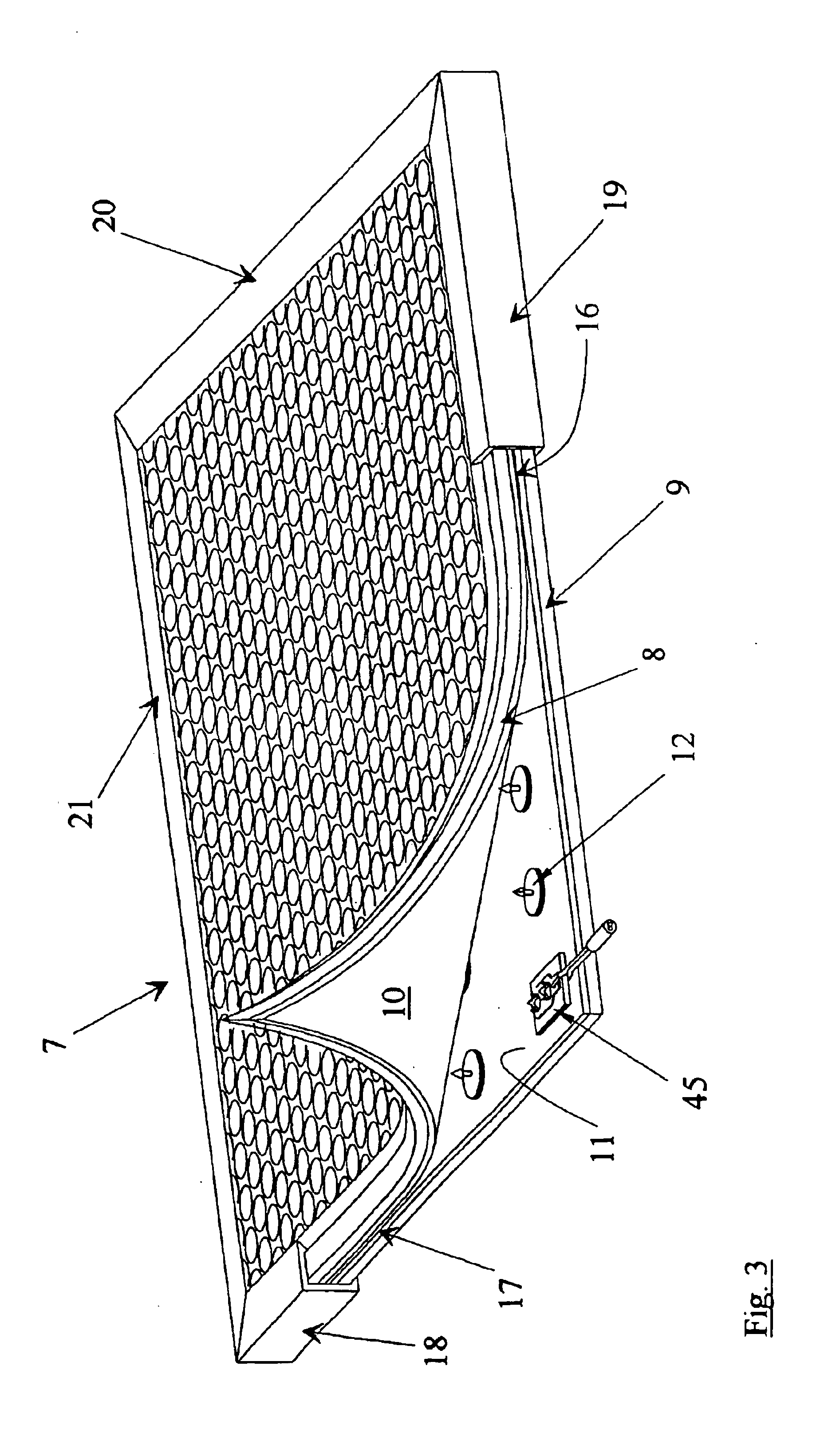

Machine guarding system having a sensing mat with status indicator lights

Owner:TAPESWITCH OF AMERICA

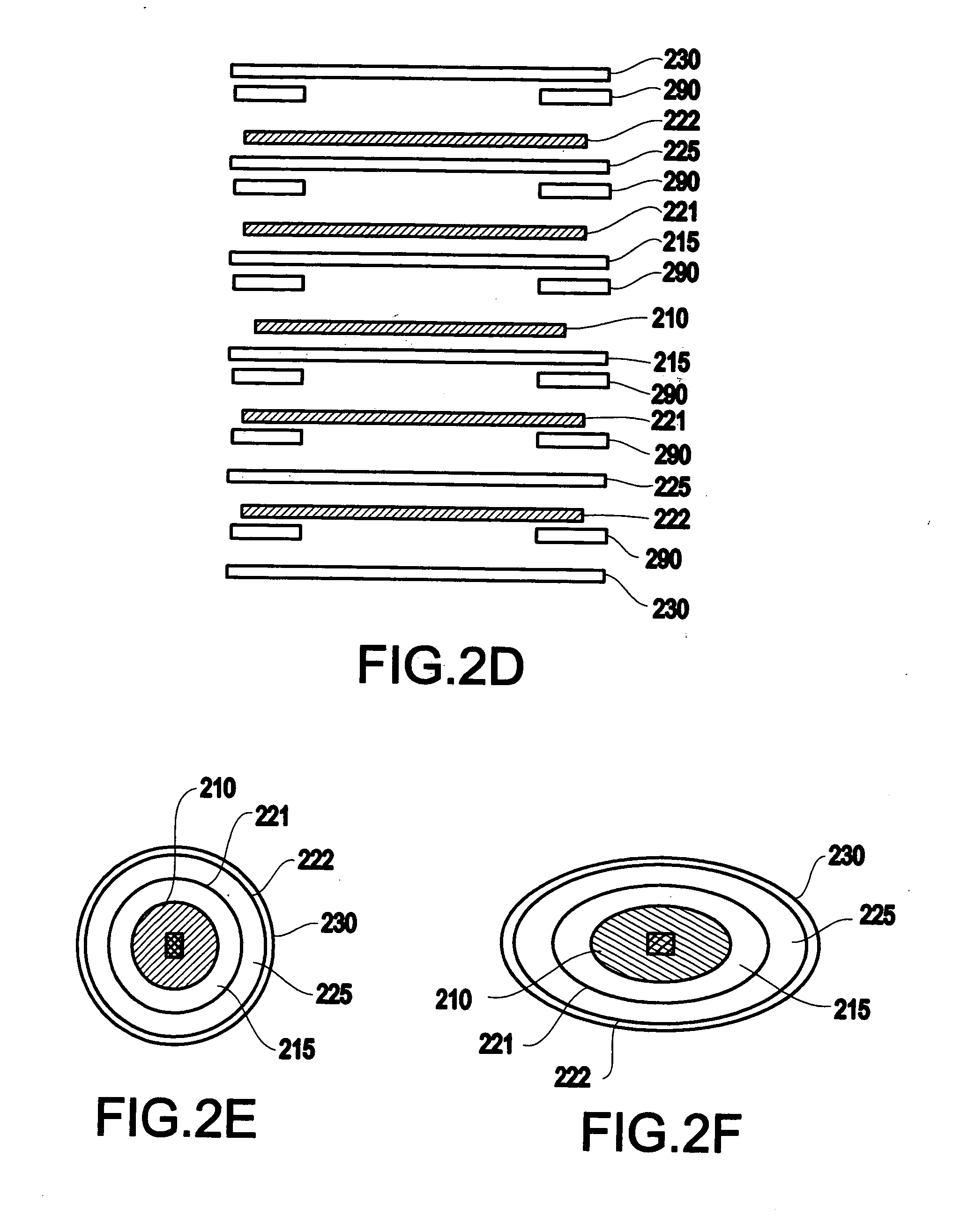

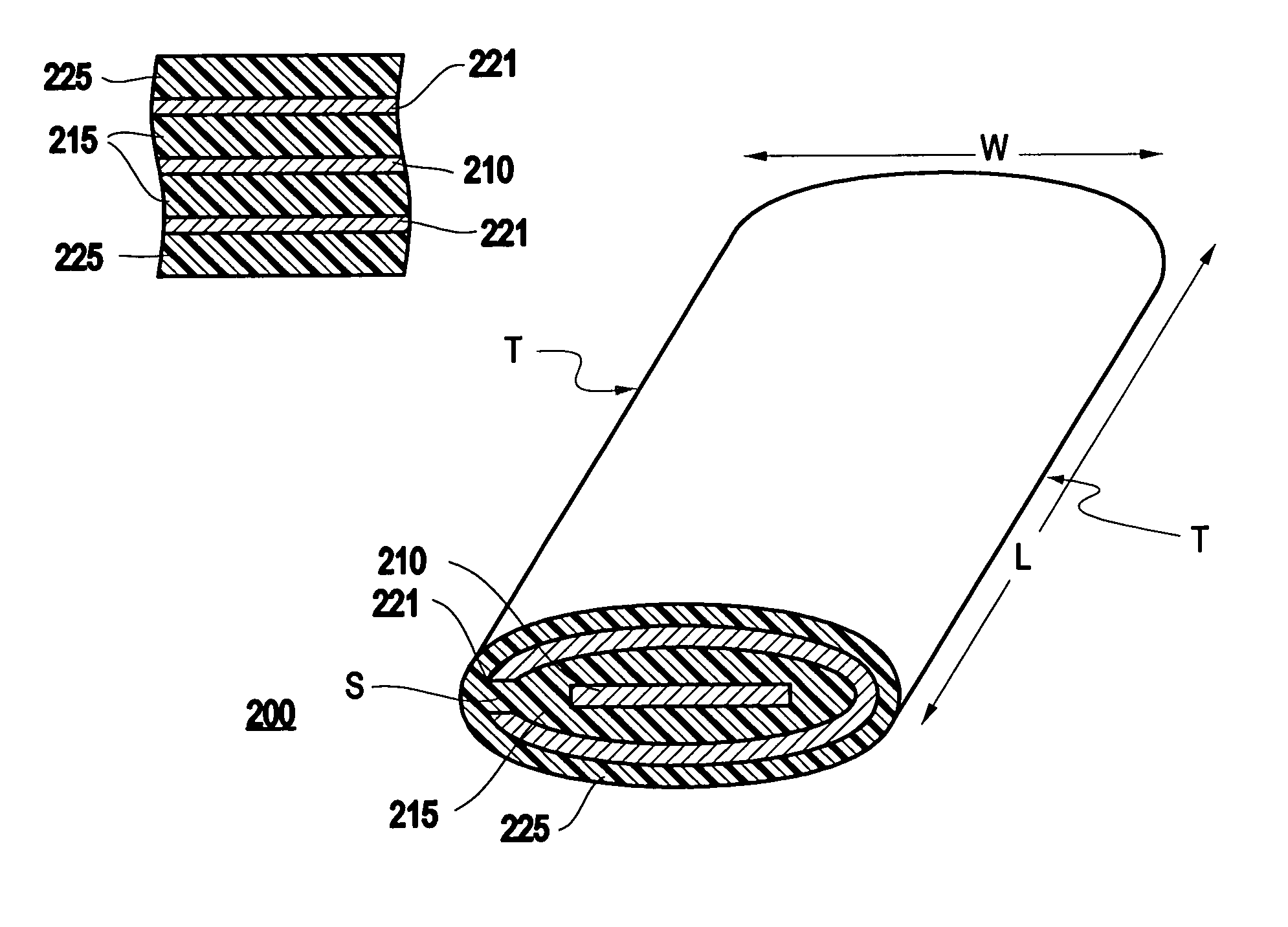

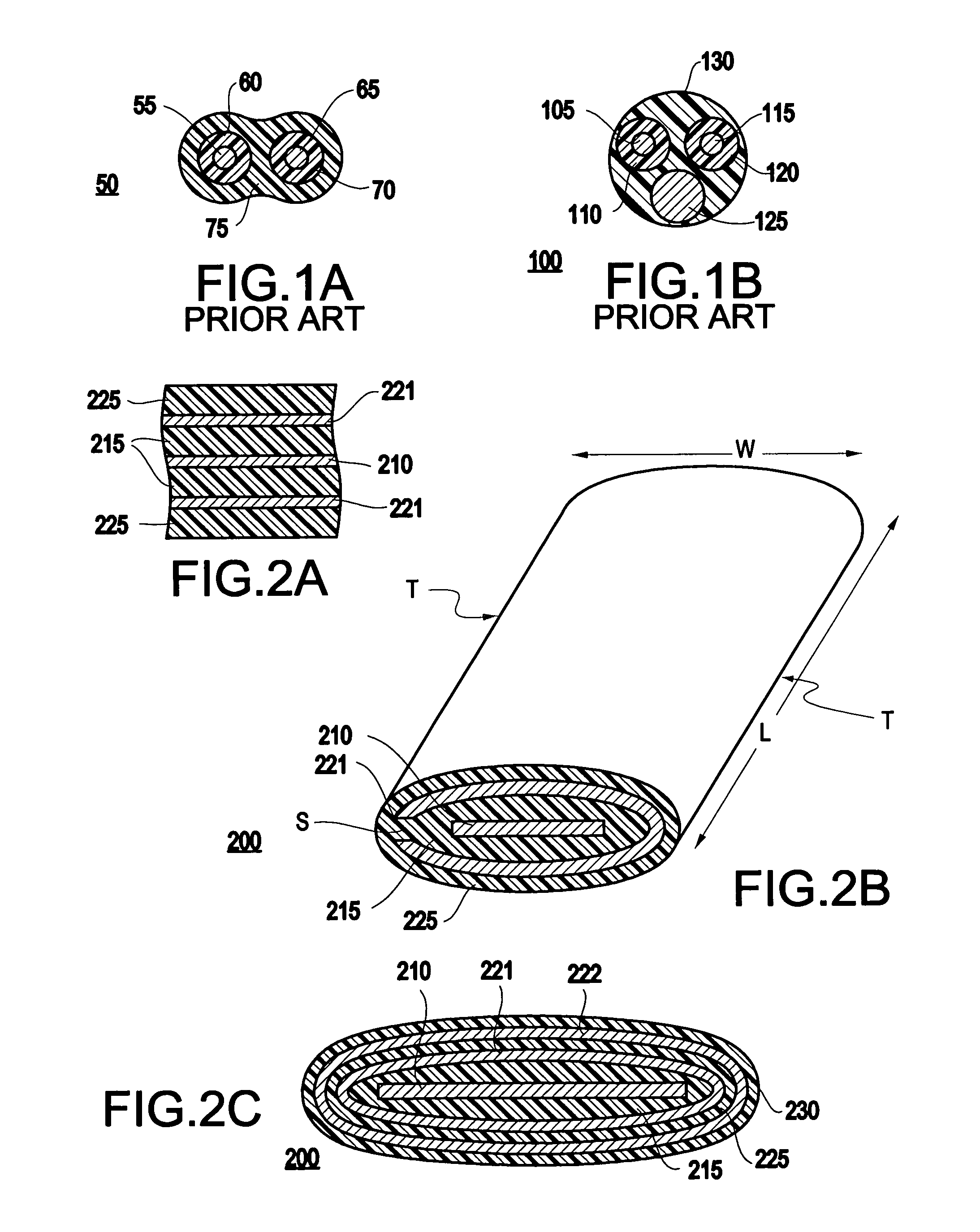

Electrical wire and method of fabricating the electrical wire

InactiveUS20050042942A1Safe and convenientEasy to makeElectrically conductive connectionsConcentric cablesElectrical conductorEngineering

Owner:SOUTHWIRE CO LLC

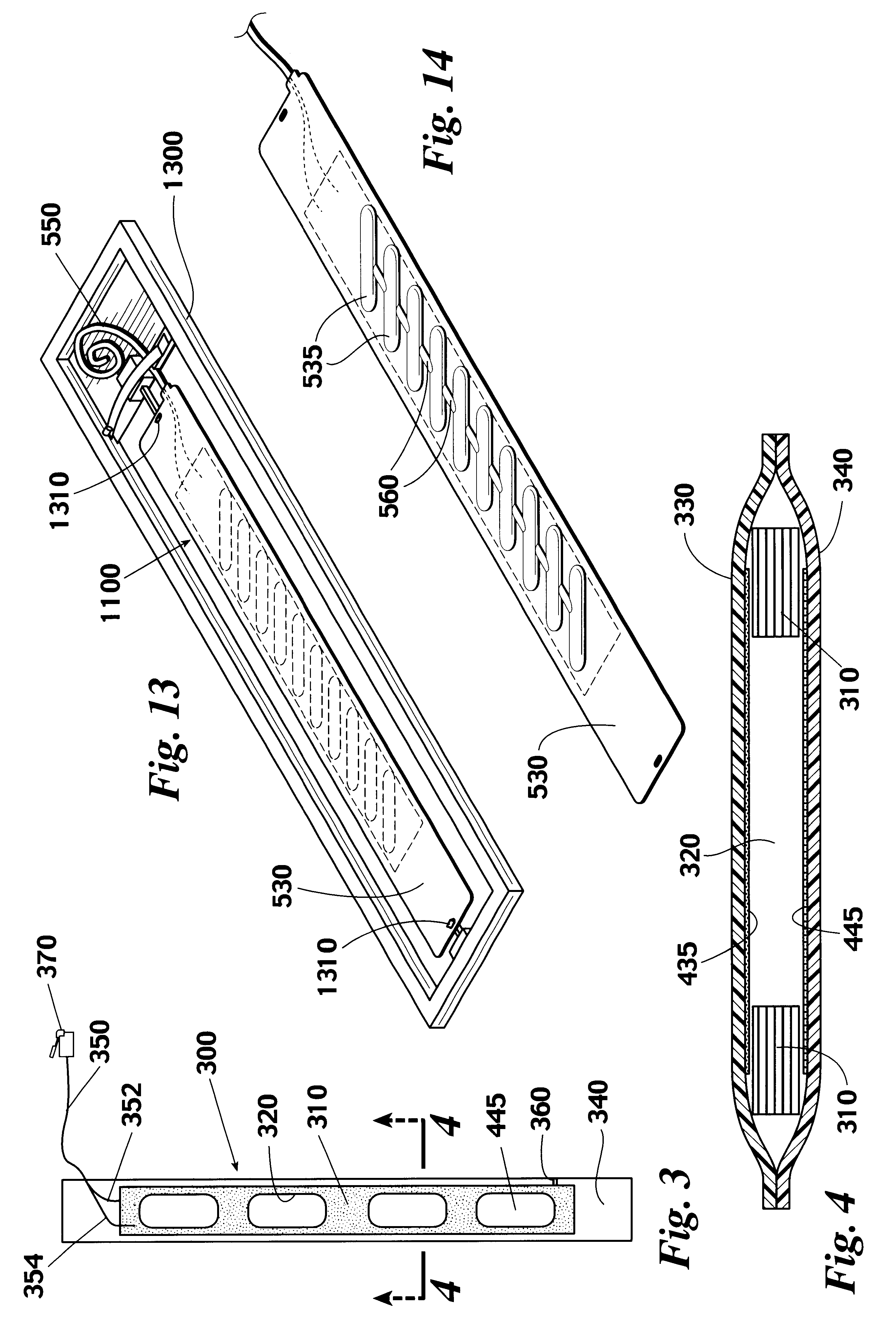

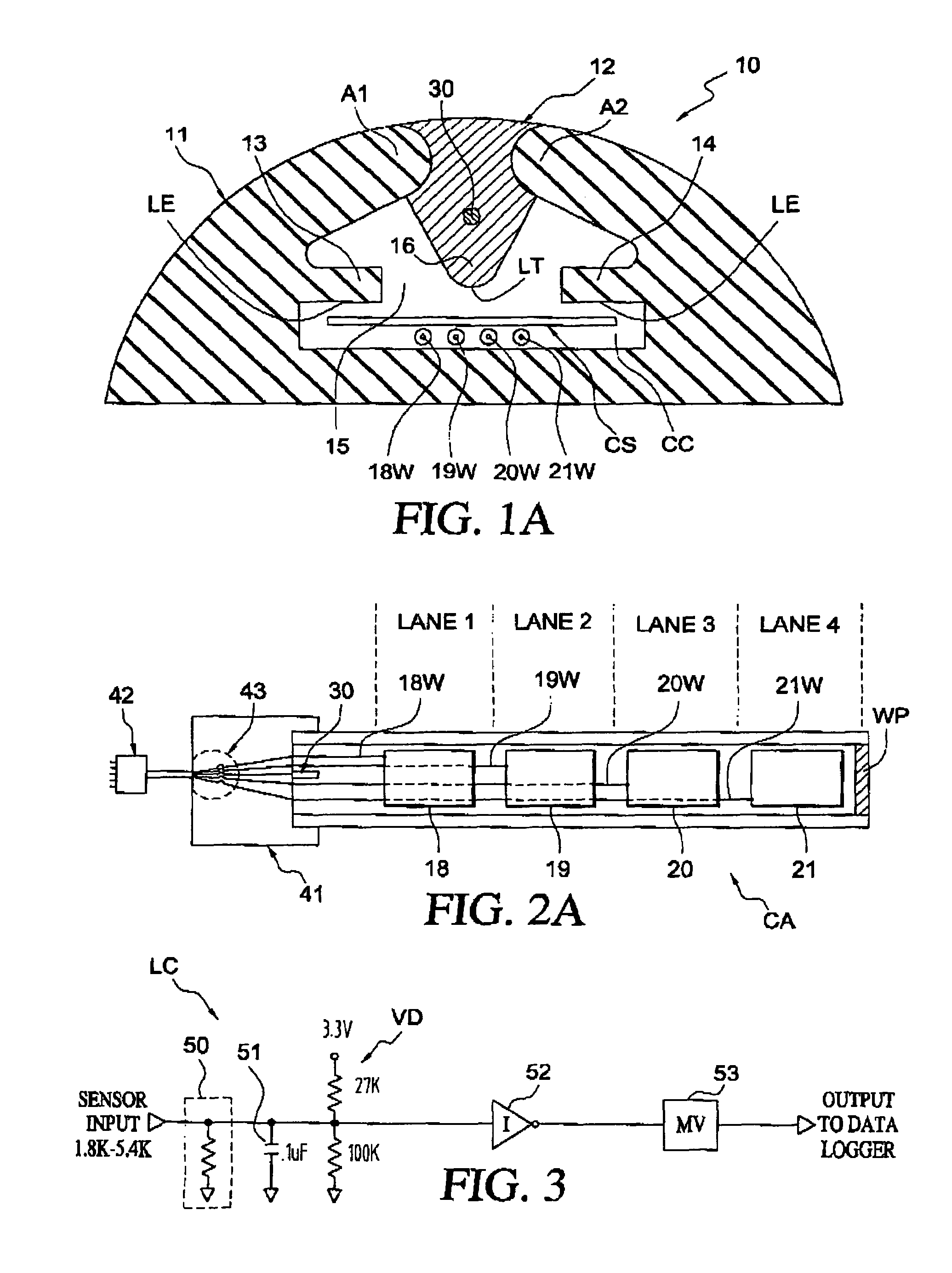

Road vehicle axle sensor

InactiveUS6469266B2Accurate and repeatable and indicationDetection of traffic movementContact operating partsMembrane switchElectrical contacts

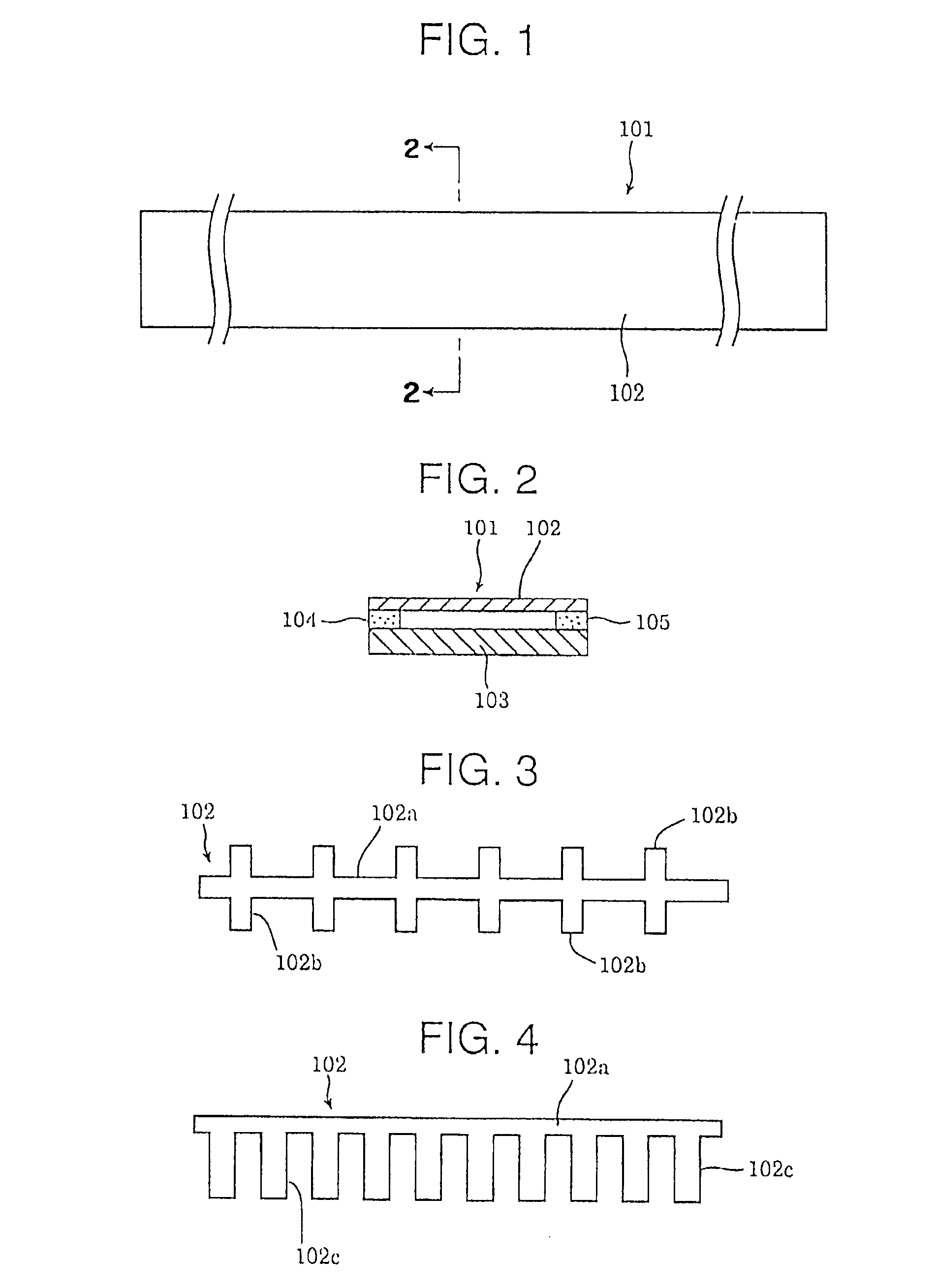

An improved vehicle road sensor is provided for signalling the passage of a vehicle over a predetermined location on a roadway. The vehicle road sensor includes a membrane switch which includes a first member and a second member. The first member includes a non-conductive substrate, a pair of electrically-conductive stripes upon the non-conductive substrate, an electrically non-conductive gap separating the electrically-conductive stripes, and an electrically-conductive lead connected to each electrically-conductive stripe. The second member includes an electrically-conductive strip which is superposed upon the electrically-conductive stripes on the first member. The second member is normally out of electrical contact with the electrically-conductive stripes on the first member. The second member is sufficiently flexible, so that, under a compressive load, it deflects to shunt across the electrically non-conductive gap, thereby to permit electric current to flow from the electrically-conductive stripes to the second member. Various arrangements of separate, but connected sensitive zones may be provided along the length of the sensor. Vehicle wheels of different widths would activate a different number of active sections, thereby approximating tire widths, for detecting the presence of one tire or two tires.

Owner:INTERNATIONAL ROAD DYNAMICS

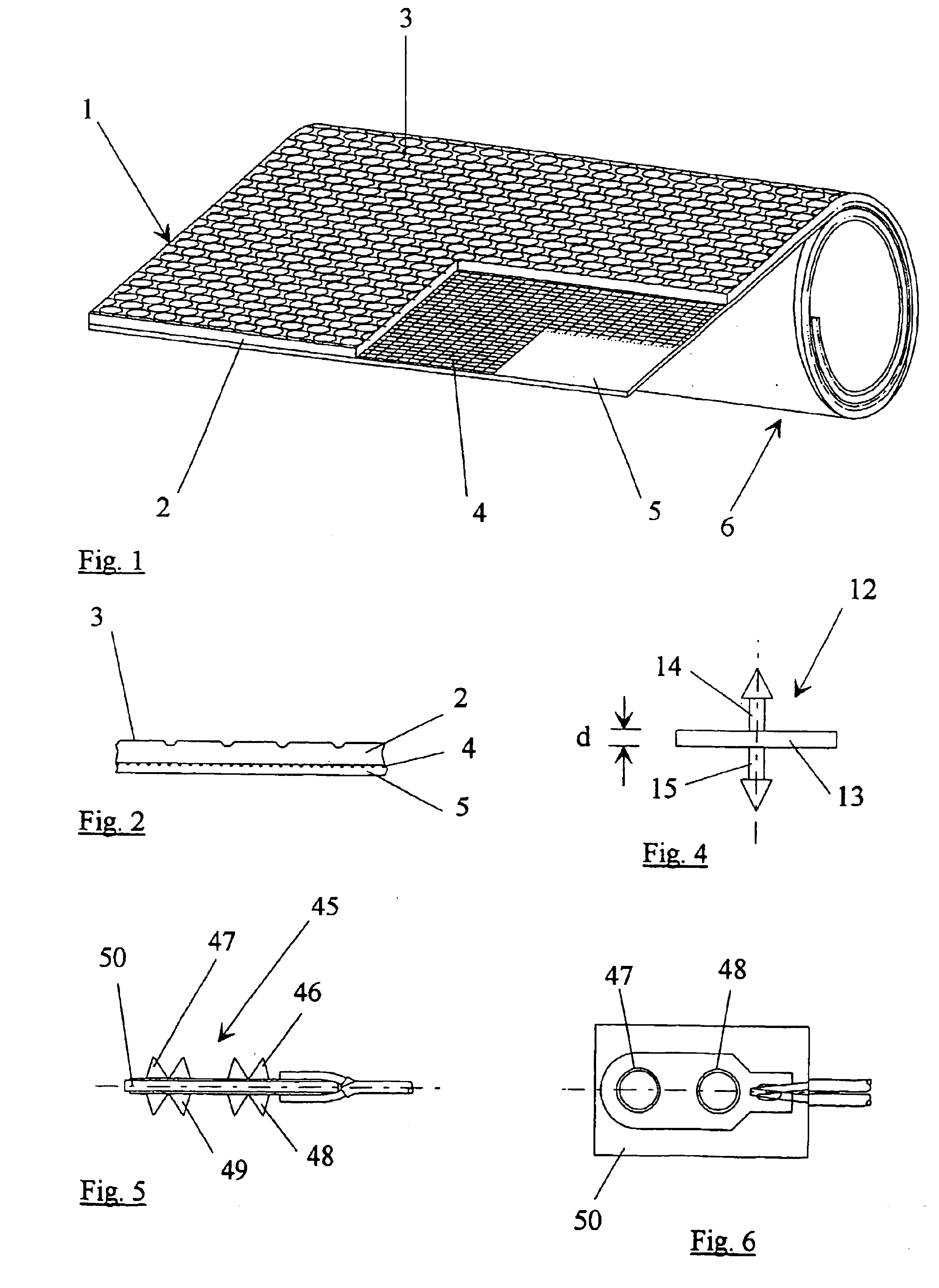

Safety contact mat

InactiveUS6888081B2Simple structural designHigh circuit reliabilityContact materialsContact surface shape/structureElastomerElectrical contacts

A safety contact mat has an upper mat half and a lower mat half with respective mutually facing spaced apart conductive layers, which are to be brought into contact in order to close an electrical contact. At least one of the mat halves is formed by a flat coextrudate of a non-conductive elastomer, a conductive elastomer as the conductive layer, and of a conductive woven material enclosed between the elastomers.

Owner:ASO ANTRIEBS UND STEUERUNGSTECHN

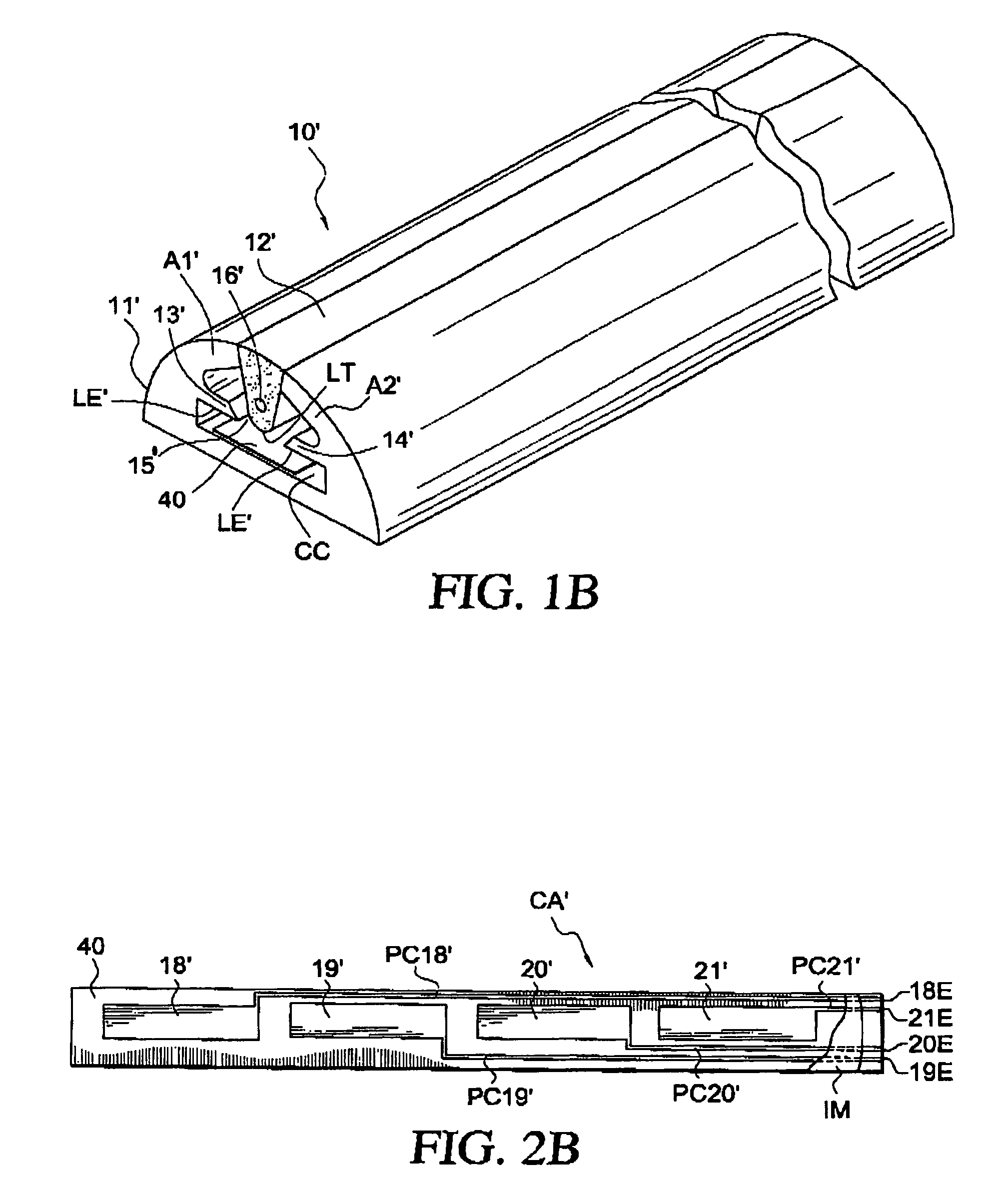

Method for manufacturing a continuous-length switch

InactiveUS6898842B2Improve securityImprove reliabilityDetection of traffic movementContact operating partsEngineeringElectrode

Disclosed is a method for manufacturing a continuous-length switch that comprises first and second electrodes. The method comprises covering at least a first surface of a first electrode with an insulating material. Then, a portion of the insulating material from the first surface of the first electrode is removed so as to provide an exposed portion of the first electrode. And then, a second electrode is placed on the insulating material and over the exposed portion of the first electrode.

Owner:IDEC CORPORATION

Electrical wire and method of fabricating the electrical wire

InactiveUS7145073B2Easy to makeSafe and convenientElectrically conductive connectionsPlastic/resin/waxes insulatorsEngineeringElectric wire

Owner:SOUTHWIRE CO LLC

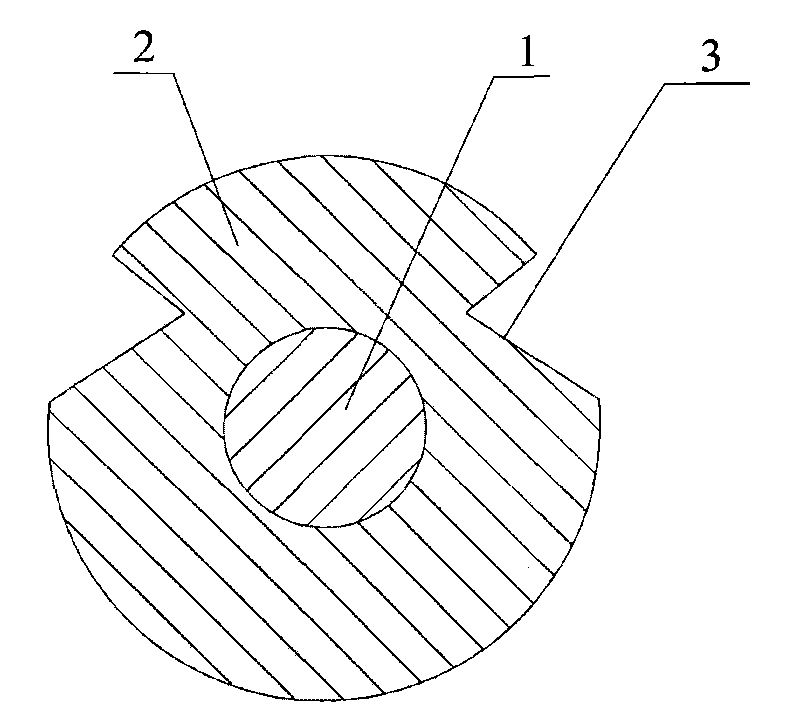

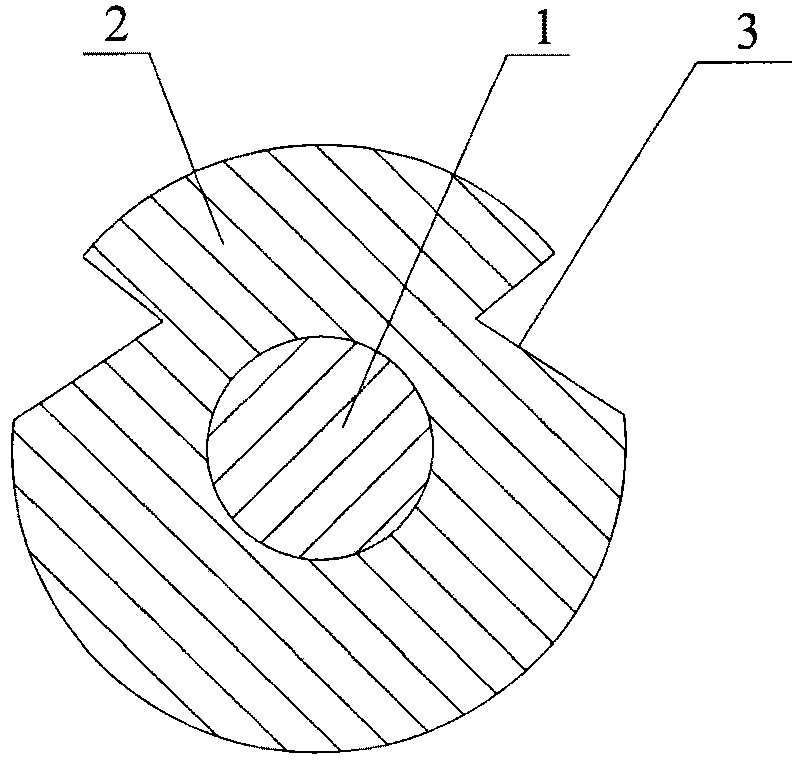

Contact cable taking alloy material to wrap carbon fiber core

InactiveCN101752032AReduce weightSolve saggingConductive layers on insulating-supportsSingle bars/rods/wires/strips conductorsFiberCarbon fibers

The invention relates to an electric transmission cable, in particular to a contact cable taking alloy material to wrap the carbon fiber core for rapid transit ralway, which is characterized in that the center of the cable is provided with a carbon fiber core; the outside of the carbon fiber core is wrapped with an alloy layer; the alloy and the carbon fiber core are arranged in a horizontal caster, or in a rolling wrapping machine, or in an alloy dip-coating device to composite a cable. The alloy is sliver copper alloy or tin copper alloy or chromium zircomium copper alloy or cadmium copper alloy or magnesium copper alloy. The section of the surface of the cable is round after being treated by cold rolling and cold drawing. The two sides of the round section are symmetrically provided with two V-shaped cable-hanging grooves which are drawn from a cold-drawing die. Compared with the existing steel-core cable, the weight of the contact cable is greatly reduced, thus effectively solving the problem of the sagging of the cable, the contact cable can work under higher temperature, the core can resist corrosion and has not the problem of corrosion between metals, so the higher current-carrying capacity can be provided and the number of the cable stand can be effectively reduced.

Owner:江阴华电新材料有限公司

Fire resistant cable

InactiveUS20100108351A1Improve resistance performanceLow viscosityMetallic oxidesContact cablesPolymer scienceElectrical conductor

Cable comprising at least one conductor and at least a fire resistant coating layer including a composition comprising: (a) at least an organic polymer having a combustion temperature range comprised between a minimum value T1 and a maximum value T2; (b) at least a glass frit; (c) at least an inert compound; wherein:—said inert compound (c) has a softening point or a melting temperature of not less than 1000° C.;—said glass frit (b) reaches a viscosity of between 107 poise and 108 poise in a selected temperature range including the combustion temperature range of said organic polymer (a), said selected temperature range being such that said glass frit (b) flows over said inert compound (c) and the burned organic polymer (a) so as to form a solid char fire resistant coating layer.

Owner:PIRELLI & C

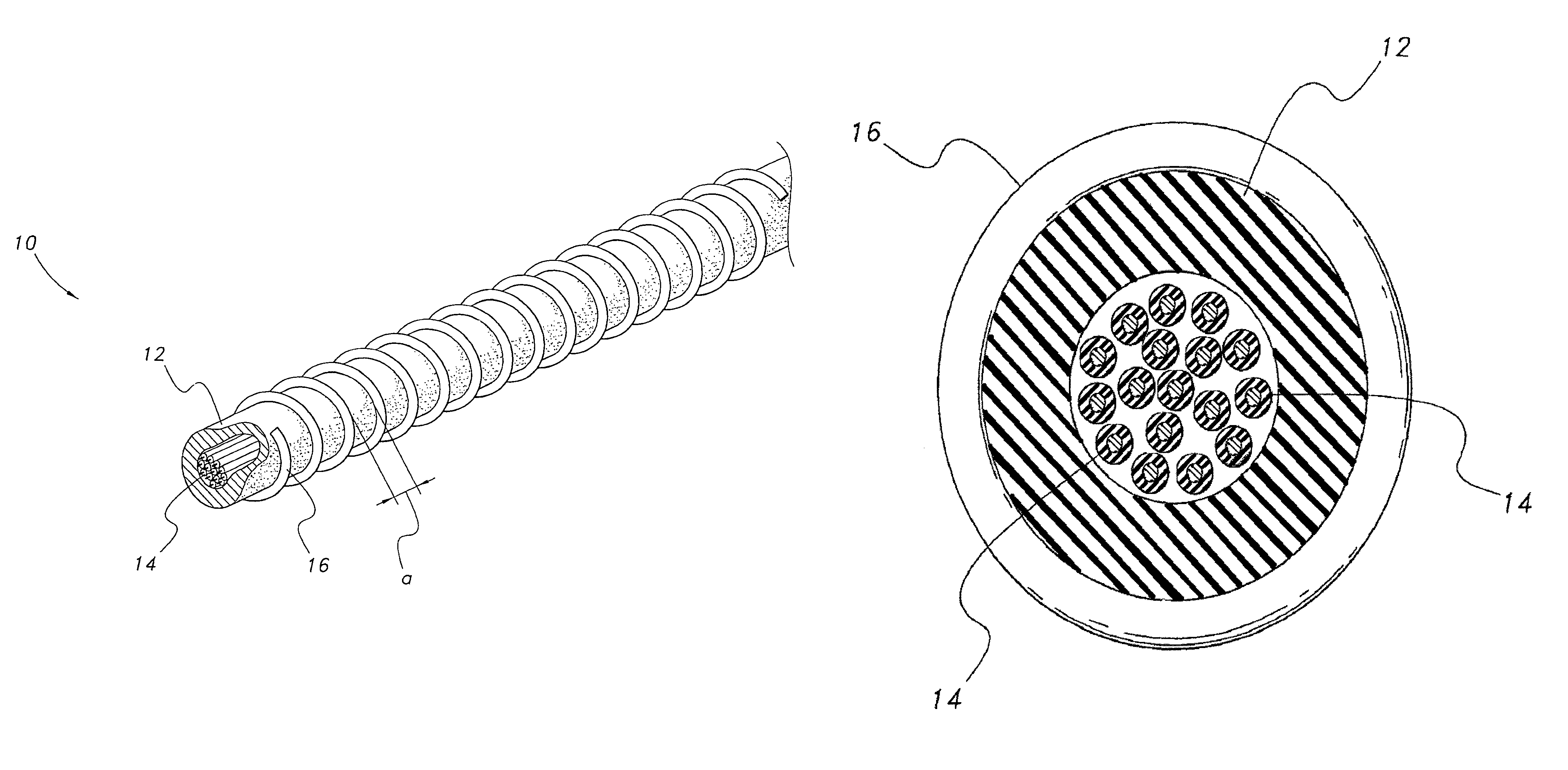

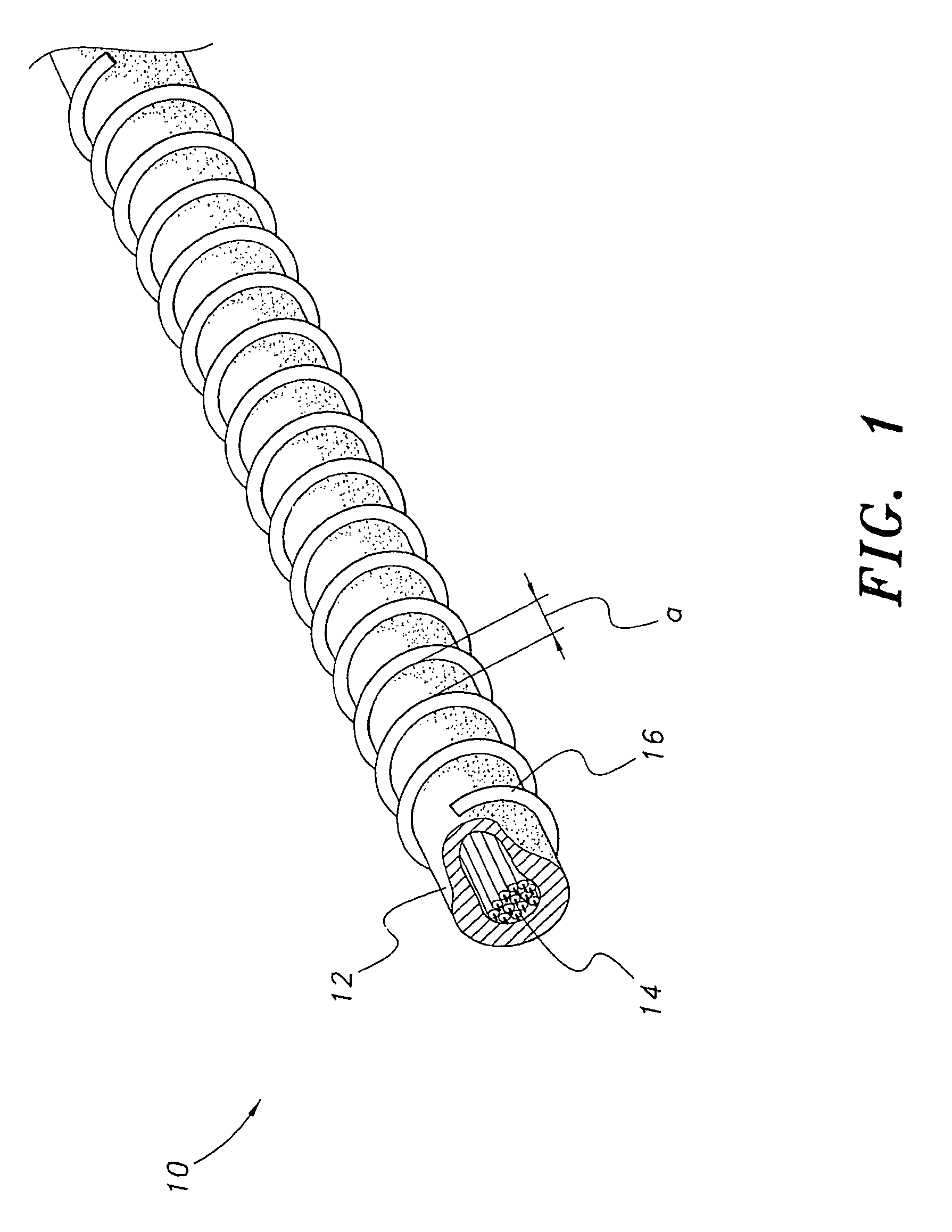

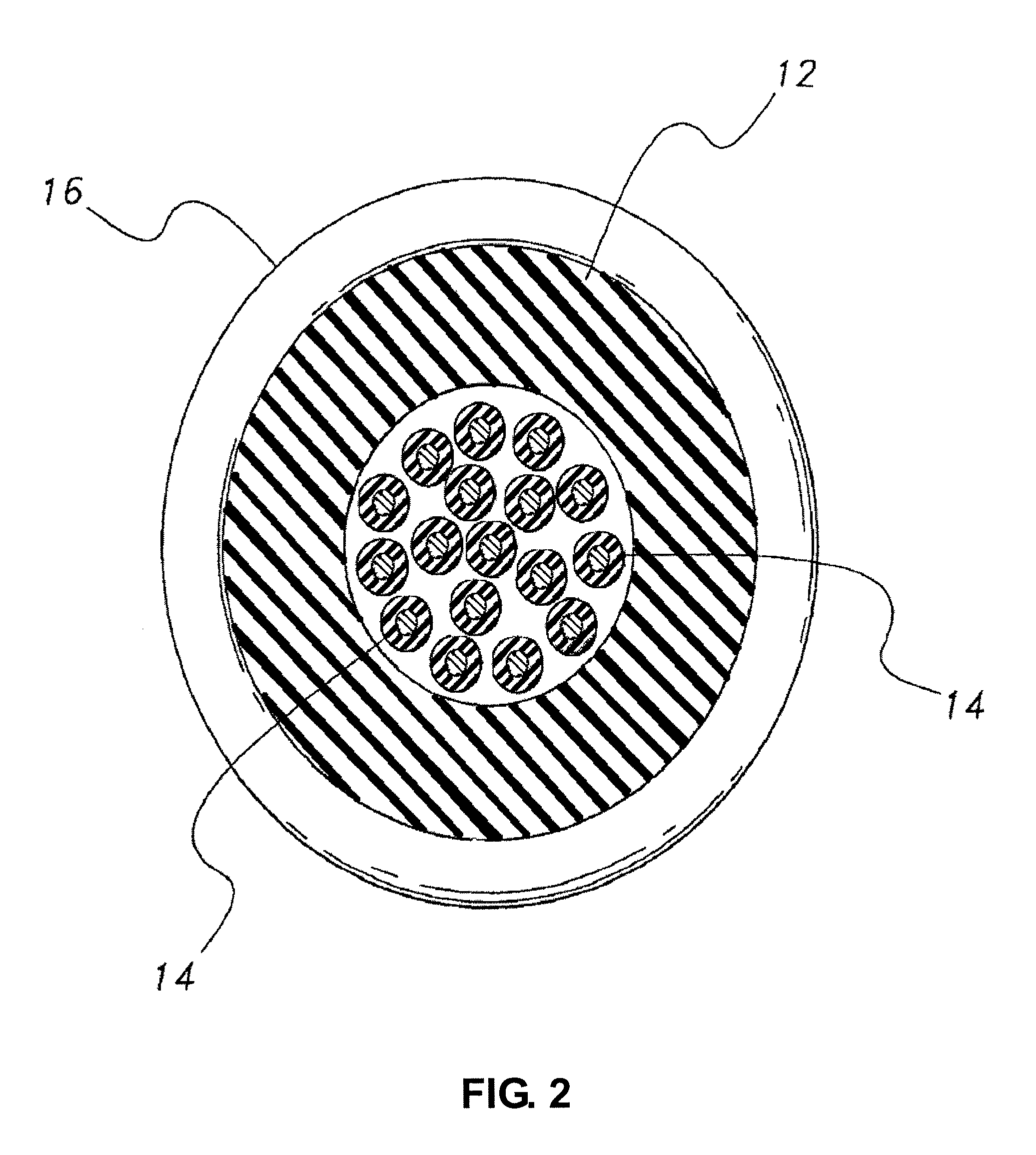

Coiled wire armored cable

The coiled wire armored cable (10) includes transmission wires (14) encased by an insulator (12). A solid protective wire (16) is spirally wound over the exterior of the insulator. The protective wire (16) is fabricated from a metal, such as steel or titanium material, and will have a gauge that prevents a rodent from chewing through the wire. The coils of the protective wire are spaced apart along the length of the cable. The spacing (a) of the coils will be less than the width of the teeth of the rodent so that the coils create a “fence” that prevents the rodent's teeth from contacting the insulator.

Owner:AMPHENOL CORP

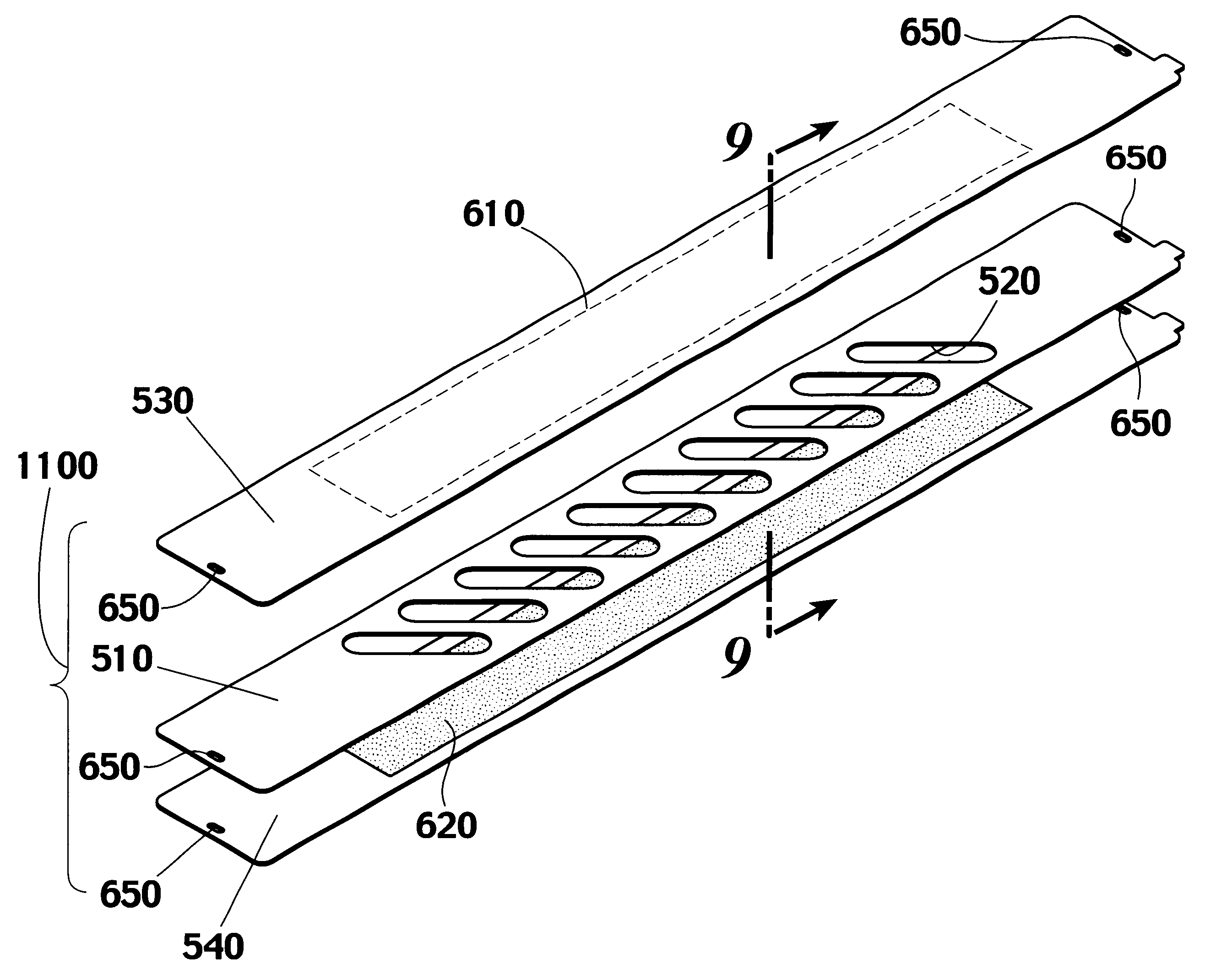

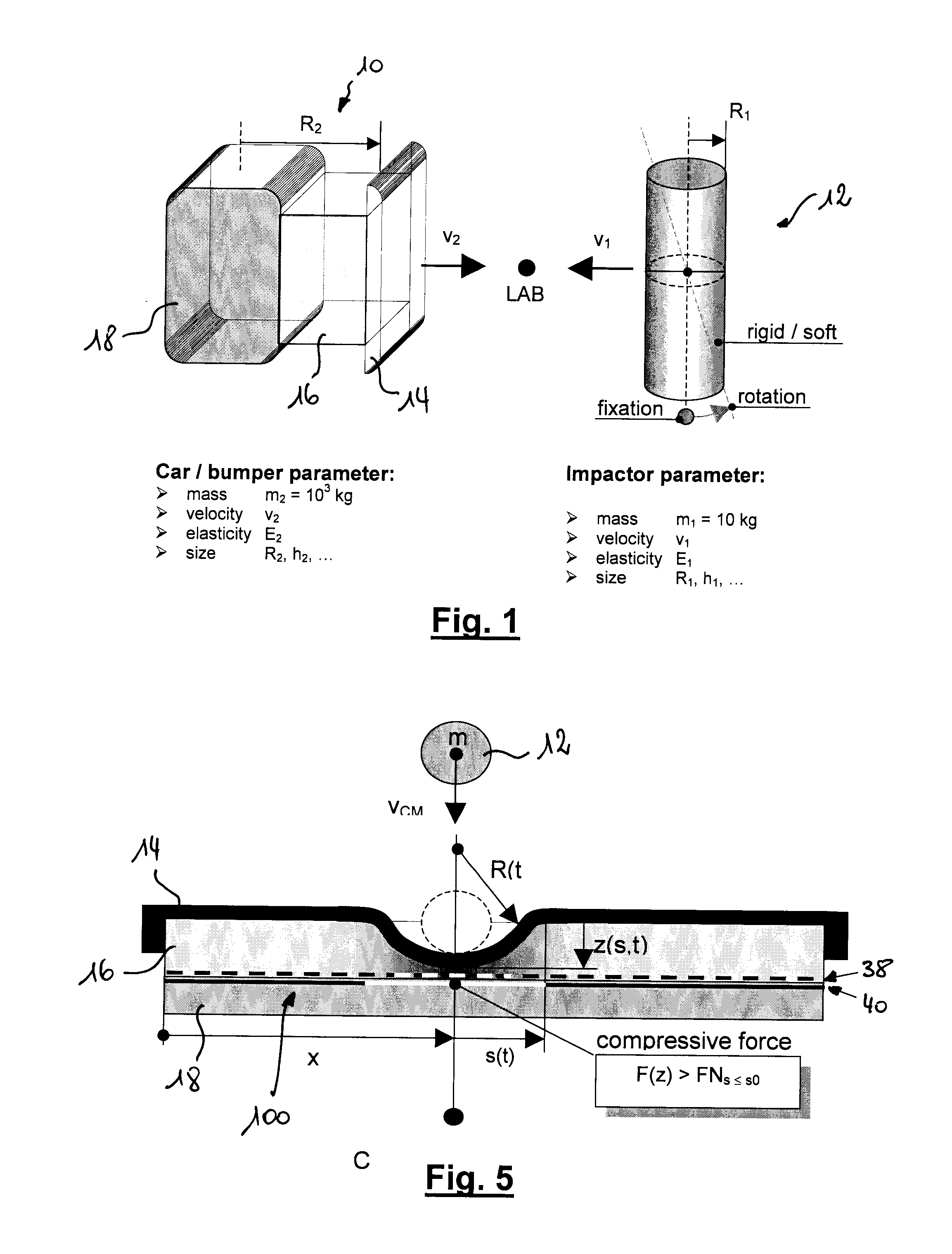

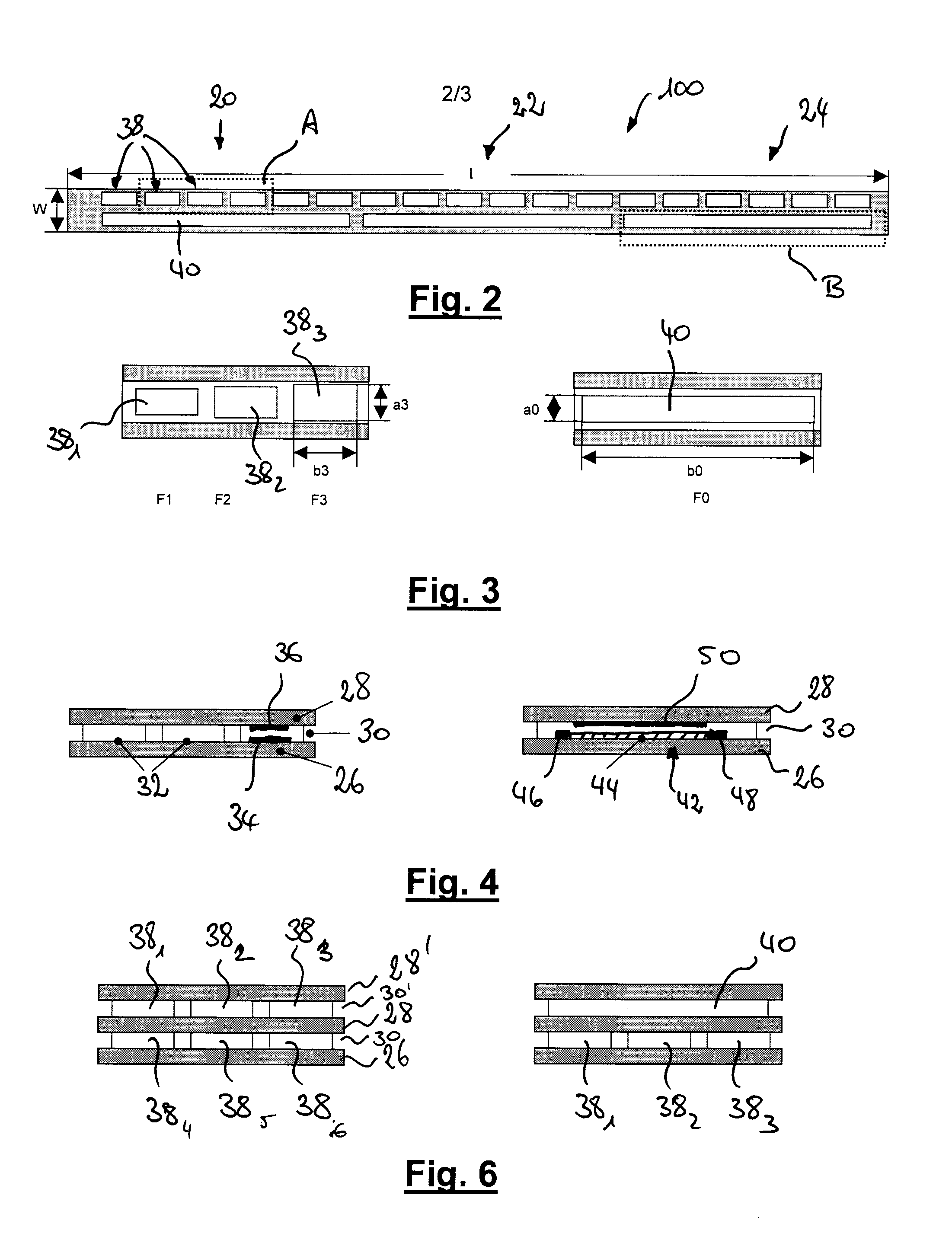

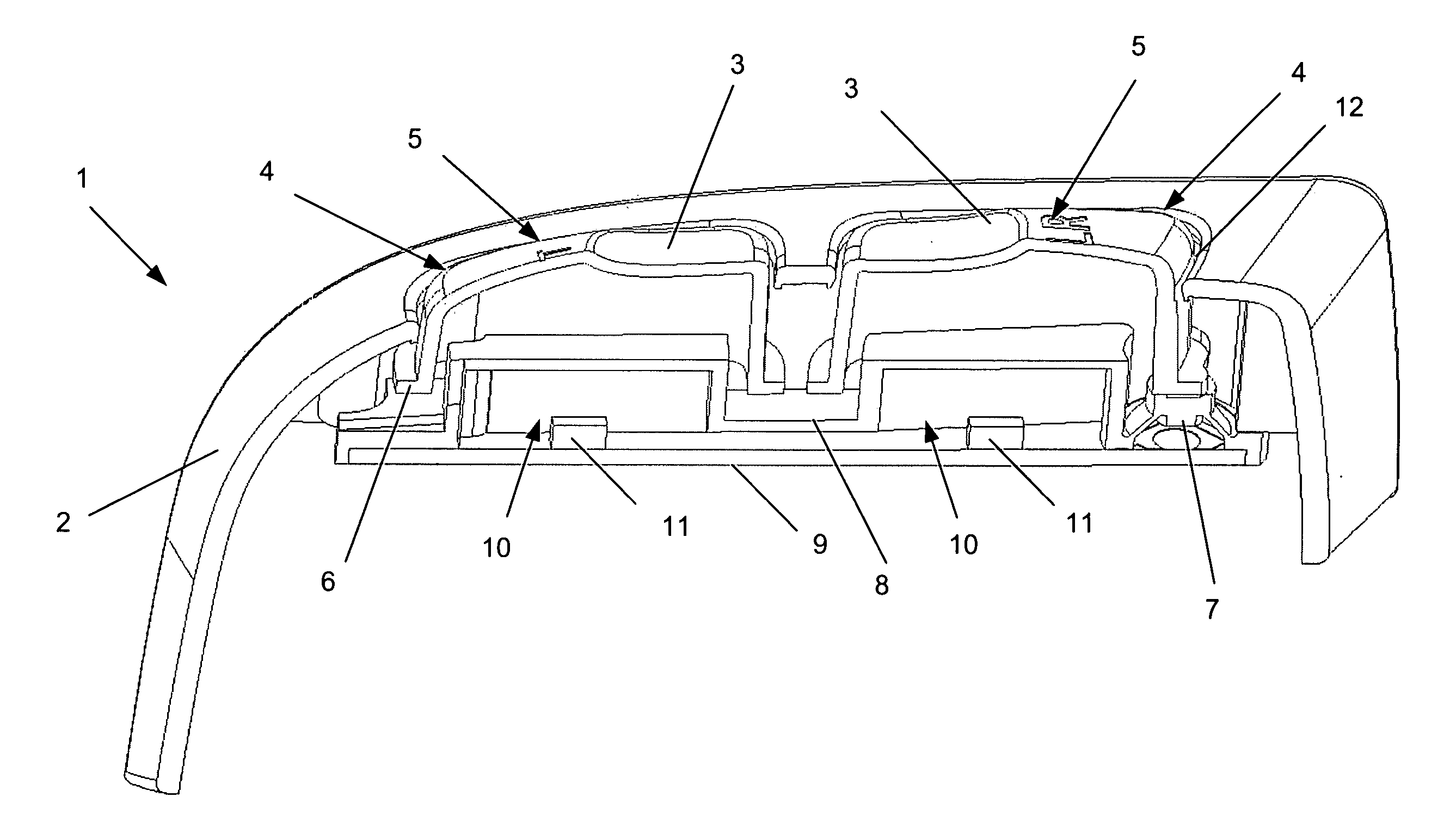

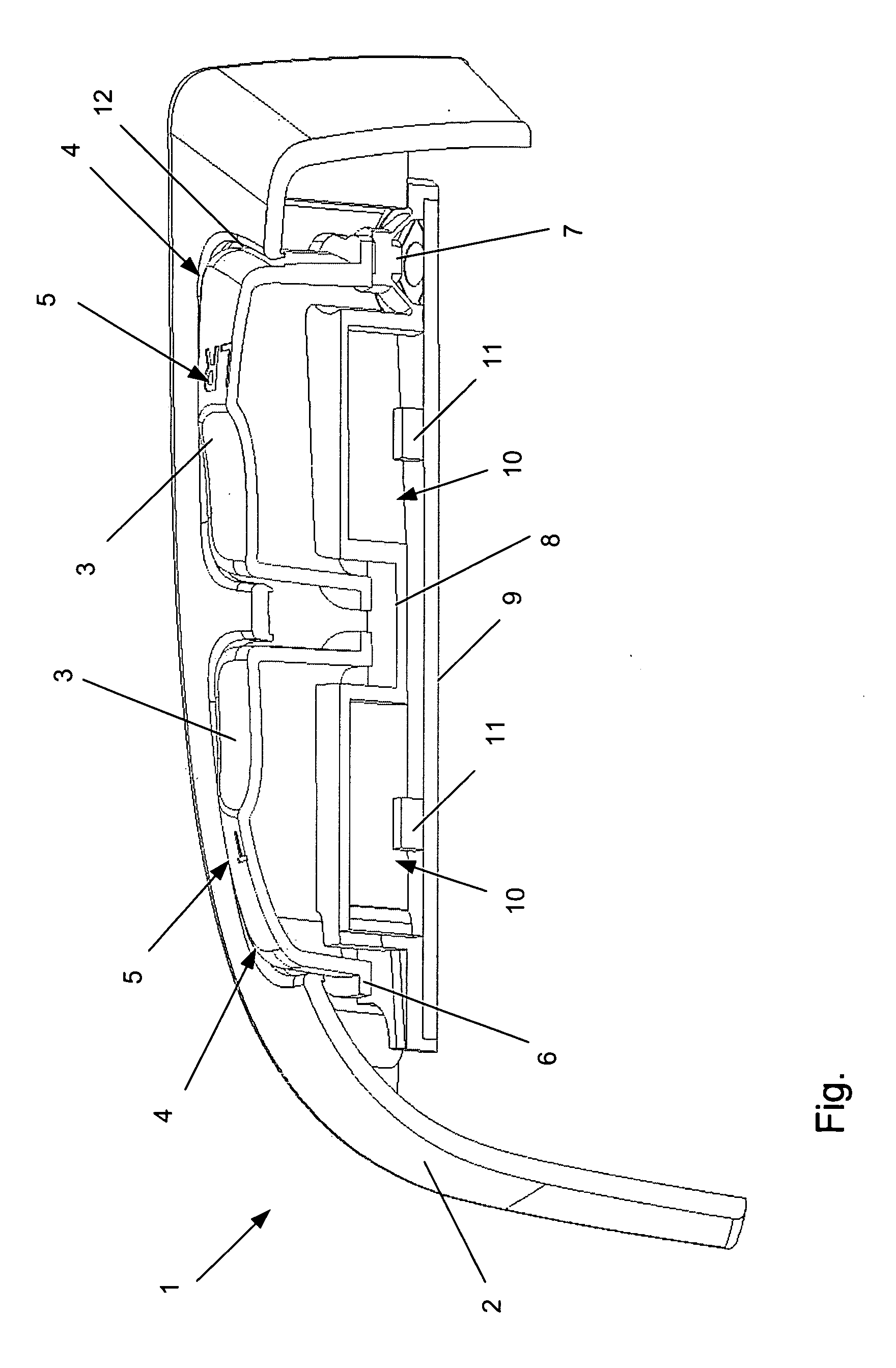

Impact Sensor System For Pedestrian Protection

ActiveUS20080210020A1Improve impactForce measurement by permanent gauge deformationPedestrian/occupant safety arrangementEngineeringBiological activation

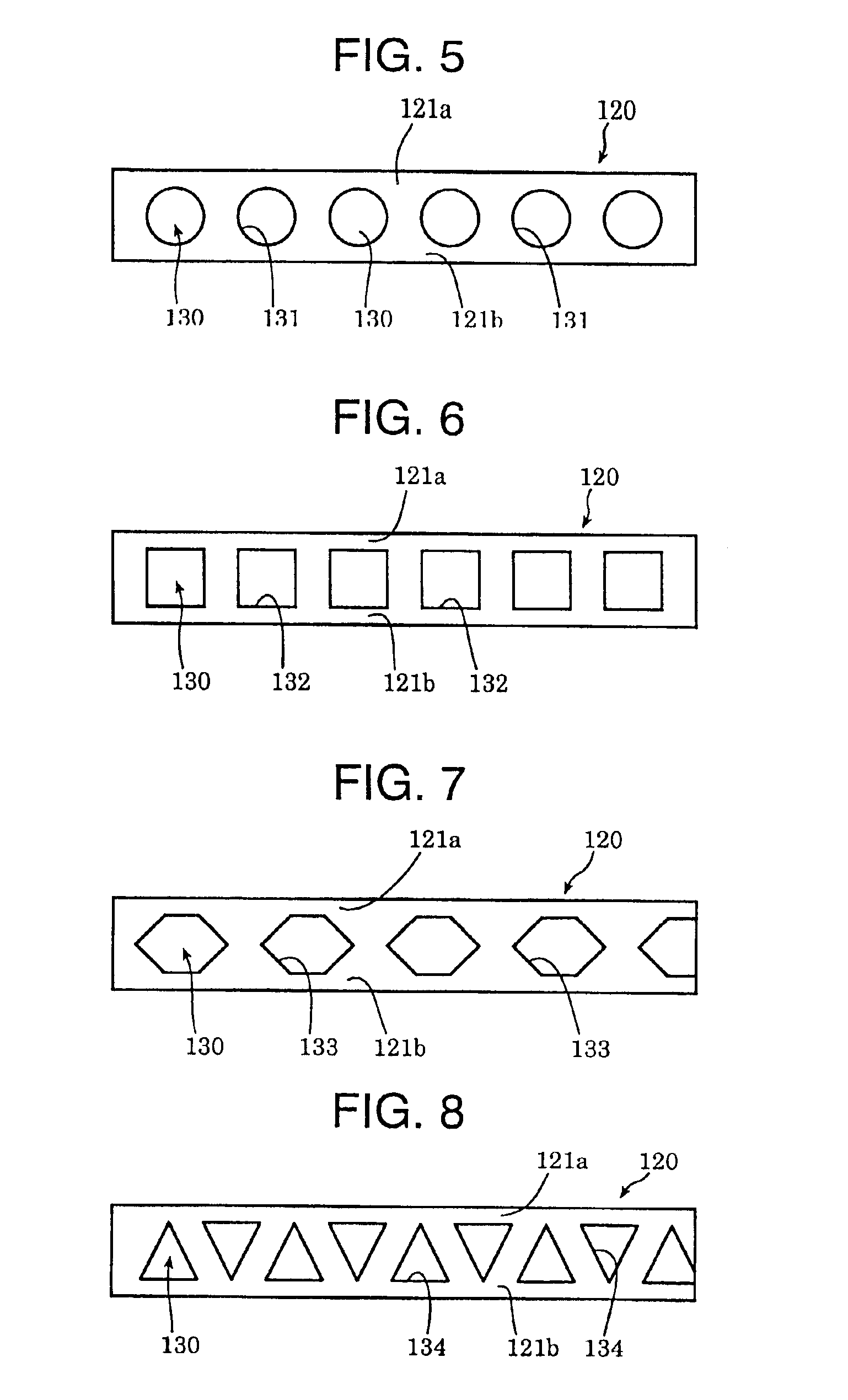

An impact sensor system for pedestrian protection comprises at least one foil-type switching element having a plurality of active areas. The foil-type switching element comprises at least a first carrier foil and a second carrier foil arranged at a certain distance by means of at least one first spacer, wherein said at least one first spacer comprises a plurality of recesses defining at least a first part of said active areas. In each active area, at least two electrode structures are arranged between said first and second carrier foils in such way that in re-sponse to a force acting on the active area of the switching element, the first and second carrier foils are pressed together against the reaction force of the elastic carrier foils and that, above a predetermined activation threshold force, an electrical contact is established between the at least two electrode struc-tures. According to the invention said foil-type switching element is configured such that the activation threshold force of a first group of said plurality of active areas is different from an activation threshold force of a second group of said plurality of active areas.

Owner:IEE INT ELECTRONICS & ENG SA

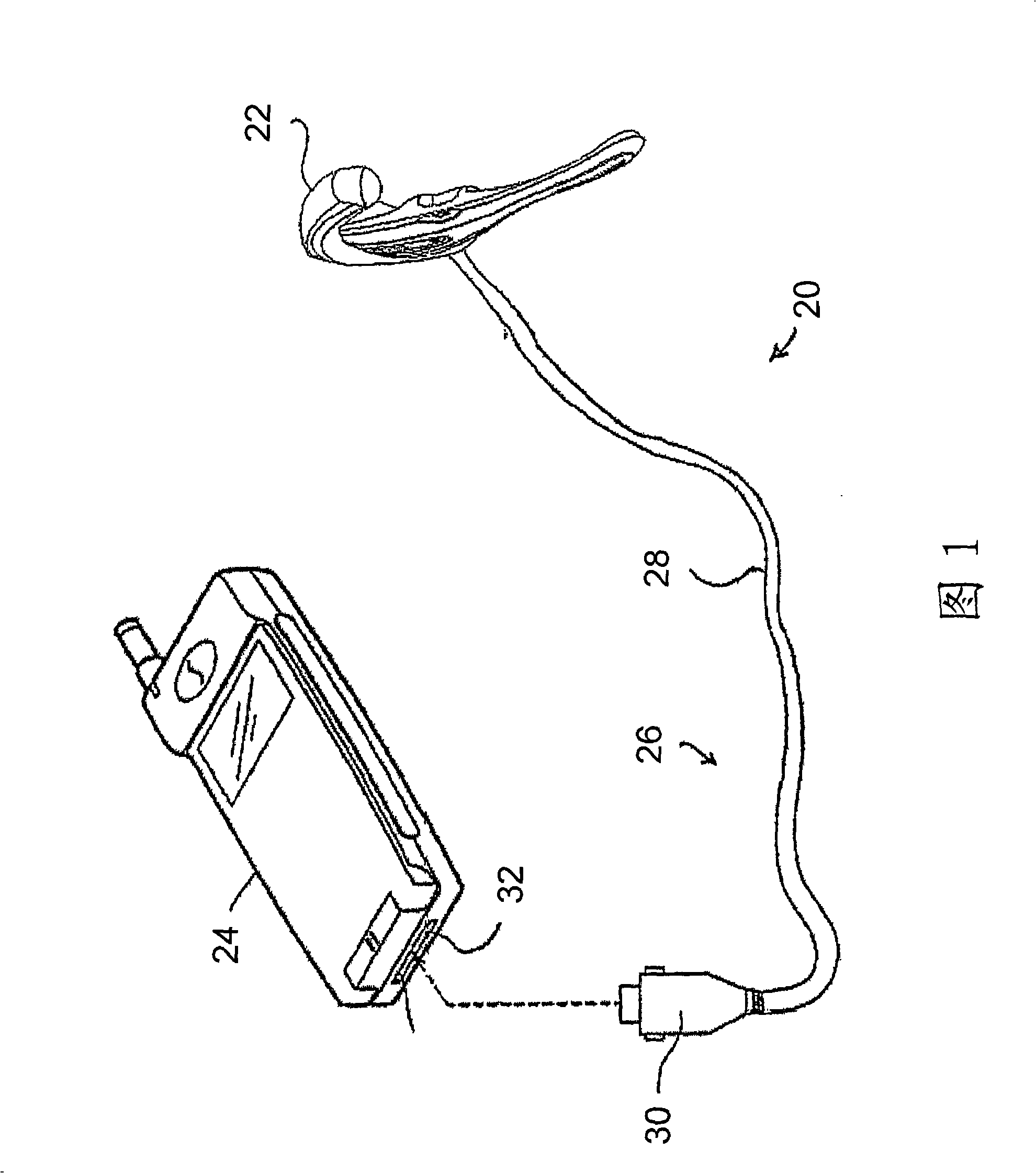

Discrete cord control and accessories having discrete cord control for use with portable electronic devices

Owner:SONY ERICSSON MOBILE COMM AB

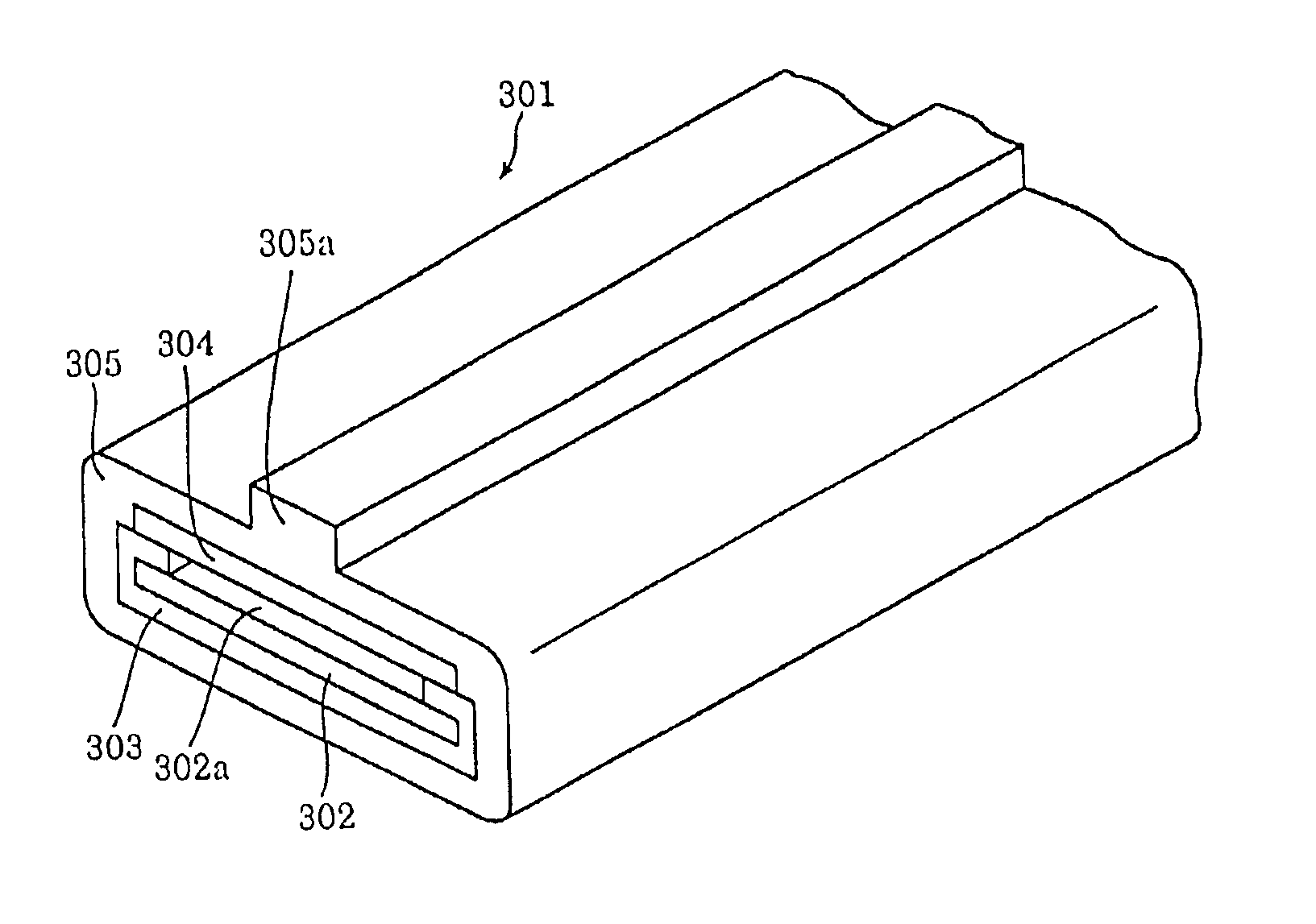

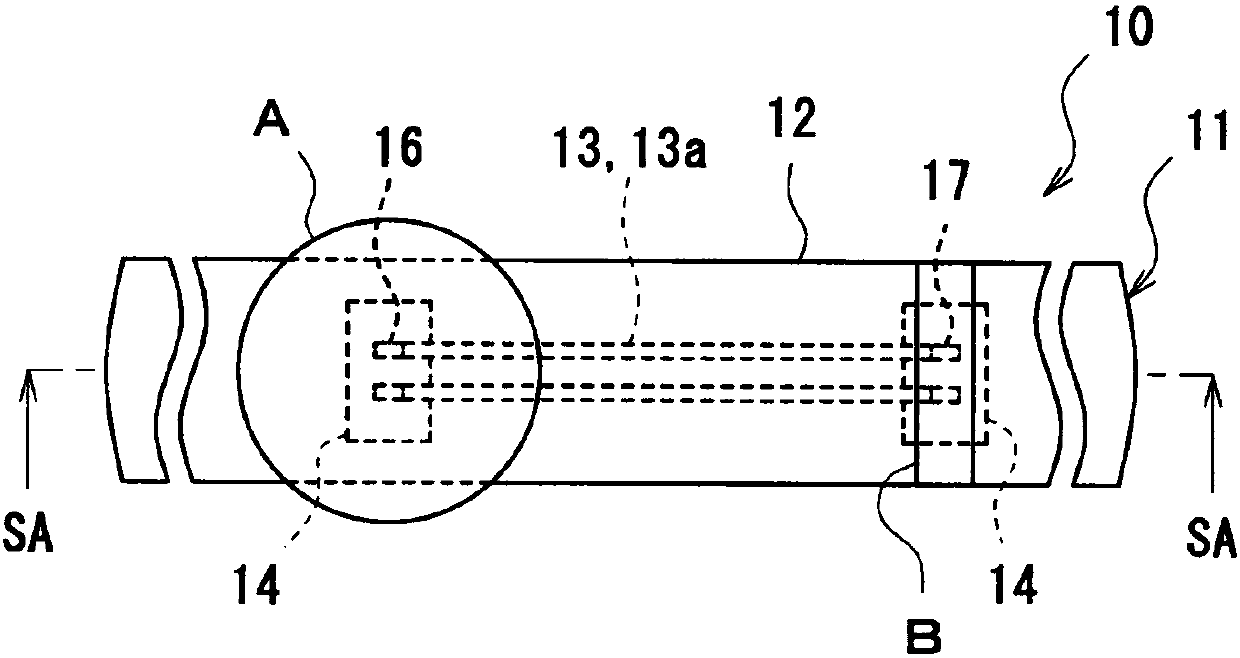

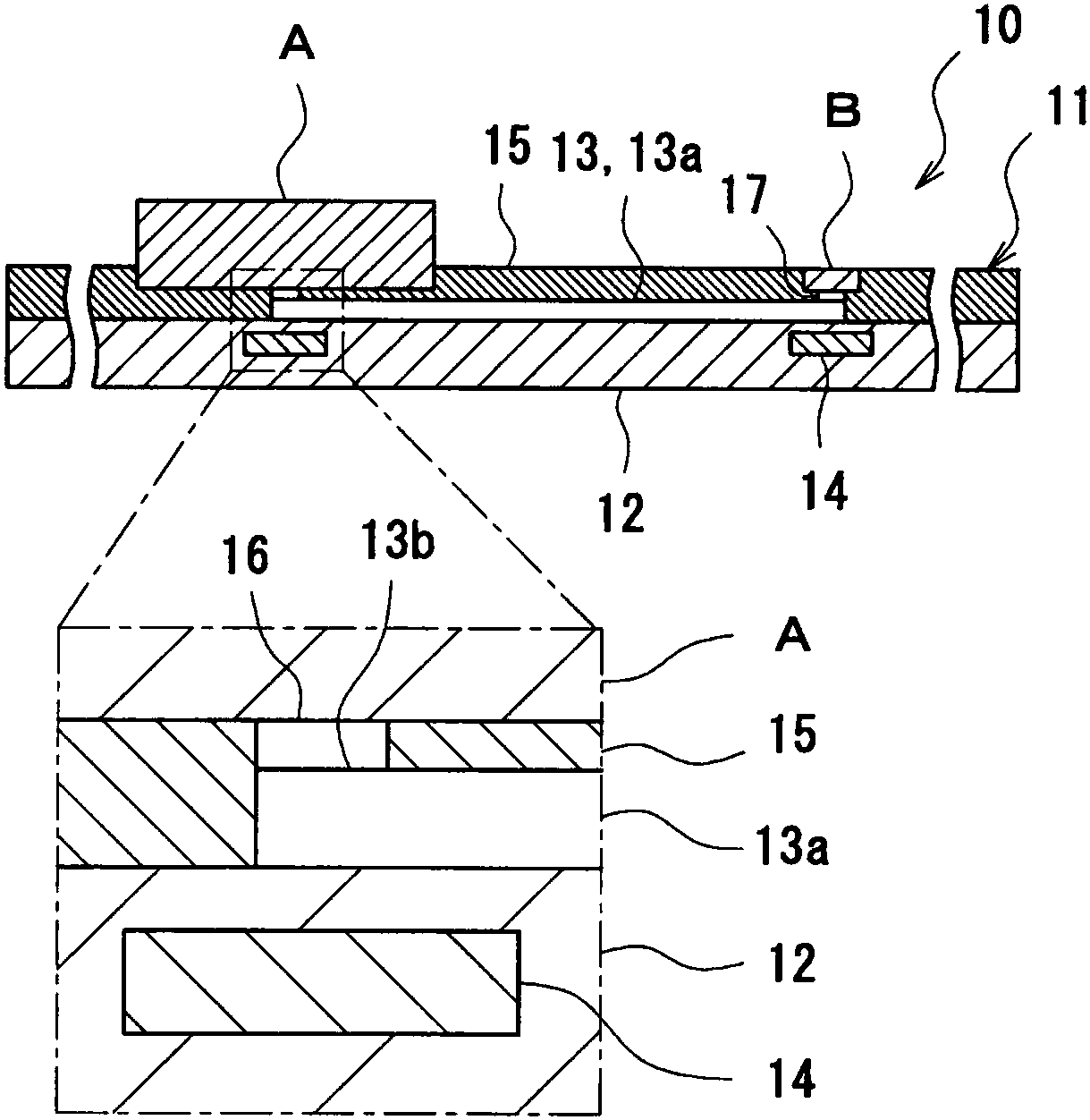

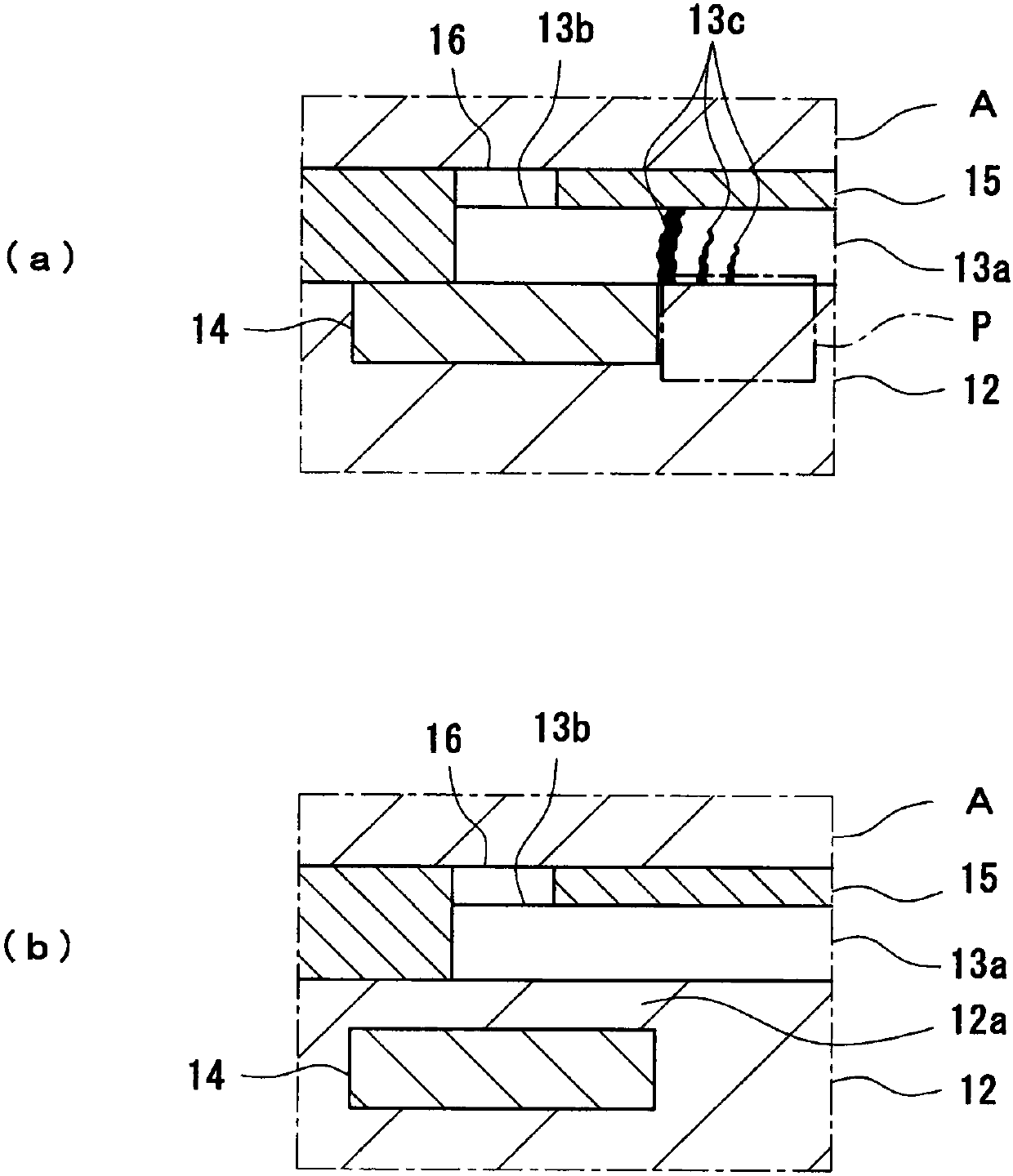

Elastic wiring member

InactiveCN107949887APrevent peelingImprove scalabilityCircuit bendability/stretchabilityPrinted circuit manufactureElectronic componentElectronic equipment

An elastic member which is used for the connection of an electronic component and an external electronic device, and which is not susceptible to change in the resistance even if stretched. An elasticwiring member 11 which is composed of: a stretchable wiring line 13 that connects a contact 16 of an electronic device main body A and a contact 17 of an electronic component with each other; and a base sheet 12 that holds the stretchable wiring line 13 and is composed of a rubber-like elastic body. The base sheet 12 is provided with a reinforcing member 14 at a position adjacent to a connection part 13b of the stretchable wiring line 13, which is connected to the contact 16, 17, when viewed from the front surface of the base sheet 12 for the purpose of suppressing stretching of the base sheet12 and preventing deformation of the stretchable wiring line 13 in the connection part 13b.

Owner:SEKISUI POLYMATECH CO LTD

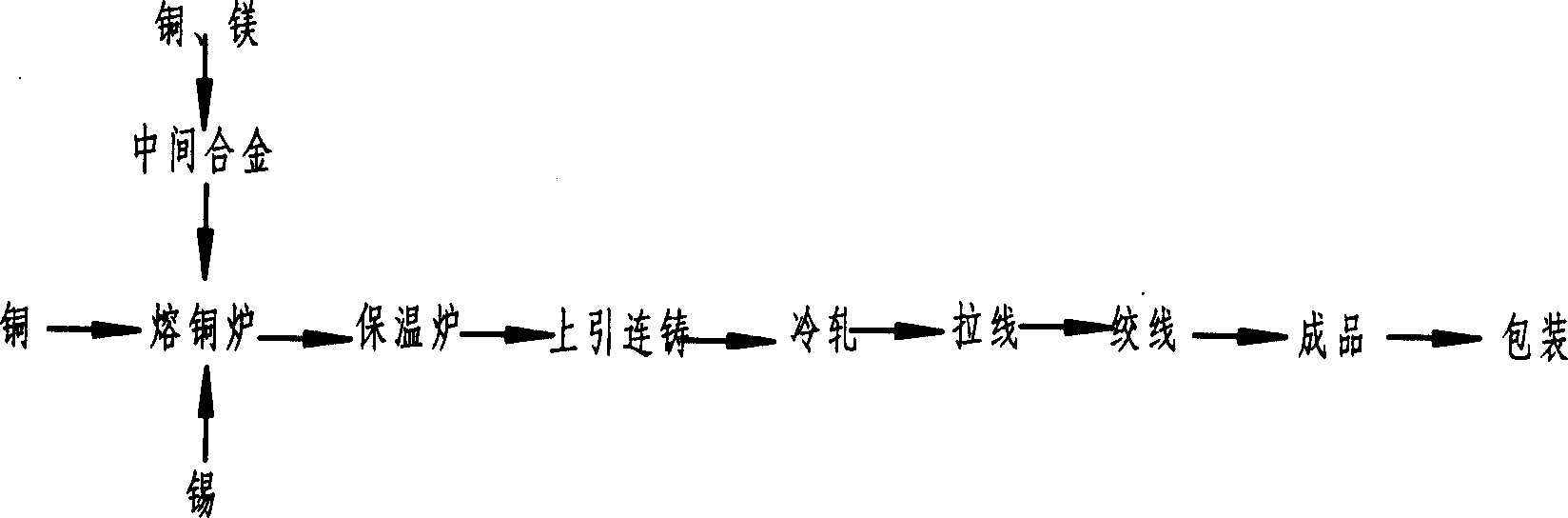

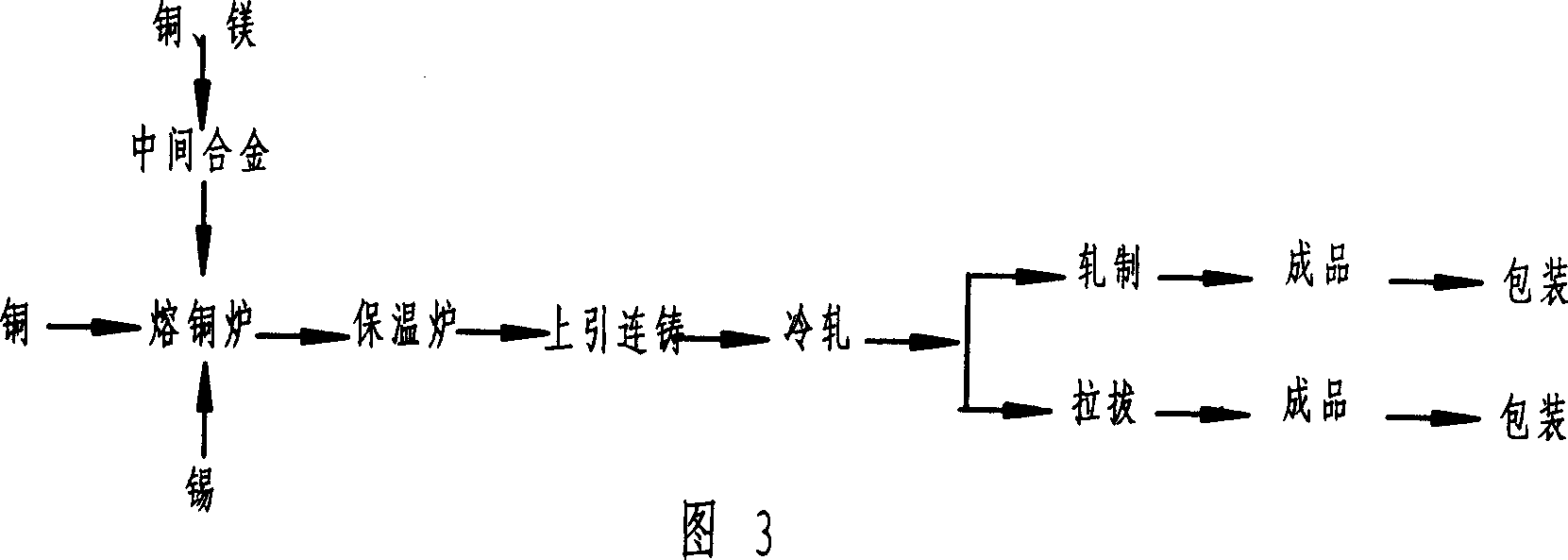

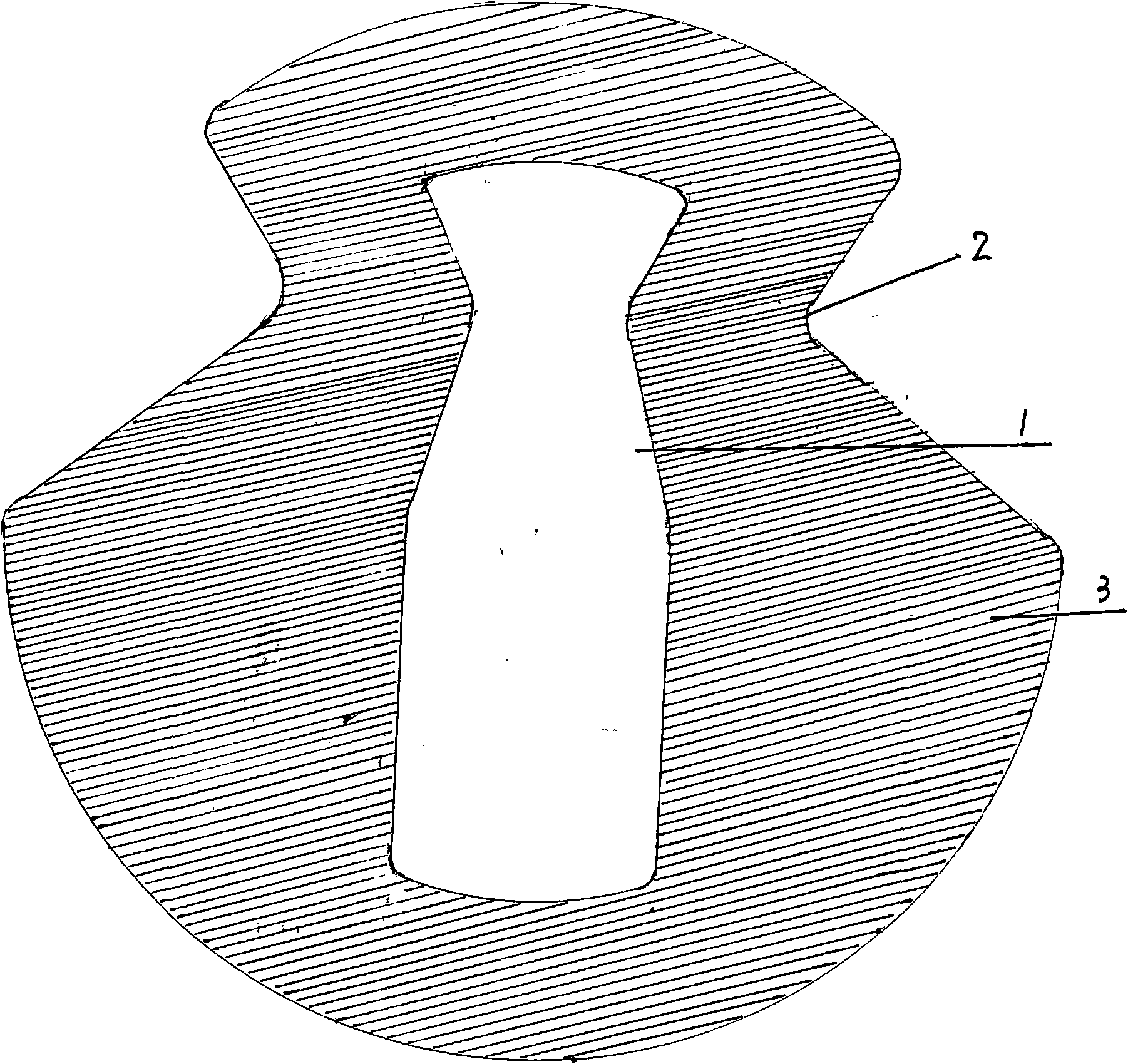

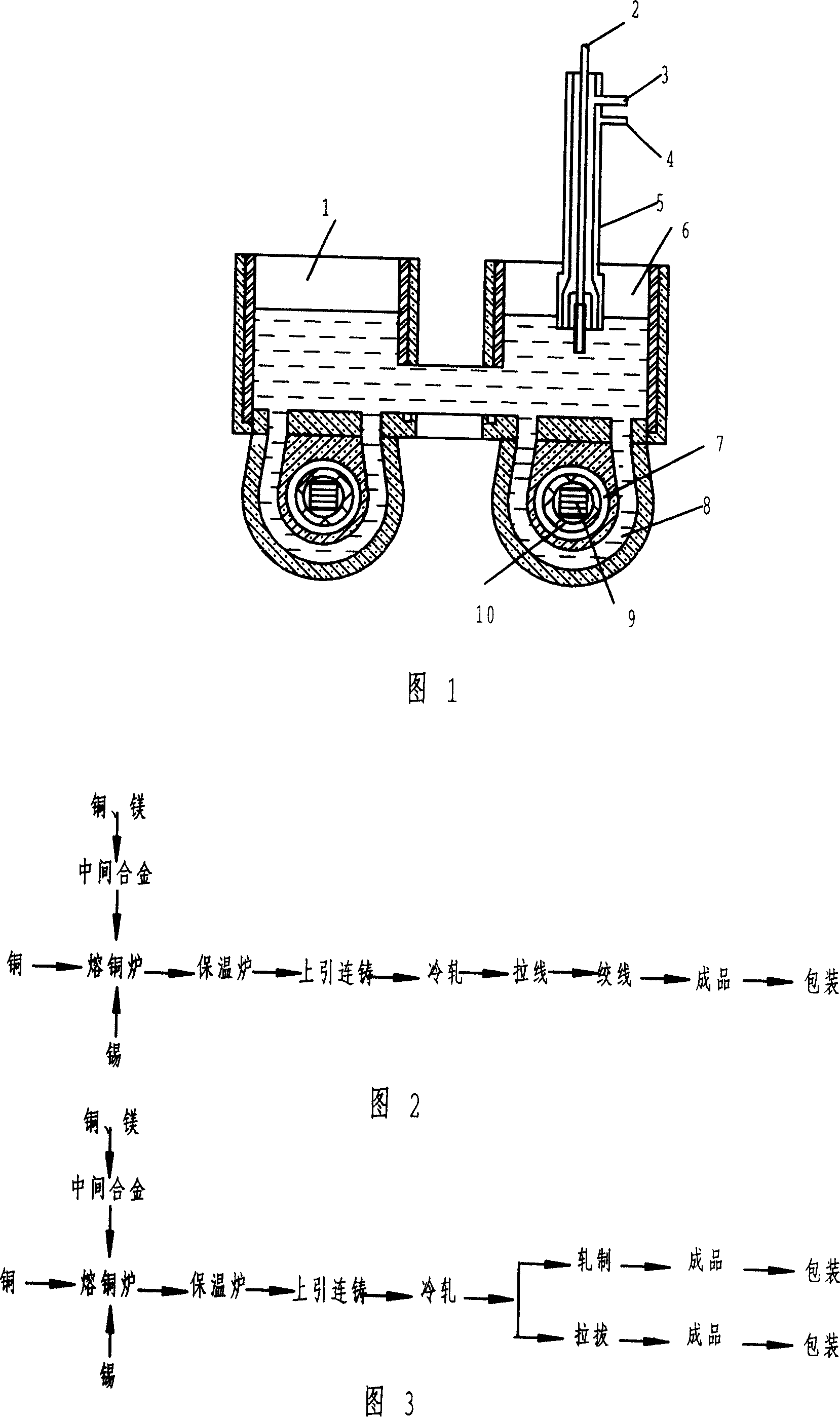

Ternary copper-alloy stranded conductor and contact line preparing method

ActiveCN1776831ASimple manufacturing processSolve chronic problemsNon-insulated conductorsContact cablesProduction rateTechnical standard

Characters are that ternary copper alloy is prepared from materials according to following weight percent: magnesium 0.10-0.50, stannum 0.10-0.4, impurity less than 0.30, and other as copper. Through procedures of melting, heat preservation, casting bars, and cold rolling, twisted line and contact wire are prepared from the ternary copper alloy. In procedure for producing twisted alloy line, and contact wire, the invention raises furnace life of melting copper furnace and ratio between product and roughcast. The ratio is near to a hundred percent, and furnace life is raised to three times so as to lower cost and raise productivity. Through measurement by relevant department, mechanical and physical properties etc. indexes of the hard twisted alloy line reaches to or exceeds relevant indexes of current twisted line of magnesium copper. Product is accorded with requirement of technical standard completely.

Owner:邢台鑫晖铜业特种线材有限公司

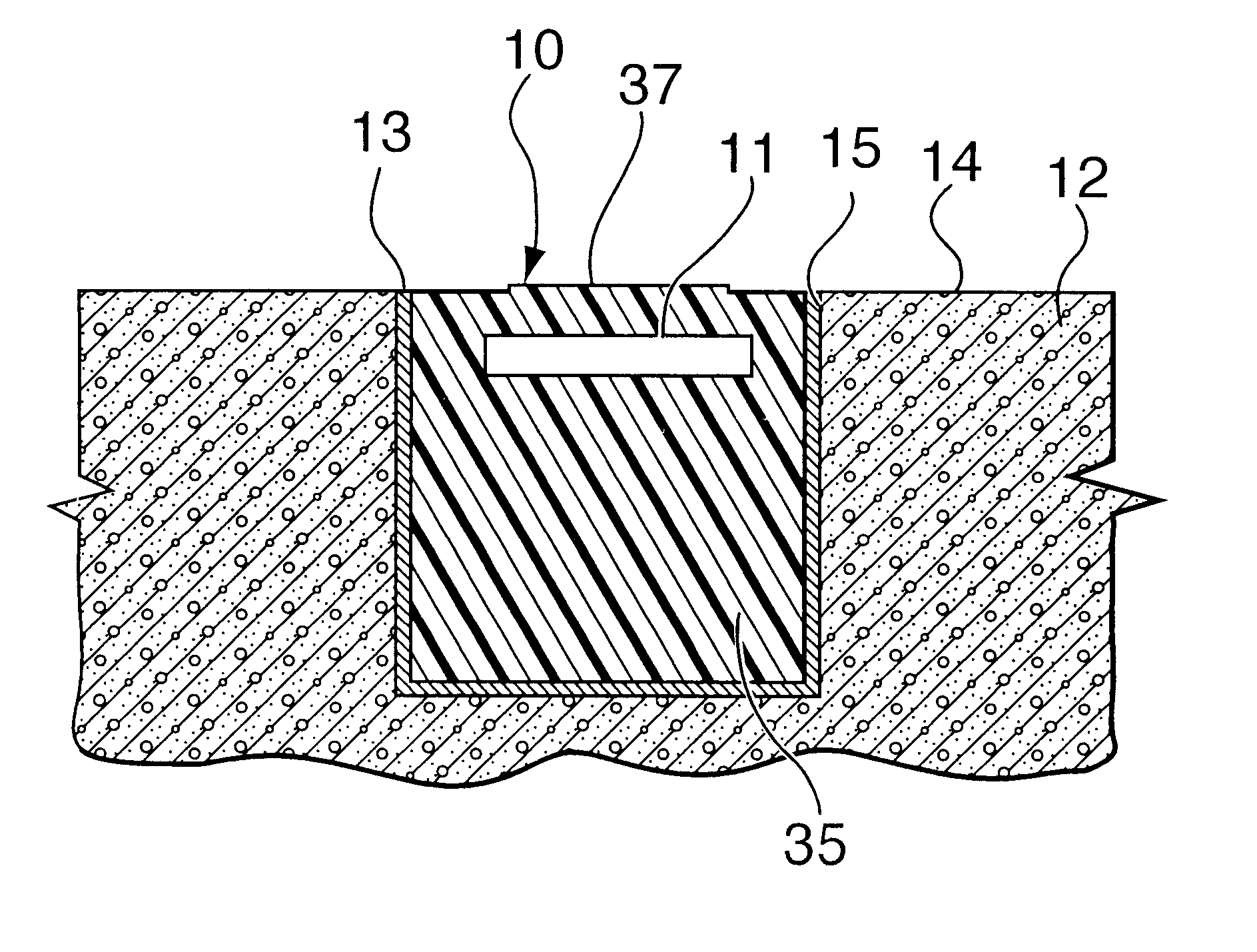

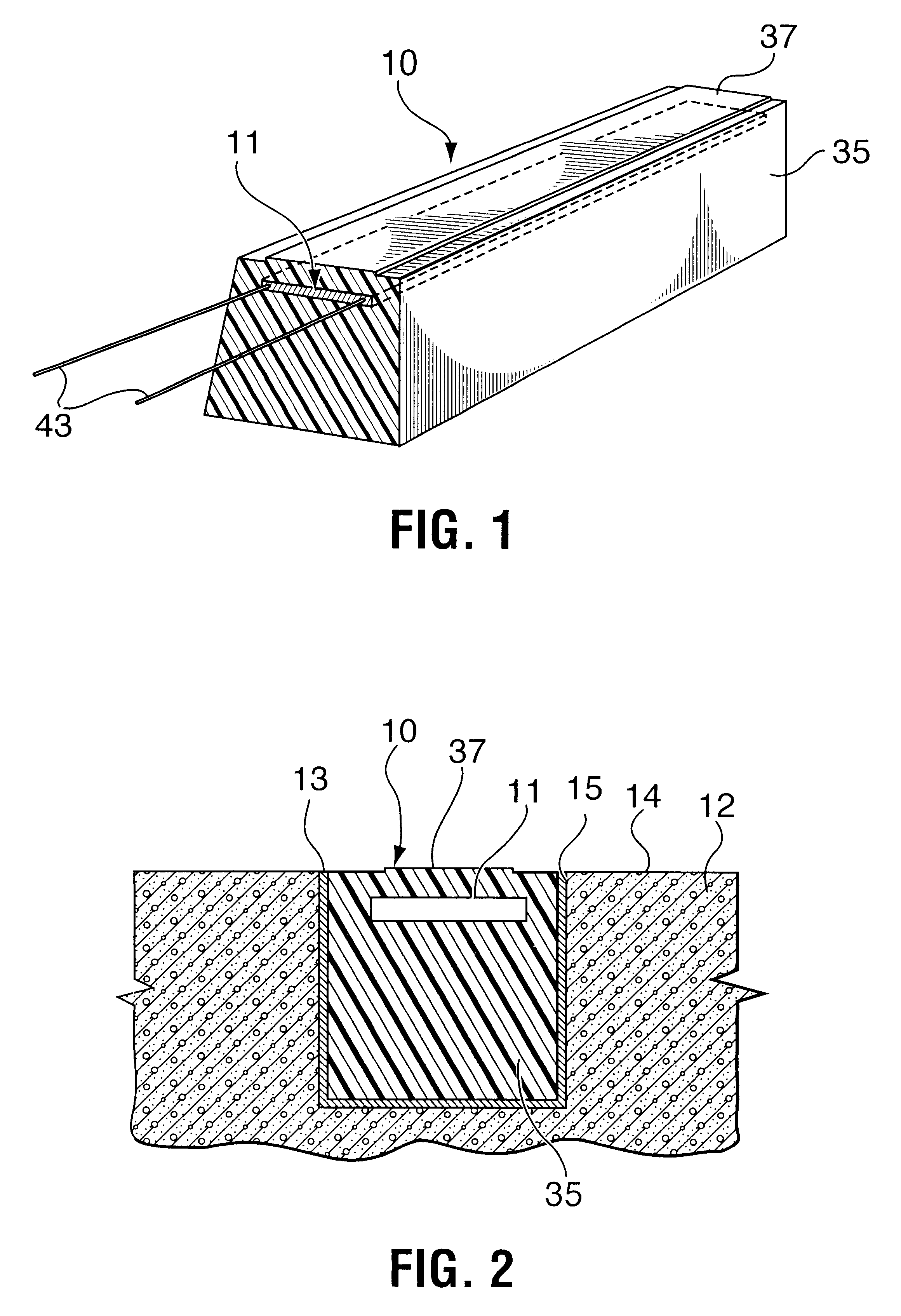

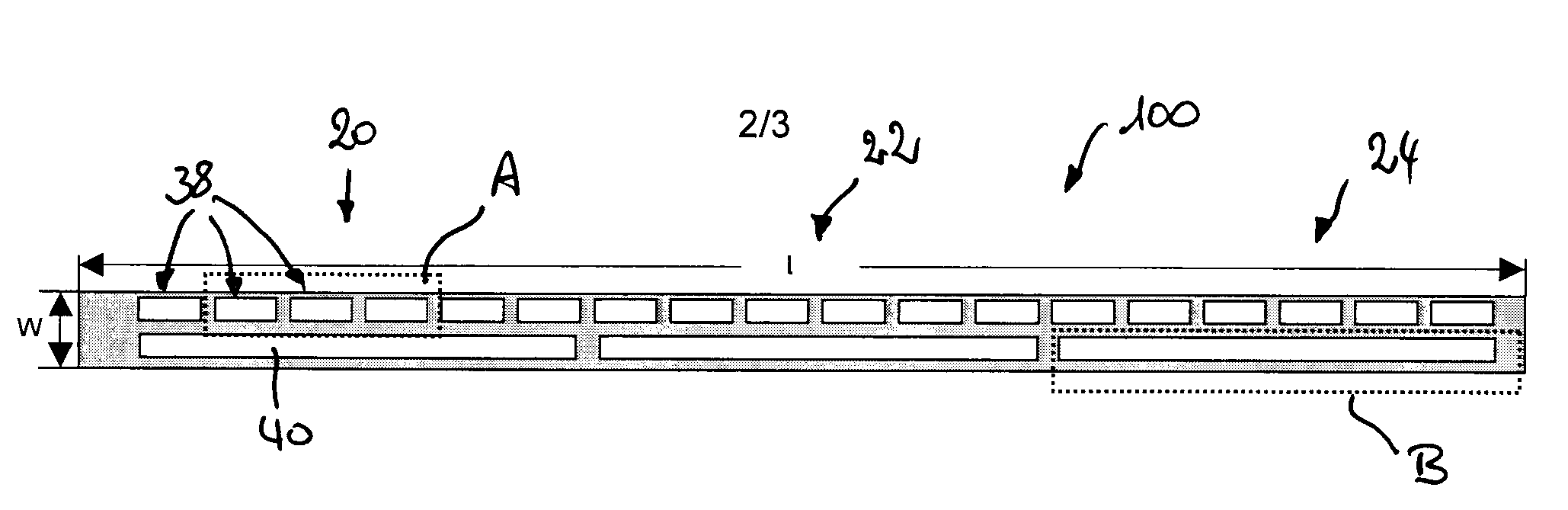

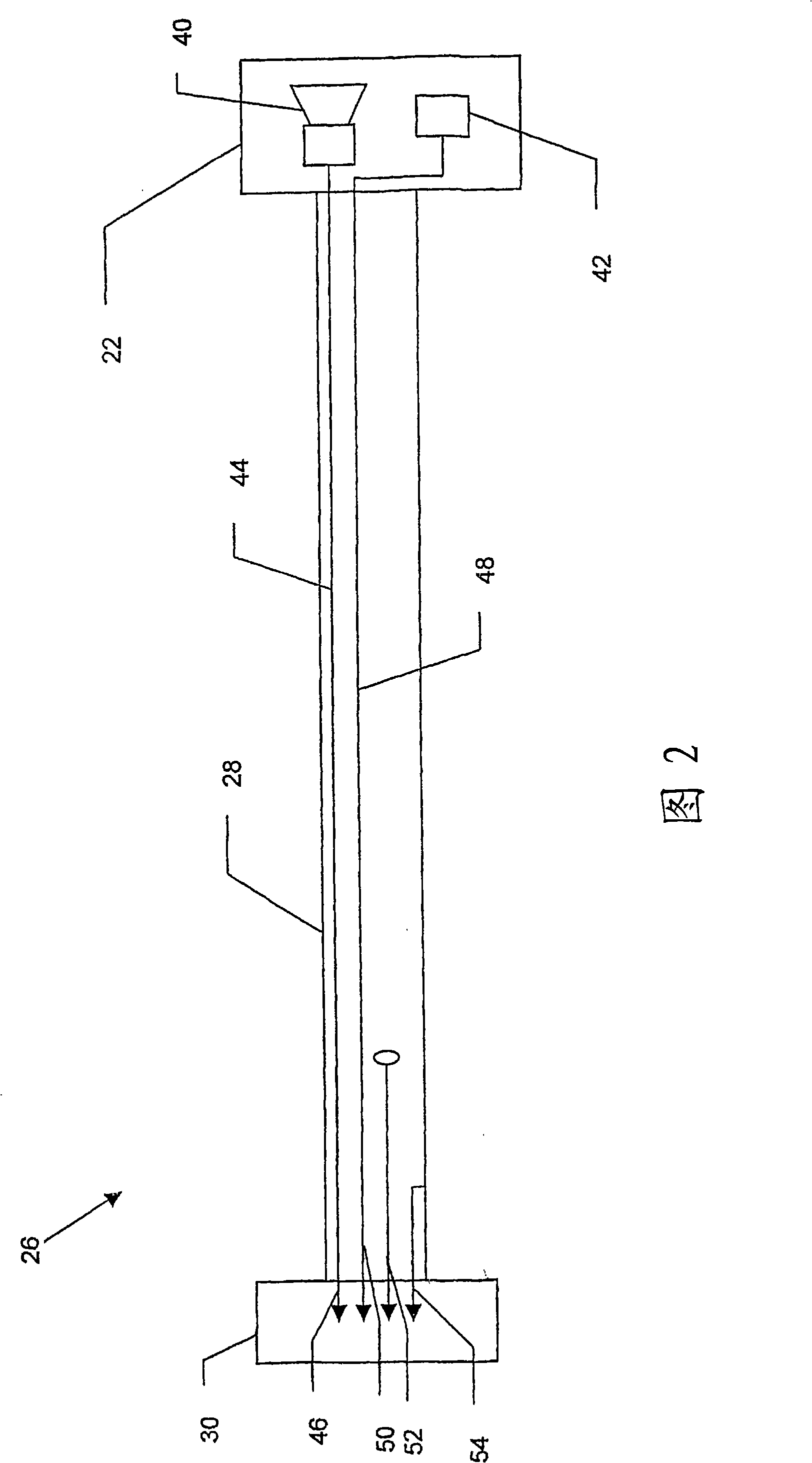

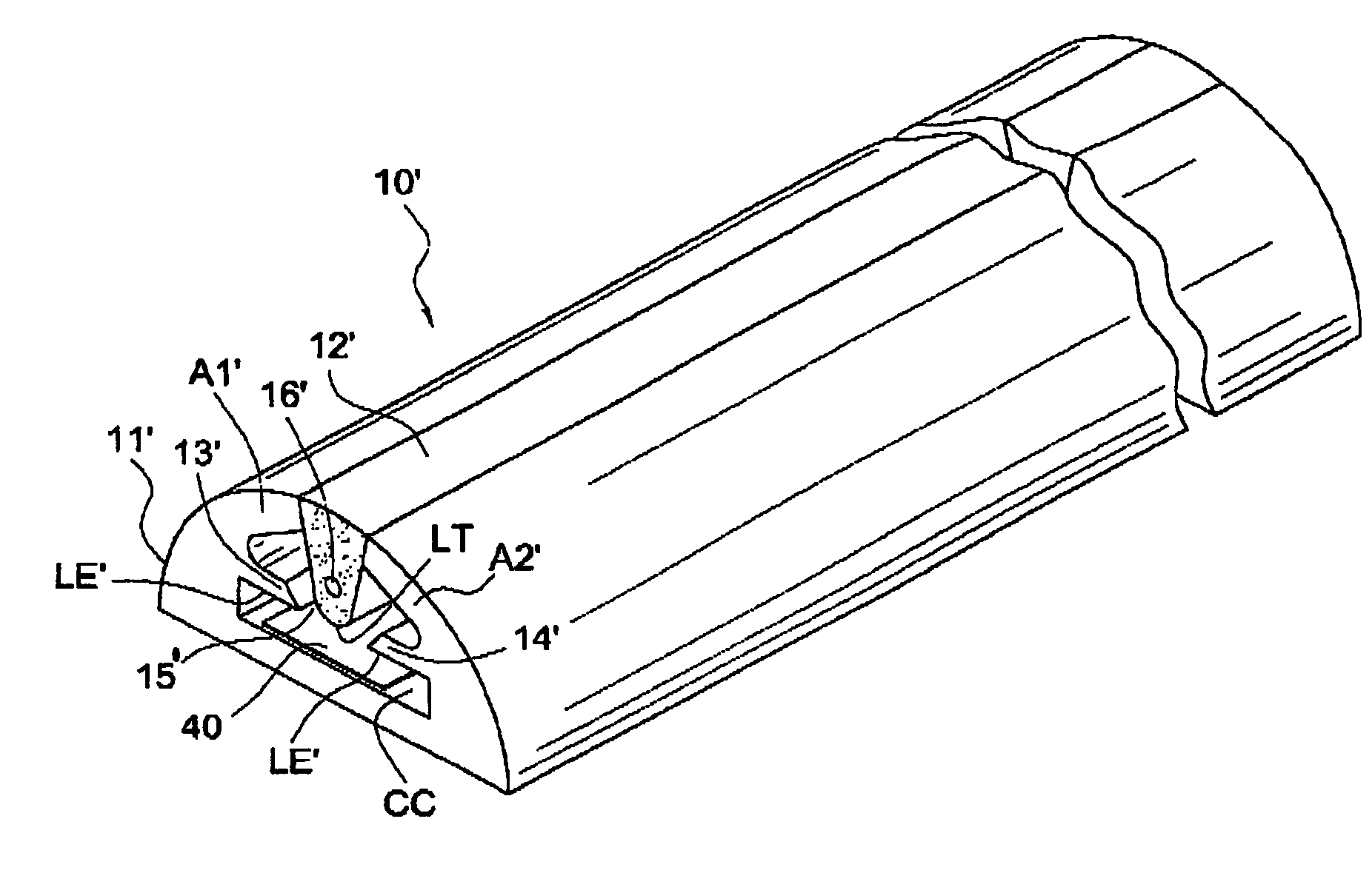

Linear pressure switch apparatus and method

InactiveUS20090120777A1Detection of traffic movementContact operating partsElectrical conductorEngineering

A linear pressure switch is described that has two conductors separated by strips of insulation. The conductors are resilient members that can vary in thickness and material along with the insulation to provide a range of switch sensitivities. The switch can include connectors and an attachment mechanism that facilitates the installation and removal the switch from a given application. In addition, the switch can ergonomically enhanced actuation. The switches can be stacked in layers and selectively have different sensitivities to provide a desired signal output for each switch in a given application. The switch can also include external coatings on the jacket which enhance the feel and resistance of the jacket to wear and misuse.

Owner:GRZAN JOHN T +2

Copper coated steel contact wire with high strength, low relaxation and high electric conductivity for electric traction

InactiveCN101527185AHigh tensile strengthHigh strengthNon-insulated conductorsContact cablesAlloyHigh intensity

The invention provides a copper coated steel contact wire with high strength, low relaxation and high electric conductivity for electric traction. A copper or a copper-silver alloy layer is coated on a high-strength and low-relaxation steel core, and the obtained product is subjected to cold rolling to obtain the copper coated steel contact wire; and the tensile strength of the copper coated steel contact wire reaches more than or equal to 600 / mm<2>, and simultaneously, the electric conductivity of the contact wire reaches more than or equal to 80 percent IACS. The contact wire has the following advantages and technical effects: 1, the tensile strength reaches more than or equal to 600 / mm<2>, simultaneously, the electric conductivity of the contact wire reaches more than or equal to 80 percent IACS, the contact wire also has the high electric conductivity of the copper and high strength, low relaxation and high yield ratio of steel, and the contact wire is suitable to apply to a high speed train with the speed of more than 300 km per hour; 2, the contact wire saves a pre-tension working procedure and reduces the construction difficult in the electric grid construction; and because of low degree of relaxation, the tension of a contact wire is more stable; 3, because of good straightening property, the straightening difficult of the contact wire is reduced in the electric grid construction; 4, the service life is long; 5, the contact wire can normally work at a higher temperature (generated due to abrasion); and 6, the power receiving capability of a pantograph is enhanced.

Owner:王康力

Ternary copper-alloy stranded conductor and contact line preparing method

ActiveCN100361235CSimple manufacturing processSolve chronic problemsNon-insulated conductorsContact cablesProduction rateTechnical standard

Characters are that ternary copper alloy is prepared from materials according to following weight percent: magnesium 0.10-0.50, stannum 0.10-0.4, impurity less than 0.30, and other as copper. Through procedures of melting, heat preservation, casting bars, and cold rolling, twisted line and contact wire are prepared from the ternary copper alloy. In procedure for producing twisted alloy line, and contact wire, the invention raises furnace life of melting copper furnace and ratio between product and roughcast. The ratio is near to a hundred percent, and furnace life is raised to three times so as to lower cost and raise productivity. Through measurement by relevant department, mechanical and physical properties etc. indexes of the hard twisted alloy line reaches to or exceeds relevant indexes of current twisted line of magnesium copper. Product is accorded with requirement of technical standard completely.

Owner:邢台鑫晖铜业特种线材有限公司

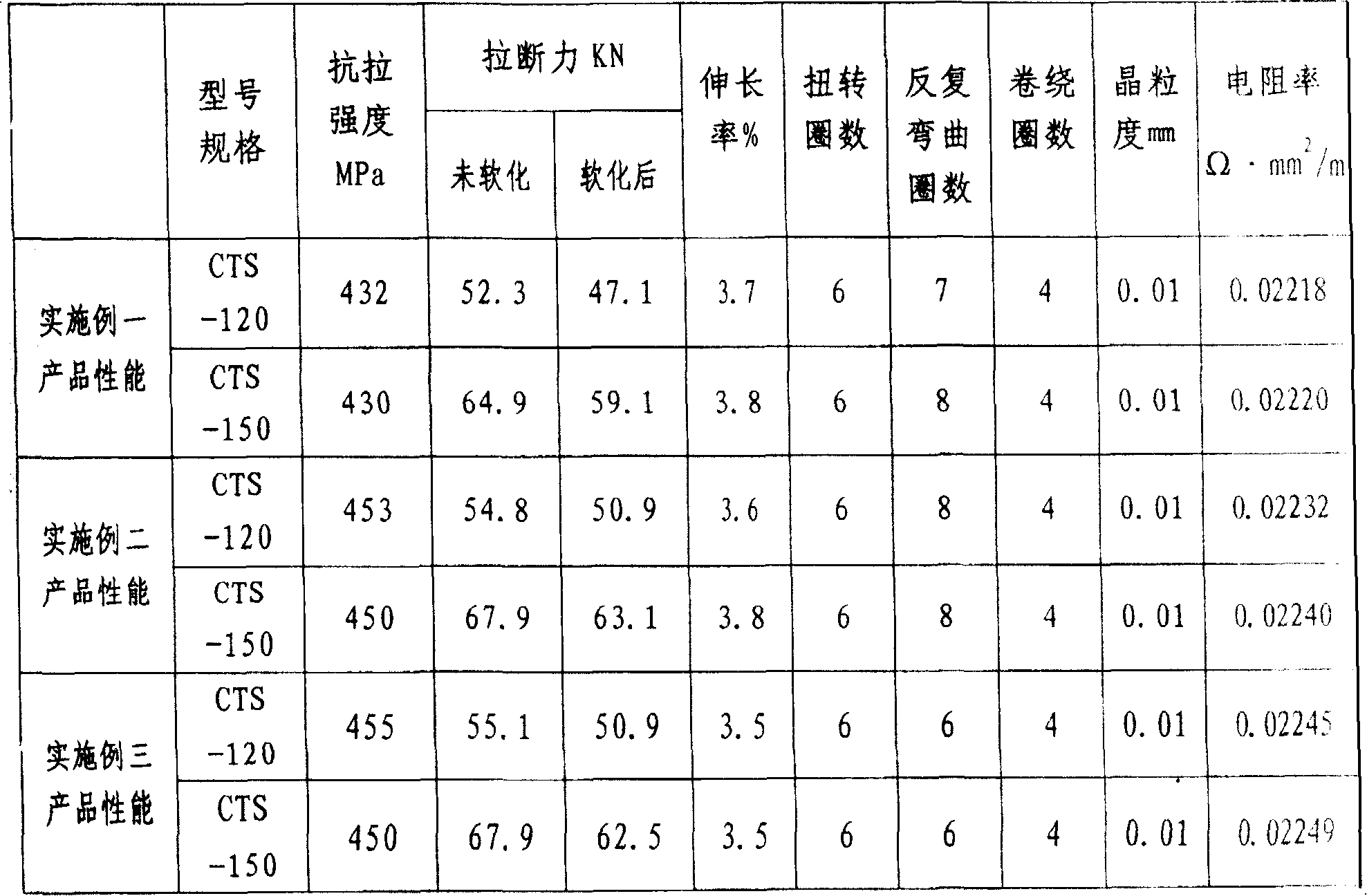

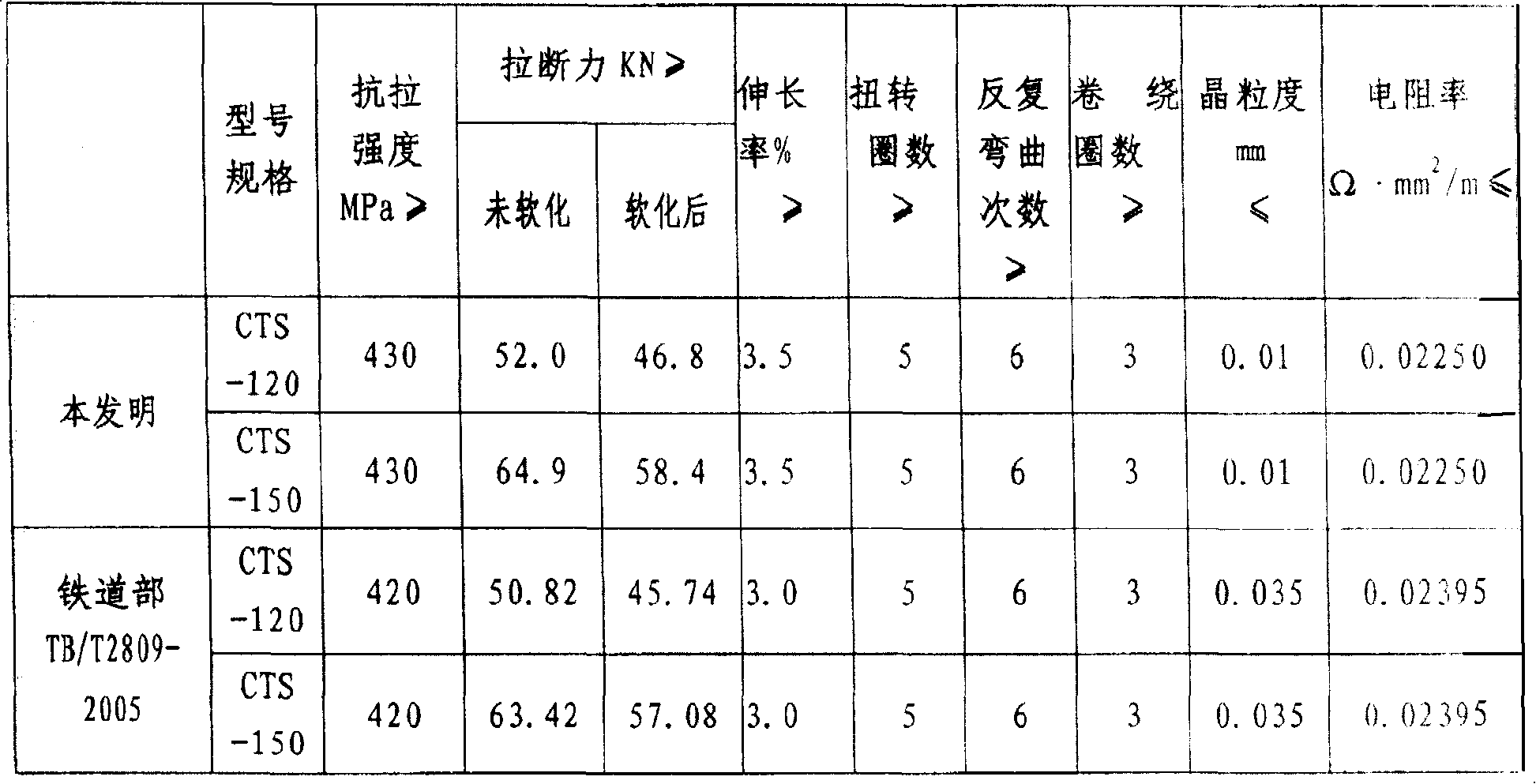

Contact line of bronze in use for electrified railroad in high speed, and preparation method

ActiveCN100411062CReduce burning lossPrecise control of ingredientsSingle bars/rods/wires/strips conductorsOther manufacturing equipments/toolsExtensibilityRare earth

Contact wire of bronze in use for electric railway in high speed is composed of copper base and additive components. The said components include stannum, zirconium, and mixed rare earths. Weight percentage of each component is as following stannum 0.15-0.35%, zirconium 0.005-0.01%, mixed rare earths 0.005-0.02%. Additive components can also include magnesium and silver. Weight percentage of magnesium is 0.005-0.01%, and weight percentage of silver is 0.01- 0.03%. Advantages are: fine grain, high intensity, good plasticity, and abrasion resistance, tensile strength larger than or equal to 430Mpa, extensibility larger than or equal to 3.5%, grain size smaller than or equal to 0.01mm, resistivity smaller than or equal 0.02250 ohm .mm2 / m, tensile strength larger than or equal to 390Mpa at softened 300 deg.C. The contact wire is applicable to electric railway in speed higher than 300 km per hour.

Owner:TAIXING SHENGDA COPPER IND CO LTD

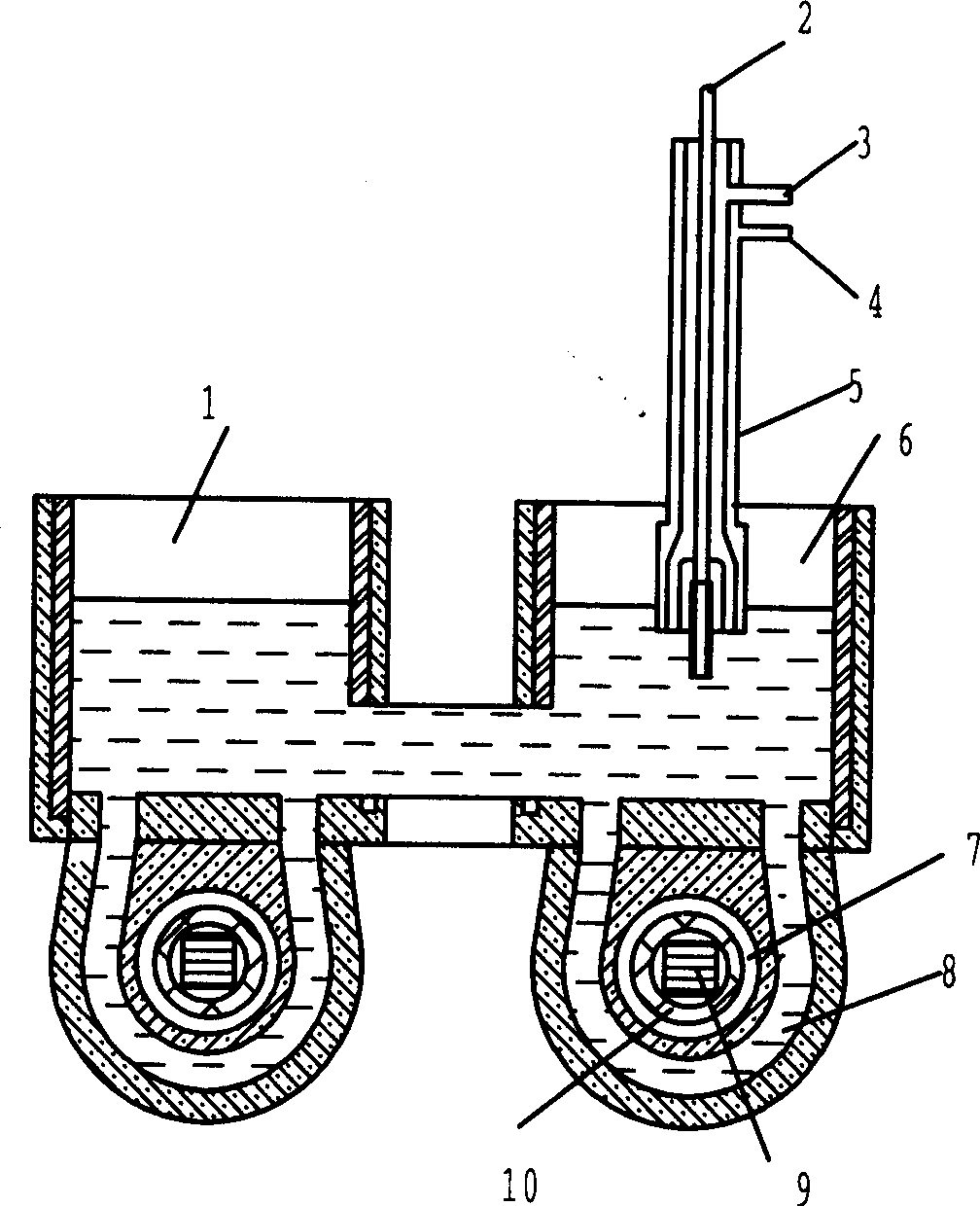

Vehicle axle sensor

InactiveUS7515068B2Simple and safe installationIncrease flexibilityAnalogue computers for vehiclesAnalogue computers for trafficEngineeringPlunger

Owner:TRAFFIC MONITORING SERVICES

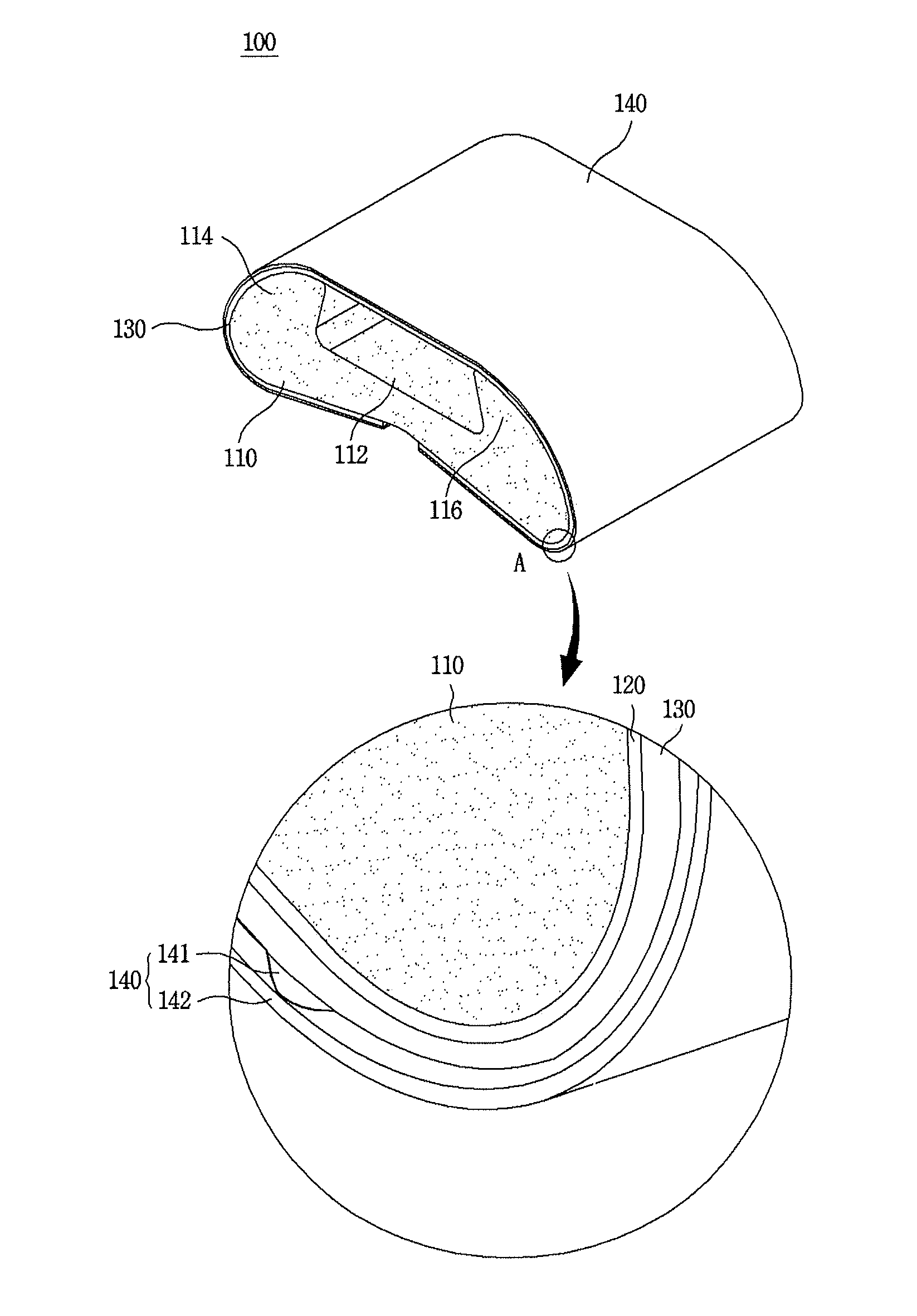

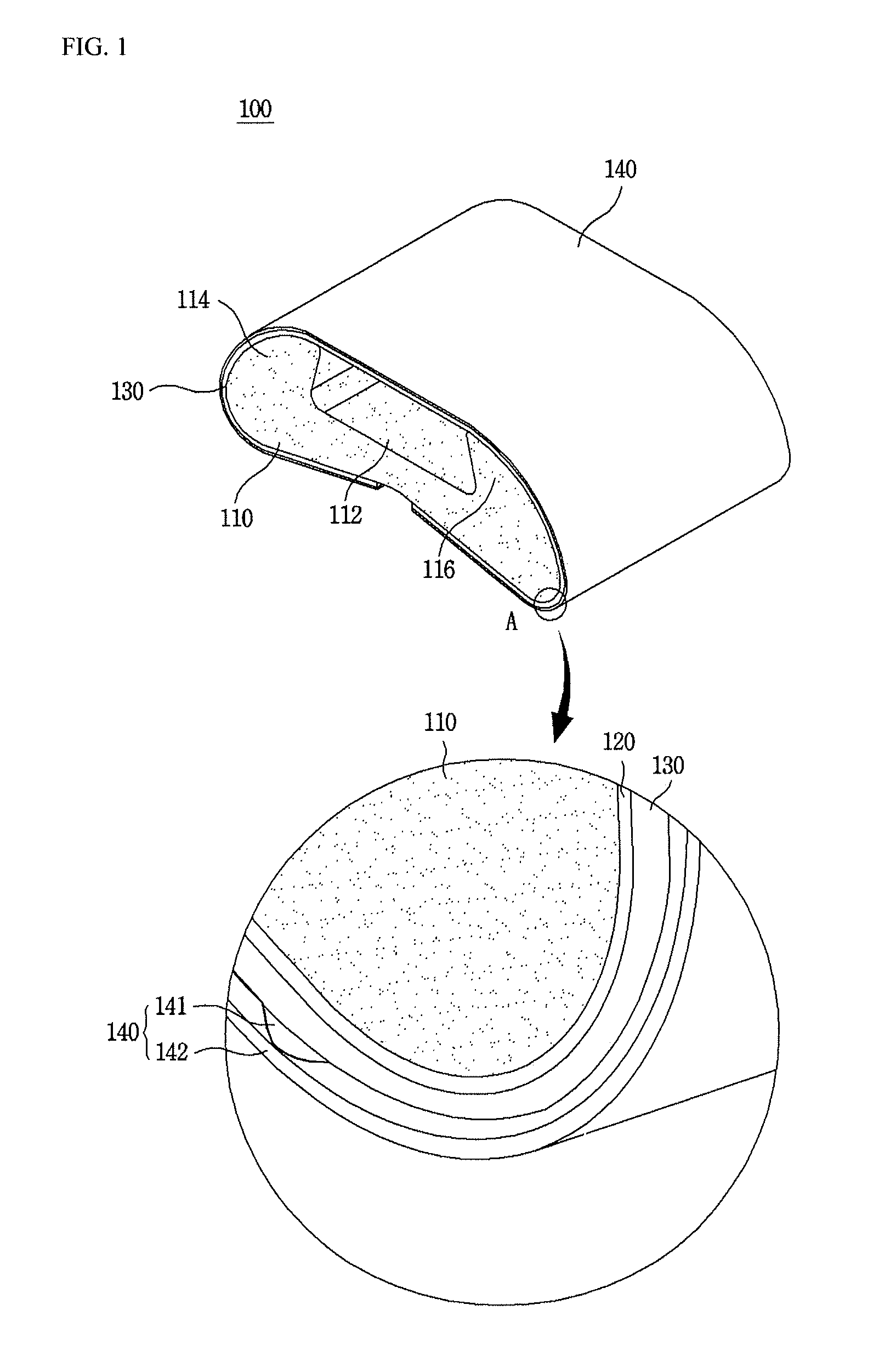

Elastic electric contact terminal adapted to small size

InactiveUS20160336093A1Stay flexibleImprove corrosion resistanceCoupling device detailsPrinted circuit aspectsMetalPolymer

Disclosed is an elastic electric contact terminal including an elastic core provided with at least one or more channels which are recessed downwardly from the top surface thereof with a predetermined width and depth and extend in a lengthwise direction, a polymer film surrounding and adhering to the elastic core, and a solderable metal layer surrounding and adhering to the polymer film, wherein both side walls of the channels elastically support an object.

Owner:JOINSET +1

Electrical conductor comprised of solid segments

ActiveUS10839986B2Large effective cross-sectionEliminate disadvantagesNon-insulated conductorsClimate change adaptationElectrical conductorMechanical engineering

An electrical conductor comprises three or more solid segments of identical shape. In cross-section, each segment comprises two sides, which are configured for flush bearing against correspondingly opposing lateral surfaces on another segment. The cross-sectional surface through all the constituent segments of the electrical conductor is describable by a closed curve having a stepless characteristic. All the constituent segments of the electrical conductor are stranded in combination.

Owner:NEXANS

Copper-aluminum composite contact wire

InactiveCN100555475CImprove straightnessMeet conductivity requirementsNon-insulated conductorsContact cablesContact networkHardness

The invention relates to a copper-aluminum composite contact wire for electrified railway and bus contact wire. Its special feature is that copper or copper alloy and aluminum or aluminum alloy bimetal are compounded into an integral wire through plastic deformation, so that the part in contact with the aluminum clip is aluminum or aluminum alloy, and the part in contact with the locomotive pantograph is copper. alloy. The comprehensive electrical conductivity of the copper-aluminum composite contact wire is 65%IACS~105%IACS; the hardness of its working part (that is, the copper or copper alloy slidingly rubbed against the pantograph) is HB90~200; the copper-aluminum composite contact wire produced by the technology of the present invention The copper-aluminum bonding force of the composite contact wire is 400-550N / cm.

Owner:JIANGXI UNIV OF SCI & TECH

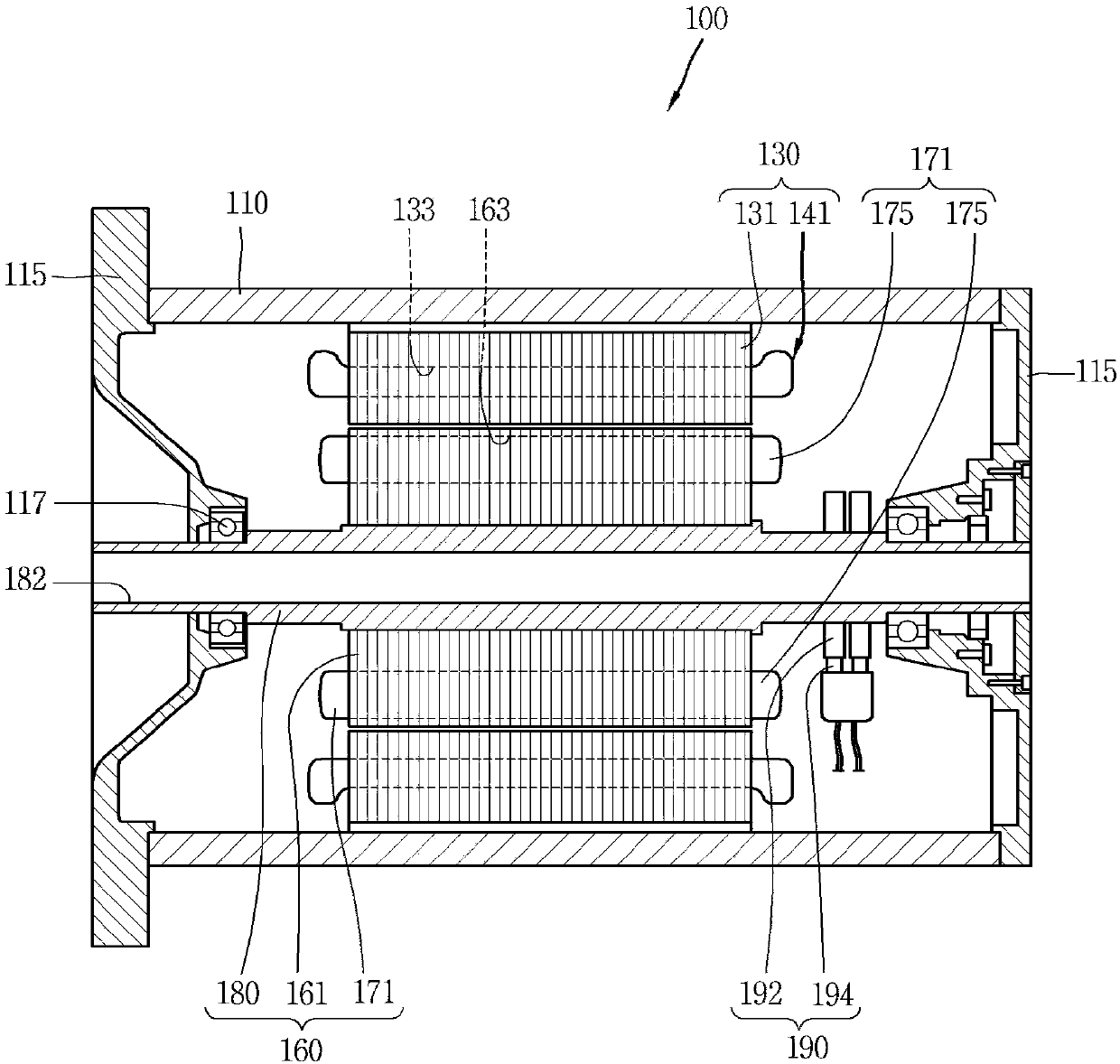

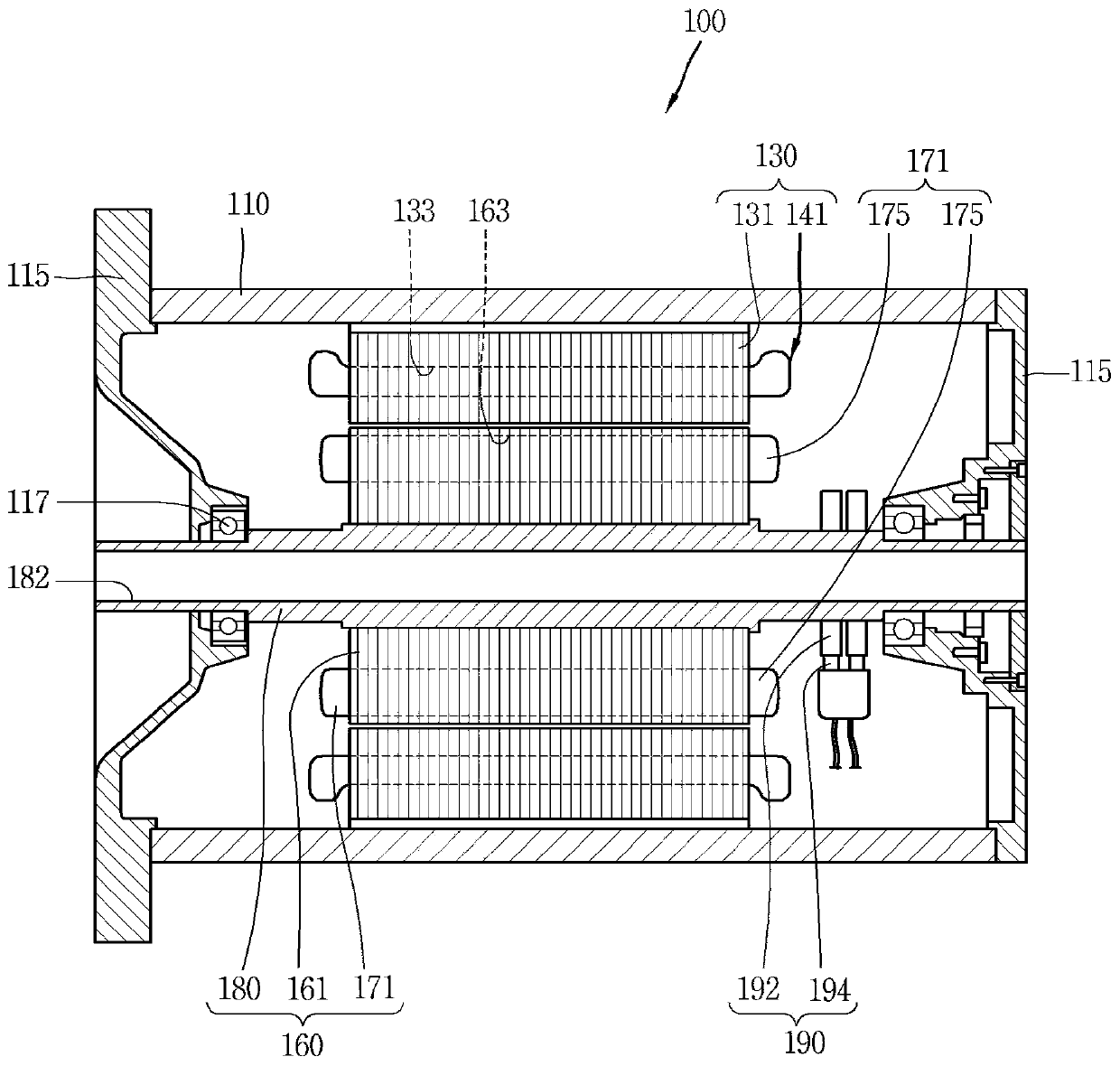

Composite insulating member, manufacturing method therefor, and electrical device comprising composite insulating member

ActiveCN107636775AFast heat releaseSpeed up heat transferPlastic/resin/waxes insulatorsContact cablesElectricityElectrical conductor

The present invention relates to a composite insulating member, a manufacturing method therefor, and an electrical device comprising the composite insulating member. The composite insulating member ofthe present invention comprises: a first insulating member formed from an electrical insulating member, and having a charging space; and a second insulating member formed from an electrical insulating member, having heat transfer performance higher than that of the first insulating member, and being charged in the charging space. Therefore, conductor insulation and conductor radiation can be promoted.

Owner:LG MAGNA E POWERTRAIN CO LTD

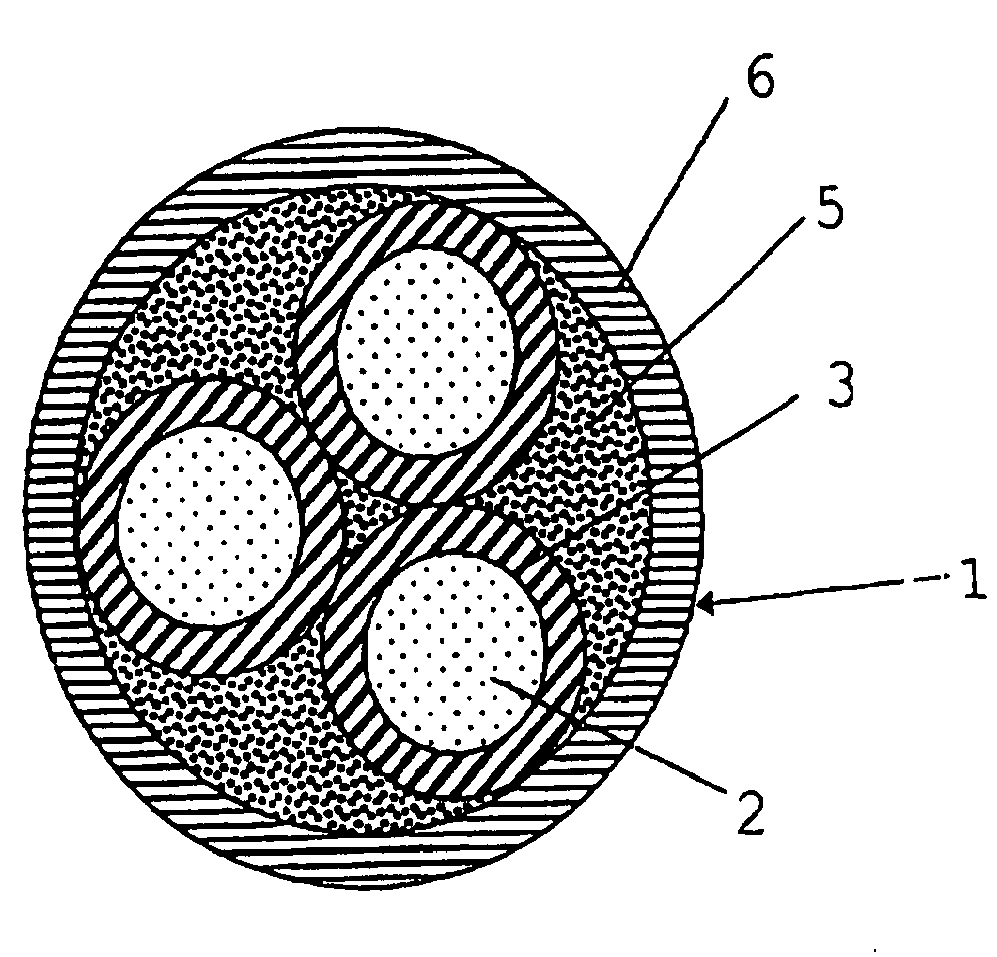

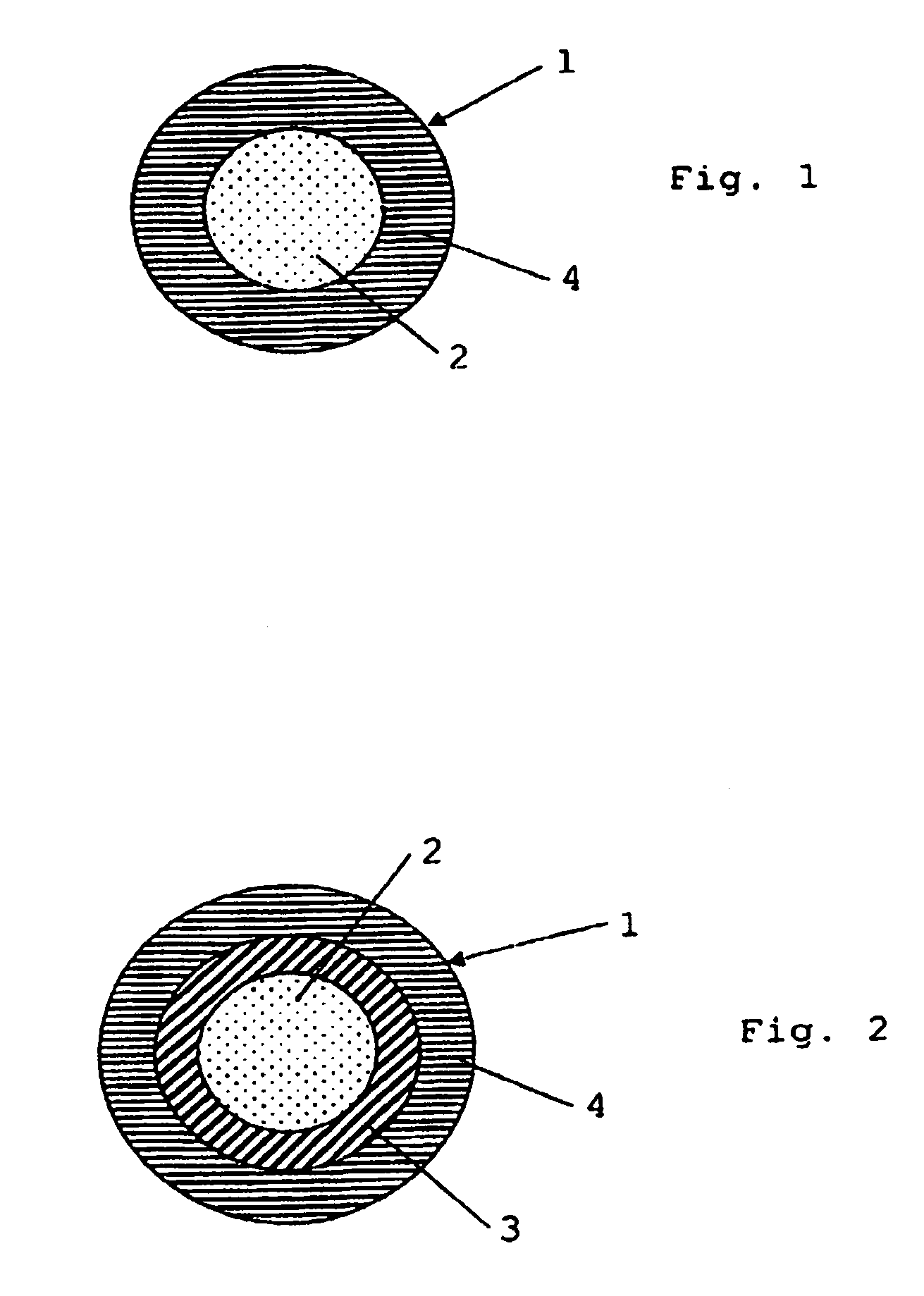

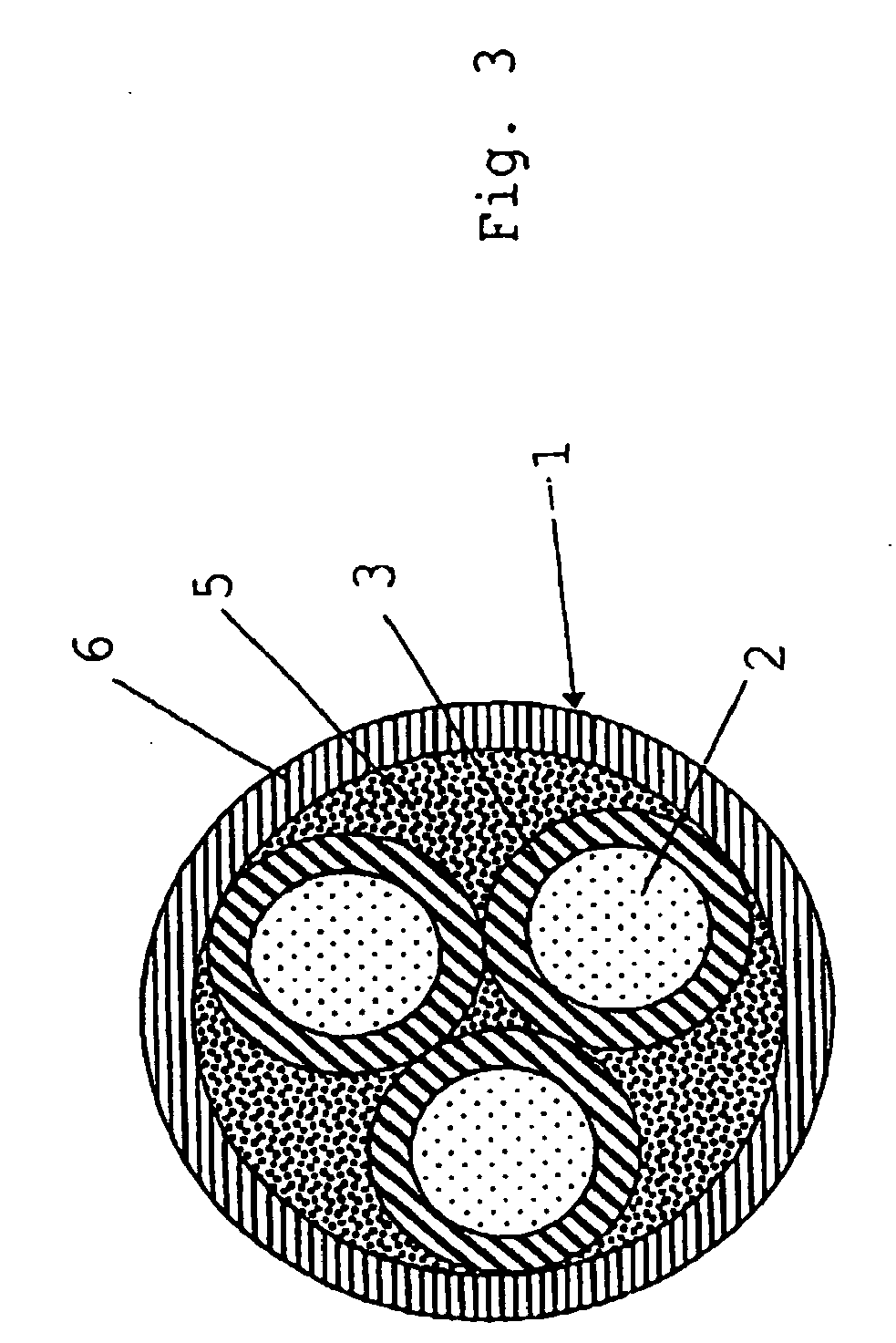

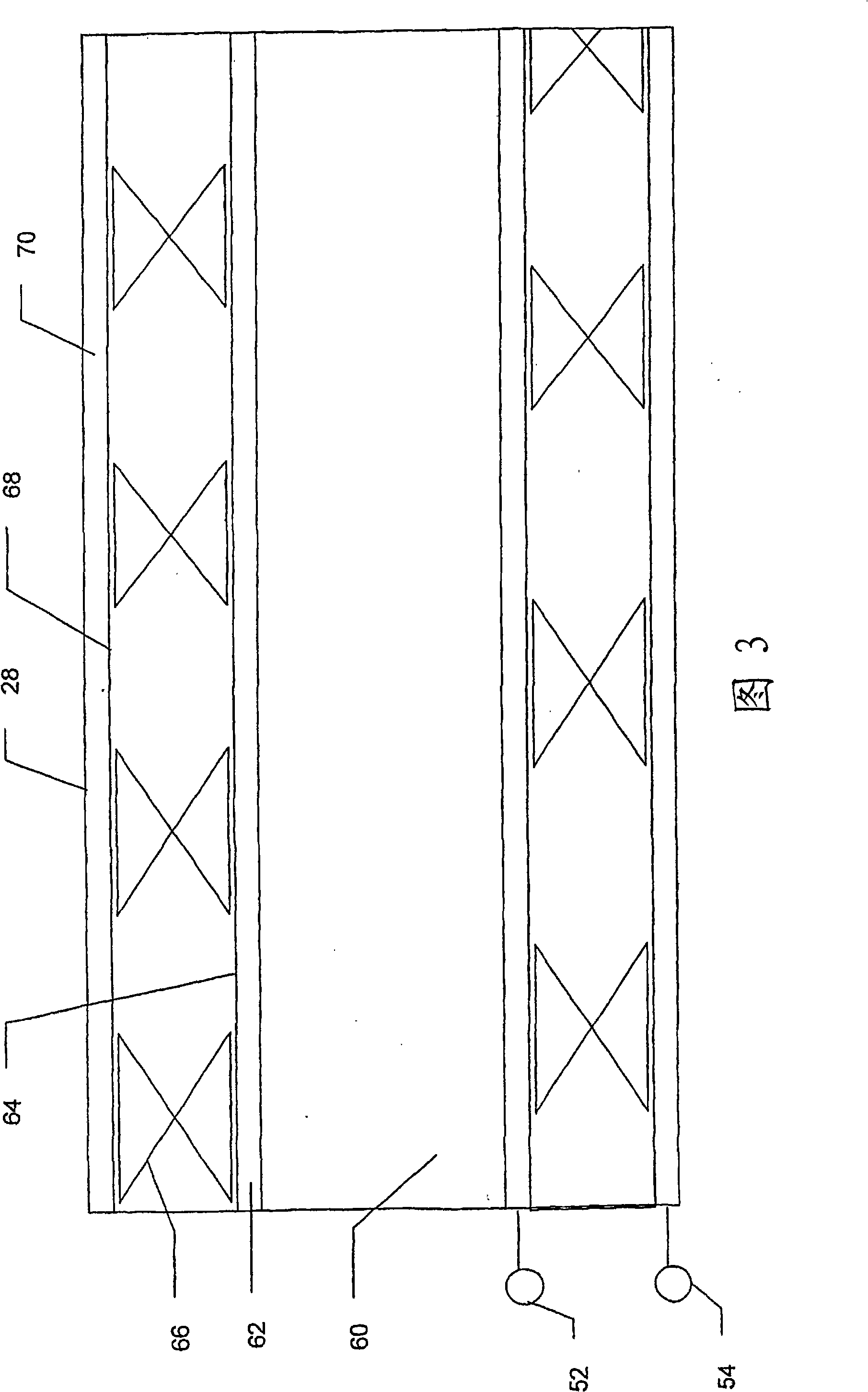

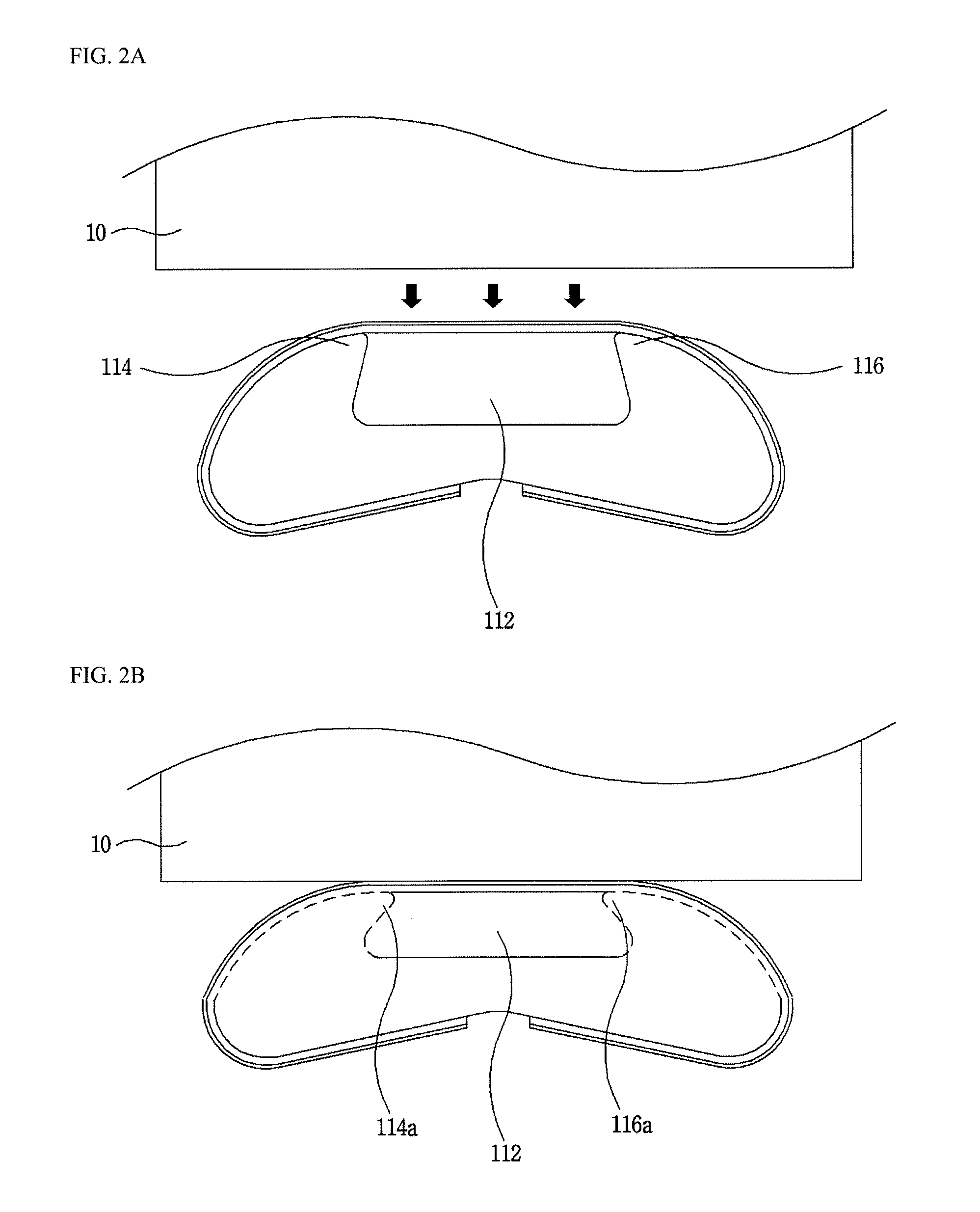

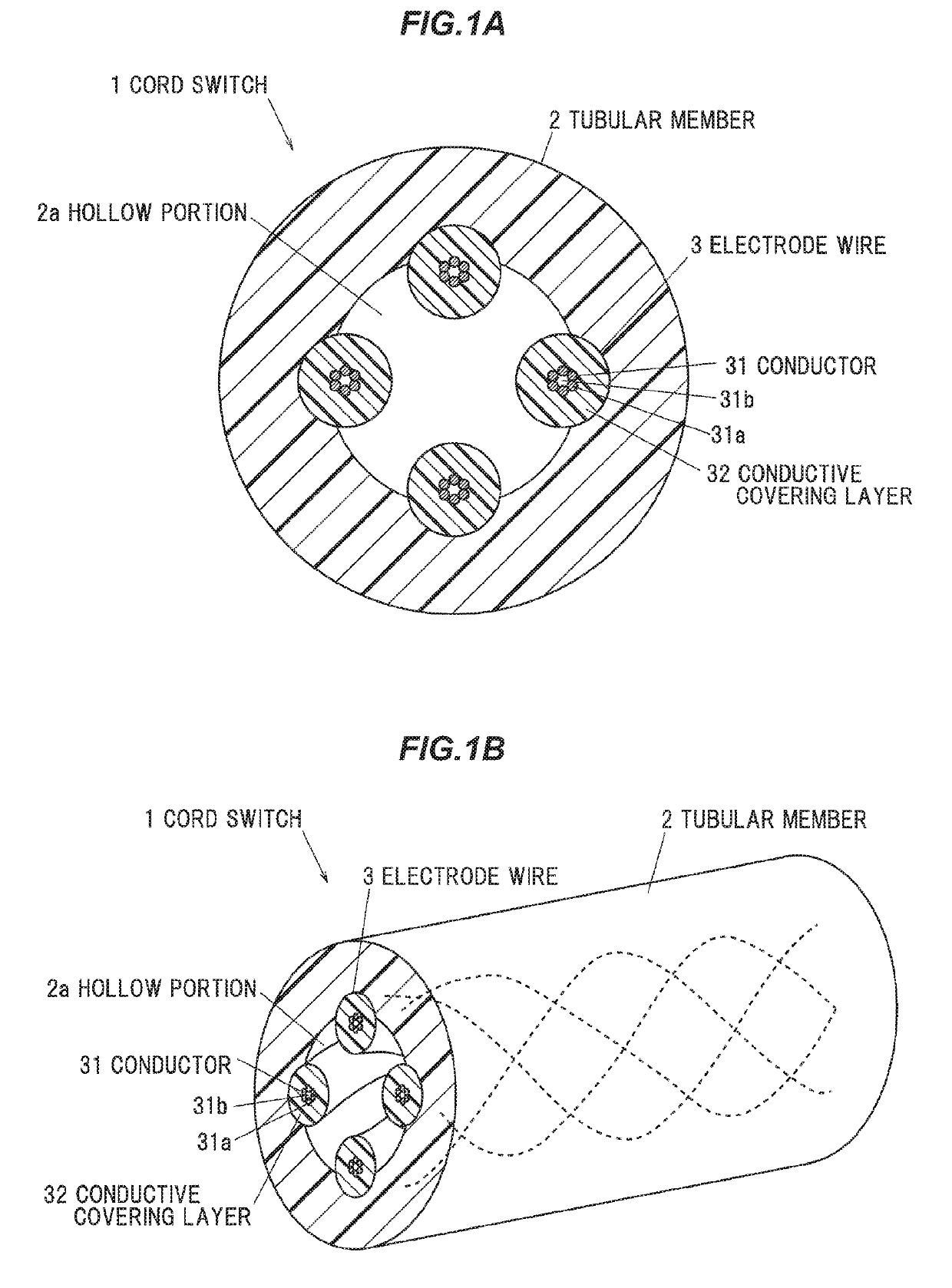

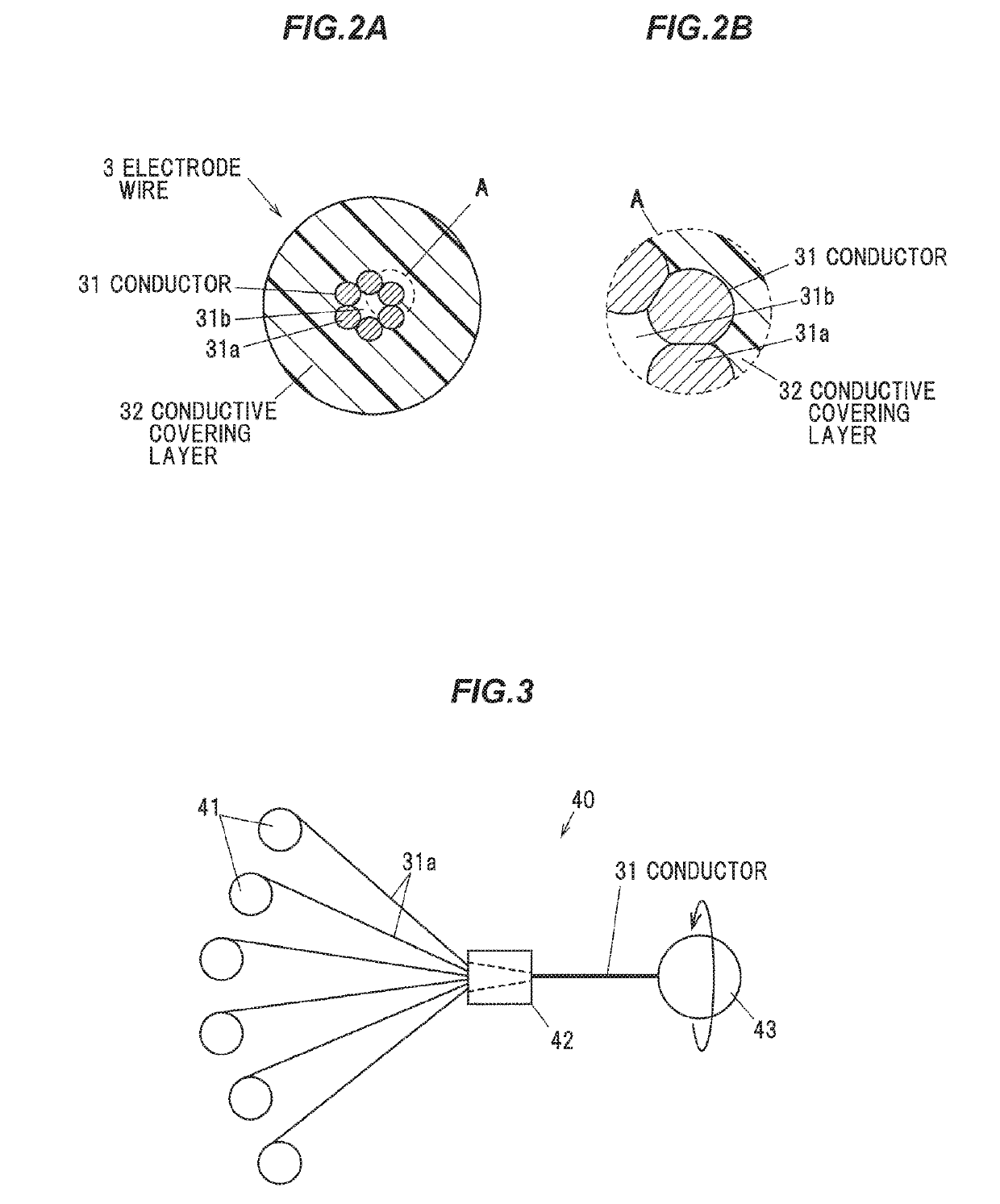

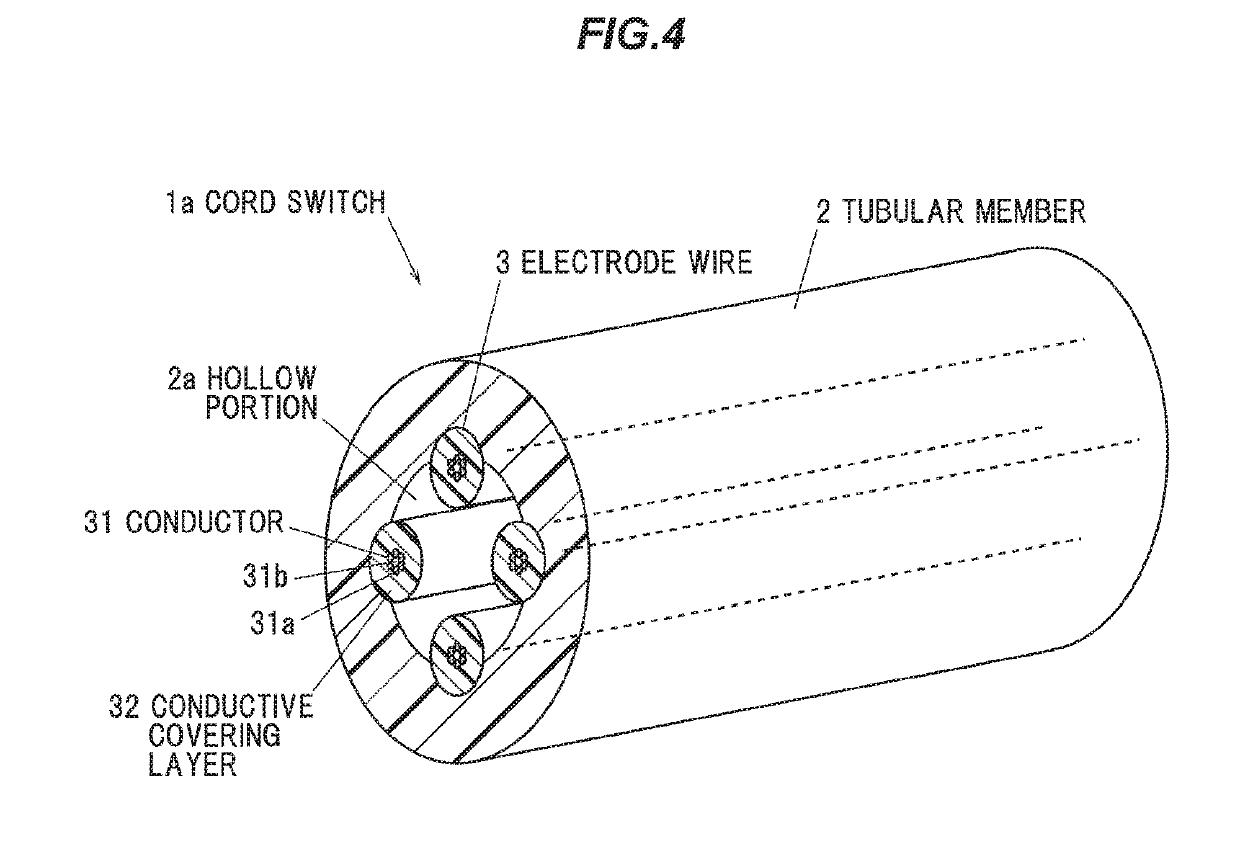

Cord switch

PendingUS20190228875A1Buckling suppressionWires contactsContact operating partsElectrical conductorMetal

A cord switch is composed of a hollow tubular member having elasticity and insulating properties, and a plurality of electrode wires disposed opposite an inner side of the tubular member and spaced apart by elastic force of the tubular member. The plurality of electrode wires each include a conductor formed by stranding a plurality of metal wires together. All of the metal wires constituting the conductors are helically stranded together.

Owner:PROTERIAL LTD

Method of producing the copper alloy contact wire

InactiveCN101178957BImprove wear resistanceImprove fatigue resistanceSingle bars/rods/wires/strips conductorsContact cablesReduction treatmentInternal oxidation

The invention provides copper alloy contact lines and a preparation method thereof. The method includes the following steps: (1) preparing Cu-Al master alloy powders, in which the content of Al is 0.21-0.53wt%, and the balance is copper; (2) using the Cu-Al master alloy powders obtained from step (1) to prepare an oxygen source of Al2O3-Cu2O, in which the weight ratio of Cu and AI keeps unchanged; (3) mixing the Cu-Al master alloy powders obtained from step (1) and the oxygen source of Al2O3-Cu2O obtained in step(2), wherein, the weight ratio of the oxygen source of Al2O3-Cu2O in the mixture is 10-25wt%; (4) carrying out internal oxidation and reduction treatment for the mixture obtained in step (3), so as to obtain alloy powders of Cu-Al2O3, in which the content of Al2O3 is 0.4-1.0wt%; (5) suppressing the alloy powders of Cu-Al2O3 obtained in step (4) into billets and then carrying out sintering treatment; (6) molding the suppressed and sintered billets obtained in step (5) into bars; (7) making the bars obtained in step (6) into contact lines with required section size by drawing. The copper alloy contact lines prepared by the method present good conductivity, high mechanical strength and softening temperature, good performance of friction and abrasion resistance.

Owner:DATANG LUOYANG SHOUYANGSHAN POWER PLANT

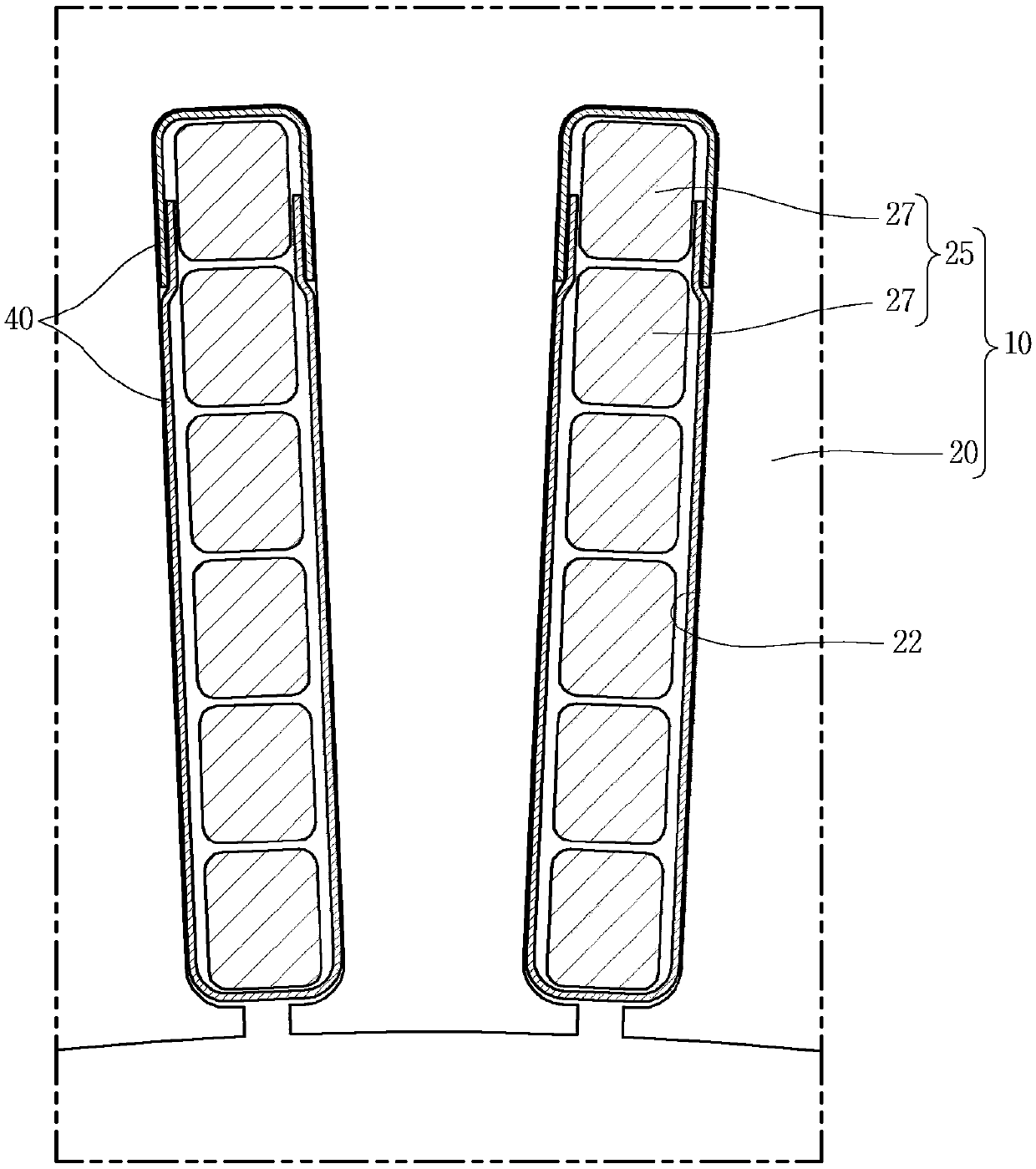

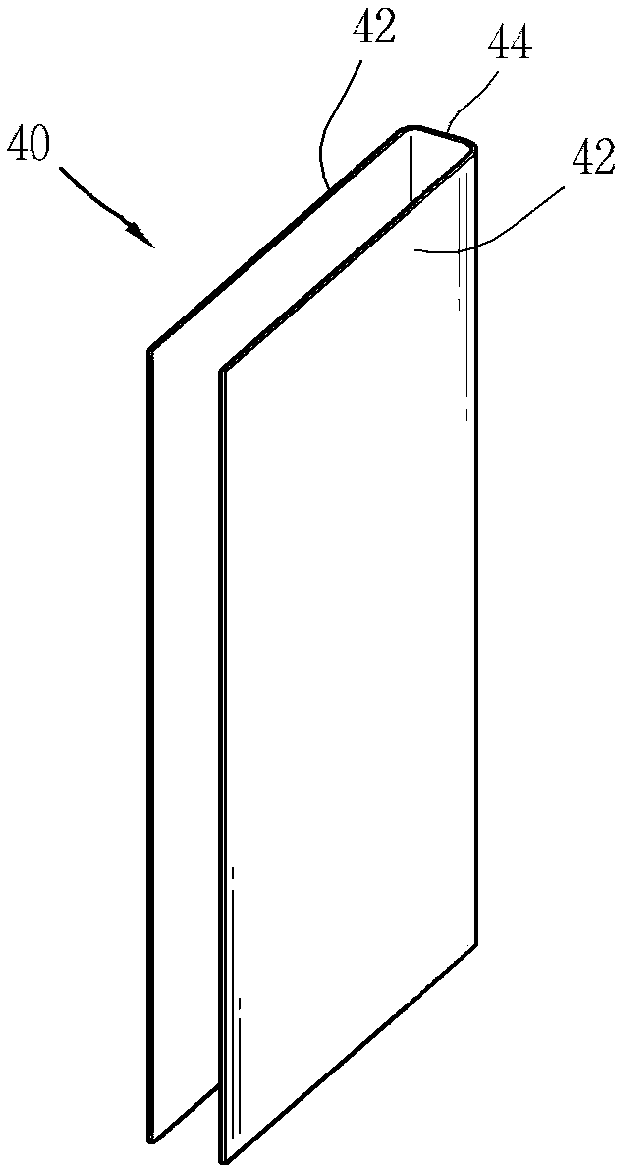

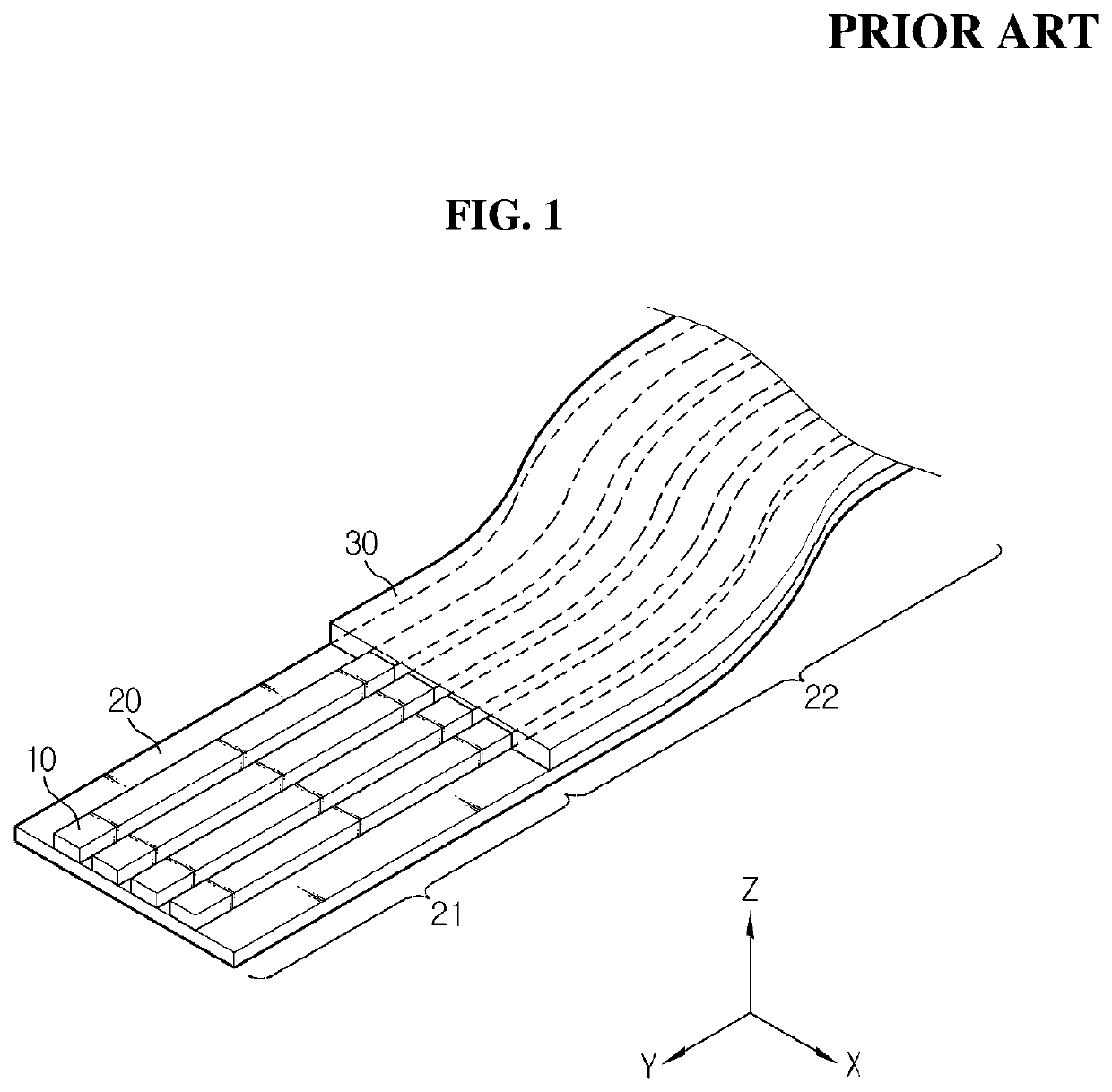

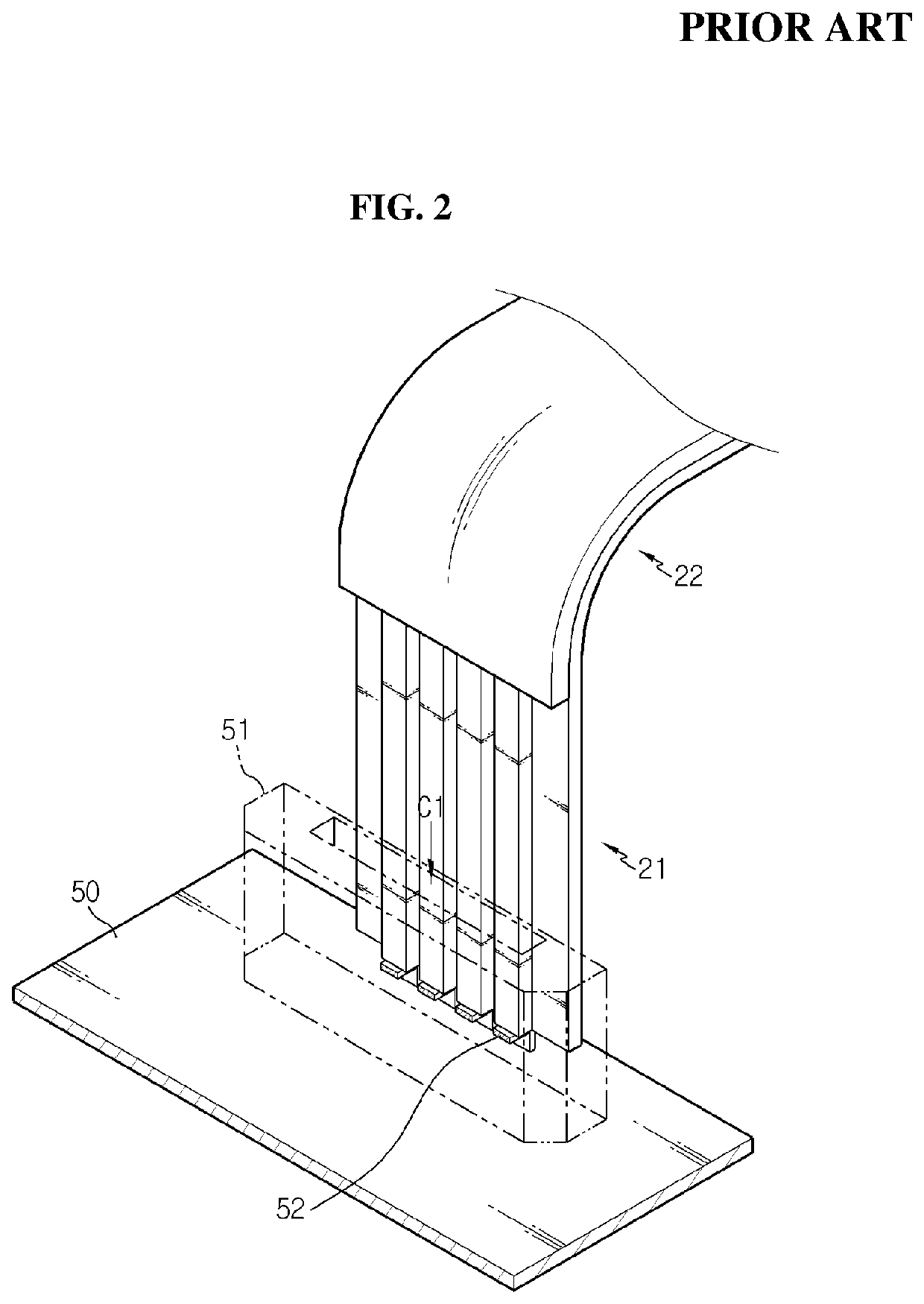

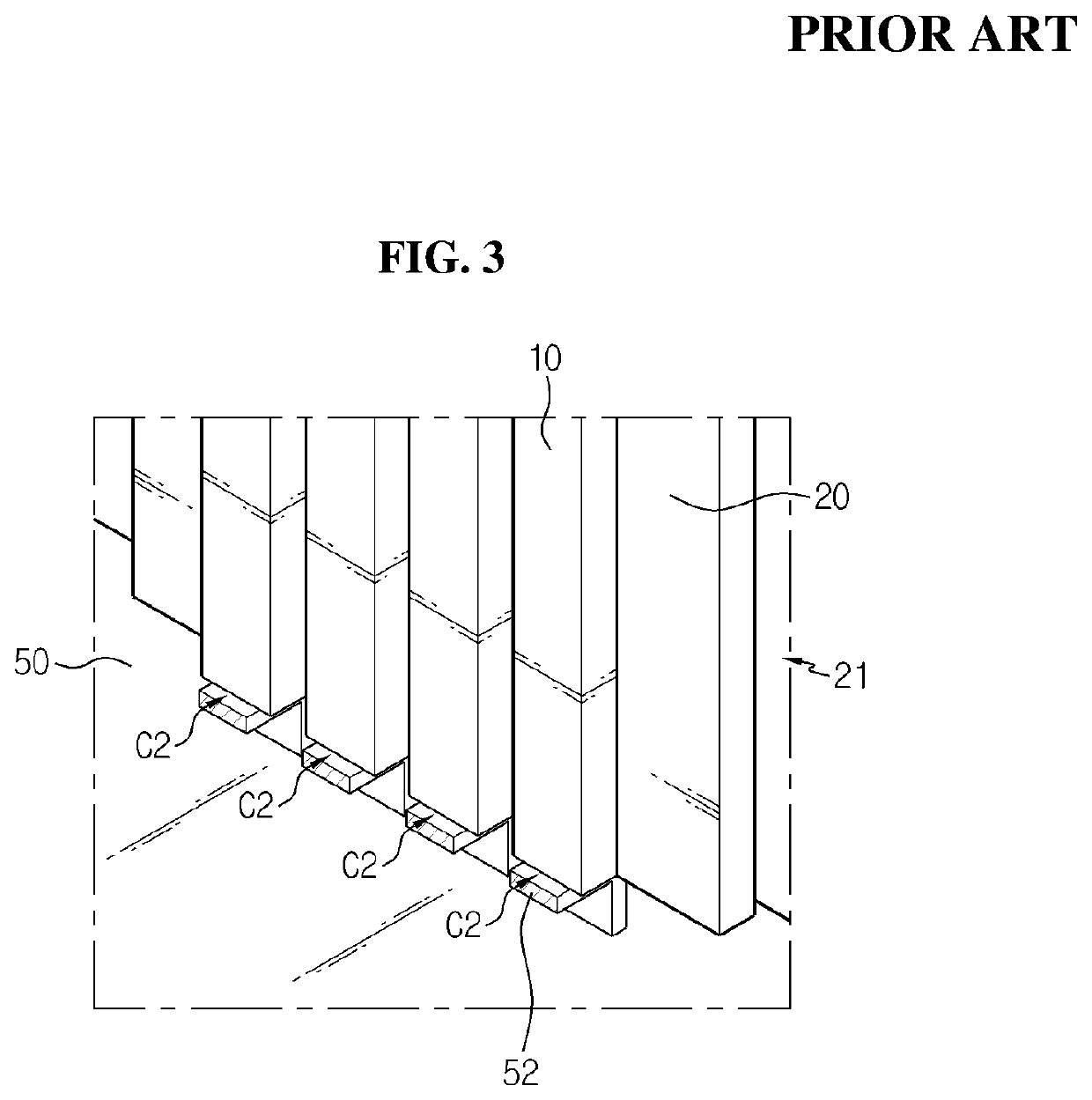

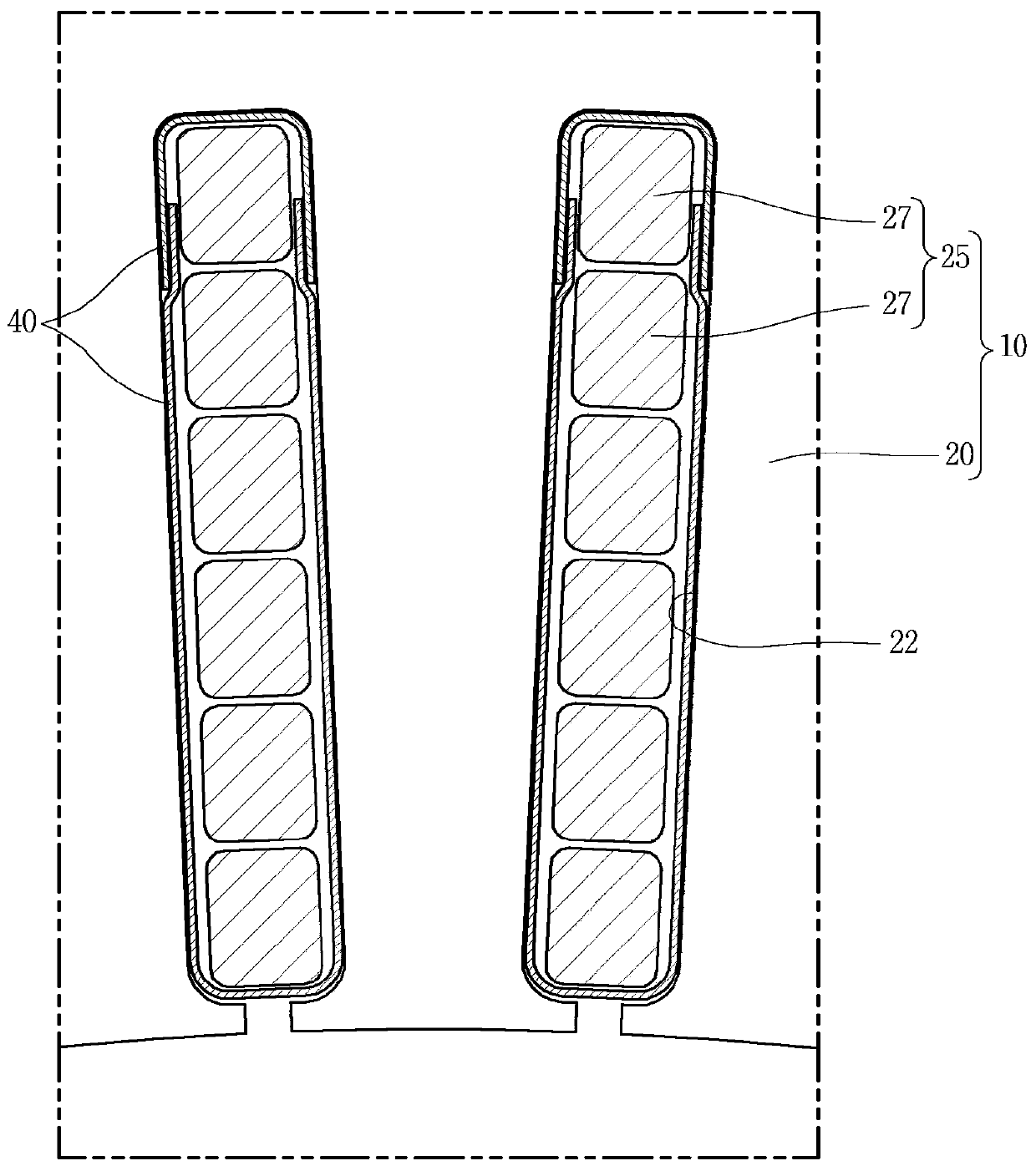

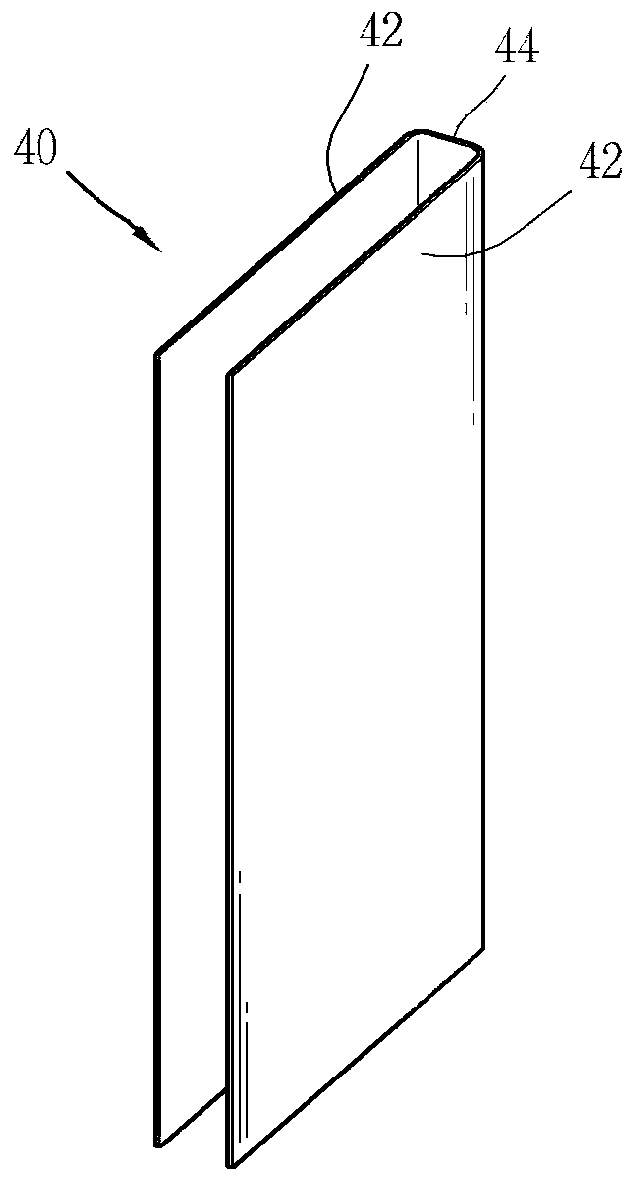

Flat cable with improved short-circuit prevention function

ActiveUS11264146B2Improve securityCoupling device connectionsFlat/ribbon cablesElectrical conductorStructural engineering

Owner:LG ENERGY SOLUTION LTD

Composite insulating member, manufacturing method thereof, and electrical device having the composite insulating member

ActiveCN107636775BFast heat releaseSpeed up heat transferPlastic/resin/waxes insulatorsContact cablesElectrical conductorEngineering

The present invention relates to a composite insulating member, a method for manufacturing the same, and an electrical device having the composite insulating member. The composite insulating member of the present invention includes: a first insulating member formed of an electrical insulating member having a filling space; and a second insulating member formed of an electrical insulating member having a higher thermal conductivity than the first insulating member. To transfer performance, the second insulating member is filled in the filling space. Thereby, the conductor can be insulated, and the heat dissipation of the conductor can be promoted.

Owner:LG MAGNA E POWERTRAIN CO LTD

Switch mat for an electrical switch

InactiveUS20060219539A1Low costNot negatively optical appearanceLegendsDetection of traffic movementEffect lightEngineering

In a switch mat for an electrical switch with a back-lit actuation element, which is stored in a housing, for action on switch contacts, at least one of the switch contacts is correlated with the switch mat. The switch mat is colored dark in such a way that, on the one hand, scatter light is absorbed by the switch mat and, on the other hand, light for the back-lighting of the actuation element is allowed through by the switch mat.

Owner:LOTZ FRIEDHELM +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com