Ternary copper-alloy stranded conductor and contact line preparing method

A ternary copper and contact wire technology, applied in the field of cable wires and wires, can solve the problems of large fluctuations in process performance, increased production costs, and low productivity, and achieve the effects of improved corrosion resistance, reduced production costs, and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

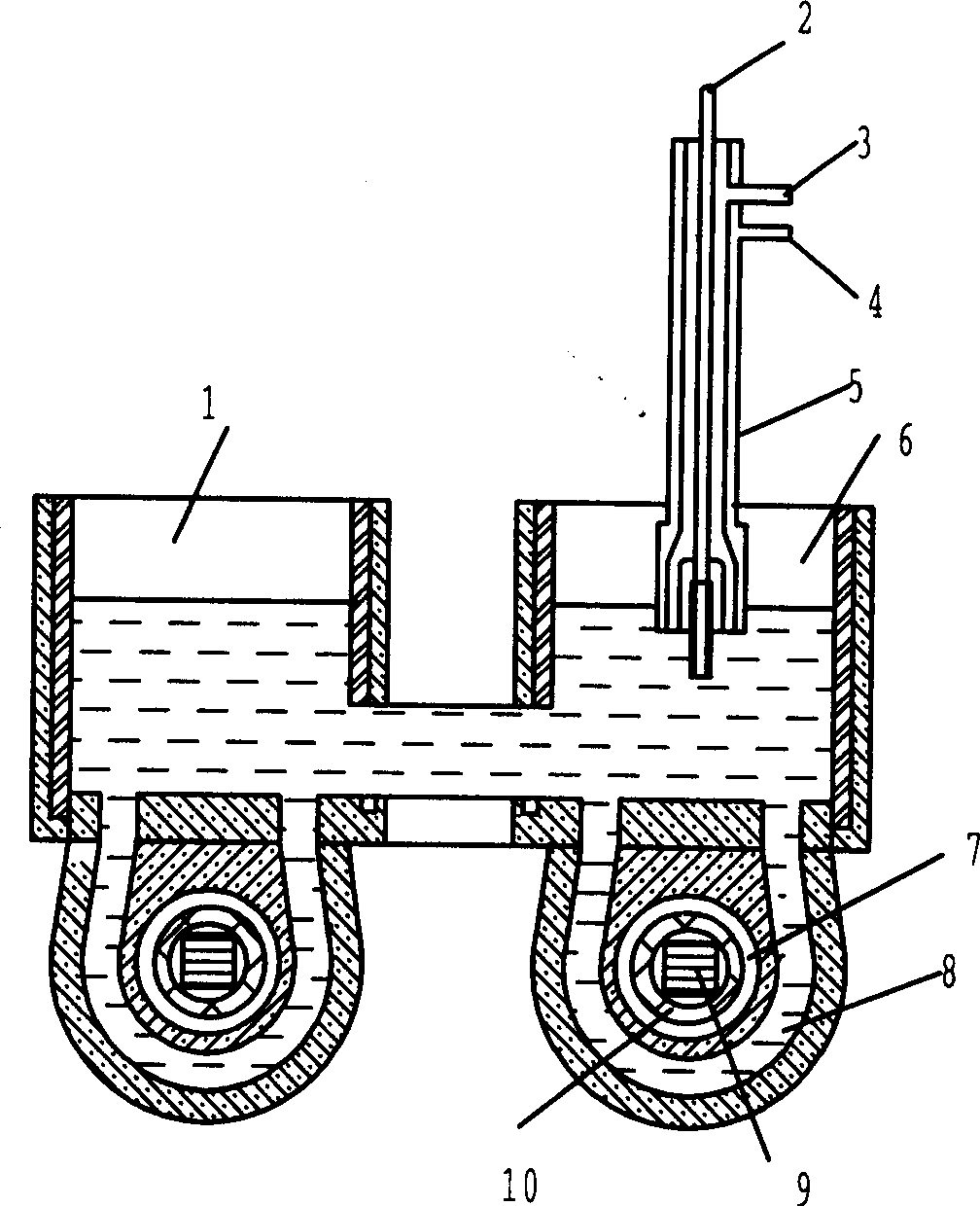

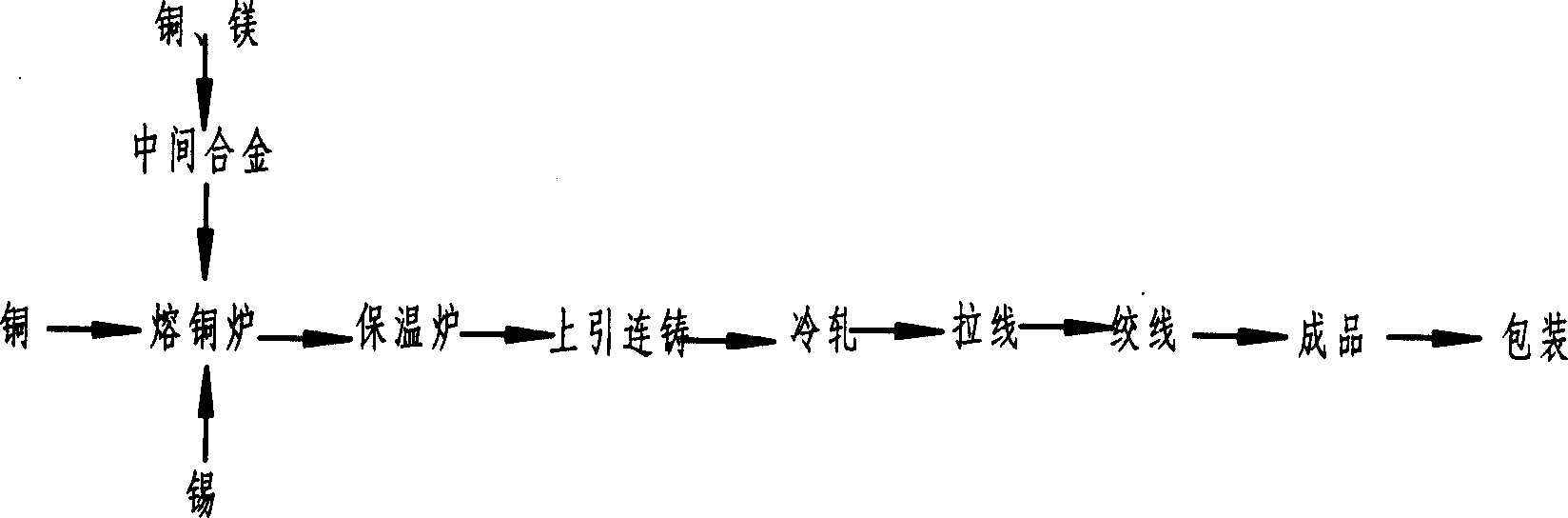

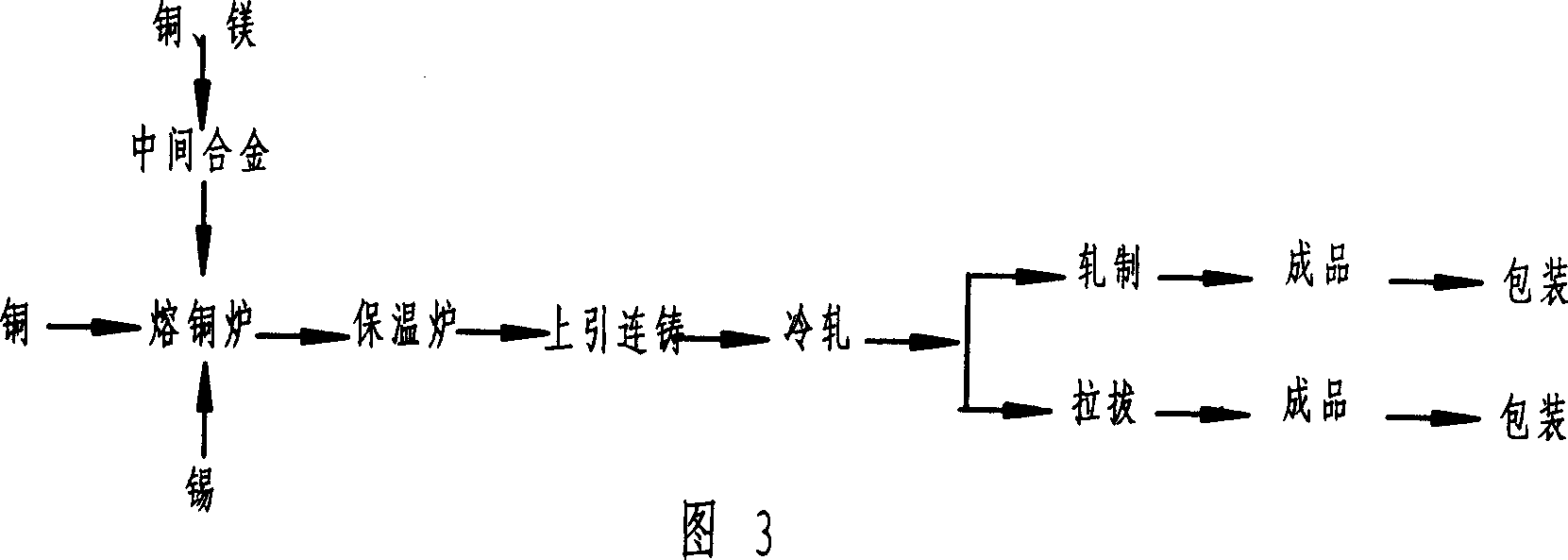

[0026] The existing manufacturing process of magnesium-copper alloy contact wires and conductors is to make rough copper alloy rods with a certain diameter through batching, melting, heat preservation, and upward continuous casting, and then processed into stranded wires or contact wires through drawing, cold rolling and other processes. Wire. Due to the corrosiveness and activity of magnesium, it will have a strong corrosion effect on the lining of the copper melting furnace and the holding furnace during the melting and heat preservation process. The furnace life is as short as 7 days and as long as one month. The frequent damage of the furnace lining not only increases the production cost, but also causes fluctuations in the process performance, so that the pass rate of the blank can only reach about 70%. In view of the above problems, the present invention changes the alloy formula and adds a small amount of magnesium and tin to the copper matrix to make a magnesium-tin-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com