A series-parallel integrated multi-effect evaporator

A multi-effect evaporator, integrated technology, applied in the direction of multi-effect evaporation, evaporator accessories, vertical tube evaporators, etc., can solve the problems of material incompatibility, difficult to guarantee life, surge, etc., to achieve reasonable structural design and utilization. The effect of maximizing sexuality and matching the balance of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

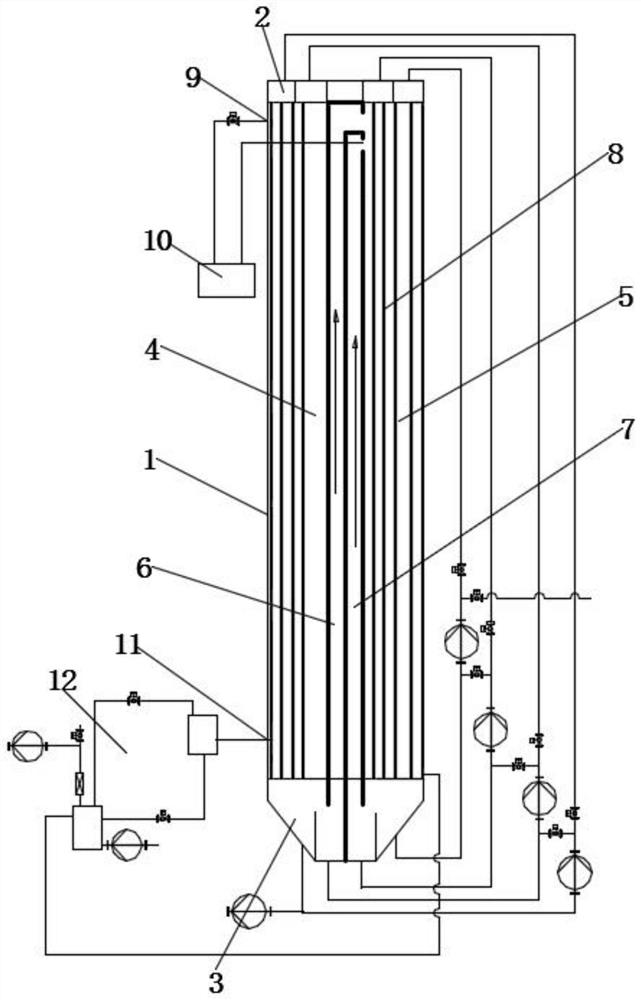

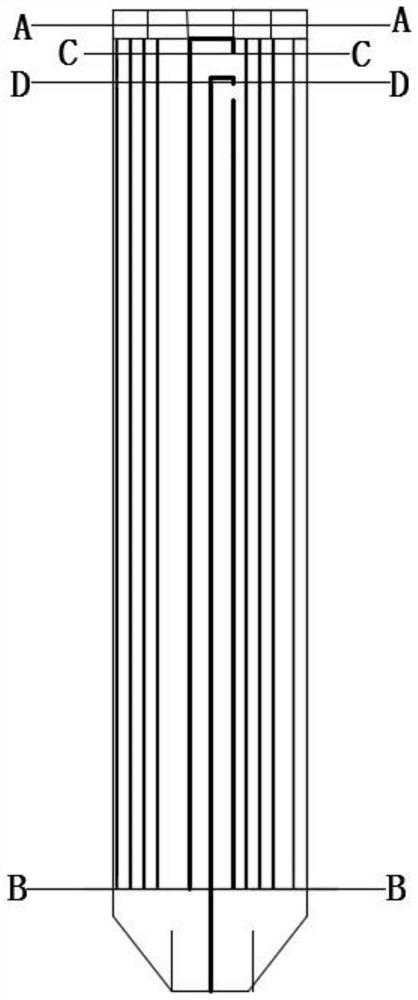

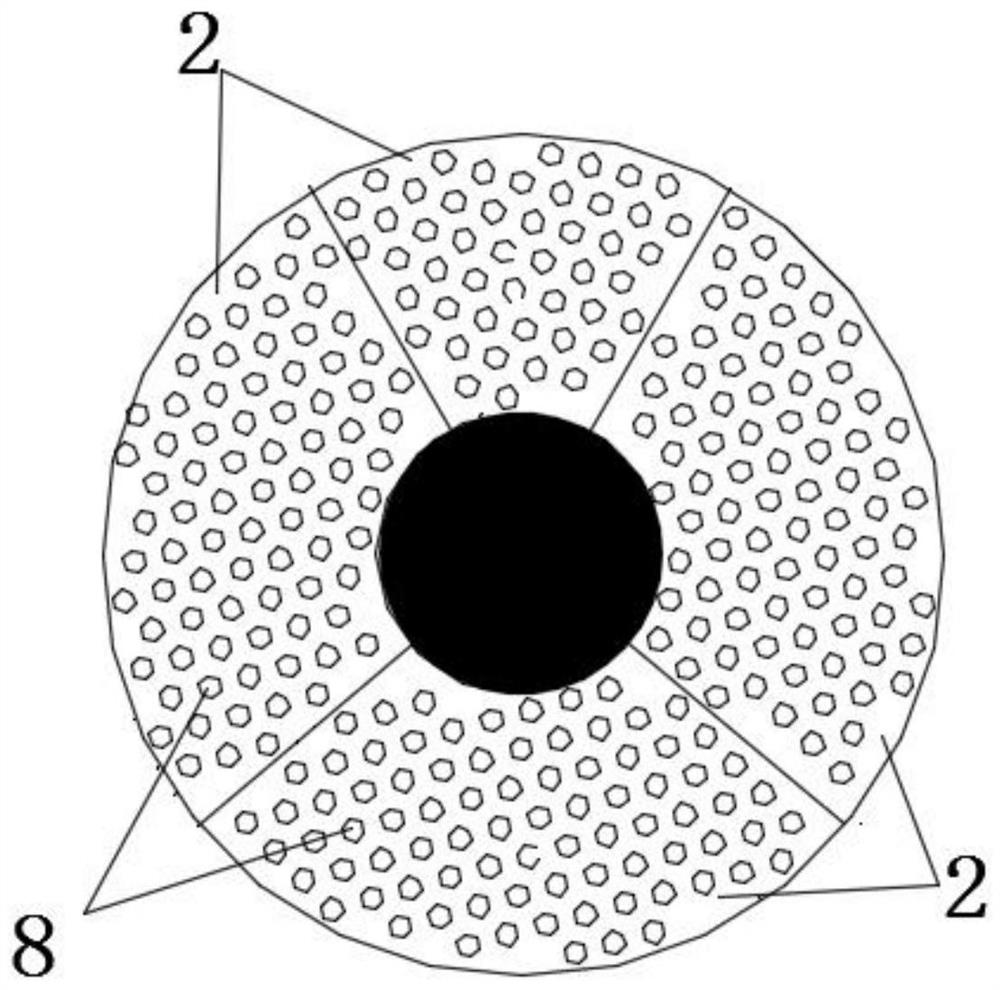

[0033] Such as Figure 1 to Figure 6 As shown, a series-parallel integrated multi-effect evaporator includes an evaporator body, and the evaporator body includes a shell 1, four feed chambers 2 arranged on the top of the shell, and four feed chambers 2 arranged at the bottom of the shell 1 and feed chambers 2 one-to-one correspondence of the four liquid accumulation cylinders 3 and the heater arranged in the shell 1;

[0034] The shell 1 is provided with two main heating chambers arranged along the length direction of the shell 1 and two main vapor-liquid separation chambers arranged along the length direction of the shell, and the two main heating chambers are respectively the first main heating chamber 4 and the second main heating chamber 5, the two main vapor-liquid separation chambers are respectively the first main vapor-liquid separation chamber 6 and the second main vapor-liquid separation chamber 7, and the first main vapor-liquid separation chamber 6 is arranged in ...

Embodiment 2

[0043] Such as Figure 7 to Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that the first main vapor-liquid separation chamber 6 is arranged outside the first main heating chamber 4, and the second main vapor-liquid separation chamber 7 is arranged outside the second main heating chamber. outside the chamber 5, and the first main heating chamber outside 4 and the second main heating chamber outside 5 are arranged on one side inside the shell 1, and the first main vapor-liquid separation chamber 6 and the second main vapor-liquid separation chamber 7 are arranged on On the other side inside the housing 1 , the four liquid collection chambers are arranged in groups of two below the first main vapor-liquid separation chamber 6 and the second main vapor-liquid separation chamber 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com