Gasoline selective hydrogenation desulfurization catalyst, and preparation method and application of catalyst

A hydrodesulfurization and selective technology, applied in refining to remove heteroatoms and other directions, can solve problems such as undisclosed S content, and achieve the effects of environmentally friendly process, high liquid yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

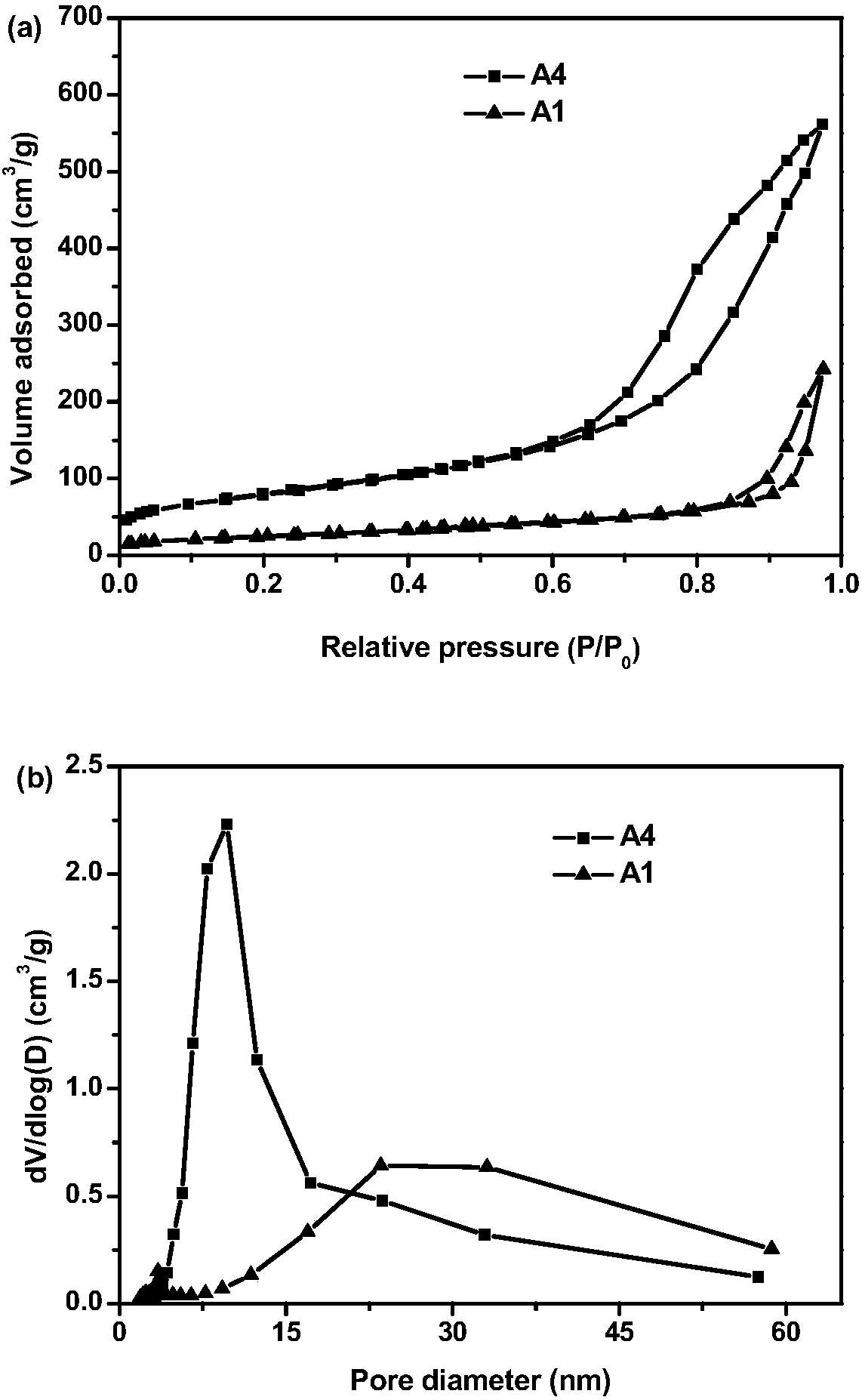

[0032] Calcining pseudo-boehmite at 550°C for 4 hours to obtain γ-Al 2 o 3 , and then weigh the resulting γ-Al 2 o 3 Disperse 4g of powder in 120ml of deionized water, stir and disperse evenly, then transfer to a 200ml hydrothermal kettle, hydrothermally treat at 180°C for 4h, after the completion of hydrothermal treatment, wash with deionized water, dry at 100°C, and heat again at 550°C Roasted for 4 hours to obtain hydrothermally treated γ-Al 2 o 3 Carrier A1, the specific surface area of A1 is 115m 2 / g, the pore volume is 0.42ml / g, and the pore size distribution is 10-60nm.

[0033] Molybdenum and cobalt were introduced on the carrier A1 by step-by-step impregnation. First, weigh 0.5016g of ammonium molybdate and dissolve it in 3.8ml of deionized water, impregnate 3g of carrier A1 with this solution, let it age for 20h, dry at 70°C overnight, and then bake at 500°C for 4h; after that, weigh 0.3604g of nitric acid Cobalt was dissolved in 3.8ml of deionized water, a...

Embodiment 2

[0035] Calcining pseudo-boehmite at 550°C for 4 hours to obtain γ-Al 2 o 3 , and then weigh the resulting γ-Al 2 o 3 Disperse 4g of powder in 120ml of deionized water, stir and disperse evenly, then transfer to a 200ml hydrothermal kettle, hydrothermally treat at 160°C for 4h, after the completion of hydrothermal treatment, wash with deionized water, dry at 100°C, and heat again at 550°C Roasted for 4 hours to obtain hydrothermally treated γ-Al 2 o 3 Carrier A2, the specific surface area of A2 is 126m 2 / g, the pore volume is 0.45ml / g, and the pore size distribution is 10-60nm.

[0036] Molybdenum and cobalt were introduced on carrier A2 by step-by-step impregnation. First, weigh 0.5016g of ammonium molybdate and dissolve it in 4.6ml of deionized water, impregnate 3g of carrier A2 with this solution, let it age for 20h, dry at 70°C overnight, and then bake at 500°C for 4h; after that, weigh 0.3604g of nitric acid Cobalt was dissolved in 4.6ml of deionized water, and t...

Embodiment 3

[0038] Calcining pseudo-boehmite at 550°C for 4 hours to obtain γ-Al 2 o 3 , and then weigh the resulting γ-Al 2 o 3 Disperse 4g of powder in 120ml of deionized water, stir and disperse evenly, then transfer to a 200ml hydrothermal kettle, hydrothermally treat at 180°C for 6h, after the completion of hydrothermal, wash with deionized water, dry at 100°C, and heat again at 550°C Roasted for 4 hours to obtain hydrothermally treated γ-Al 2 o 3 Carrier A3, the specific surface area of A3 is 90m 2 / g, the pore volume is 0.38ml / g, and the pore size distribution is 10-60nm.

[0039] Molybdenum and cobalt were introduced on carrier A3 by stepwise impregnation. First, weigh 0.5016g of ammonium molybdate and dissolve it in 3.2ml of deionized water, impregnate 3g of carrier A3 with this solution, let it age for 20h, dry it at 70°C overnight, and then bake it at 500°C for 4h; after that, weigh 0.3604g of nitric acid Cobalt was dissolved in 3.2ml of deionized water, and this solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com