Railway vehicle brake valve grinding machine

A technology for railway vehicles and brake valves, which is applied in the direction of grinding machine tools, grinding tools, grinding devices, etc., which can solve the problems of difficult to meet the requirements of production efficiency and grinding quality, unreasonable design, and imperfect technology, etc., and achieve compact structure and design. Reasonable, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

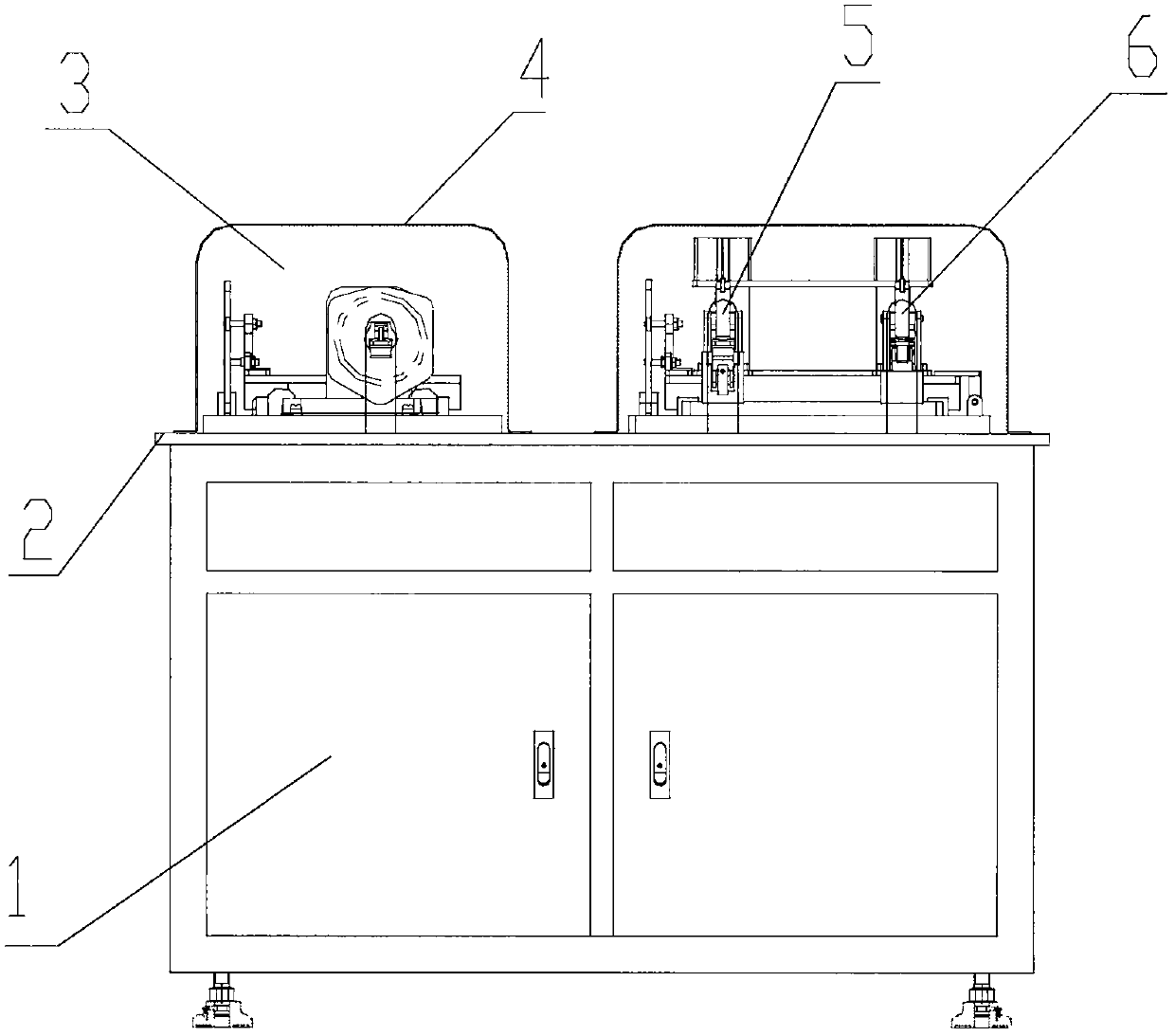

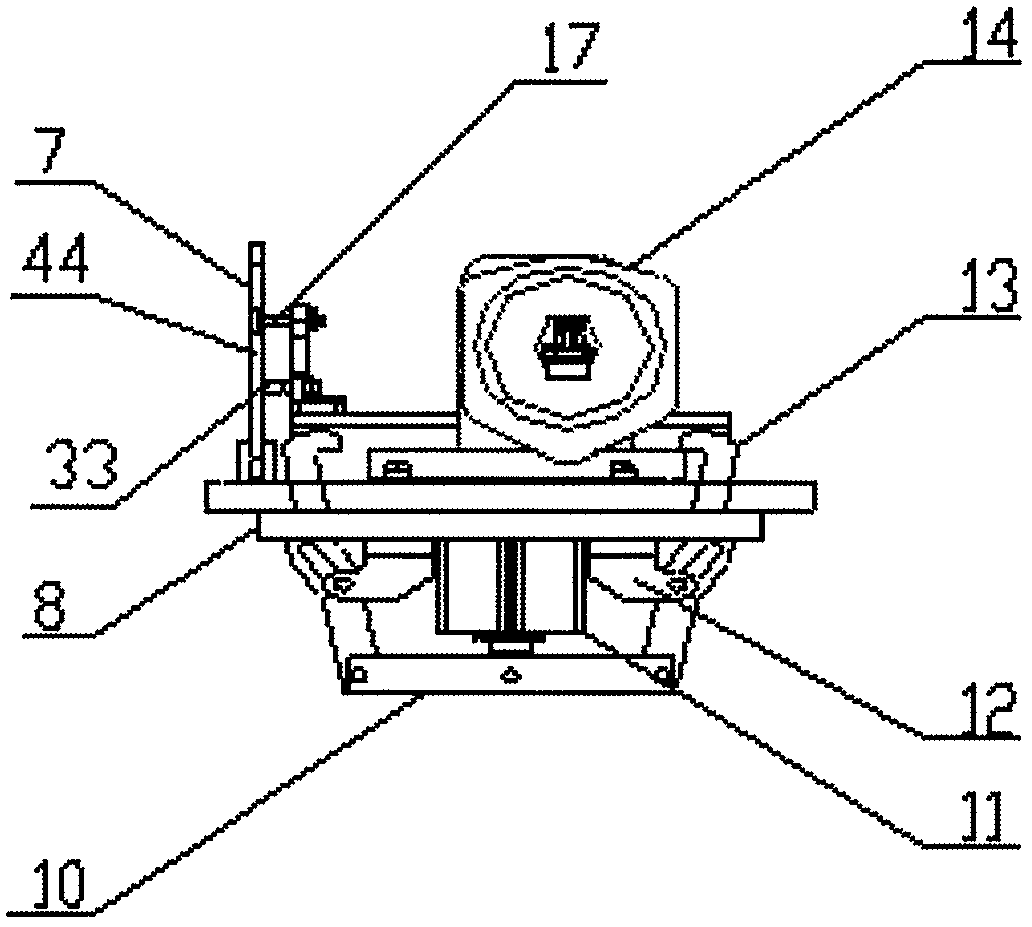

[0023] 1. Please refer to the attached figure 1 : The whole machine consists of the main body (1), the workbench (2), the valve body grinding station (3), the protective cover (4), the plane grinding station above the slide valve (5), and the plane grinding station below the slide valve ( 6) Composition, the structure of the three stations is basically the same, and each station is composed of a reciprocating mechanism (42), a pressing mechanism (43), and a power transmission mechanism (44), and each station has a The shield (4) protects, only the clamp tooling is different.

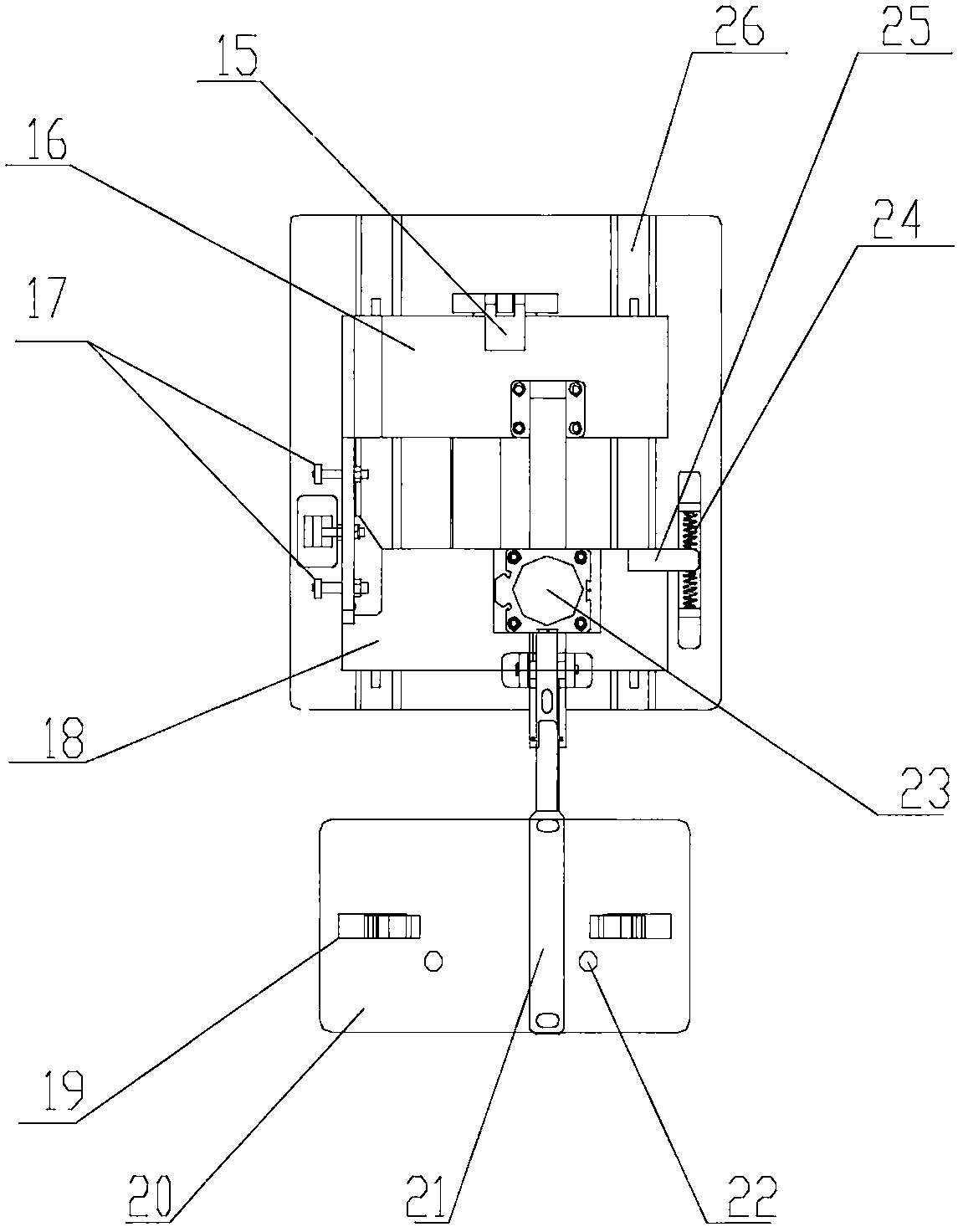

[0024] 2. Please refer to the attached image 3 : The reciprocating mechanism (42) consists of a linear guide (26) installed on the workbench (2), a connecting plate (15), a grinding cylinder (34), and a sliding plate 1 (1) installed on the linear guide (26). 16), the bent plate 2 (32) installed on the slide plate 1 (16), the pin (35) at the front end of the bent plate 2 (32), the adjustment spring (36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com