Deviation rectifier of paper folder gluer

The technology of a deviation correcting device and a folder gluer is applied to deviation correcting devices. It can solve the problems of inaccurate processing, loss, laborious manual adjustment, etc., and achieve the effects of good pressure consistency, extended service life, and stable deviation correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

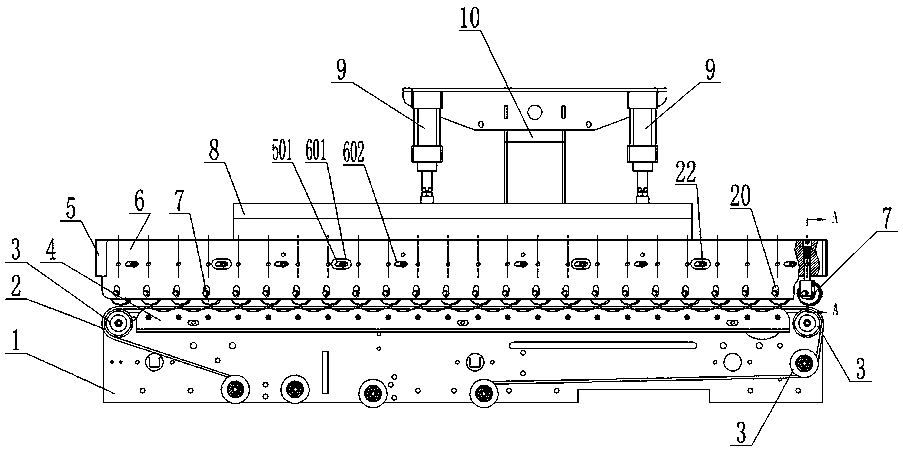

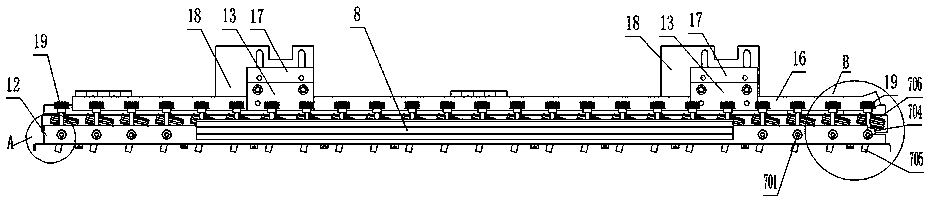

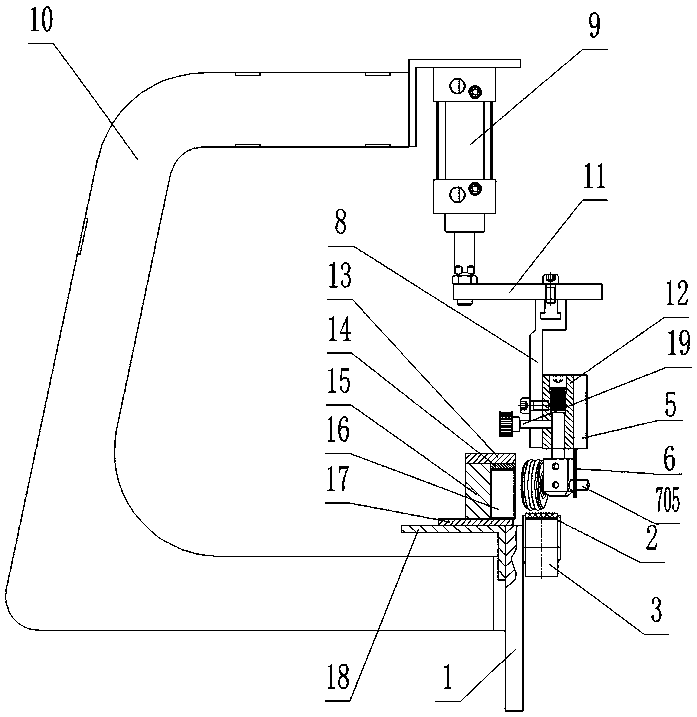

[0025] like Figure 1 to Figure 7 Shown: a rectifying device for a folder gluer, including a vertical plate 1, a conveyor belt guide wheel 3 is provided on the vertical plate 1, a conveyor belt 2 for conveying cardboard is wound around the conveyor belt guide wheel 3, and a The parallel bar 16 also includes a support seat 12 and a deviation correcting pressure wheel mechanism 7. The support seat 12 is horizontally arranged above the conveyor belt 2 and is parallel to the conveyor belt 2. The deviation correction connecting plate 8 is installed on the outer surface of the support seat 12, and the deviation correction connecting plate 8 passes through The connecting plate 11 is linked with the piston end of the lifting control cylinder 9. The lifting control cylinder 9 is installed on the support arm 10, and the support arm 10 is fixedly installed on the outer surface of the vertical plate 1. 1. The deviation correction pressure wheel 706, the lifting slide bar 703 is movably in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com