Patents

Literature

62results about How to "Steering stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

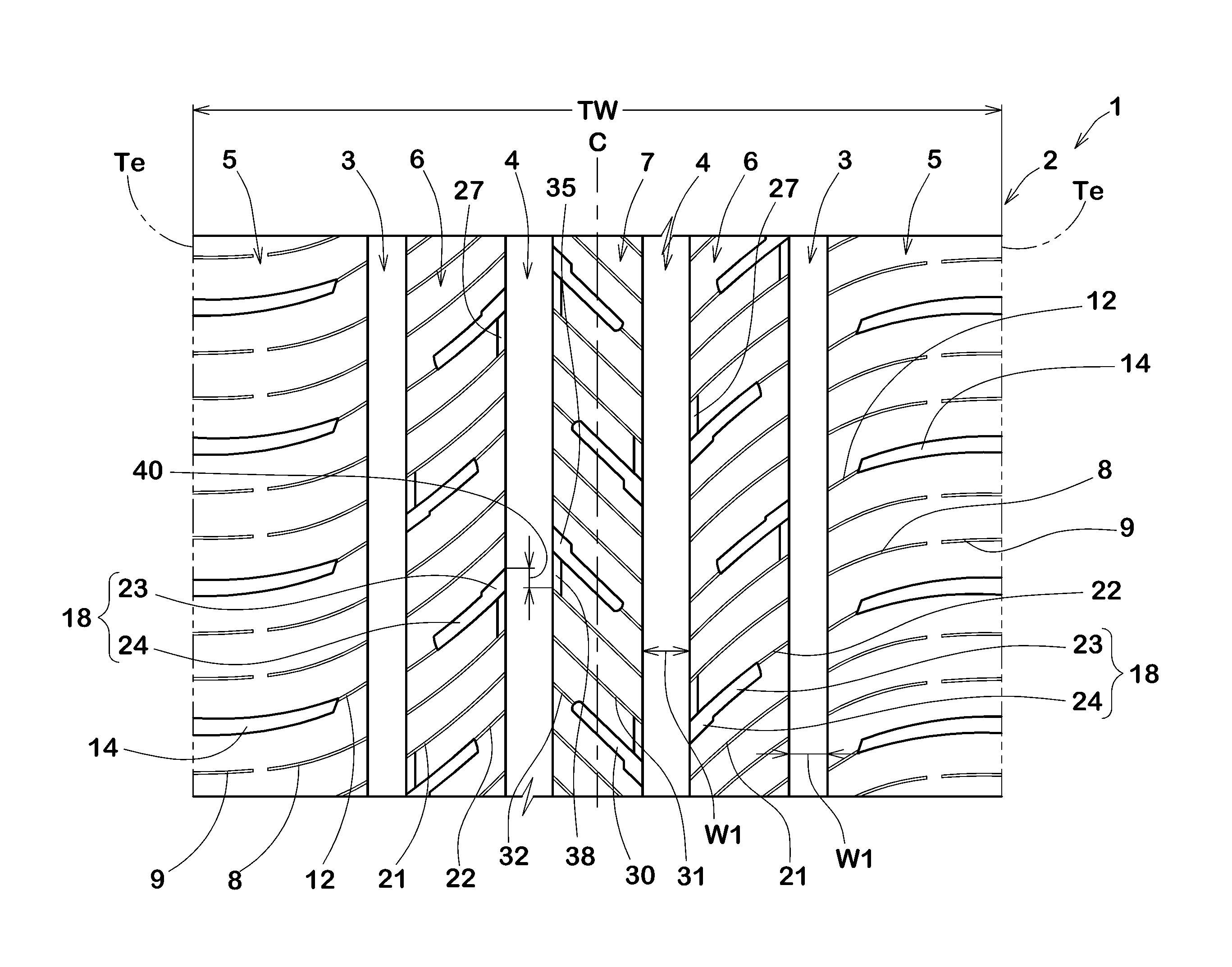

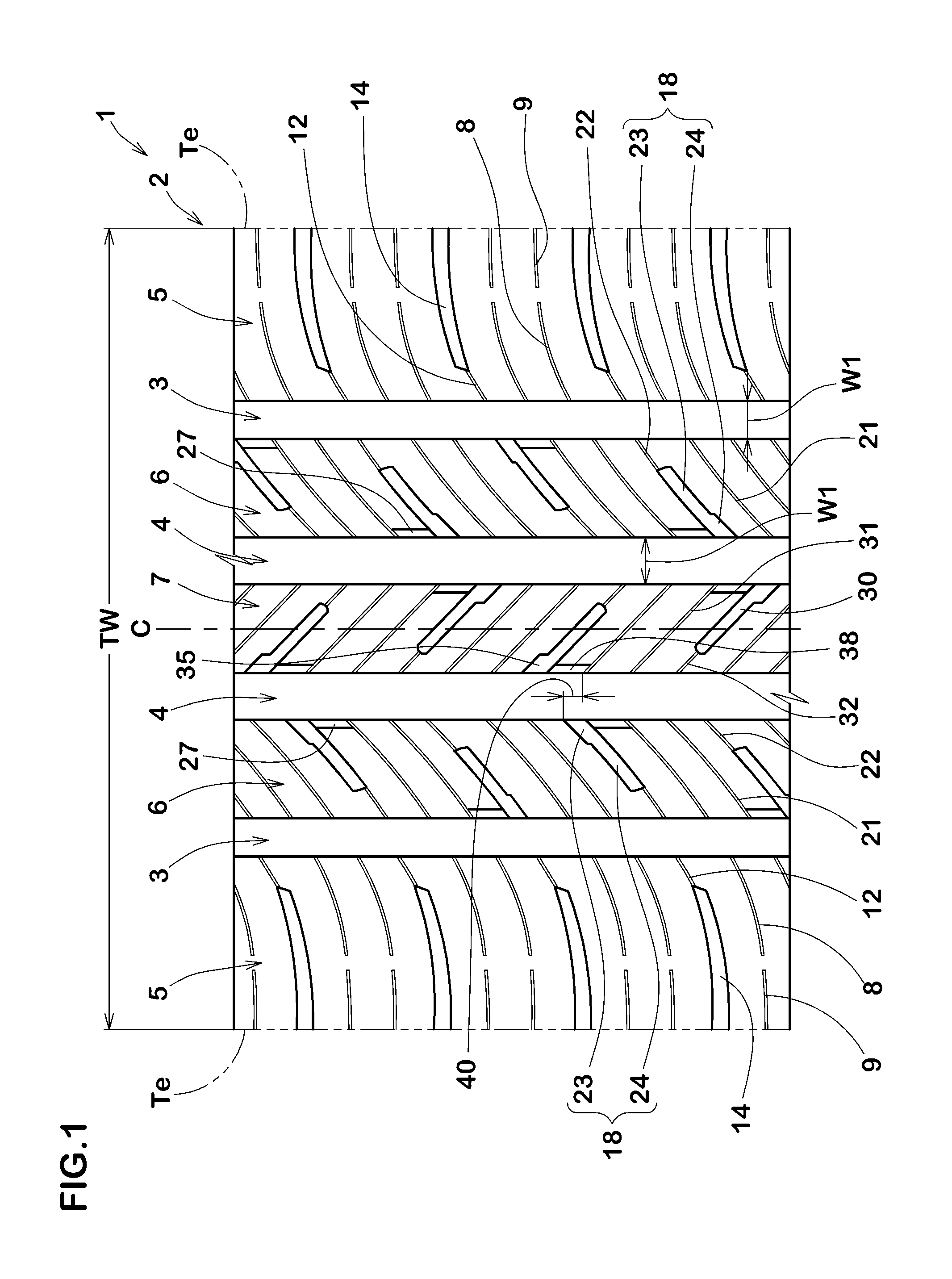

Pneumatic tire

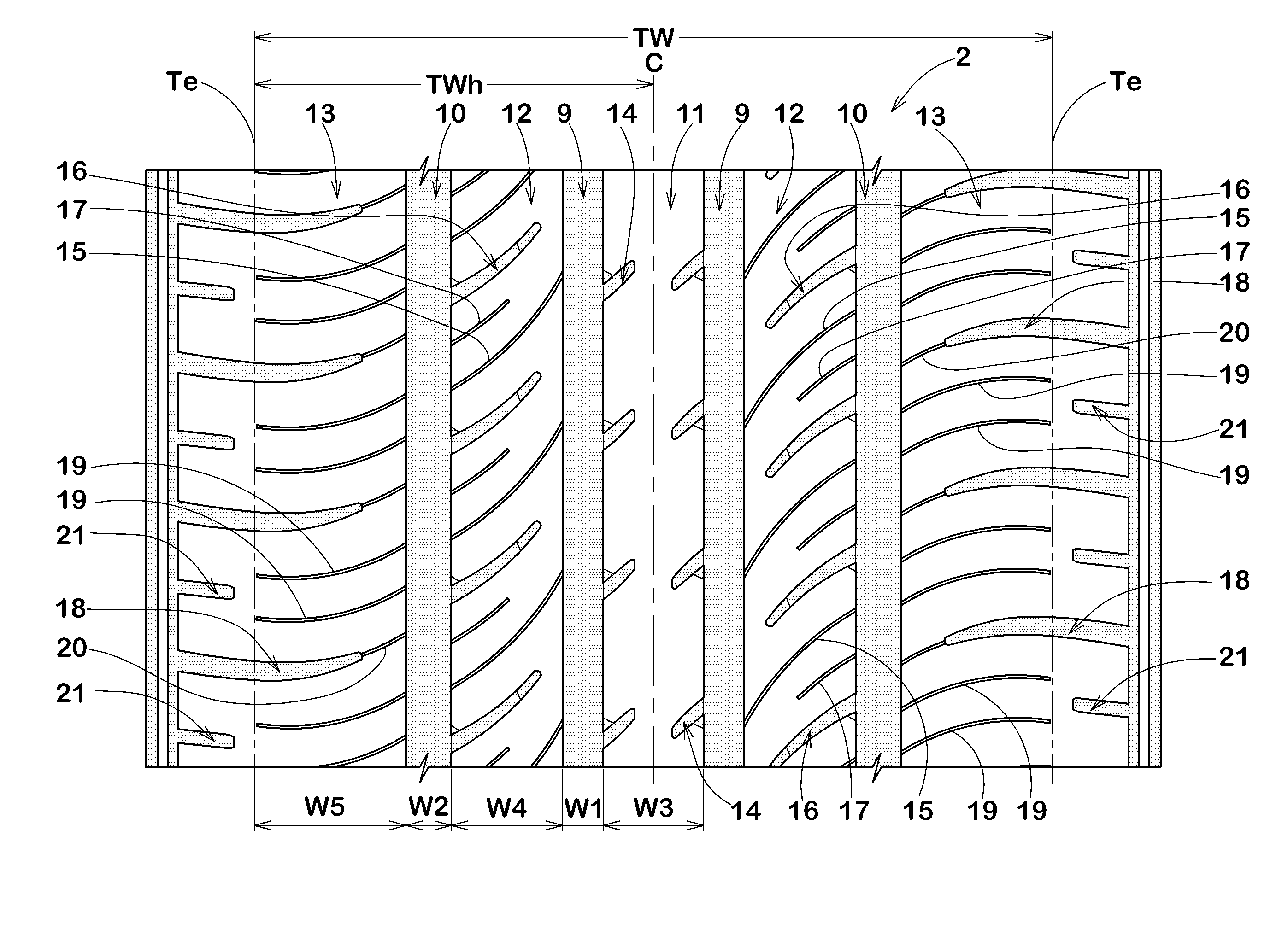

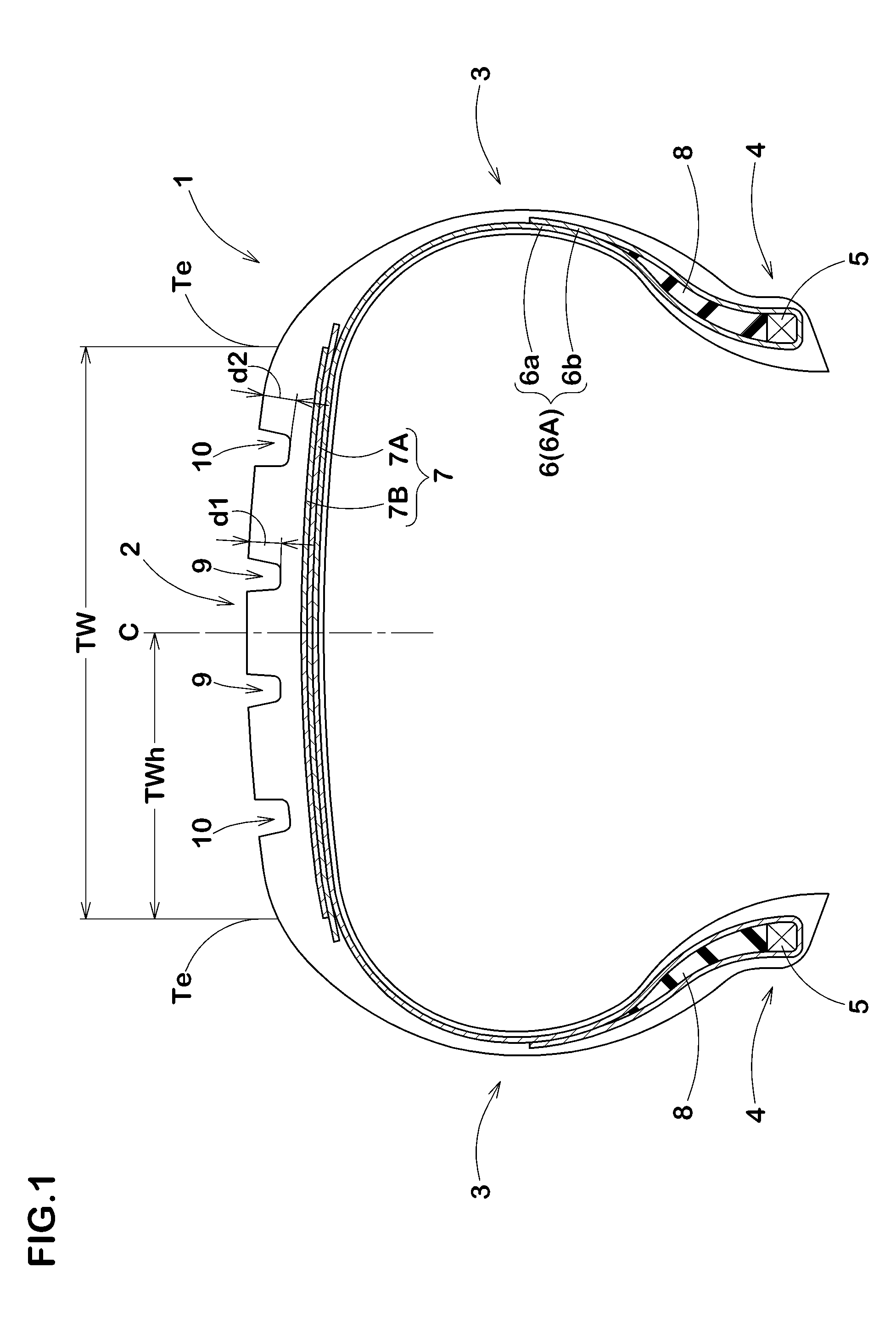

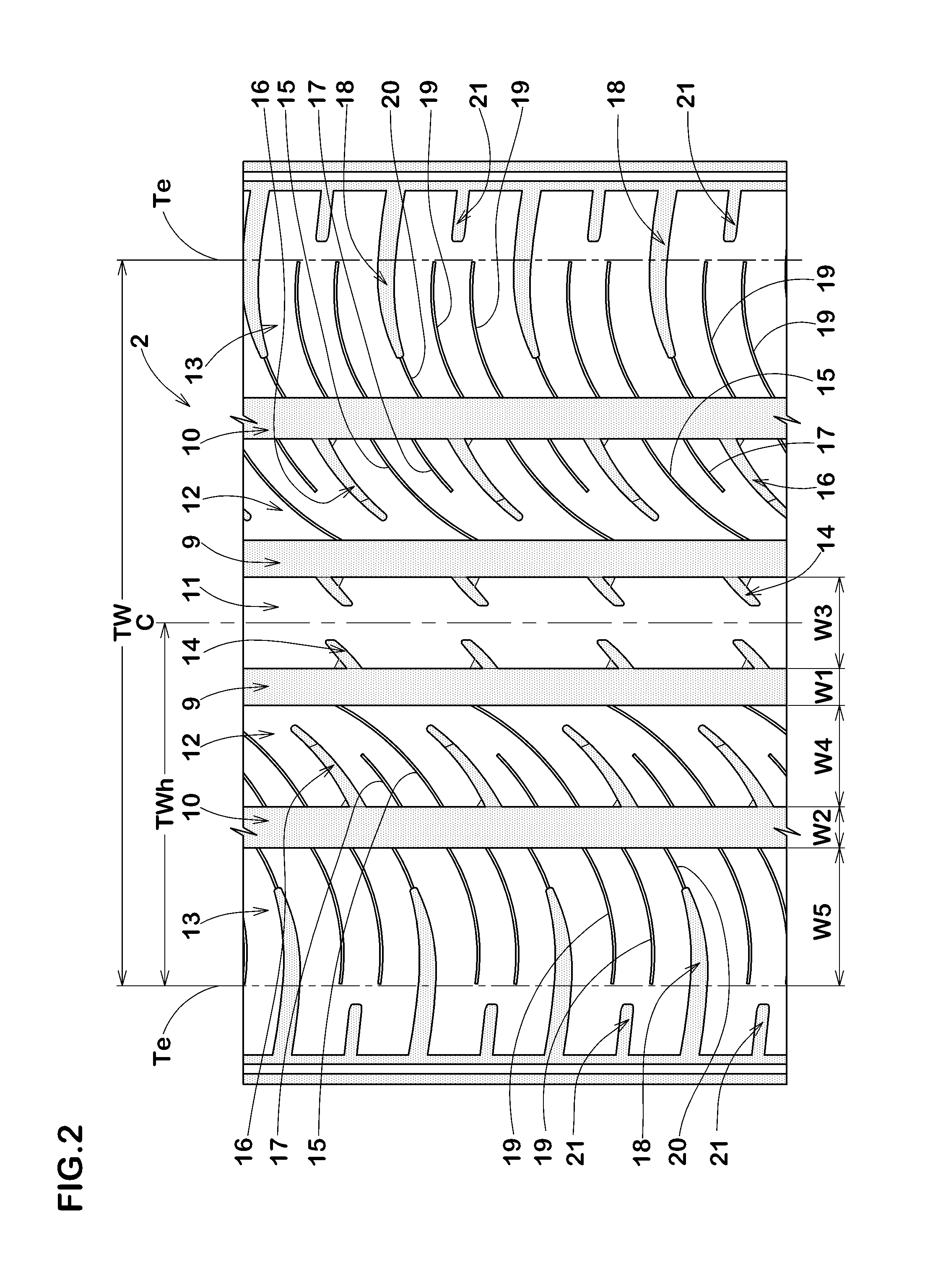

ActiveUS20160082780A1Improved in ice/snow performanceImprove steering stabilityTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

InactiveUS20050109437A1Improve wettabilitySteering stabilityTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

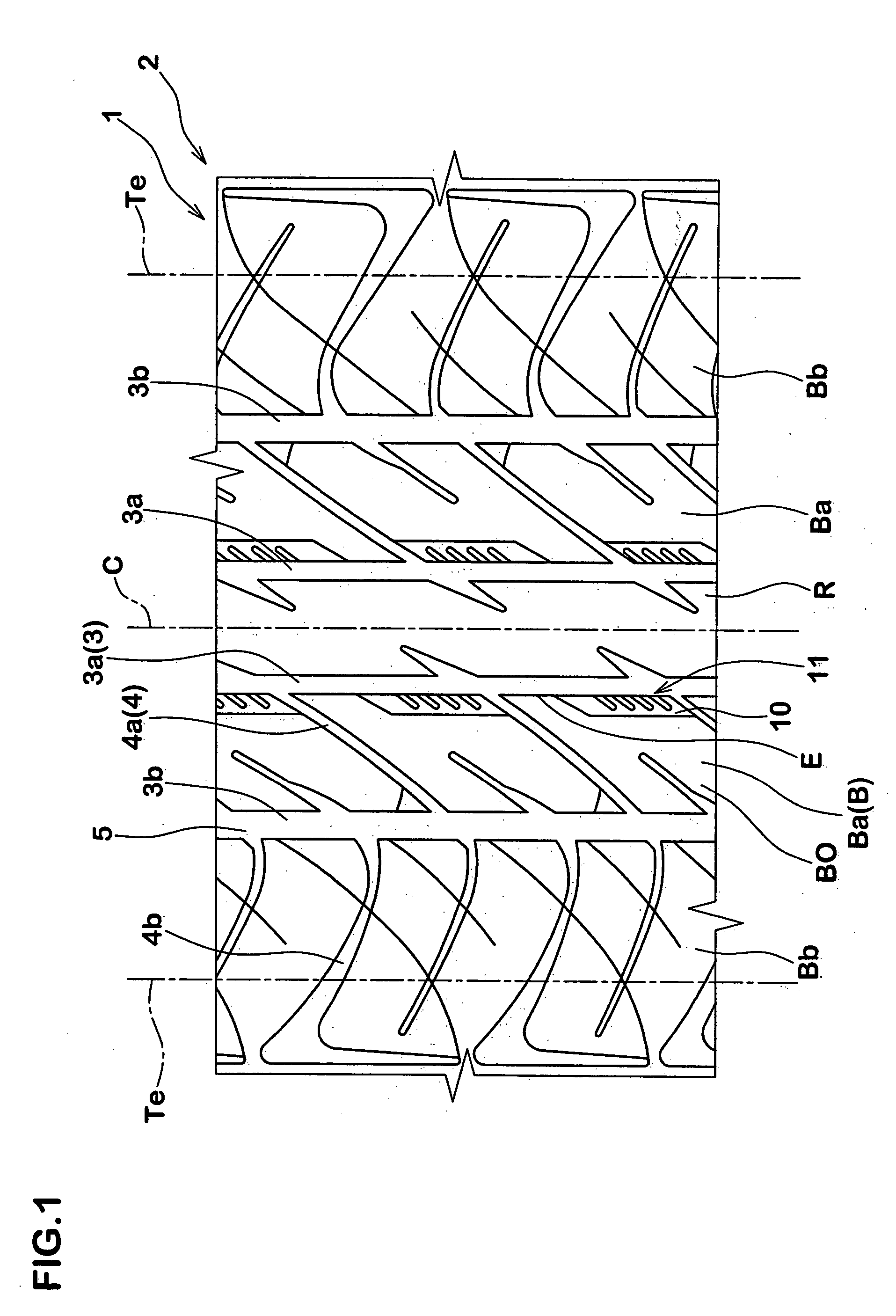

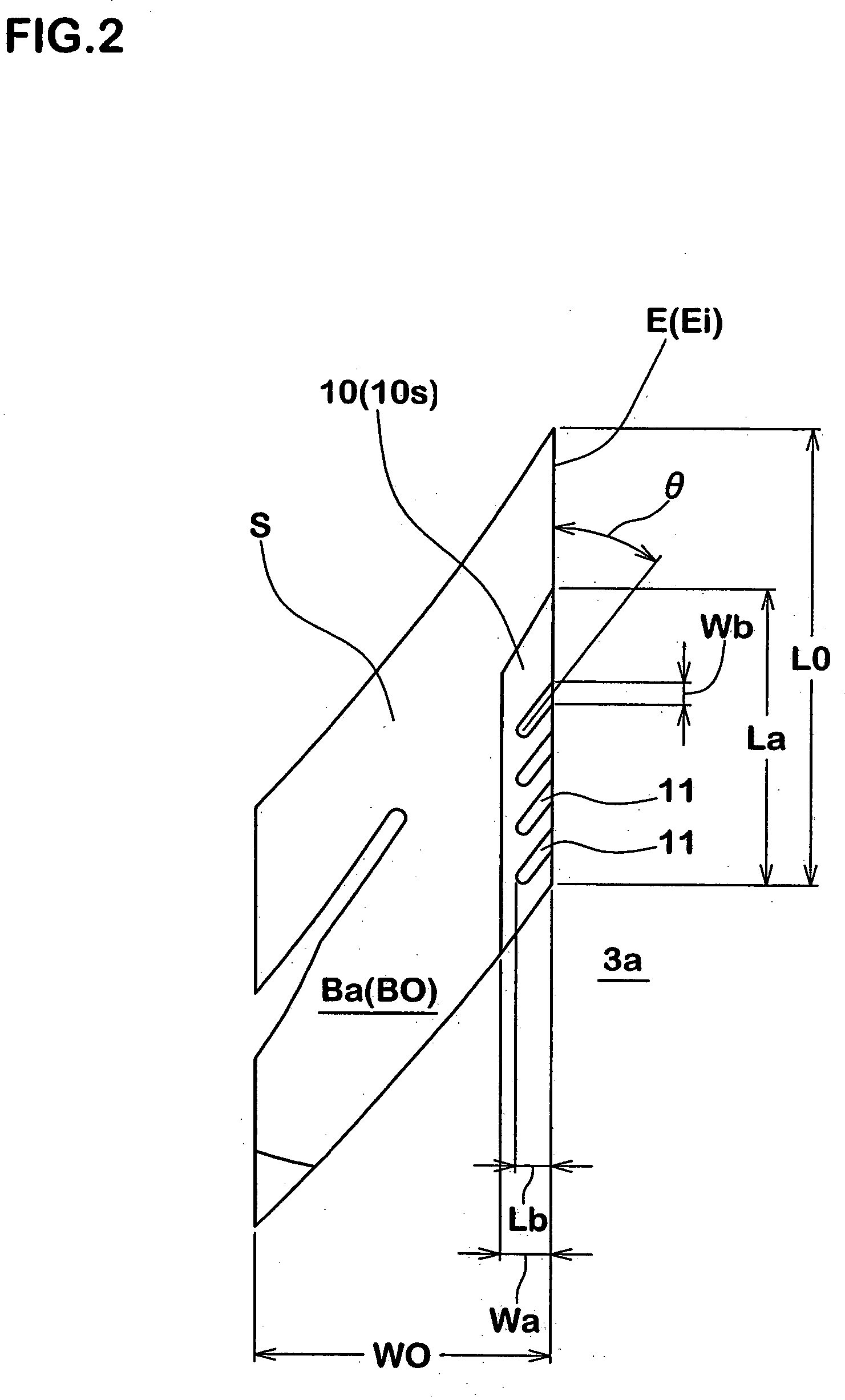

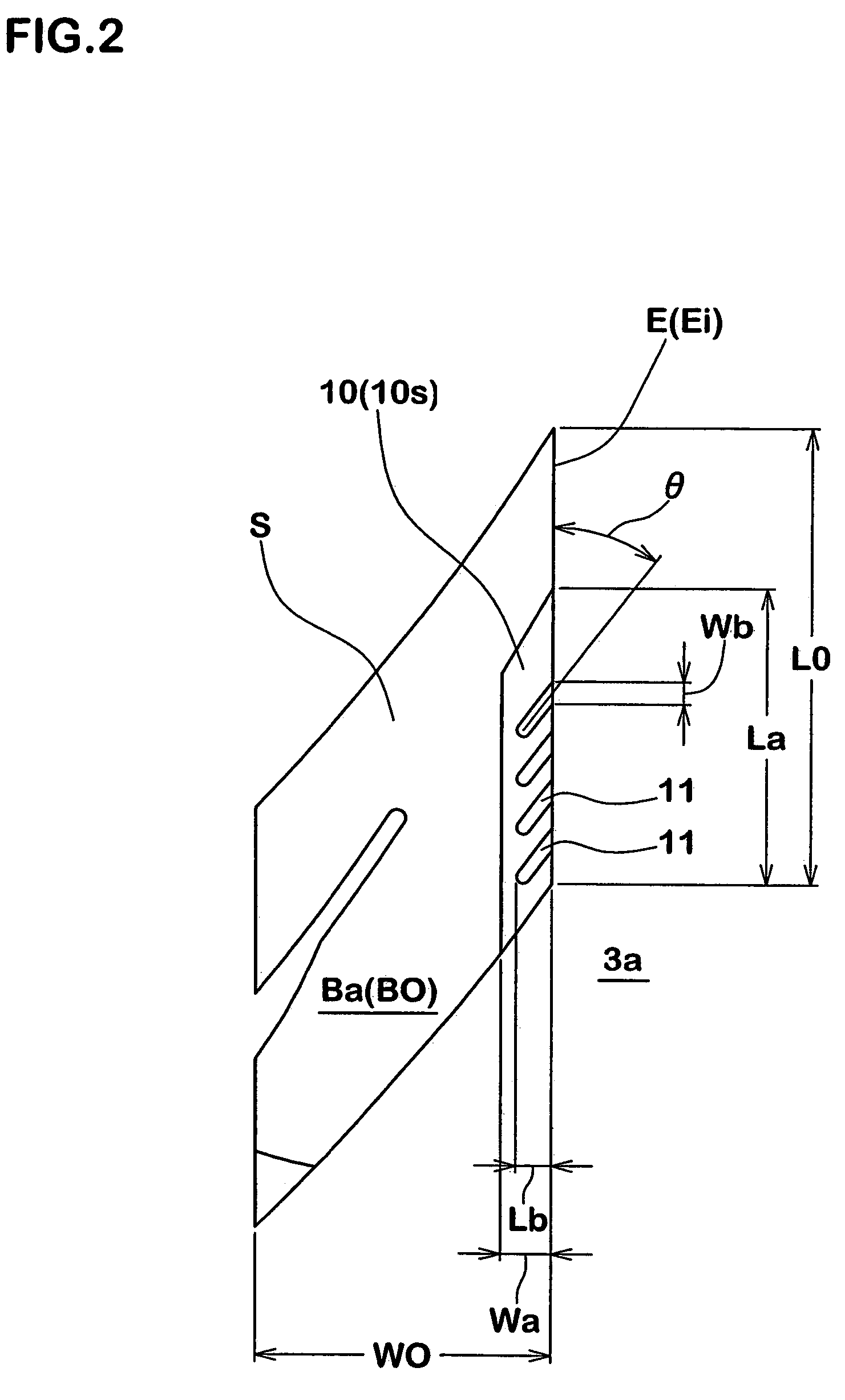

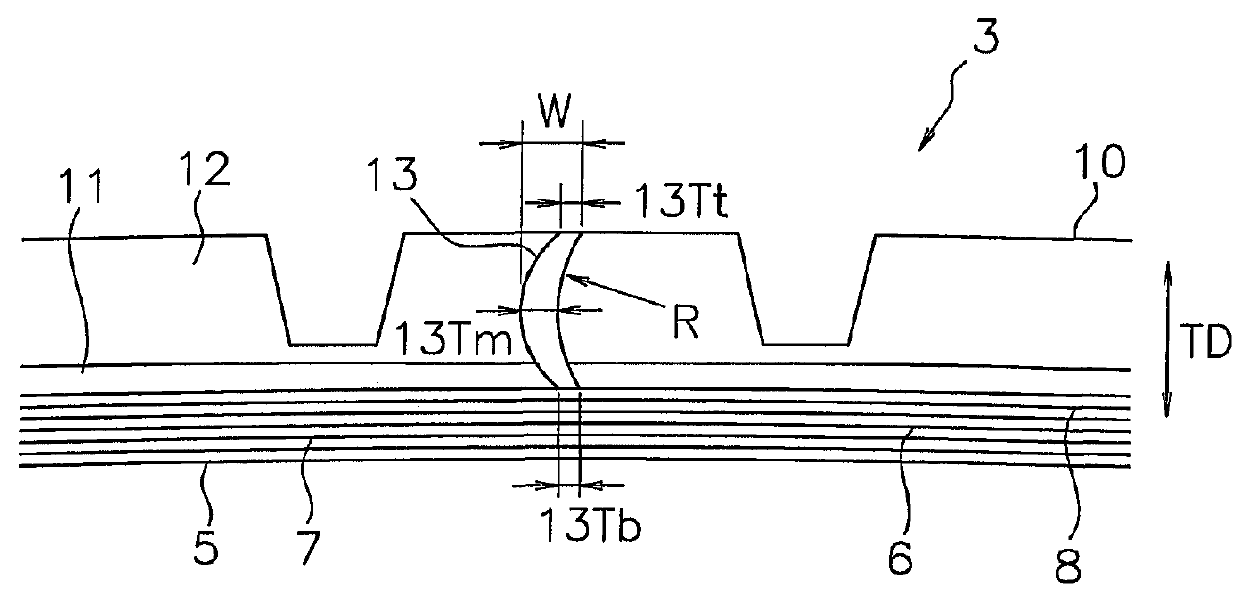

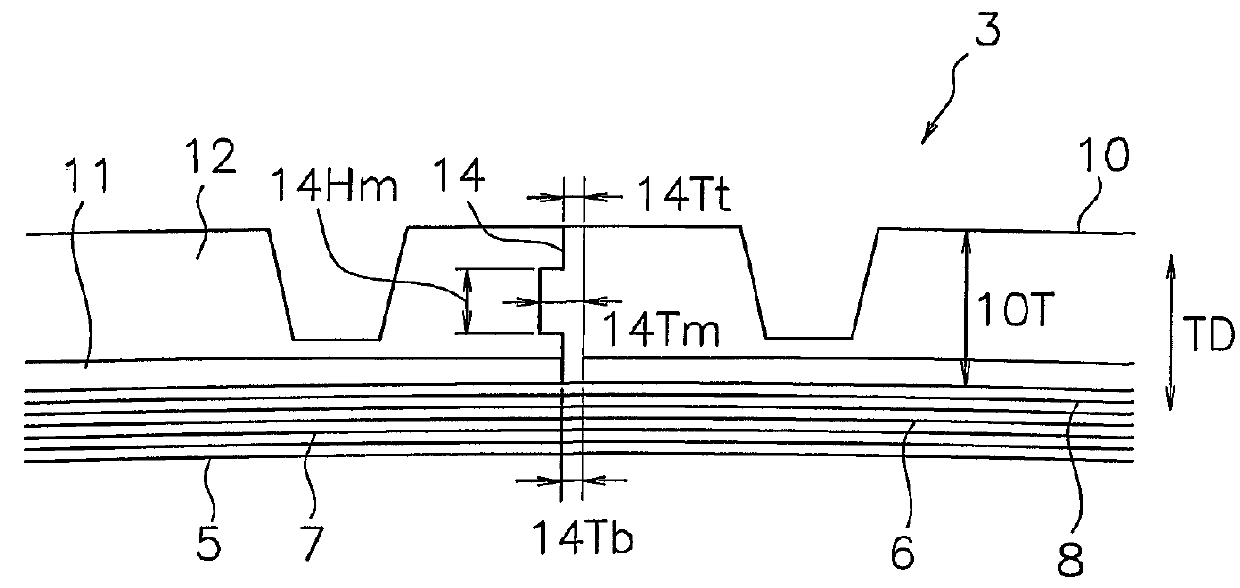

The present invention aims to improve the wet performance while securing steering stability and holding down degradations in noise performance to minimum, and for this purpose, a pneumatic tire in which blocks are disposed at intervals at a tread portion thereof is arranged in that concave blocks with stepped concave portions that extend along block side edges, which face circumferential main grooves, and having a depth from a block top surface that corresponds to 20 to 70% of a block height are provided. The concave portions have a length in a tire circumferential direction of 40 to 95% of a length of the block side edges in the tire circumferential direction and a width in a tire axial direction of 2 to 20 mm.

Owner:SUMITOMO RUBBER IND LTD

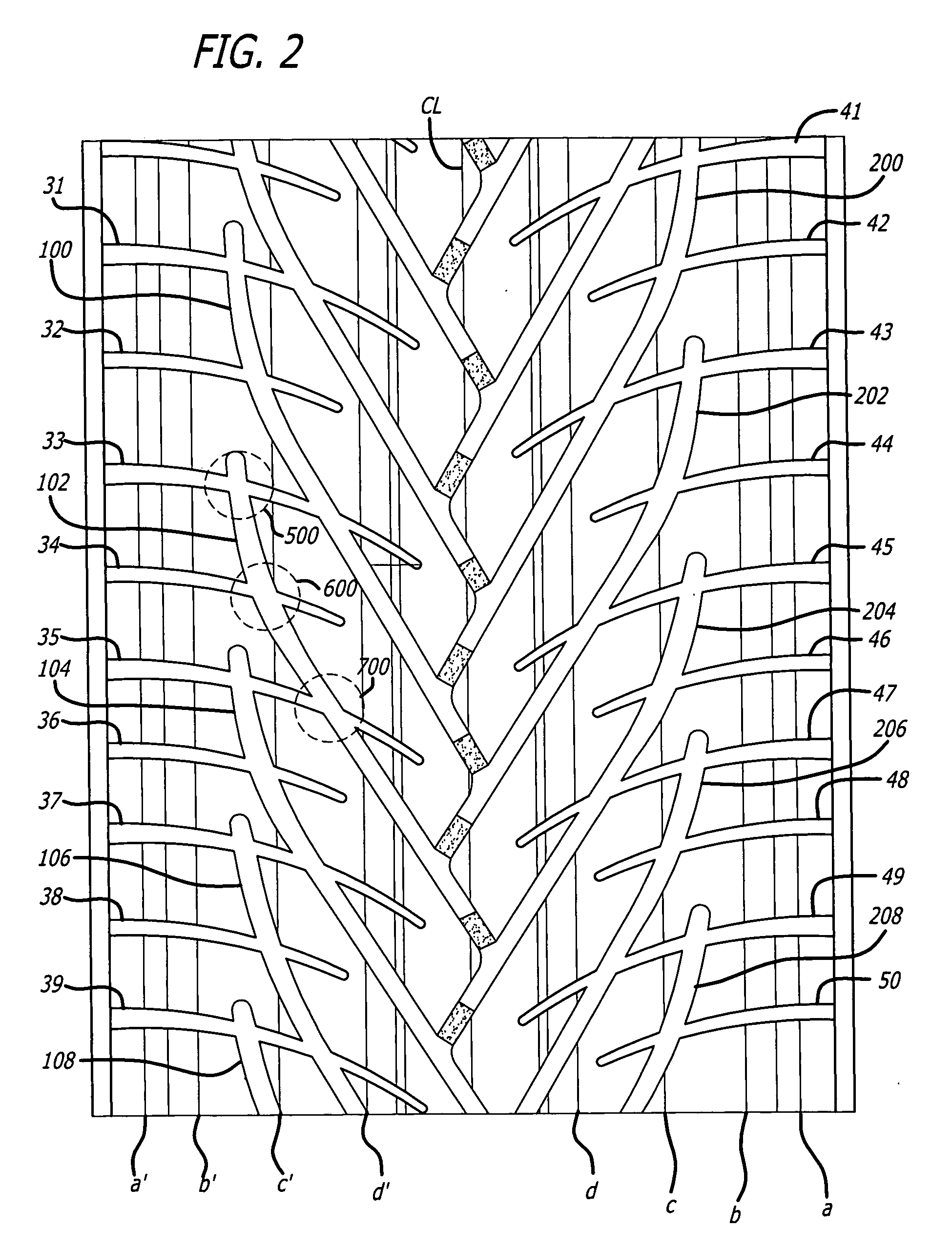

Pneumatic tire tread

InactiveUS20060185776A1Improve performanceSteering stabilityTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

Owner:SOUTH CHINA TIRE & RUBBER

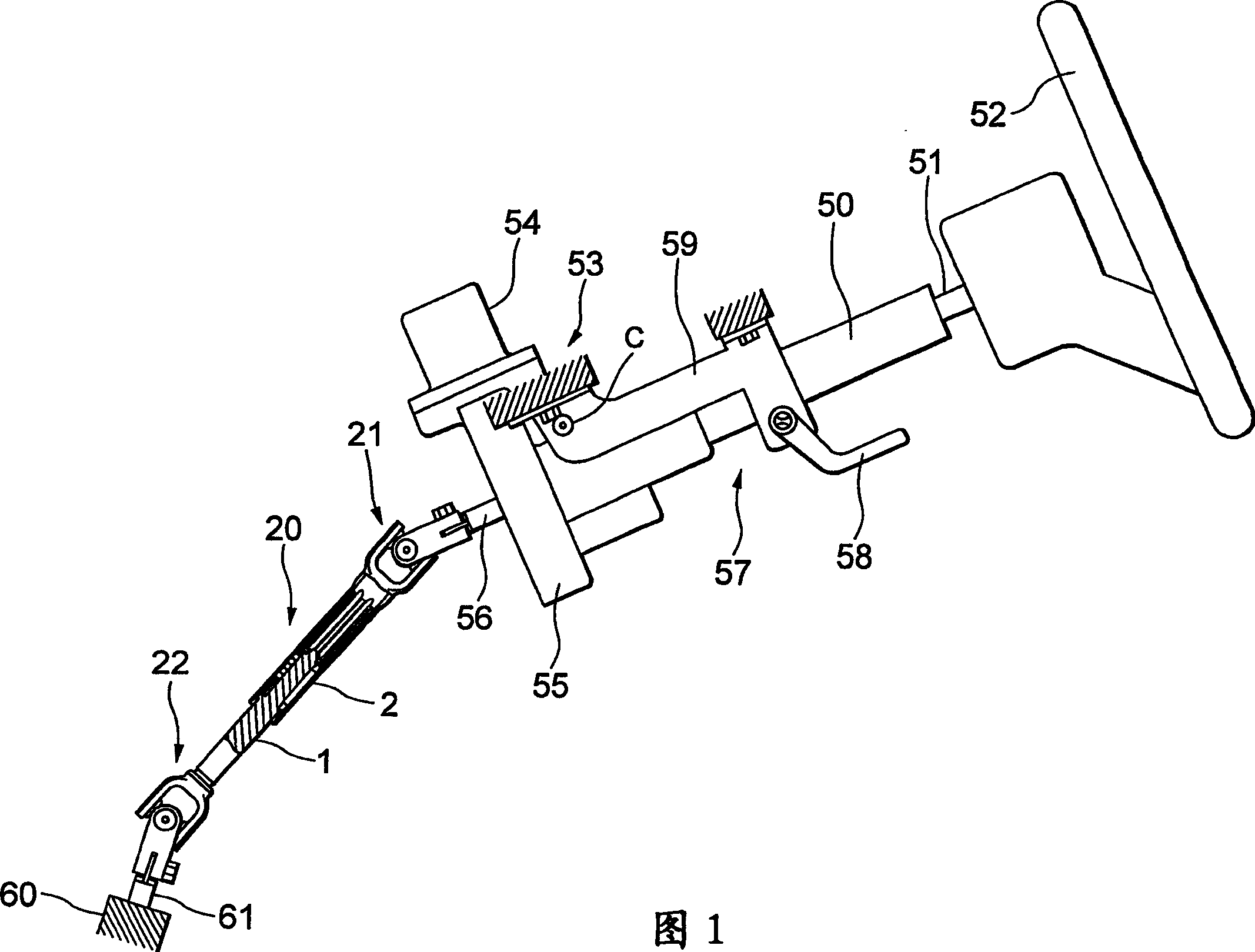

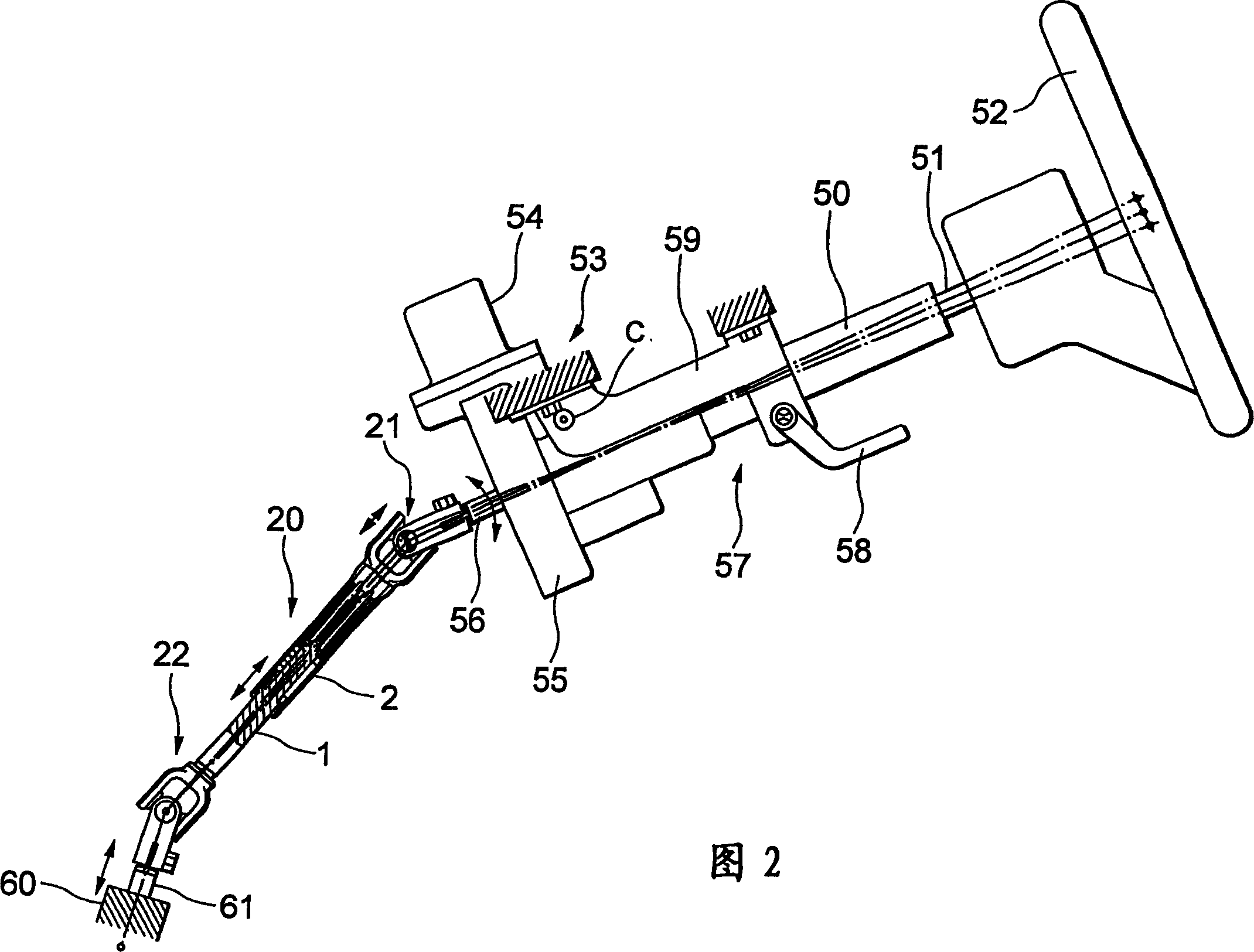

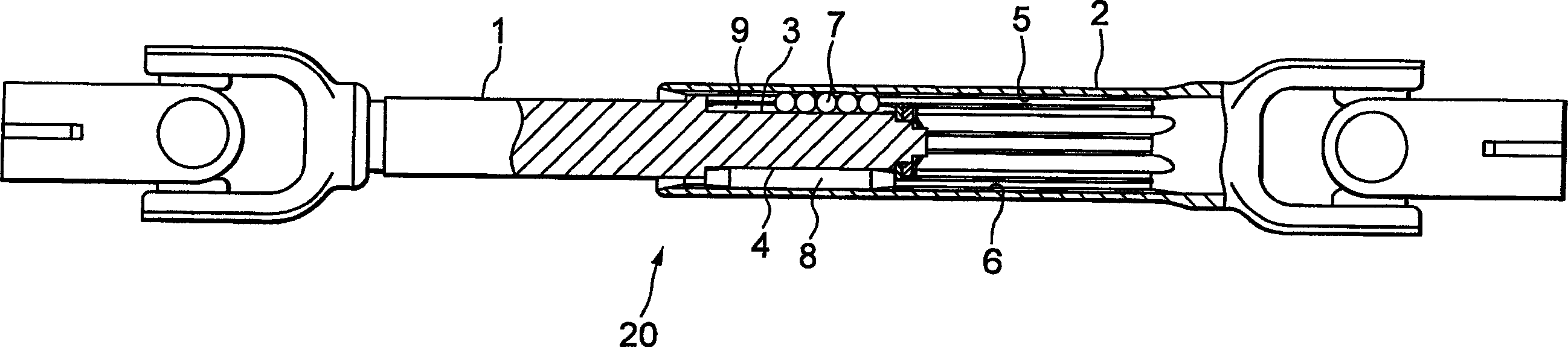

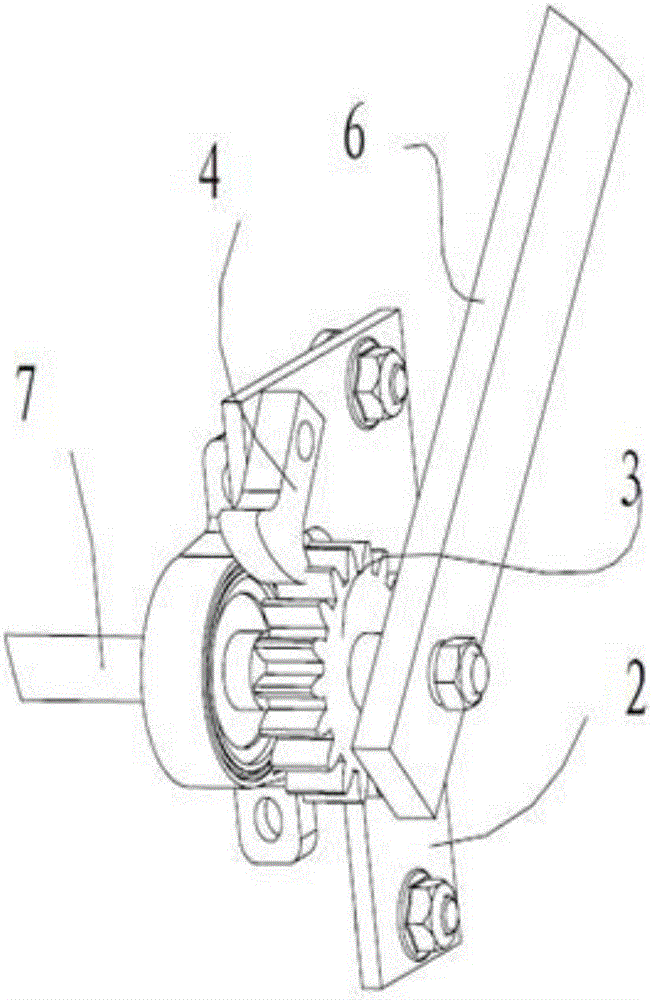

Steering device for motor vehicle

InactiveCN1745013AOptimize locationSteering stabilityClutchesYielding couplingElectric power steeringControl theory

There is disclosed a steering apparatus for a vehicle in which a steering power of a steering shaft is assisted by a column-assist type electric power steering apparatus so that the steering power is transmitted to steer the wheels by means of a steering mechanism, in which a telescopic shaft with a male shaft and a female shaft fitted to each other to be mutually unrotatable and slidable is interposed between an output shaft of said column-assist type electric power steering apparatus and an input shaft of the steering mechanism.

Owner:NSK LTD +1

Pneumatic tire

ActiveUS20140305563A1Reduce the numberImprove wear resistanceTyre tread bands/patternsNon-skid devicesMechanical engineering

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveUS20160039249A1Improve steering stabilitySubstantial rigidityTyre tread bands/patternsNon-skid devicesAutomotive engineering

Owner:TOYO TIRE & RUBBER CO LTD

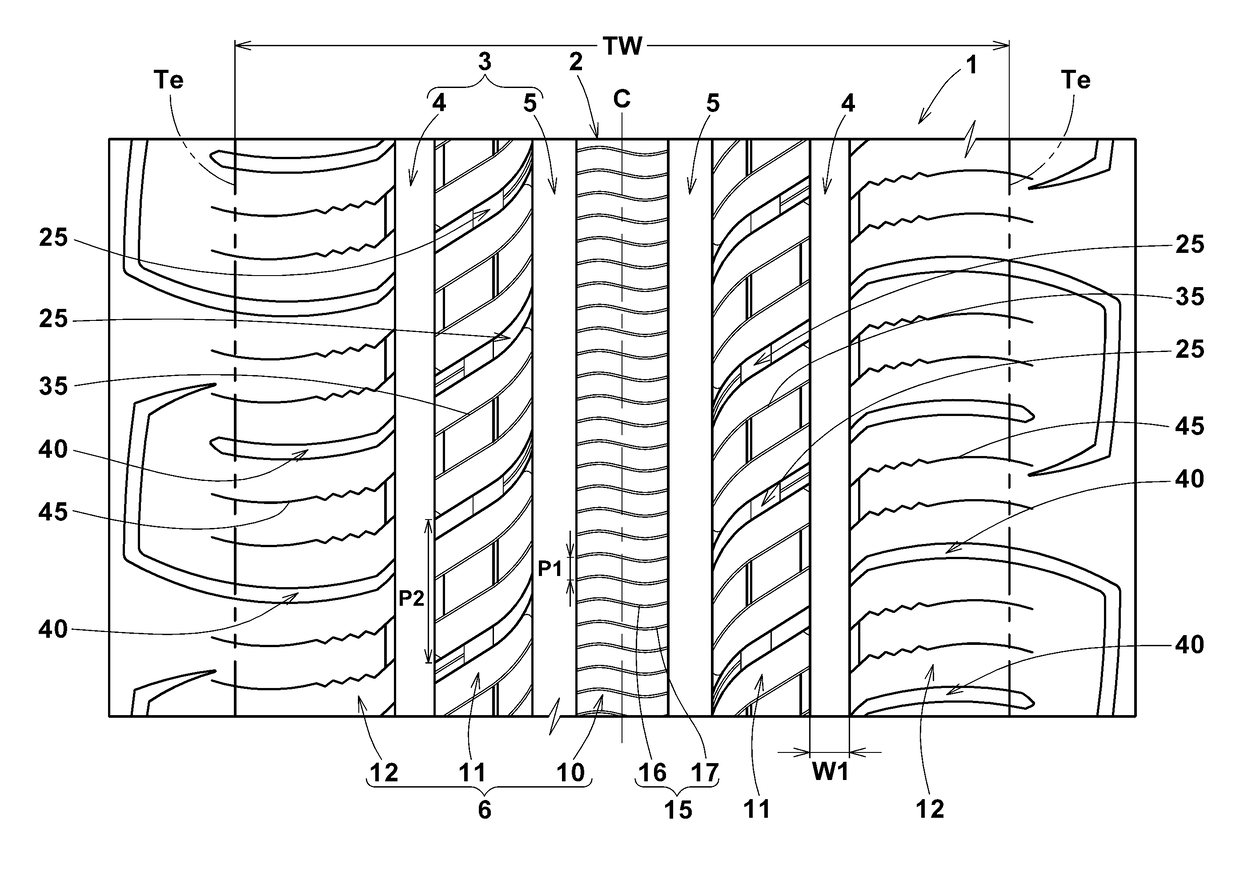

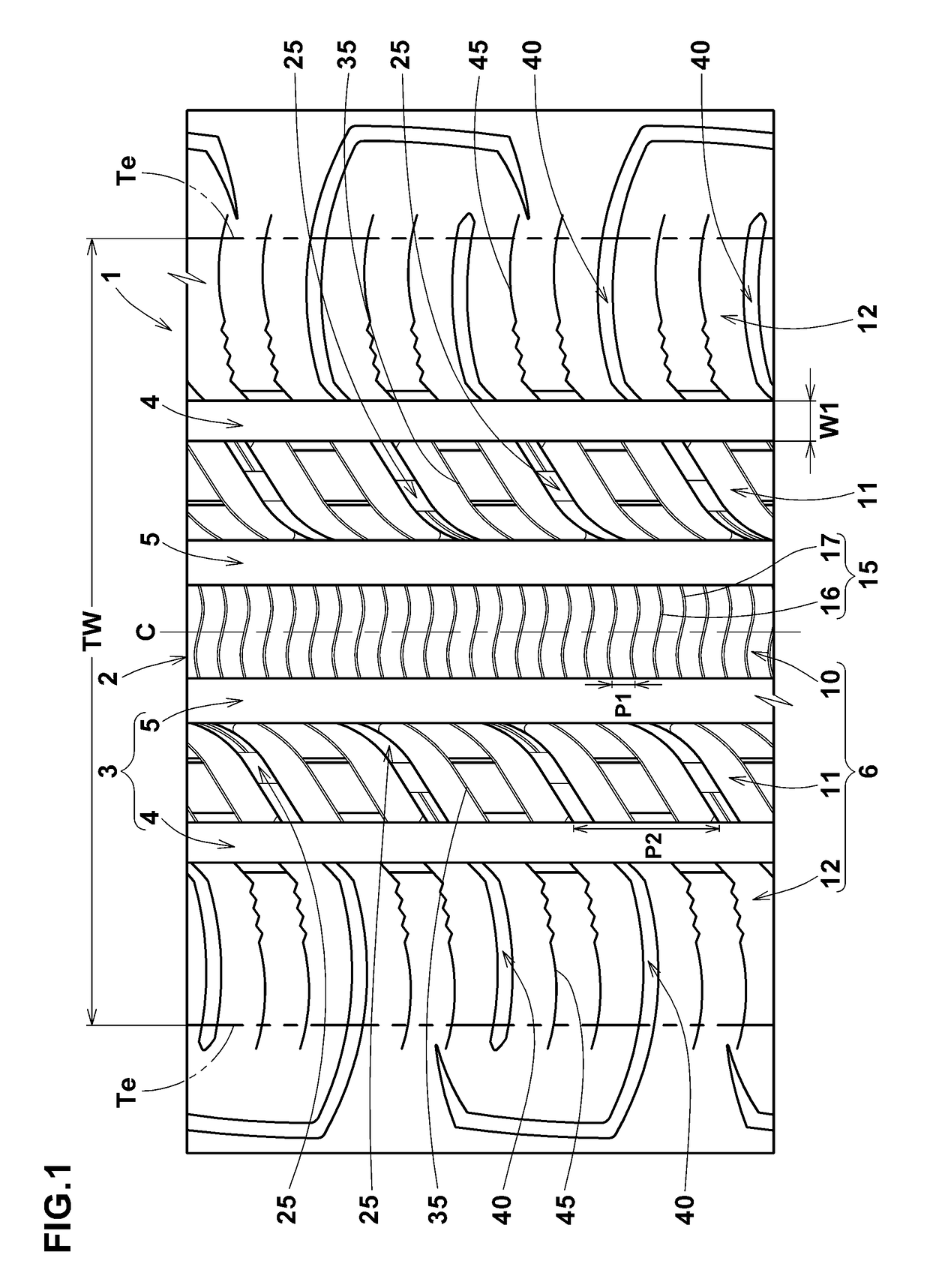

Pneumatic tire with tread having blocks

InactiveUS7438101B2Improve wettabilitySteering stabilityTyre tread bands/patternsNon-skid devicesMechanical engineeringTread

The present invention aims to improve the wet performance while securing steering stability and holding down degradations in noise performance to minimum, and for this purpose, a pneumatic tire in which blocks are disposed at intervals at a tread portion thereof is arranged in that concave blocks with stepped concave portions that extend along block side edges, which face circumferential main grooves, and having a depth from a block top surface that corresponds to 20 to 70% of a block height are provided. The concave portions have a length in a tire circumferential direction of 40 to 95% of a length of the block side edges in the tire circumferential direction and a width in a tire axial direction of 2 to 20 mm.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

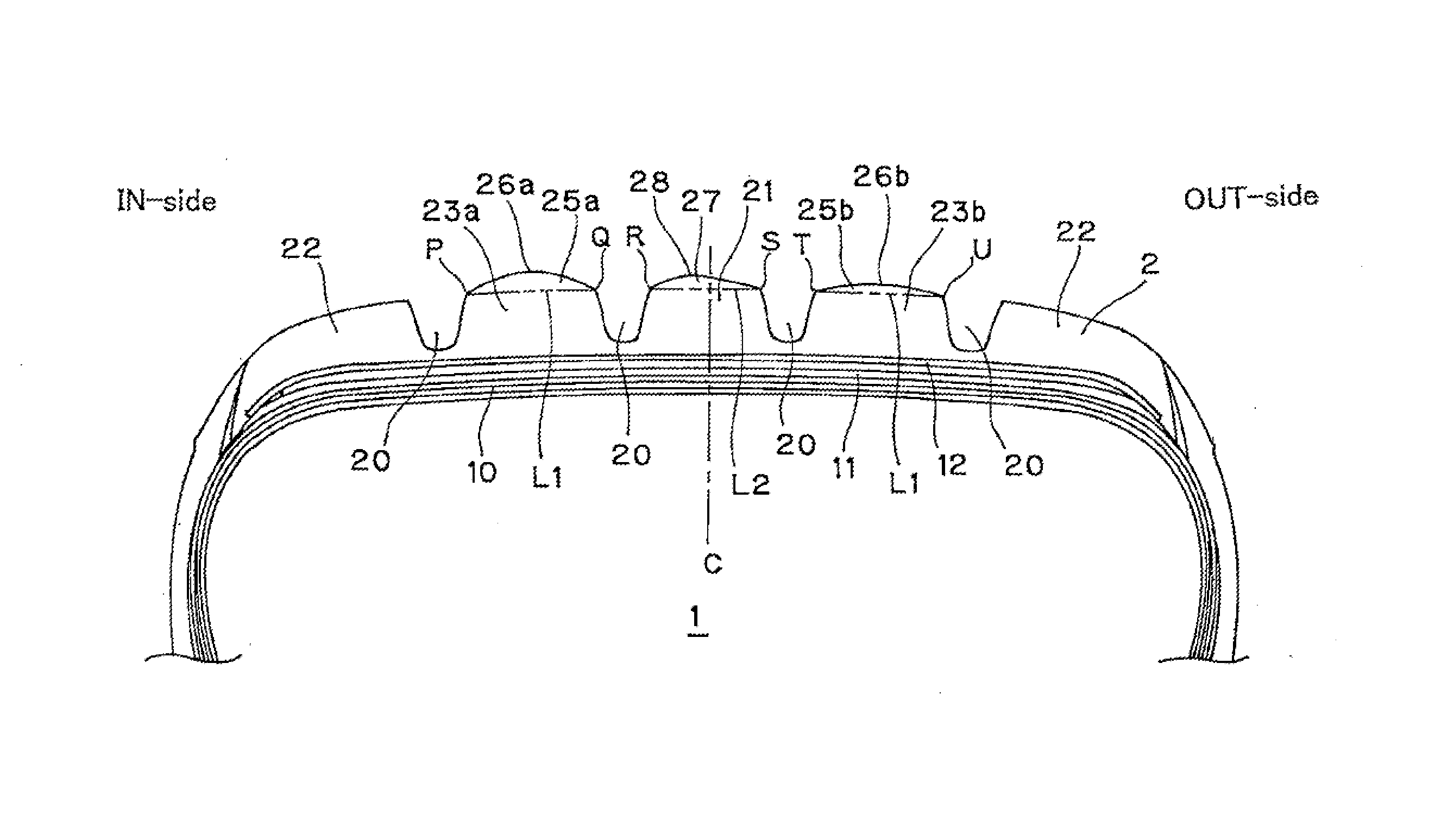

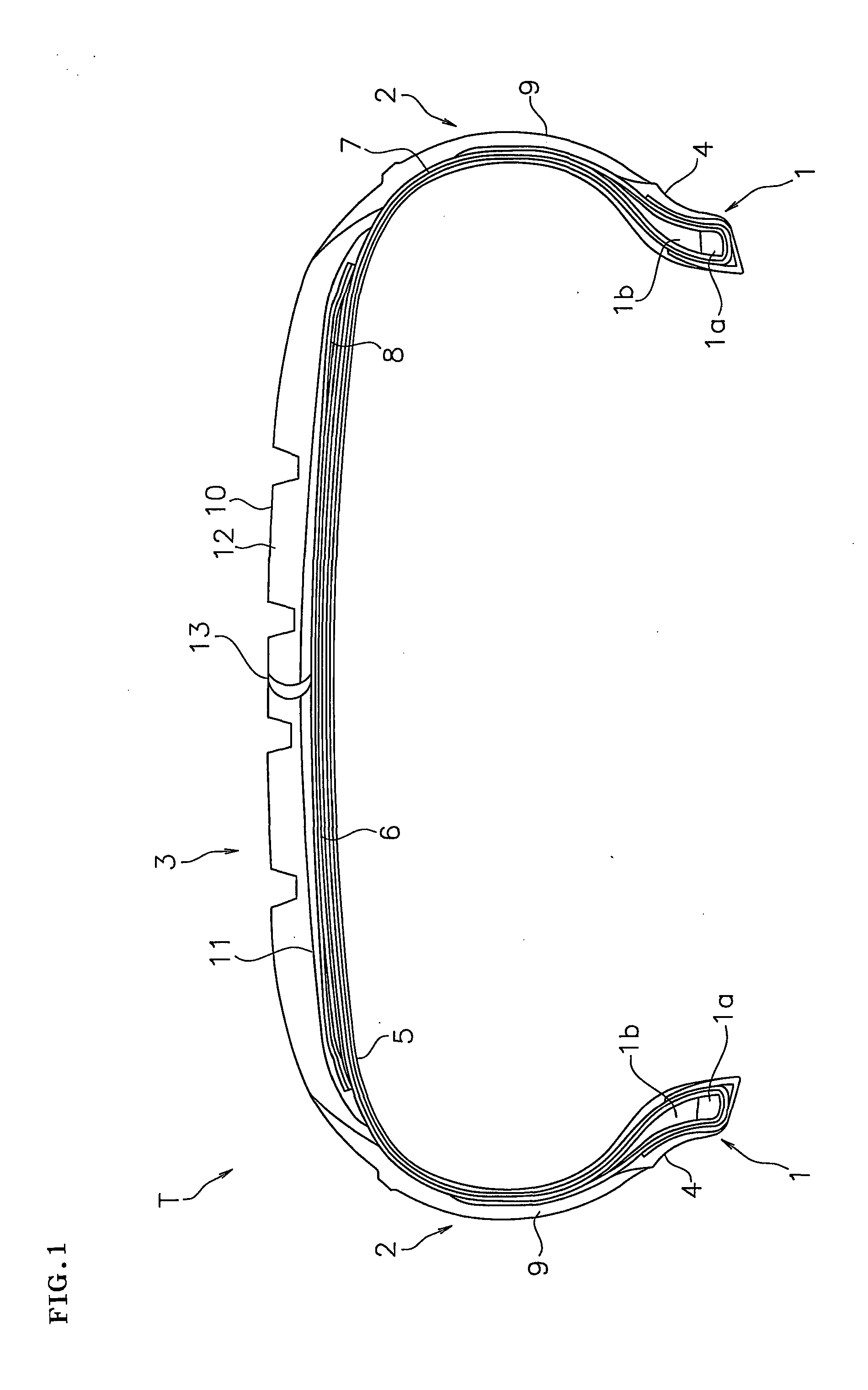

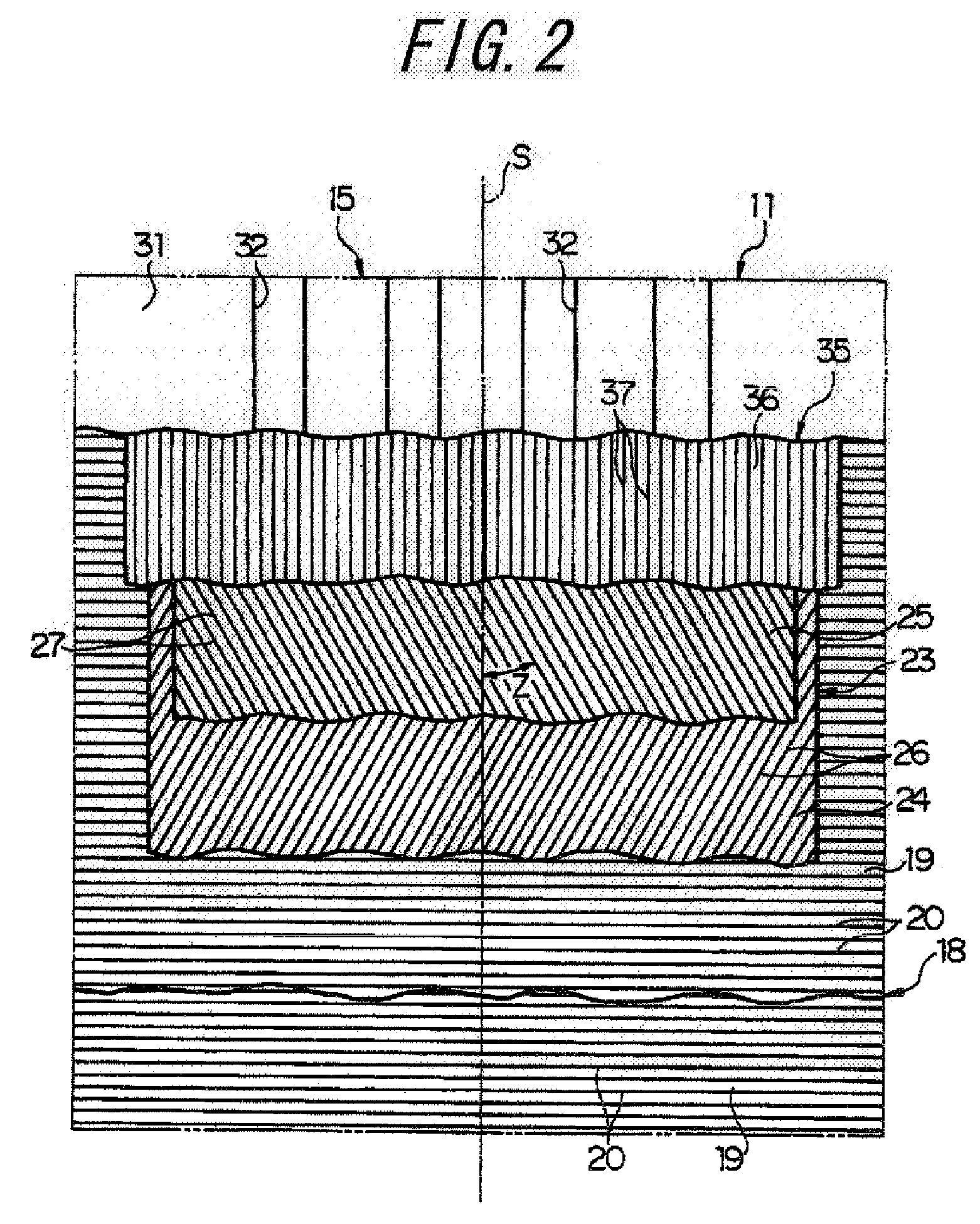

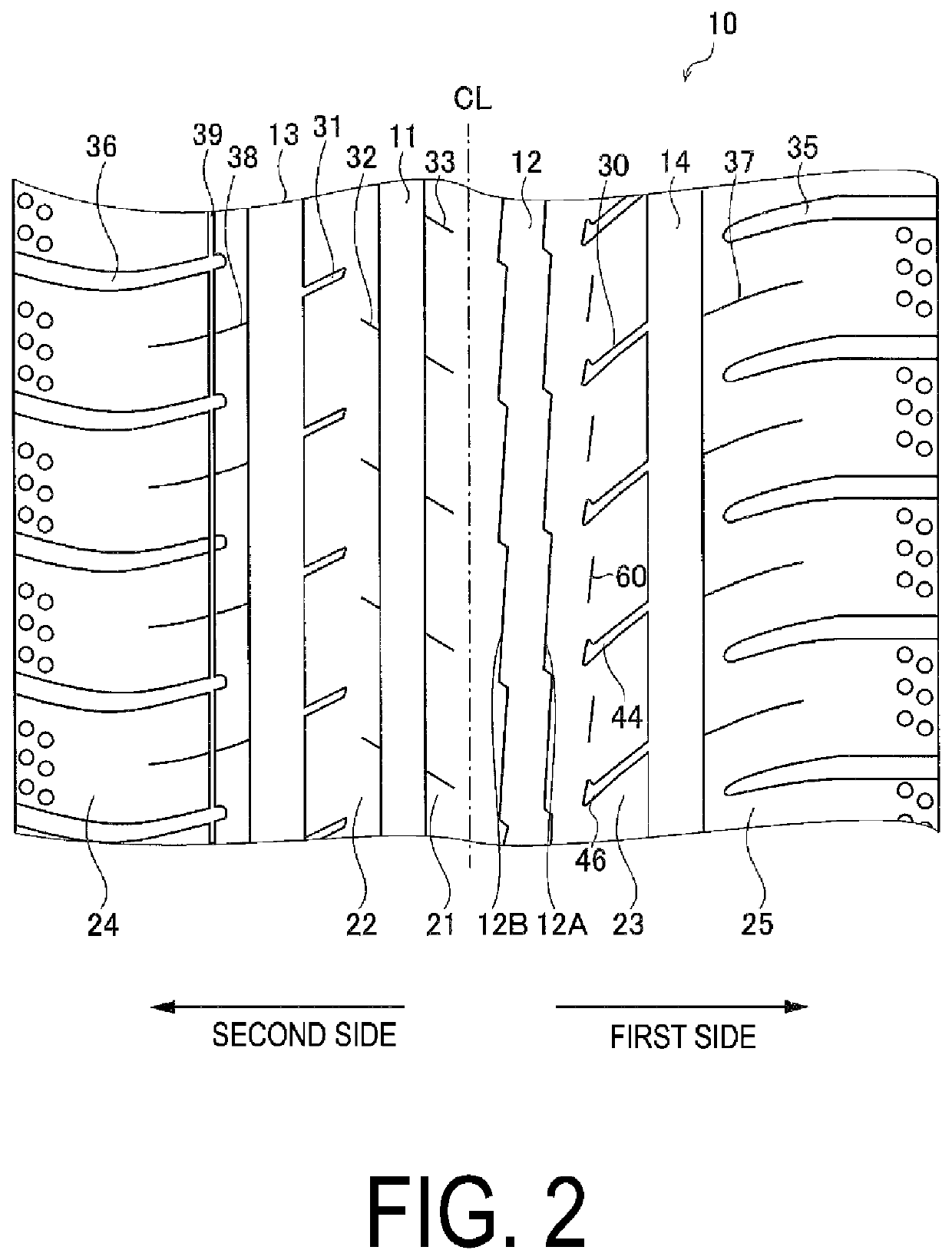

ActiveUS20130025753A1Securing steering stabilityMaintain a rigid balanceTyre tread bands/patternsRolling resistance optimizationGround contactEngineering

A pneumatic tire has a tread rubber provided in an outer side of a carcass layer in a tread portion. the tread rubber has a cap portion which is formed by a non-conductive rubber and constructs a ground-contacting surface, a base portion which is provided in an inner side in the tire diametrical direction of the cap portion, and a conductive portion which is formed by a conductive rubber and extends in a thickness direction of the tread rubber so as to reach a bottom surface of the tread rubber from the ground-contacting surface. A thickness of the conductive portion is made relatively large in a center portion in the thickness direction of the tread rubber, and the thickness of the conductive portion is made relatively small in both end portions in the thickness direction of the tread rubber.

Owner:TOYO TIRE & RUBBER CO LTD

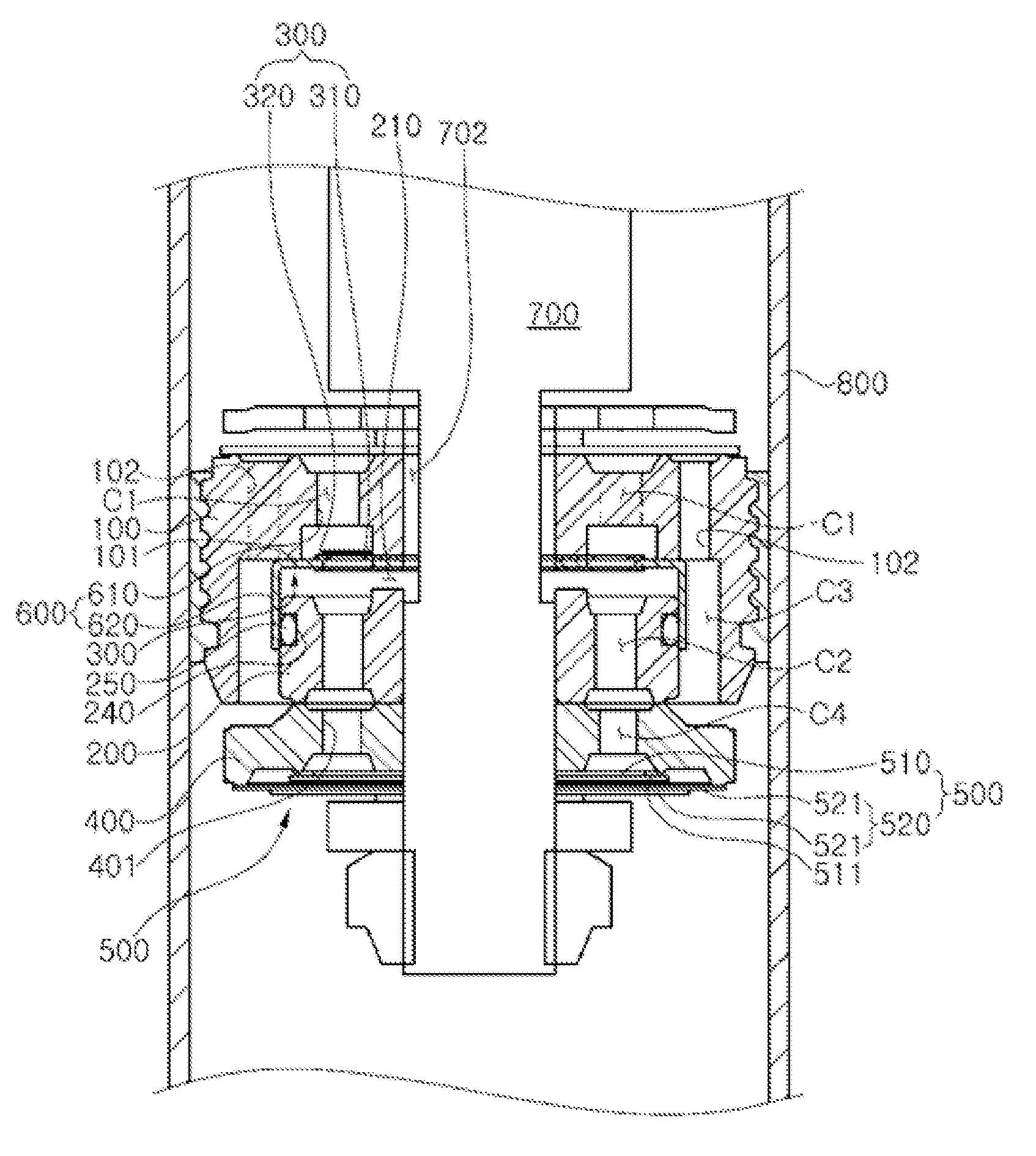

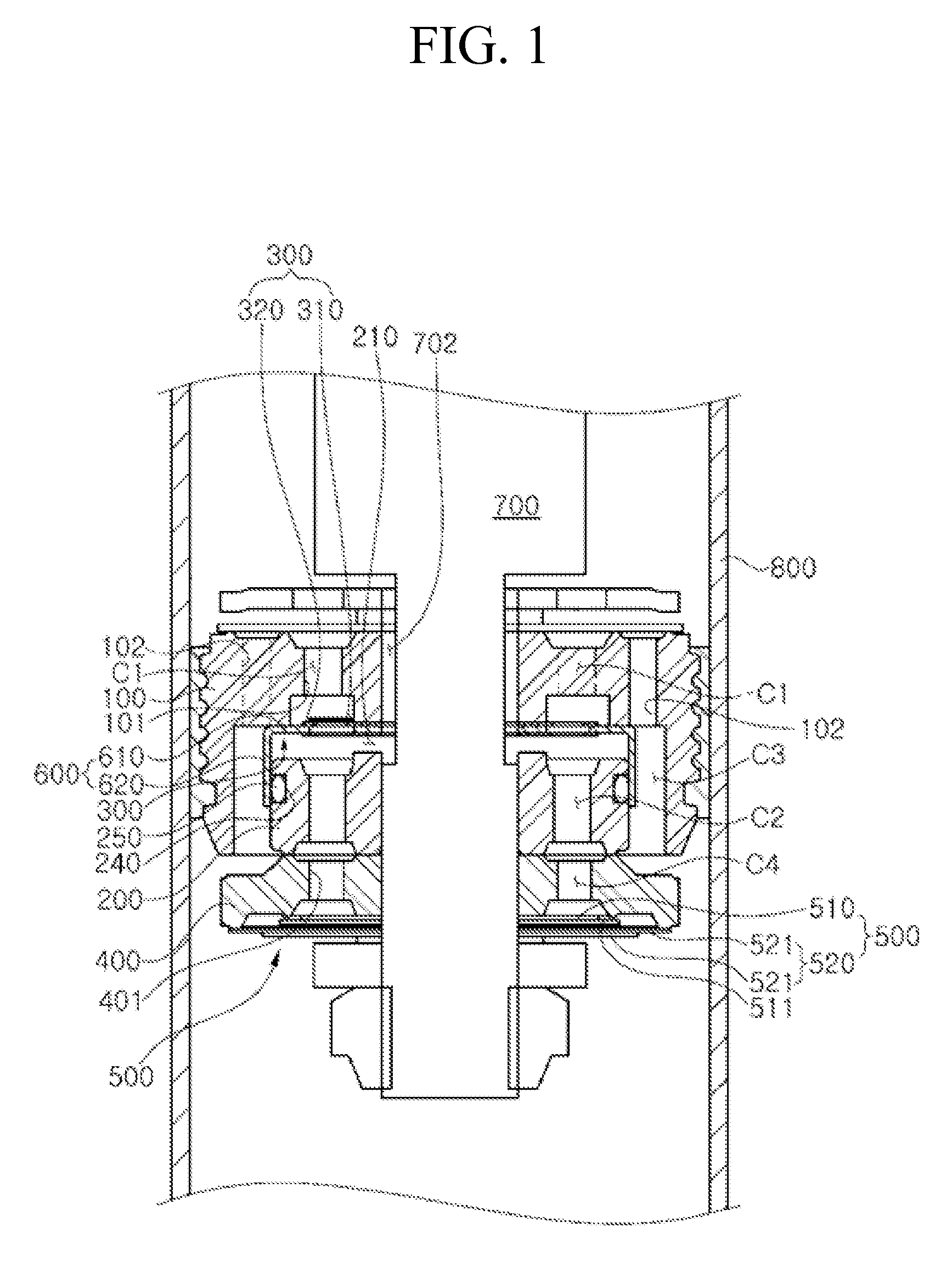

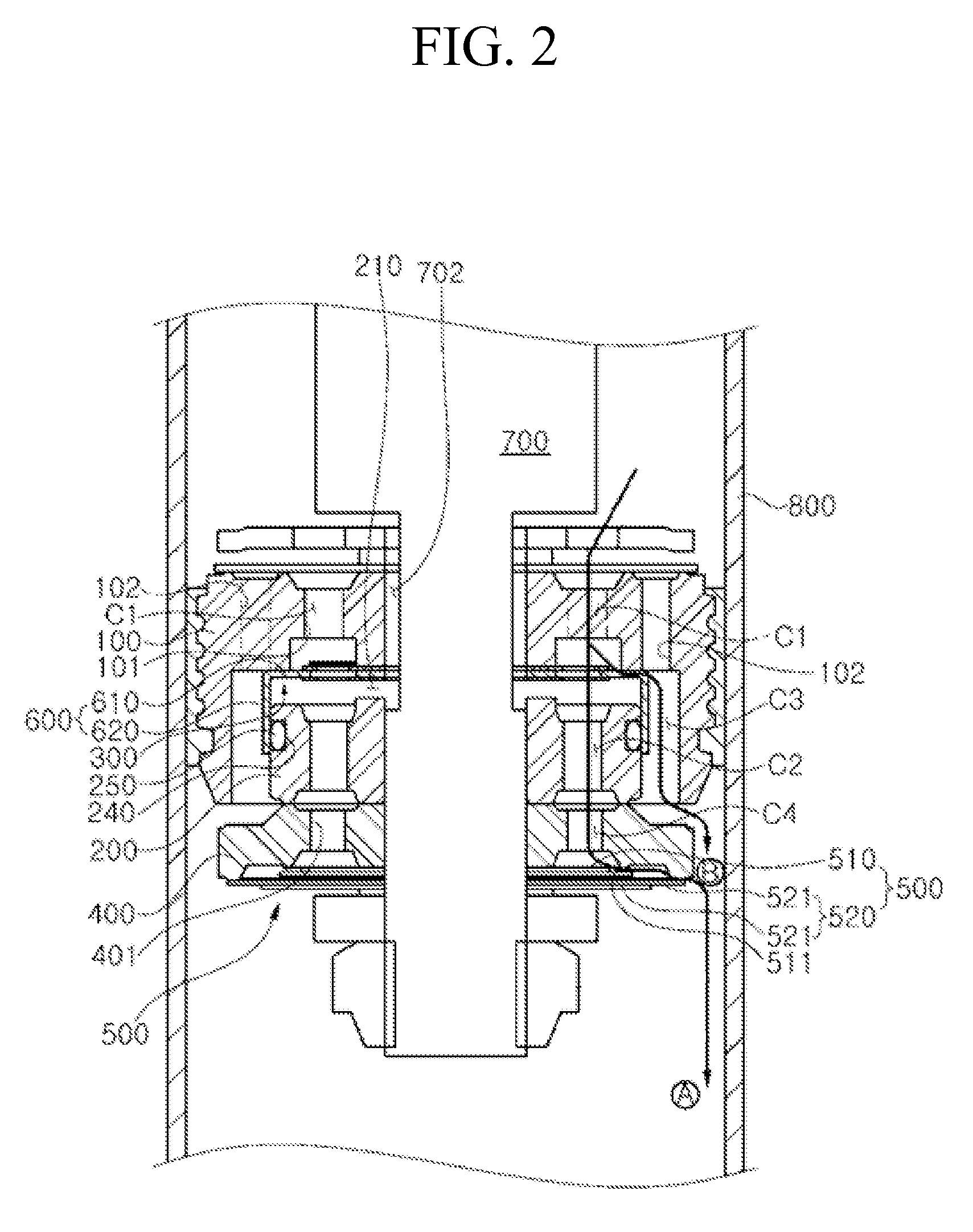

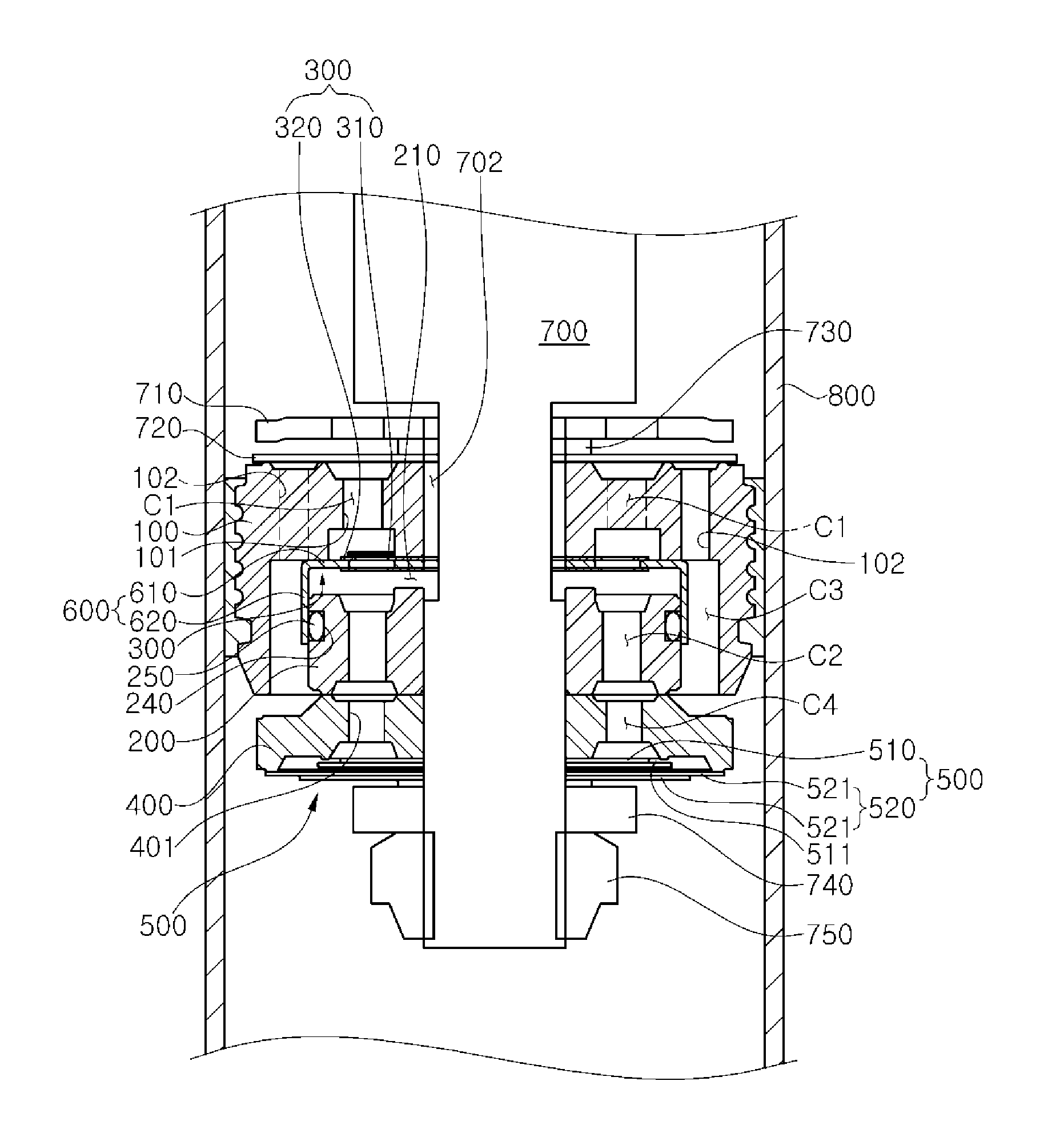

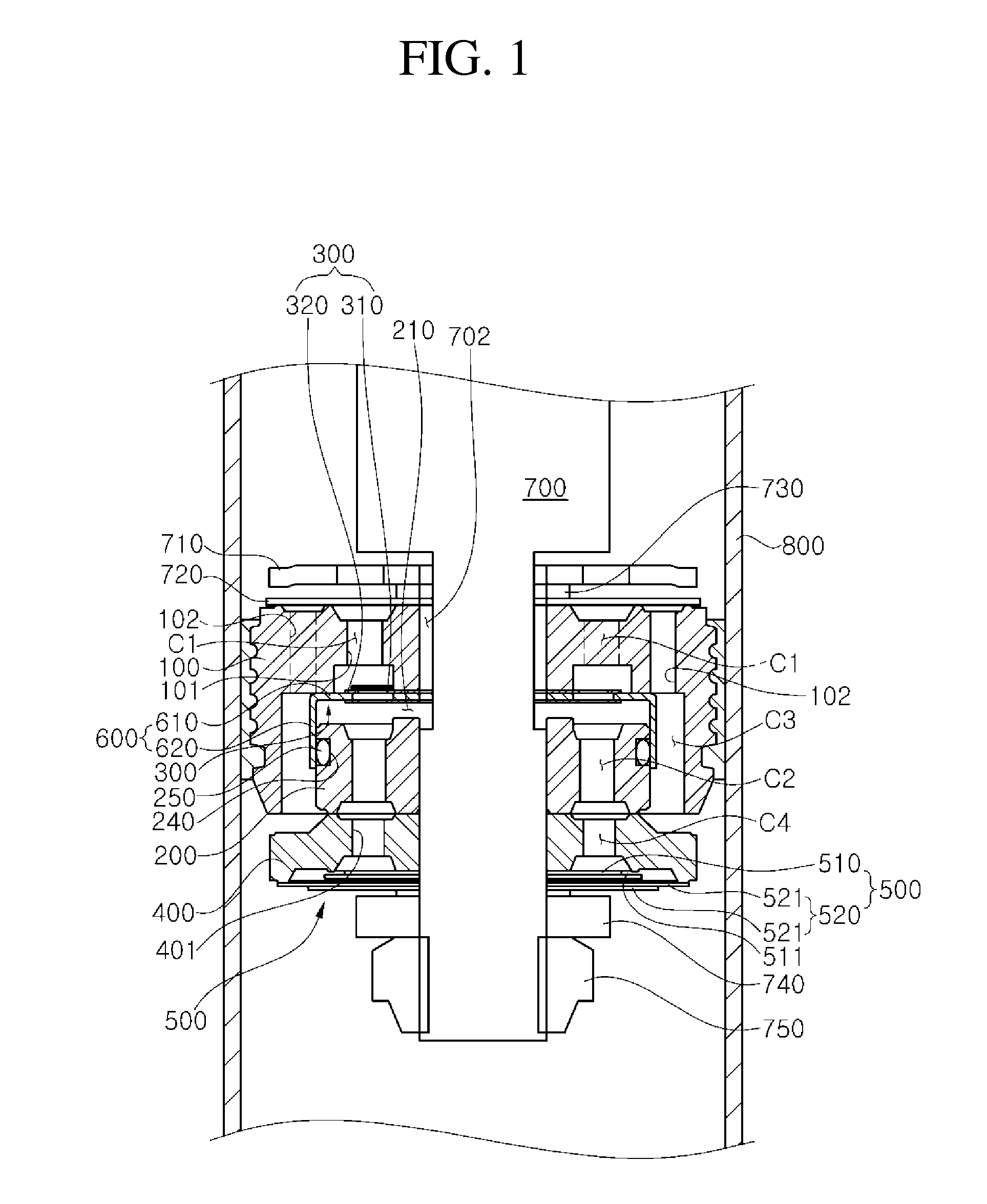

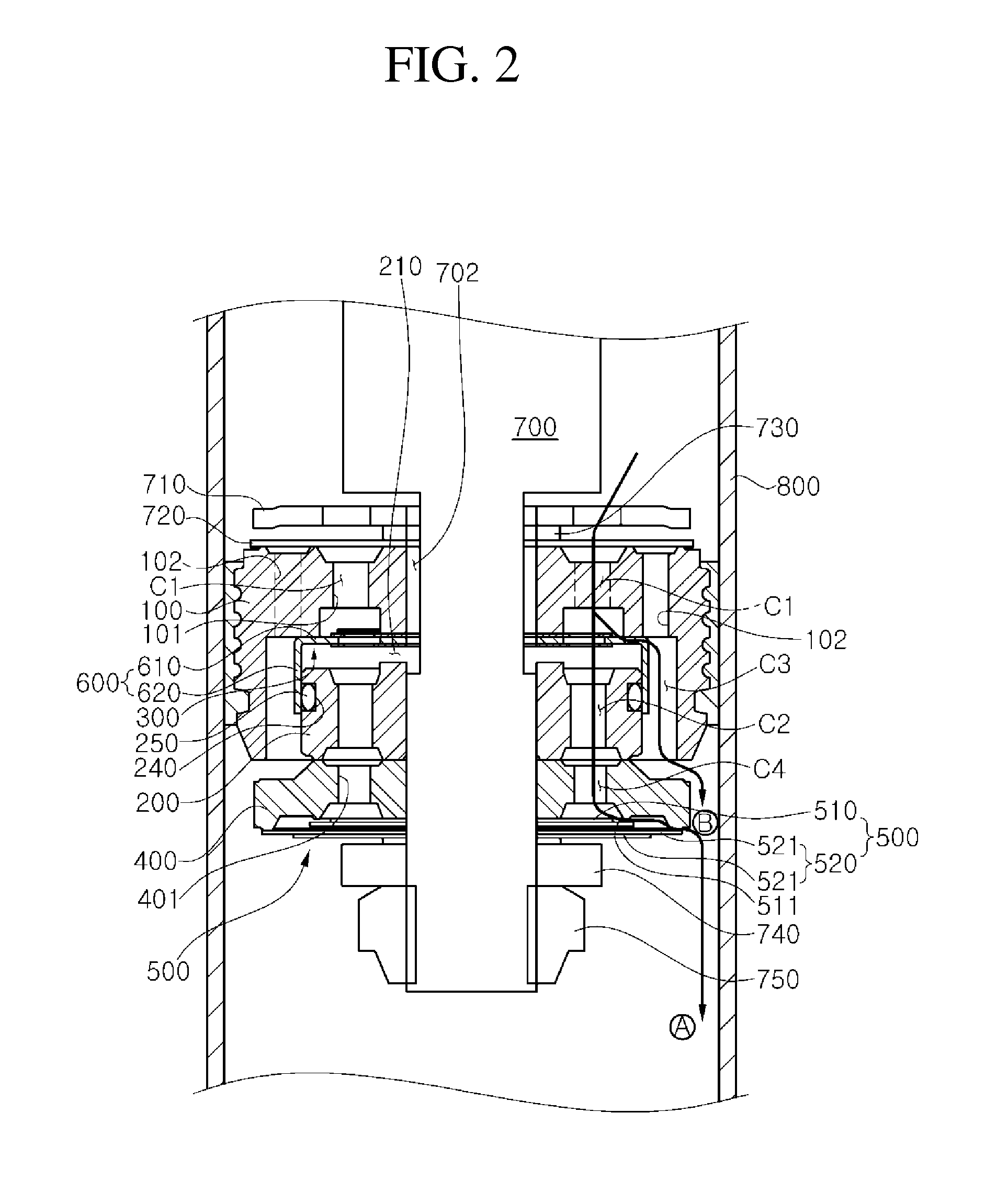

Shock absorber

ActiveUS9212719B2Steering stabilityReduce damping forceSpringsShock absorbersSmall amplitudeEngineering

In a high-frequency mode (a small-amplitude mode), a shock absorber opens a guide member to reduce a damping force. In a low-frequency mode (a large-amplitude mode), the shock absorber prevents the guide member from being opened by increasing a pressure of a second pressure chamber formed between a second piston (lower piston) and a pilot valve through a groove (passage) formed in an outer periphery of a piston rod. A main damping force is generated through the second pressure chamber and a disk valve assembly. Therefore, it is possible to provide a round ride comfort having a damping feeling and ensure a steering stability through a linear vehicle control.

Owner:HL MANDO CORP

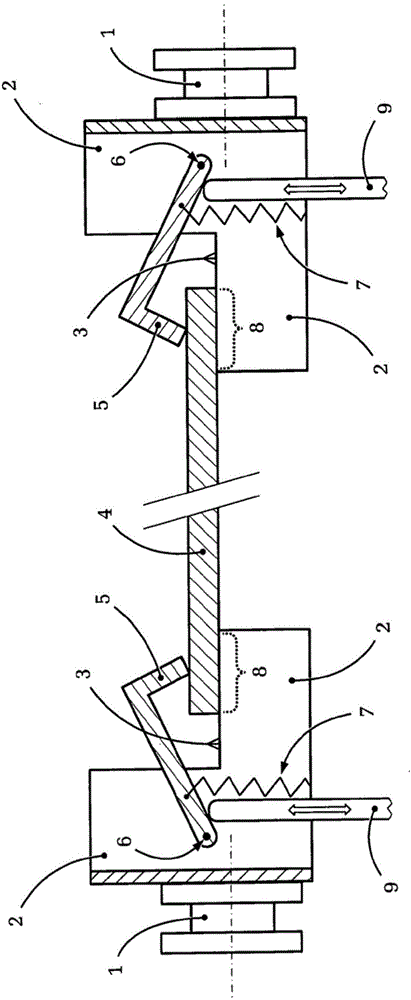

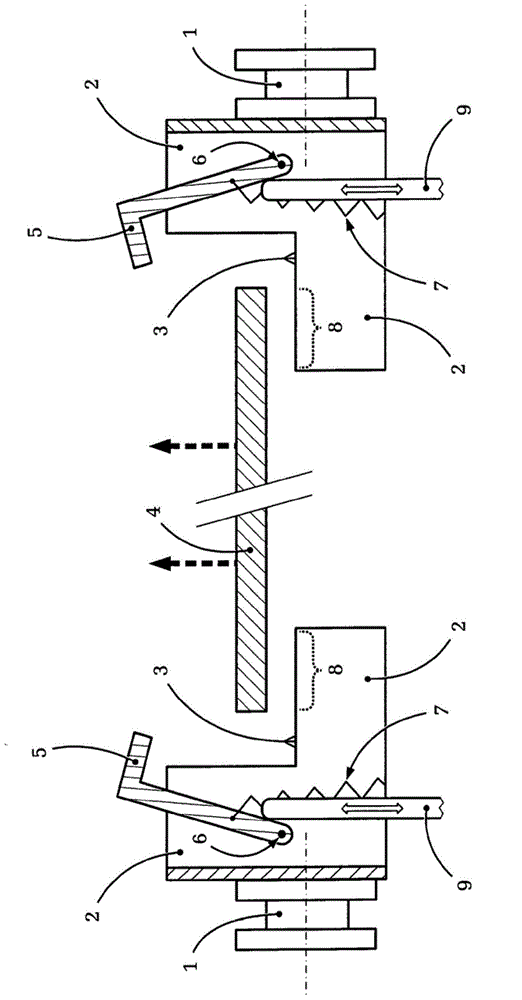

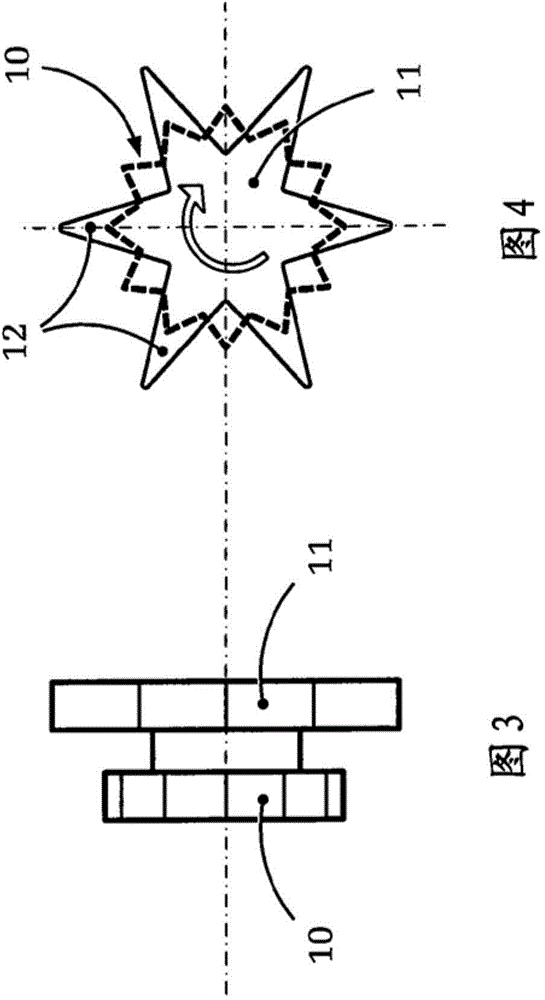

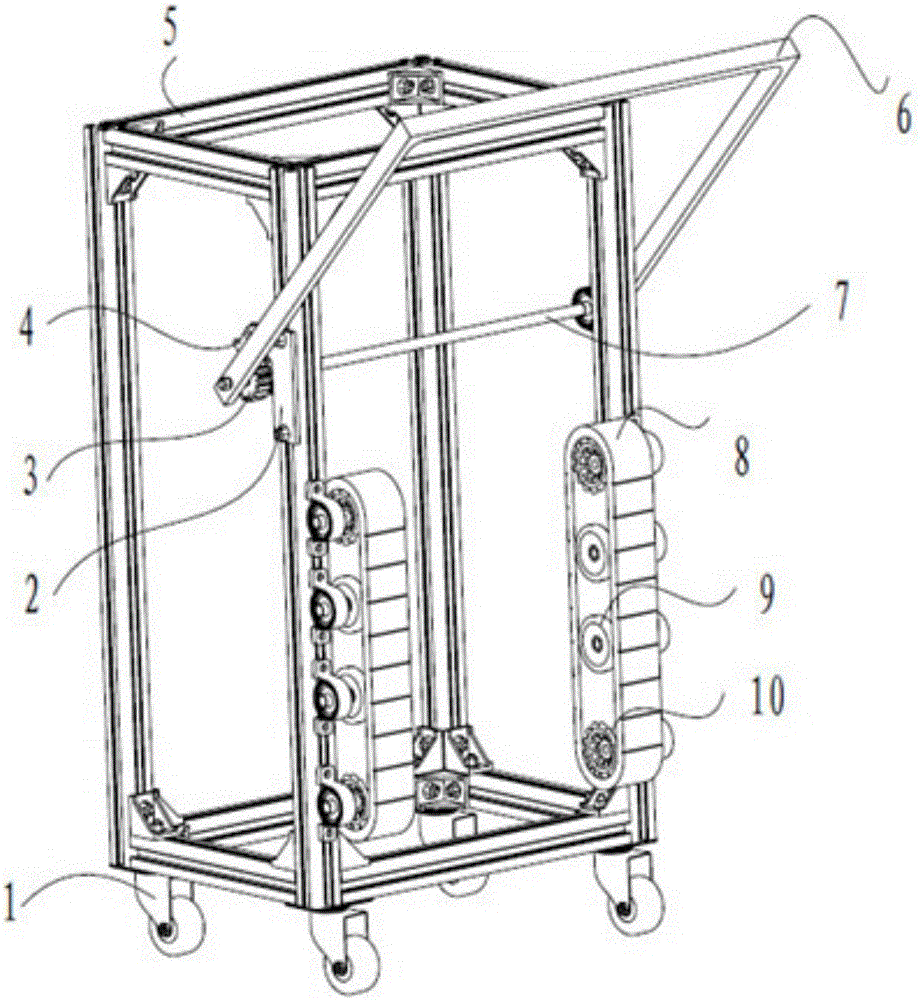

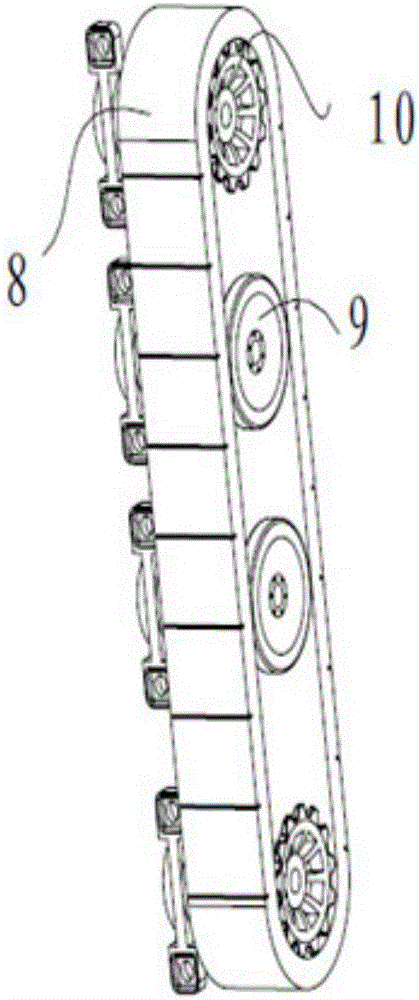

Conveyor device for printed circuit boards

The invention relates to a conveyor device for printed circuit boards (4). The conveyor device comprises a carrier means (1) that continuously circulates between conveyor wheels and is linearly guided in some sections. On said carrier means (1), at least one carrier element (2) is arranged for placing the printed circuit board (4) in order for it to be supported, as well as at least one resilient clamping element (5) for clamping the printed circuit board (4) onto said carrier element (2). The clamping element (5) can be moved back and forth, using a switching device (9), between a clamping element (5) opening position in which the printed circuit board (4) can be loosely placed on said carrier element (2), and a clamping element (5) spring-loaded closure position in which the printed circuit board (4) can be pressed onto the carrier element (2) by the clamping element (5).

Owner:ERSA GMBH

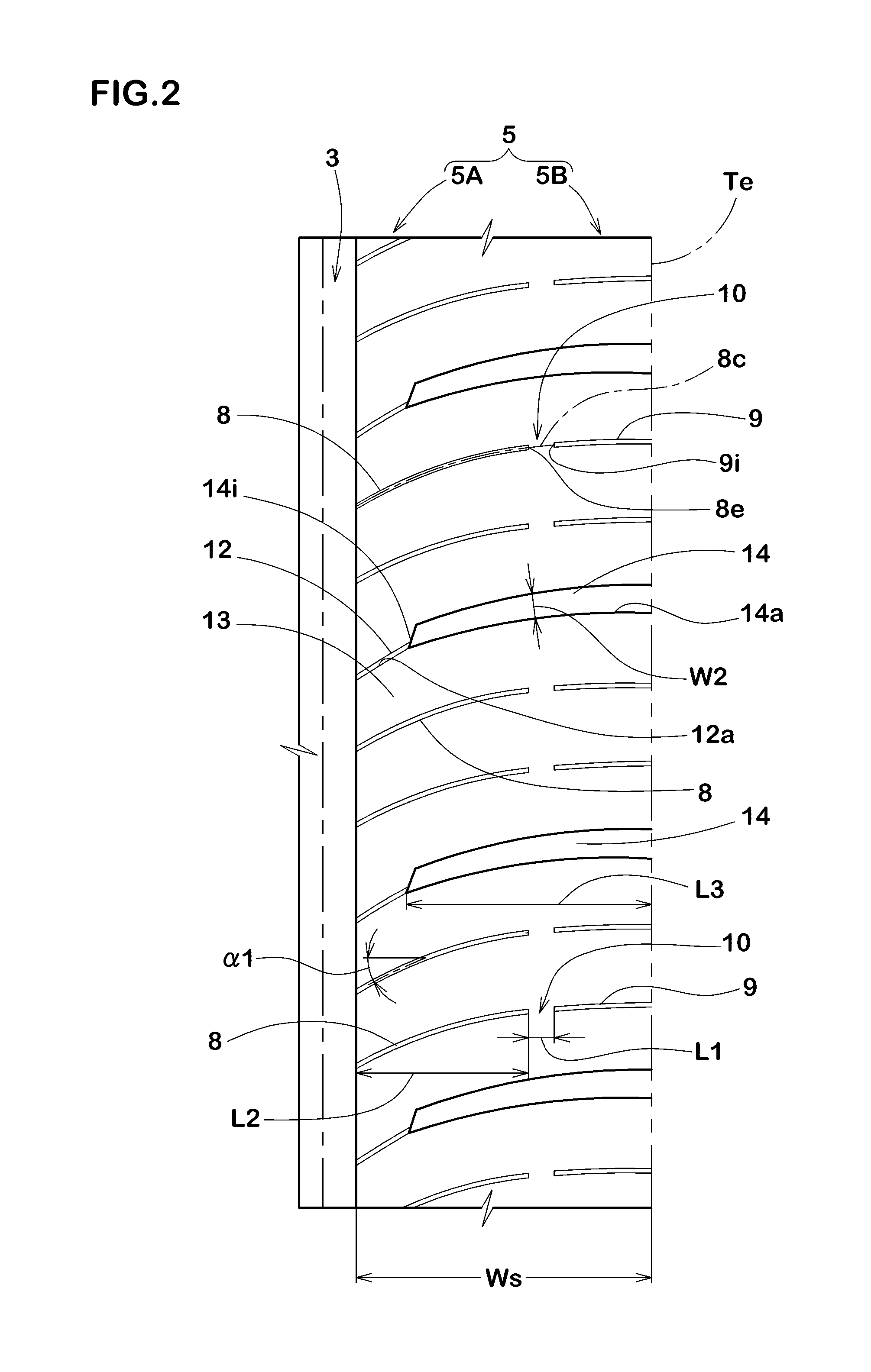

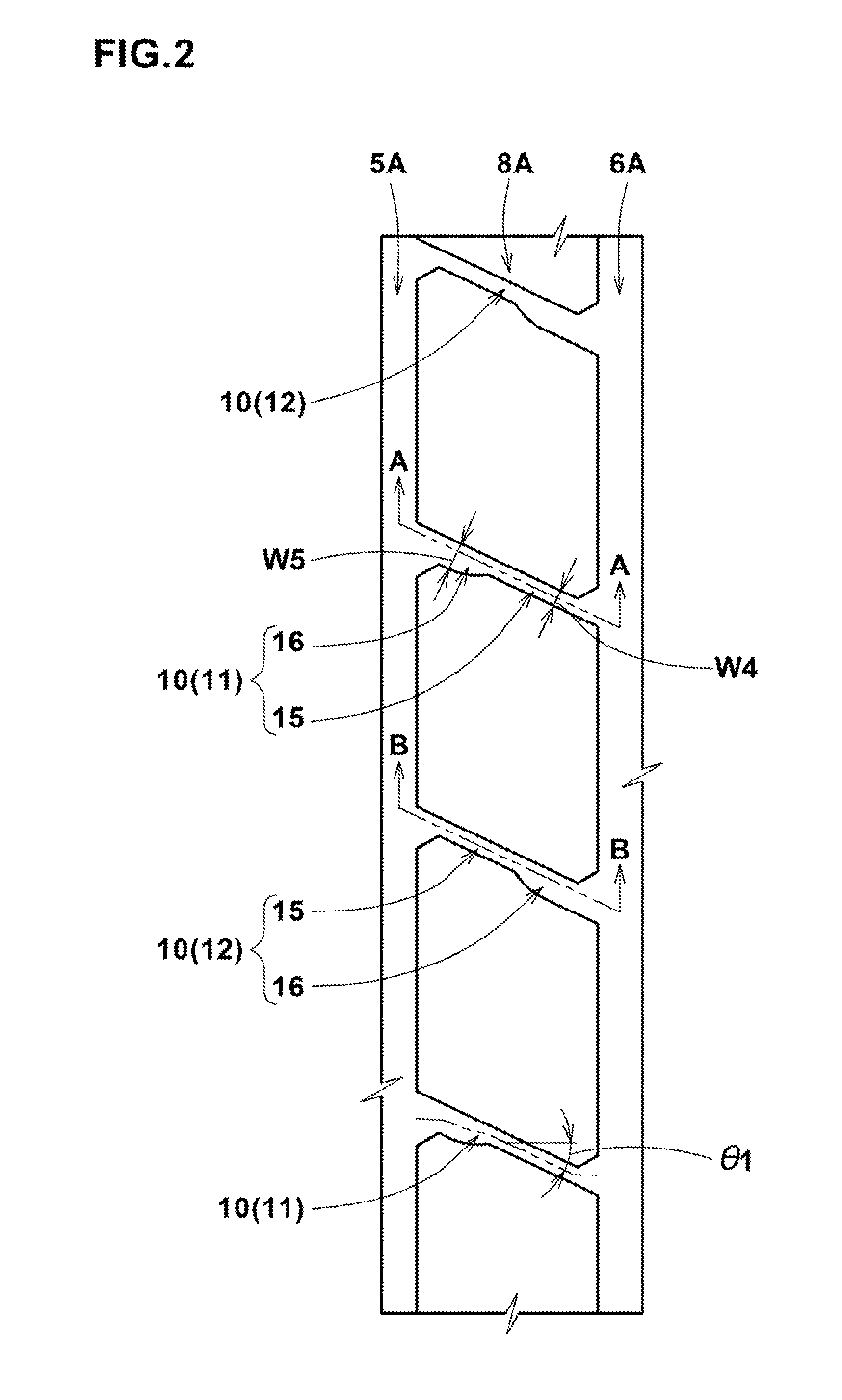

Pneumatic Tire

ActiveUS20170232800A1Improve steering stabilityOptimizationTyre tread bands/patternsEngineeringTread

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveUS20160332489A1Improve steering stabilitySteering stabilityTyre tread bands/patternsTransverse grooveEngineering

Owner:SUMITOMO RUBBER IND LTD

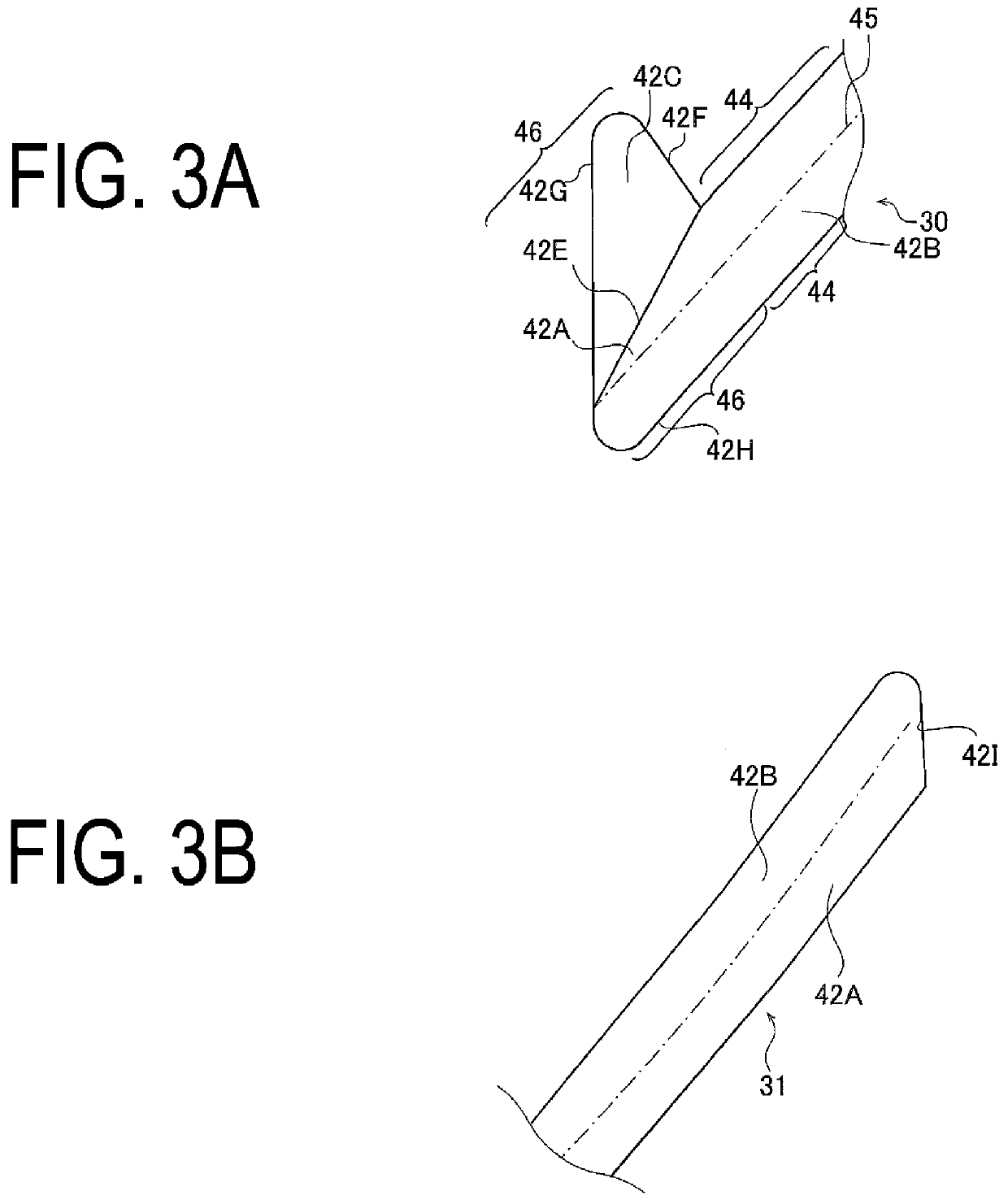

Pneumatic tire

InactiveUS20140238562A1Modulus rubber hardnessHigh modulusTyre tread bands/patternsMeridian circleEngineering

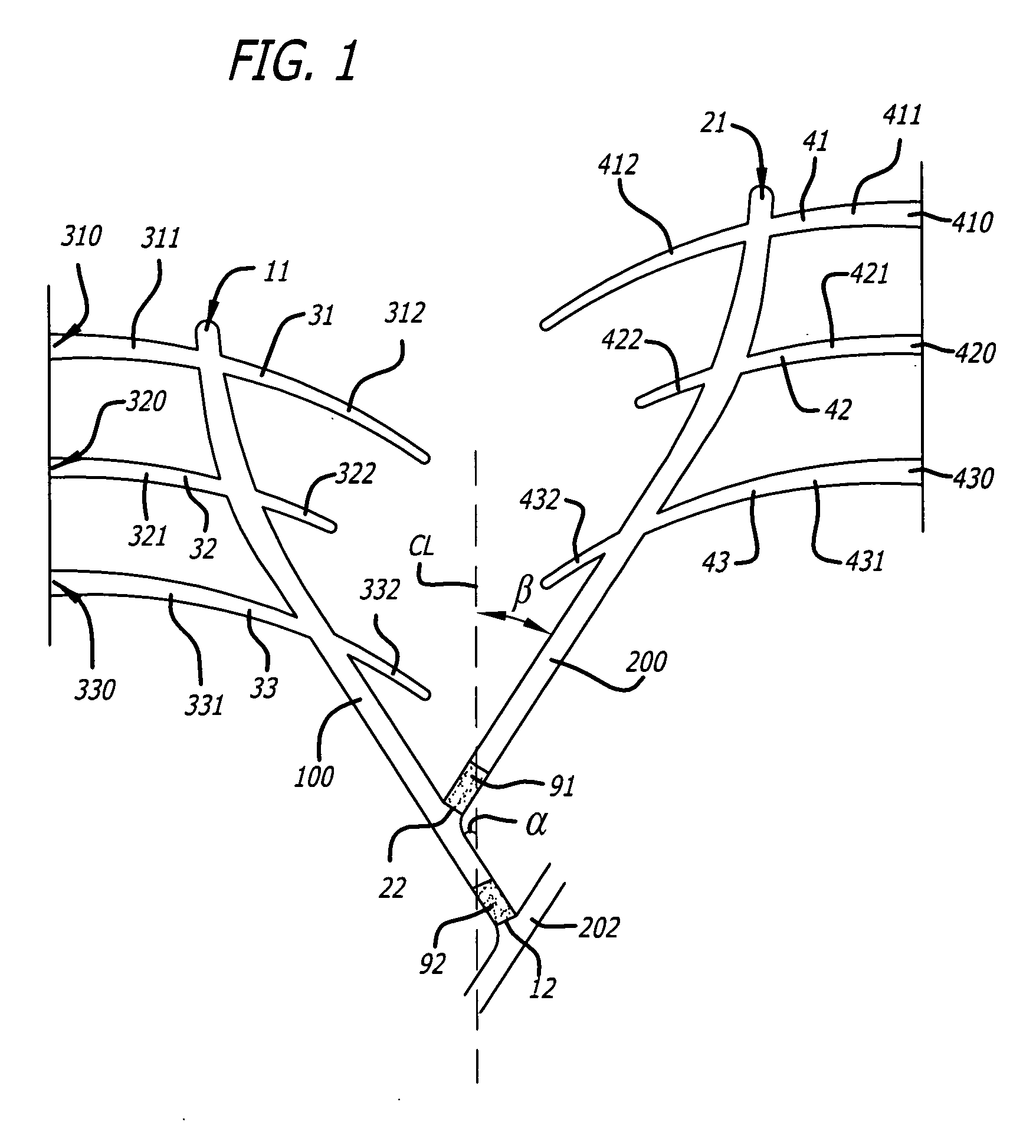

A tire has a tread rubber and a conductive portion. The conductive portion is formed so as to connect the ground surface and a side surface of a side end portion of the tread rubber in a tire meridian circle cross section. The conductive portion having a rubber hardness which is different from the tread rubber, and has a stem portion and a plurality of branch portions. The stem portion heads for an inner side in the tire width direction from the side surface of the side end portion of the tread rubber so as to terminate at an inner portion of the tread rubber. The plurality of branch portions are branched from a plurality of positions of the stem portion so as to head for an outer side in the tire width direction and be exposed to an outer surface of the tire.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic tire with tread having cap portion, base portion and conductive portion

ActiveUS9333812B2Reduce rolling resistanceImprove wet braking performanceTyre tread bands/patternsRolling resistance optimizationGround contactMechanical engineering

A pneumatic tire has a tread rubber provided in an outer side of a carcass layer in a tread portion. the tread rubber has a cap portion which is formed by a non-conductive rubber and constructs a ground-contacting surface, a base portion which is provided in an inner side in the tire diametrical direction of the cap portion, and a conductive portion which is formed by a conductive rubber and extends in a thickness direction of the tread rubber so as to reach a bottom surface of the tread rubber from the ground-contacting surface. A thickness of the conductive portion is made relatively large in a center portion in the thickness direction of the tread rubber, and the thickness of the conductive portion is made relatively small in both end portions in the thickness direction of the tread rubber.

Owner:TOYO TIRE & RUBBER CO LTD

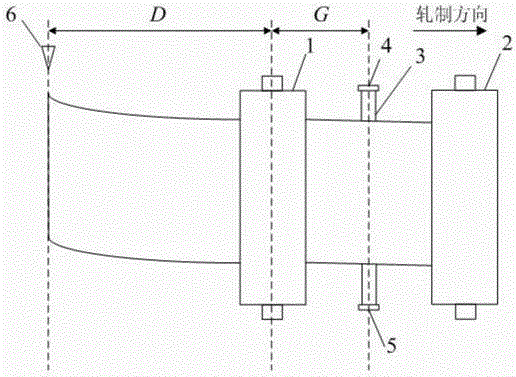

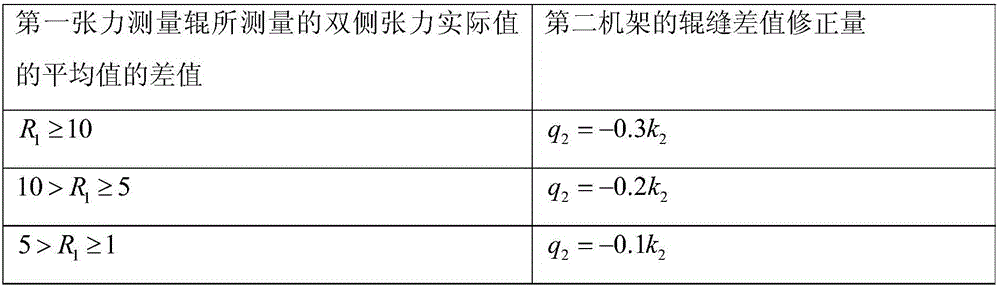

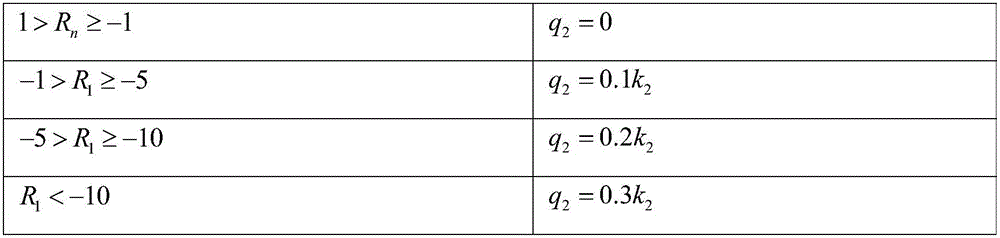

Correction method for tail of strip of continuous rolling unit

ActiveCN105921525ARealize deviation controlAccurate timingRoll mill control devicesMeasuring devicesInstabilityEngineering

The invention discloses a correction method for the tail of a strip of a continuous rolling unit, and relates to the technical field of metal pressure machining. The method comprises the following steps that a start signal of a strip tail correction program is set, and the strip tail correction program is started when a metal detector arranged at an inlet of the continuous rolling unit detects the tail of an intermediate billet rolled piece; the difference value of roll gaps on the double sides of a second rack of the continuous rolling unit is calculated and corrected; the difference value of roll gaps on the double sides of each of the rest of racks of the continuous rolling unit is calculated and corrected; and self-learning is carried out on the correction factor of the correction value of the difference value of the roll gaps on the double sides of each rack. The correction method solves the problems that in tail lateral bending correction in the existing intermediate billet rolling process, lagging and instability exist, and consequently the correction effect is poor.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

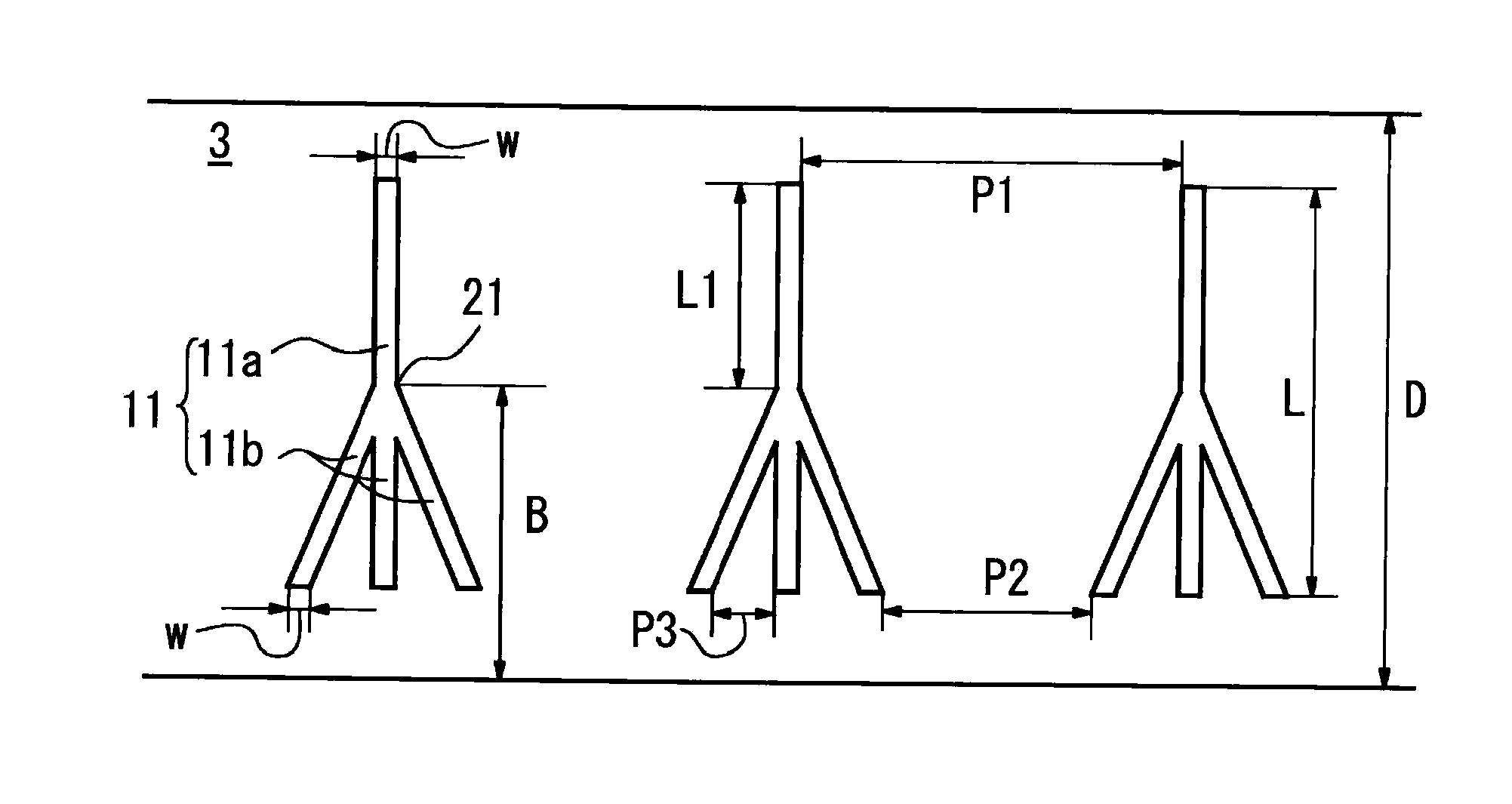

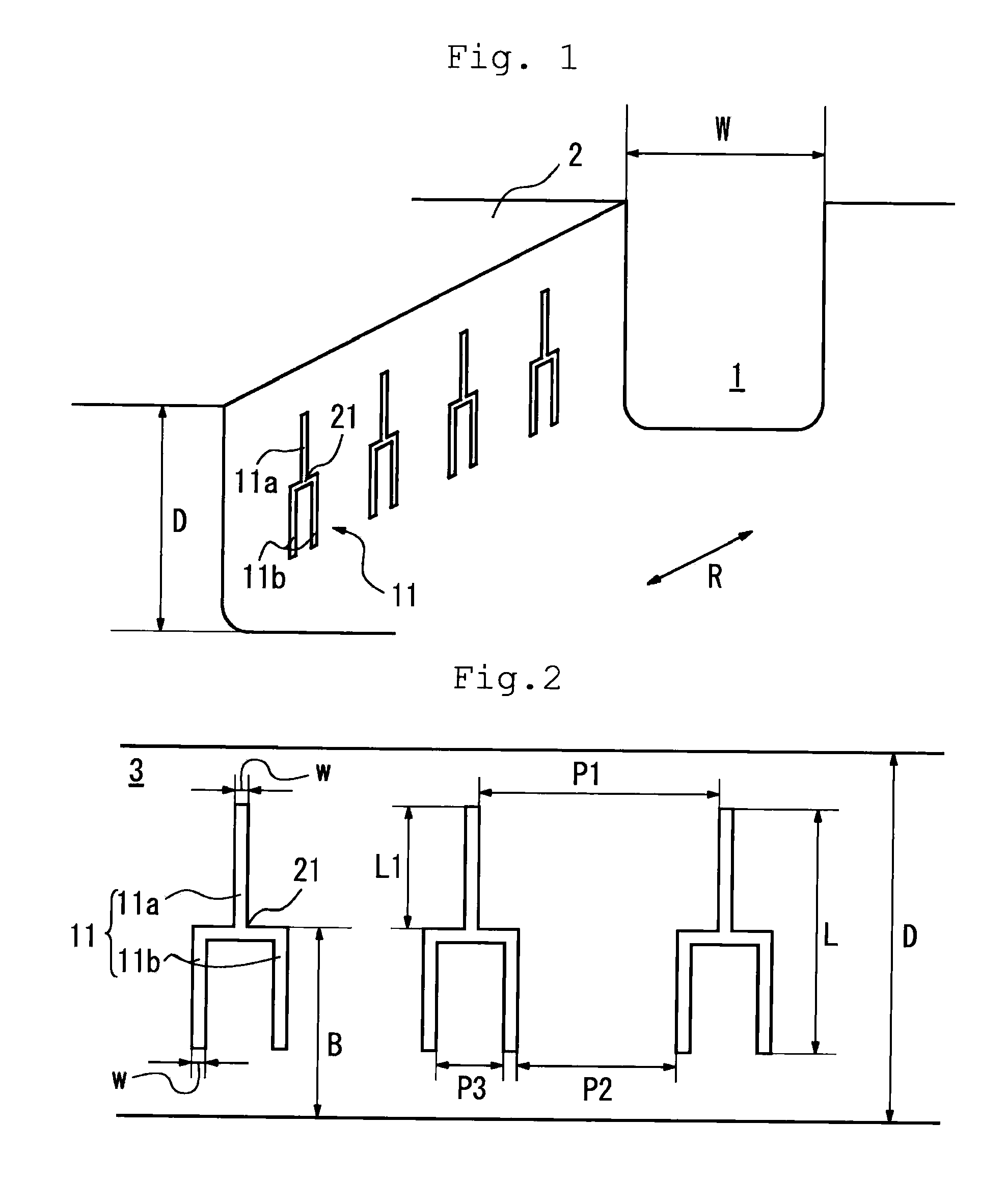

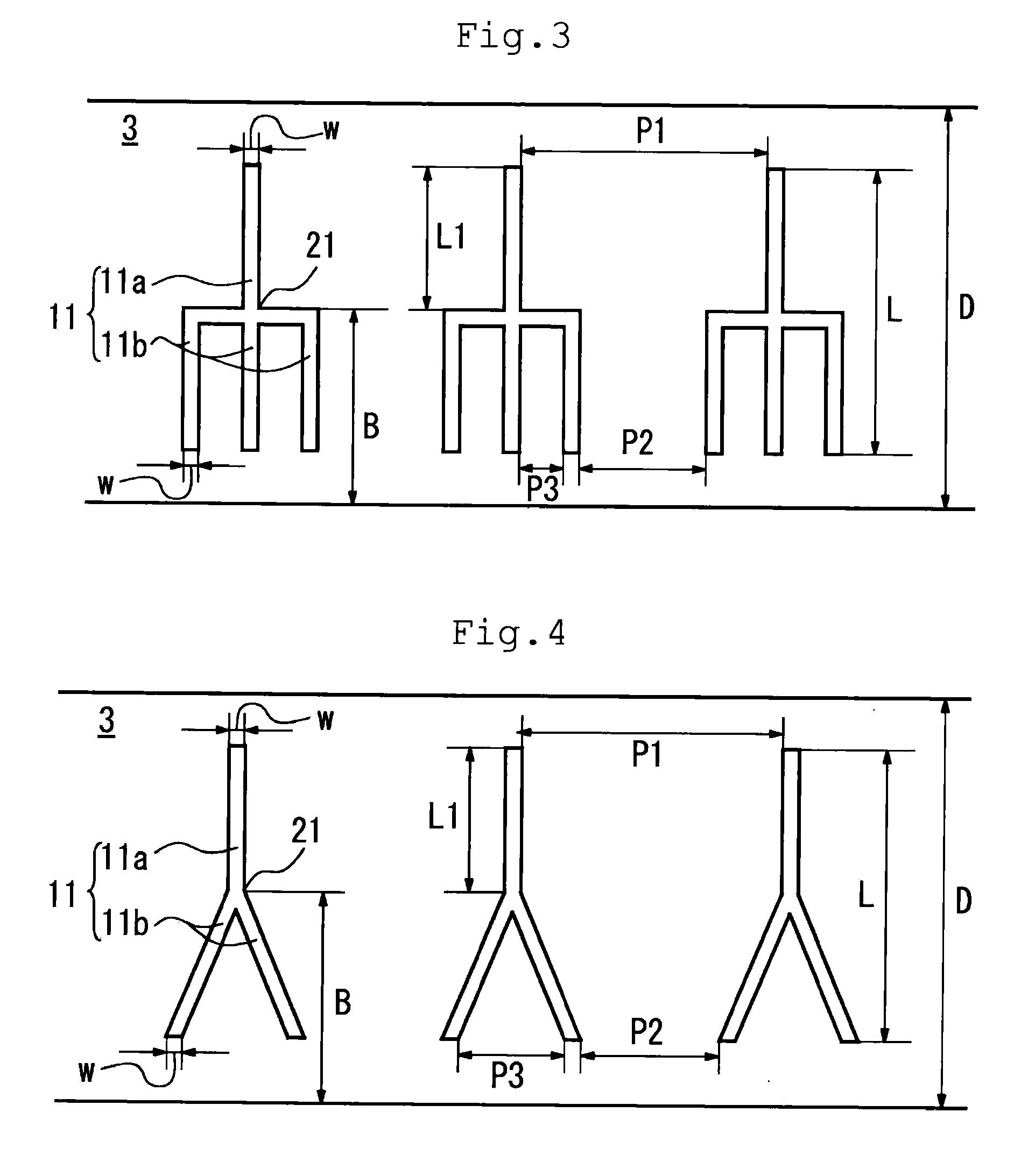

Pneumatic Tire

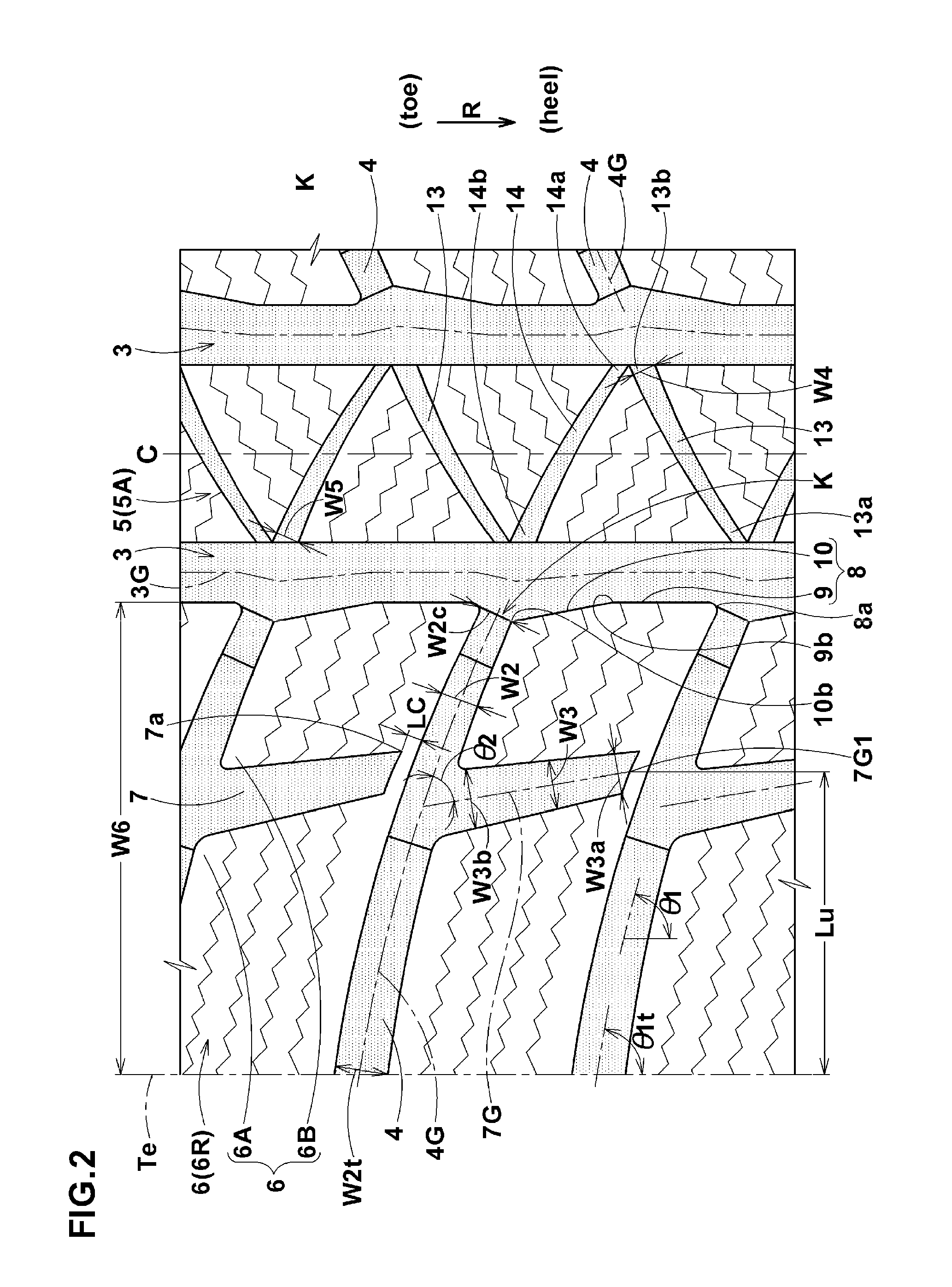

InactiveUS20100288408A1Reduce stiffnessIncrease airflowTyre tread bands/patternsNon-skid devicesResonanceNoise level

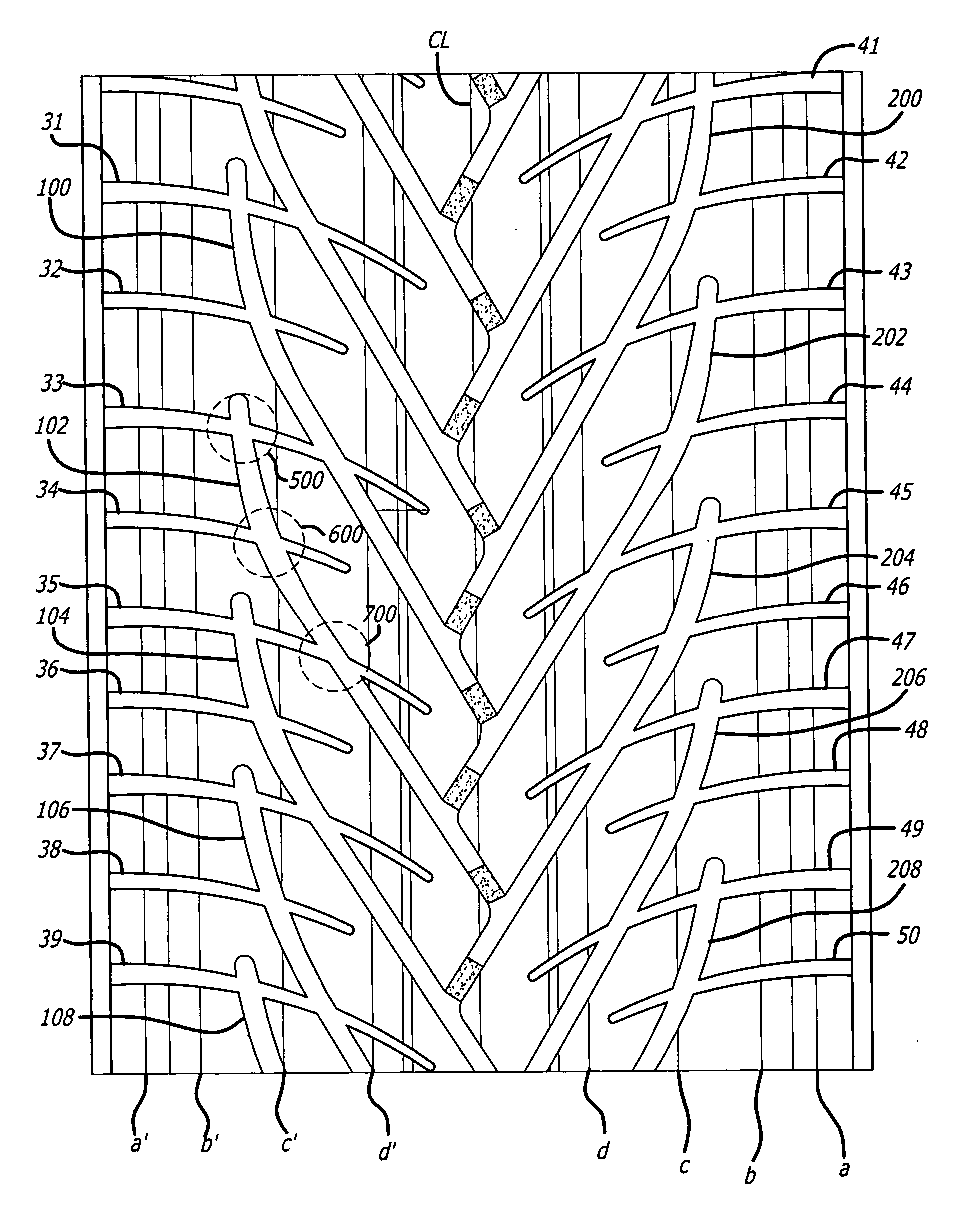

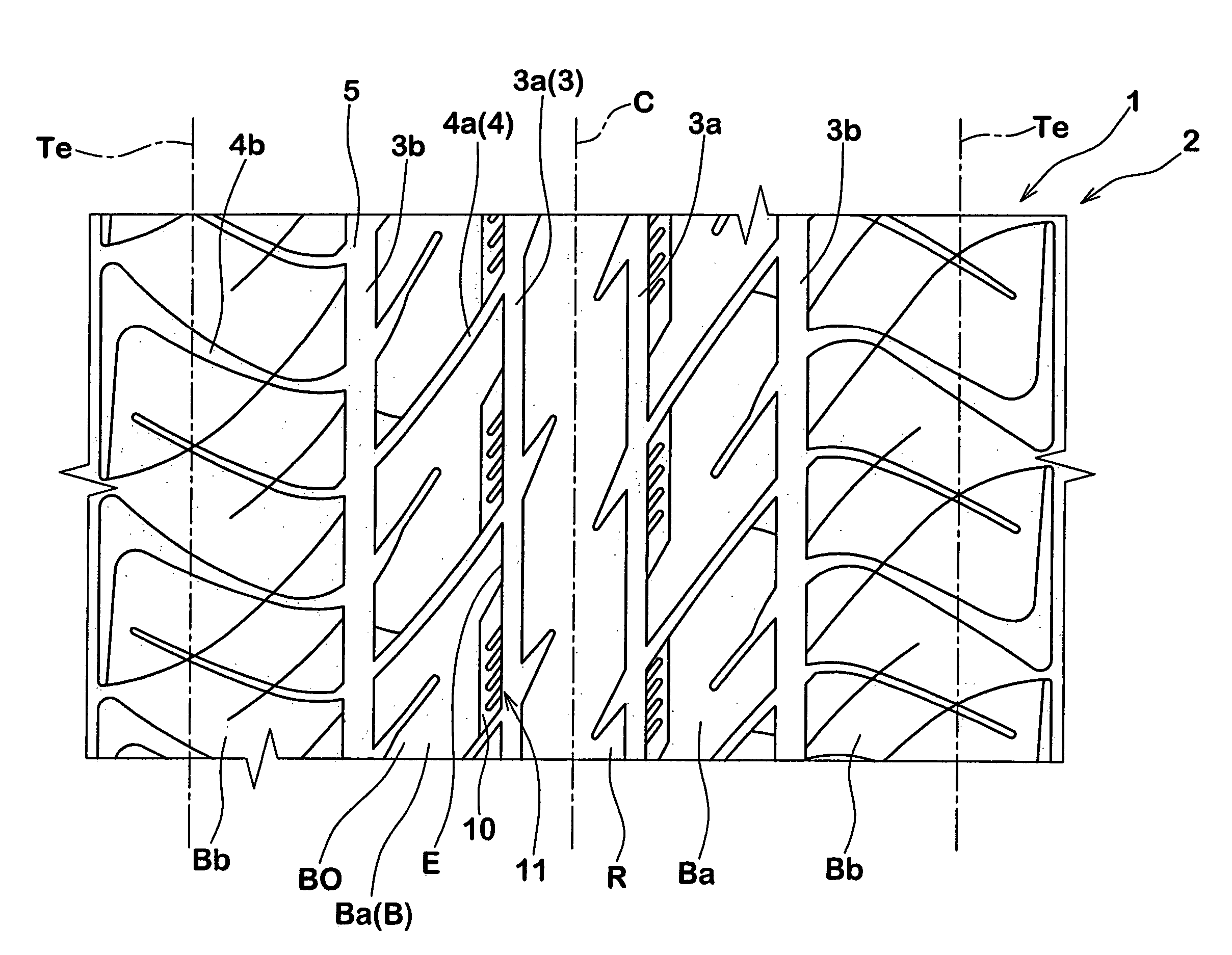

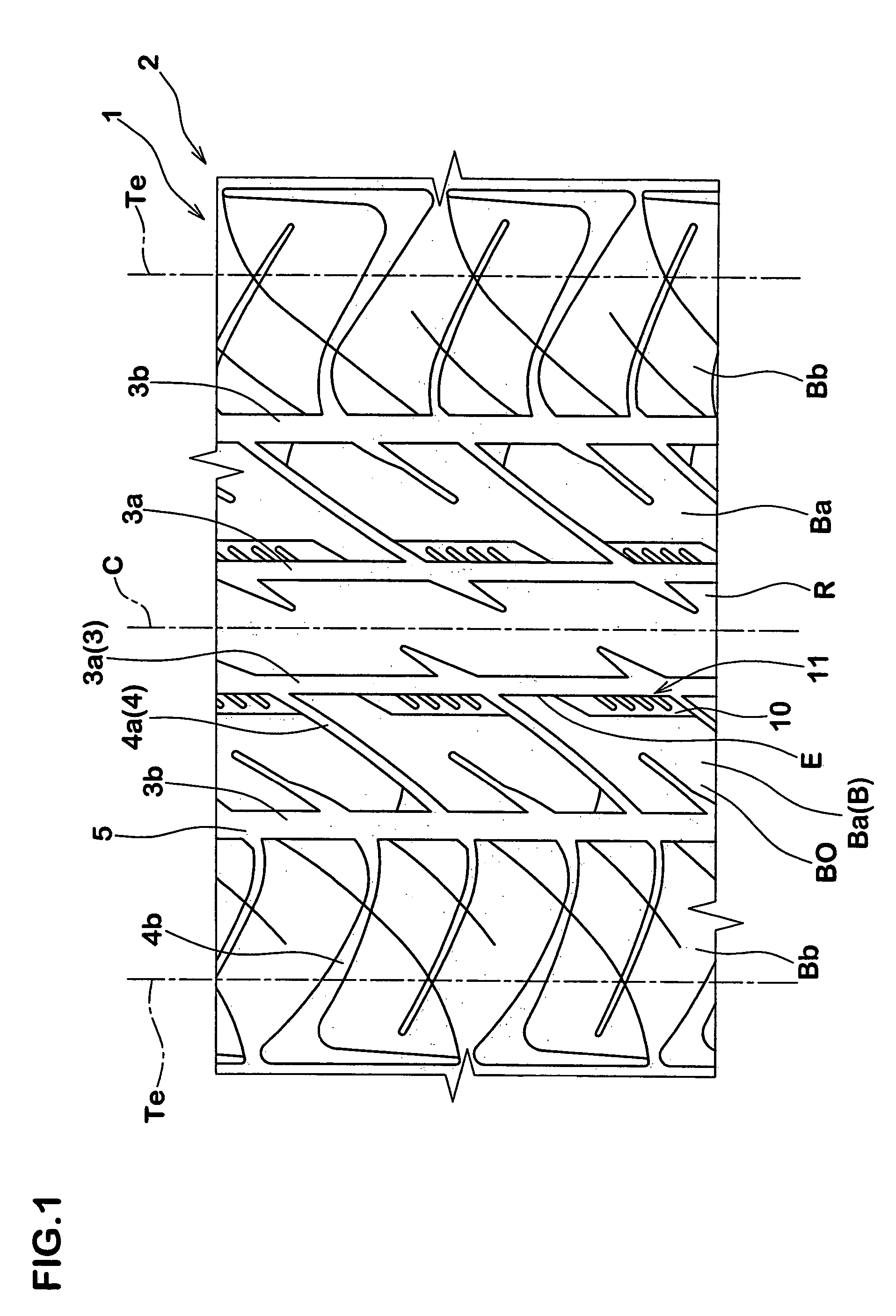

A pneumatic tire with improved steering stability without raising air columnar resonance noise level is provided. The pneumatic tire comprises upper thin grooves 11a extending from a branch point 21 in the depth direction of a main groove on the tread surface side and a plurality of lower thin grooves 11b extending from the branch point 21 in the depth direction of the main groove on the groove bottom side, which are formed at intervals along the tire circumferential direction R in a sidewall of the main groove and a distance B from the groove bottom of the main groove 1 to the branch point 21 is 30 to 60% of the depth D of the main groove 1.

Owner:TOYO TIRE & RUBBER CO LTD

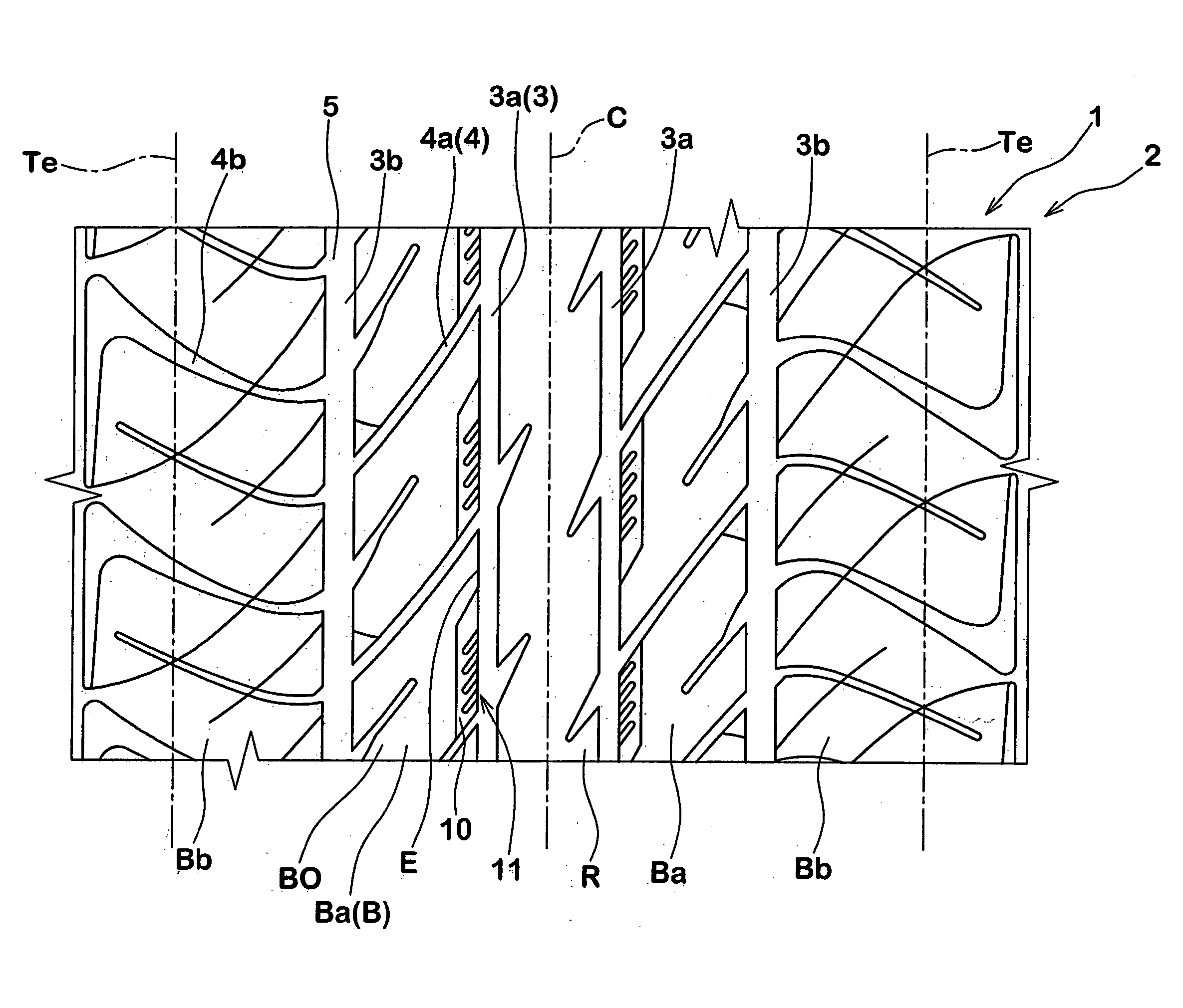

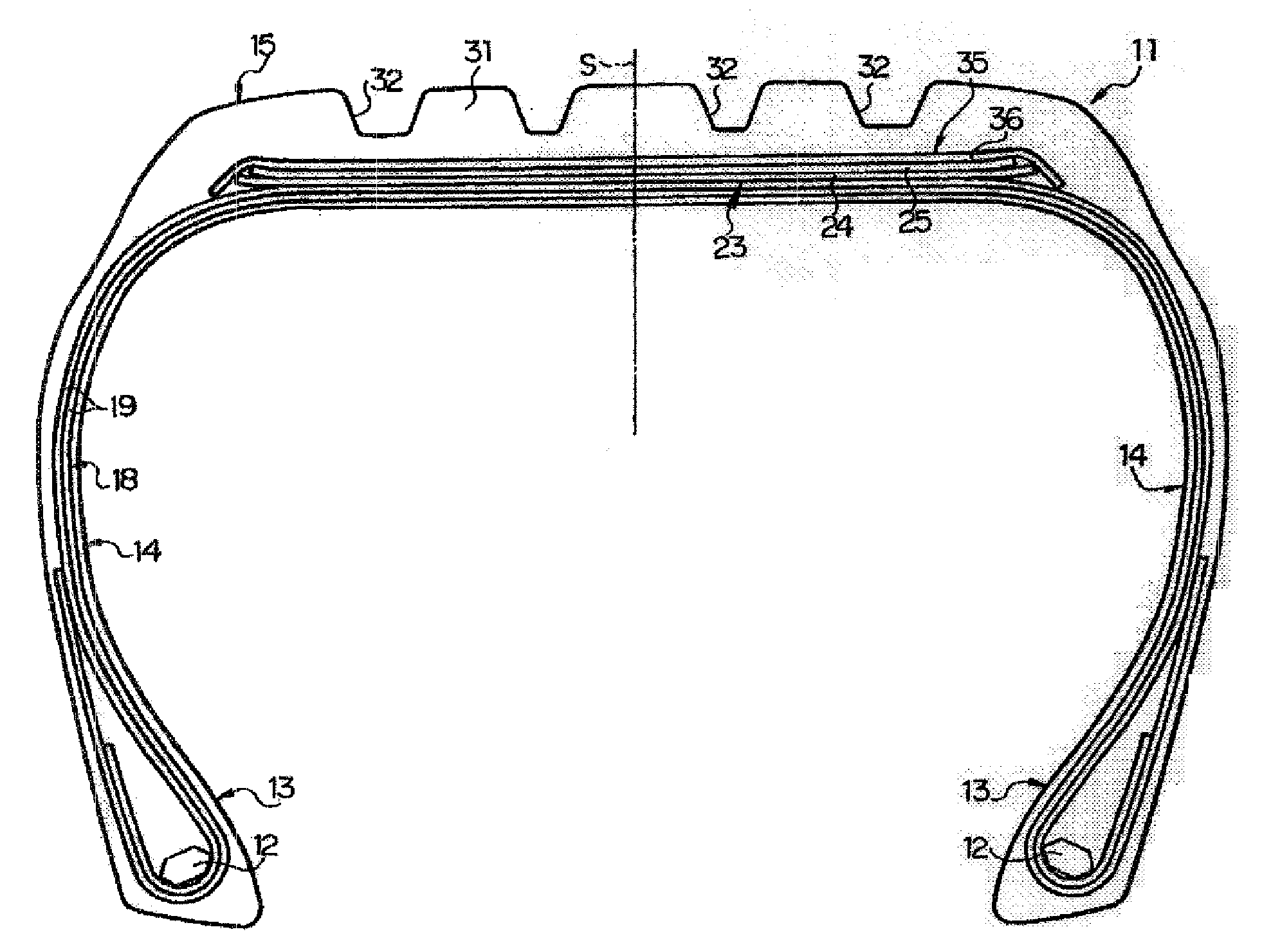

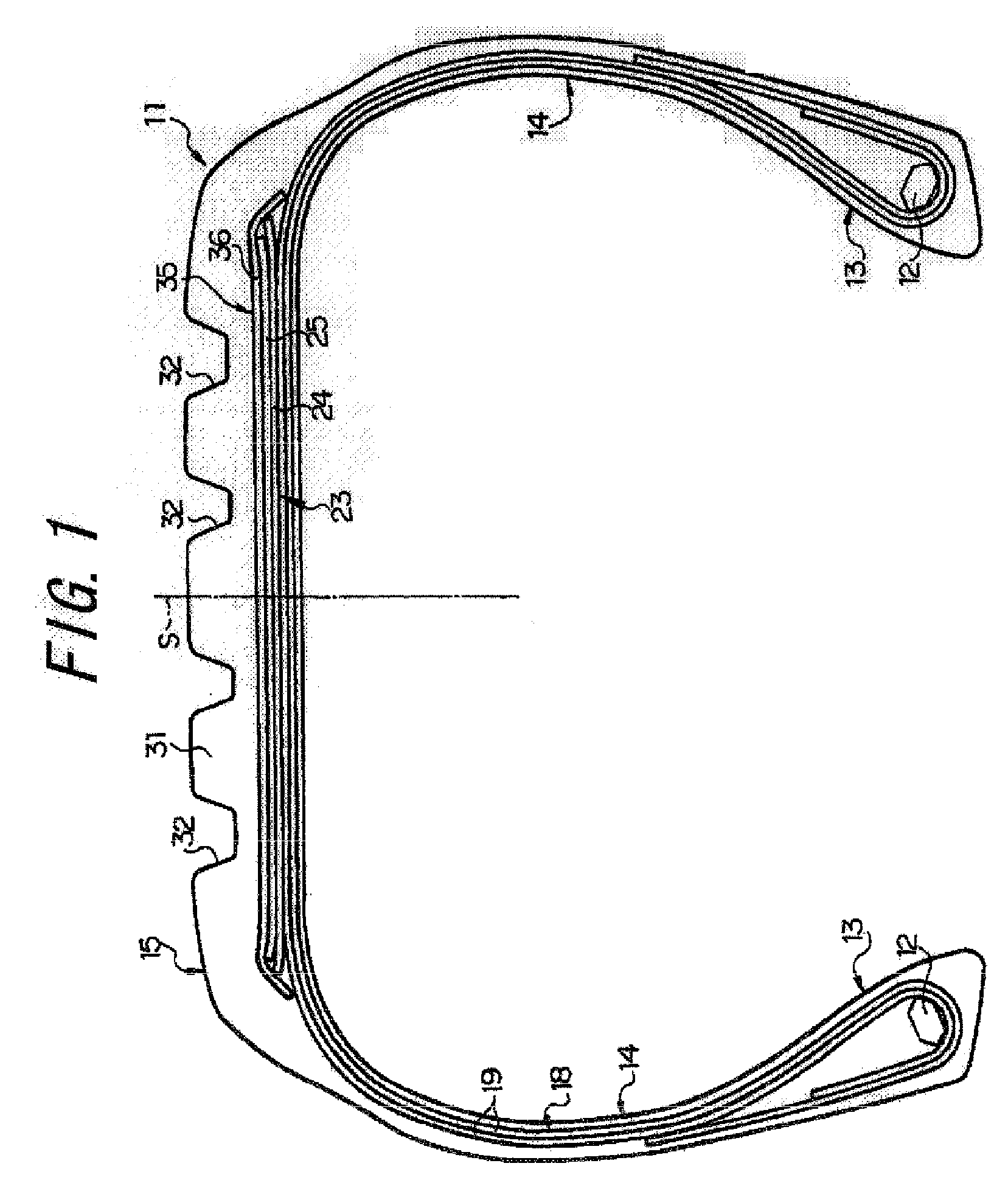

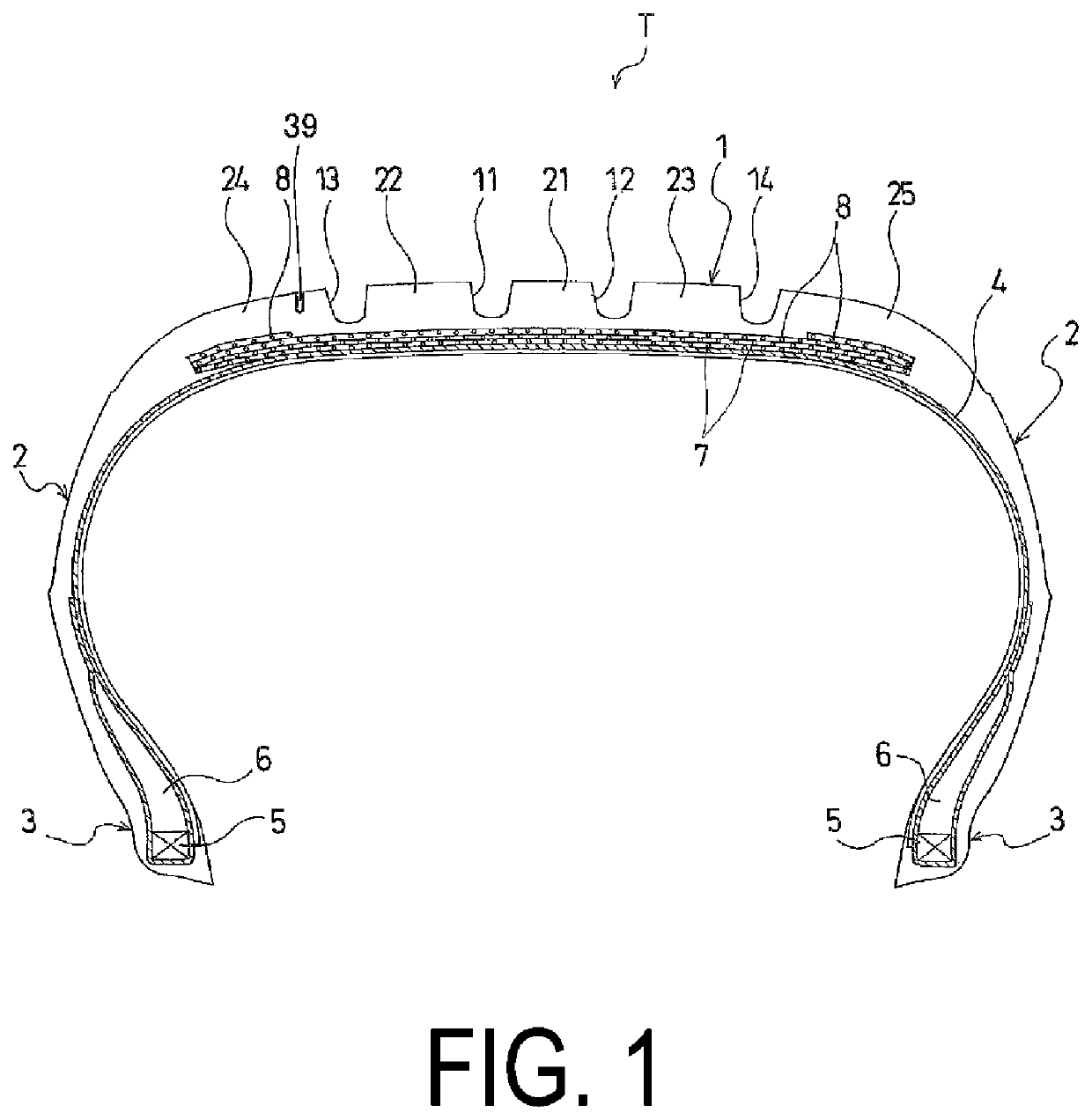

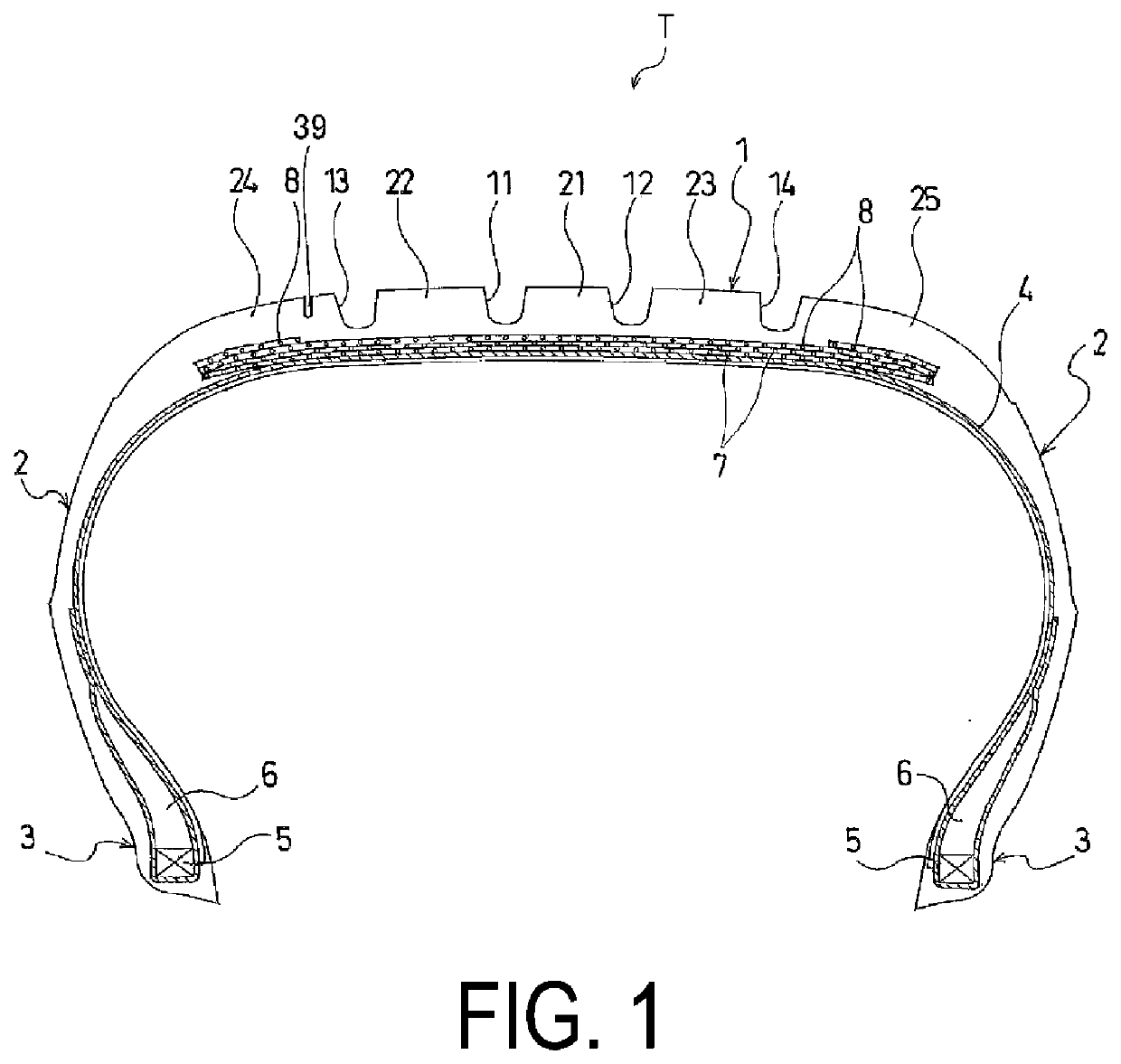

Pneumatic Tire

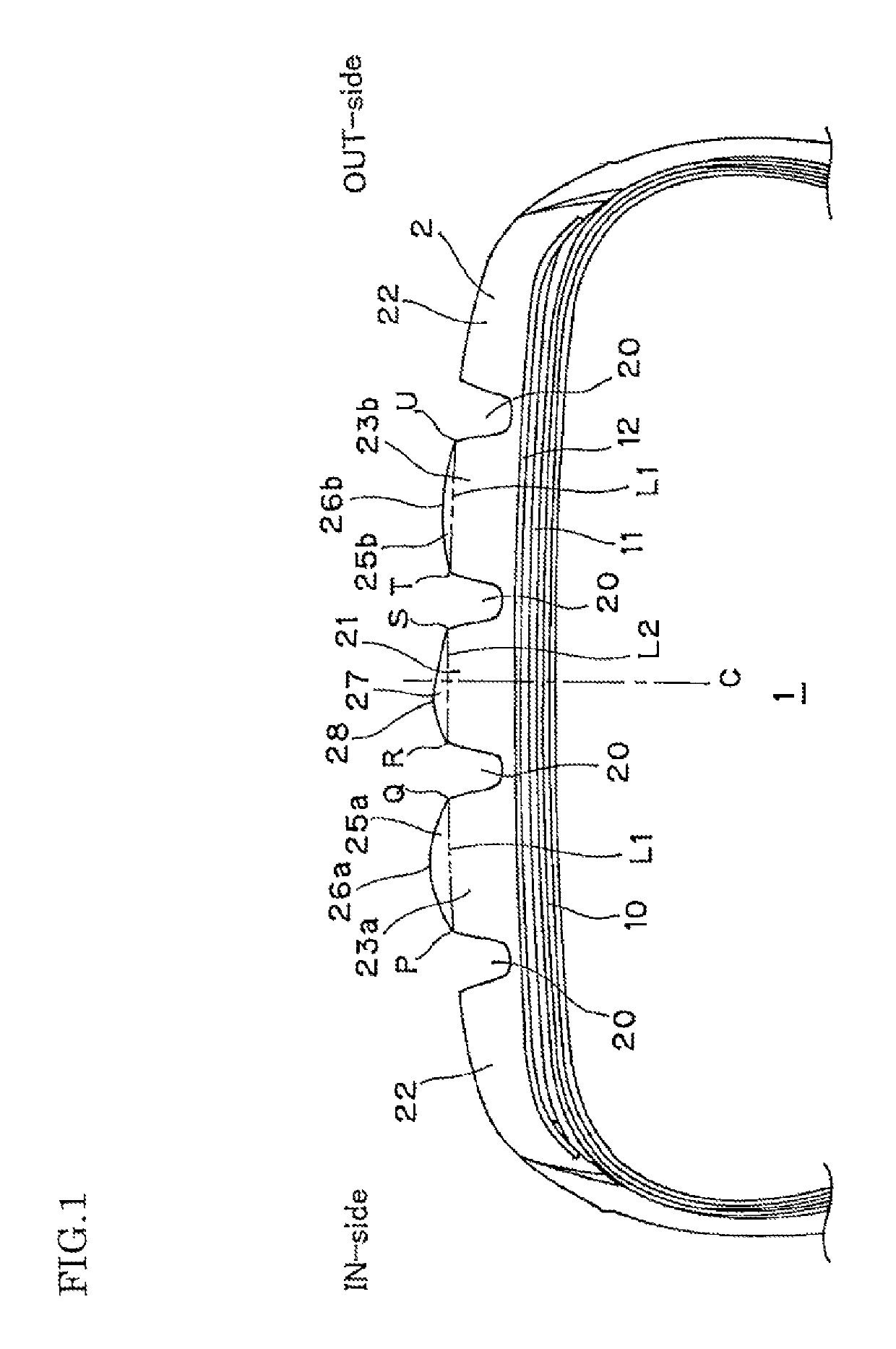

InactiveUS20090008017A1Increase ground contact areaImprove steering stabilityPneumatic tyre reinforcementsWheelsGround contactEngineering

There is provided a pneumatic tire in which a belt reinforcement layer is placed and capable of increasing both riding comfort and steering stability. Circumferential bending rigidity of a contact belt ply 25 placed in contact with the belt reinforcement layer 35 is made higher than circumferential bending rigidity of a remote belt ply 24, and thus the belt reinforcement layer 35 having high circumferential bending rigidity and the contact belt ply 25 having next high circumferential bending rigidity are collected near a neutral axis of bending positioned near a boundary thereof. Thus, composite circumferential bending rigidity of the belt layer 23 and the belt reinforcement layer 35 is reduced to reduce a vertical spring constant of the pneumatic tire 11 and increase a ground contact length.

Owner:BRIDGESTONE CORP

Luggage case

The invention discloses a luggage case. The luggage case comprises a case body, and except for normal luggage case wheels, a moving structure is added on the side surface of the case body to help the luggage case to achieve the vertical or horizontal motional functions, such as climbing stairs, so that manpower can be saved and the efficiency can be improved. The luggage case has the advantages of reasonable design, simpliness, easy implementation, high implementability, high efficiency, labor economization and the like.

Owner:广州市谷希欧皮具有限公司

Pneumatic tire

ActiveUS20120285594A1Sacrificing steering stabilityReduce stiffnessTyre tread bands/patternsNon-skid devicesEngineeringTread

Owner:SUMITOMO RUBBER IND LTD

Styrene-based polymer, styrene-based copolymer, rubber composition and pneumatic tire

InactiveUS20090171029A1High molecular weightImprove steering stabilitySpecial tyresPolymer sciencePolystyrene

This invention relates to a styrene-based (co)polymer capable of improving tan δ of a rubber composition while ensuring a fracture resistance of the rubber composition by adding to the rubber composition, and more particularly to a styrene-based polymer obtained by homopolymerizing a styrene derivative and having a weight average molecular weight as converted to polystyrene of 2×103 to 50×103, and a styrene-based copolymer obtained by copolymerizing styrene and at least one of styrene derivatives and having a weight average molecular weight as converted to polystyrene of 2×103 to 50×103.

Owner:BRIDGESTONE CORP

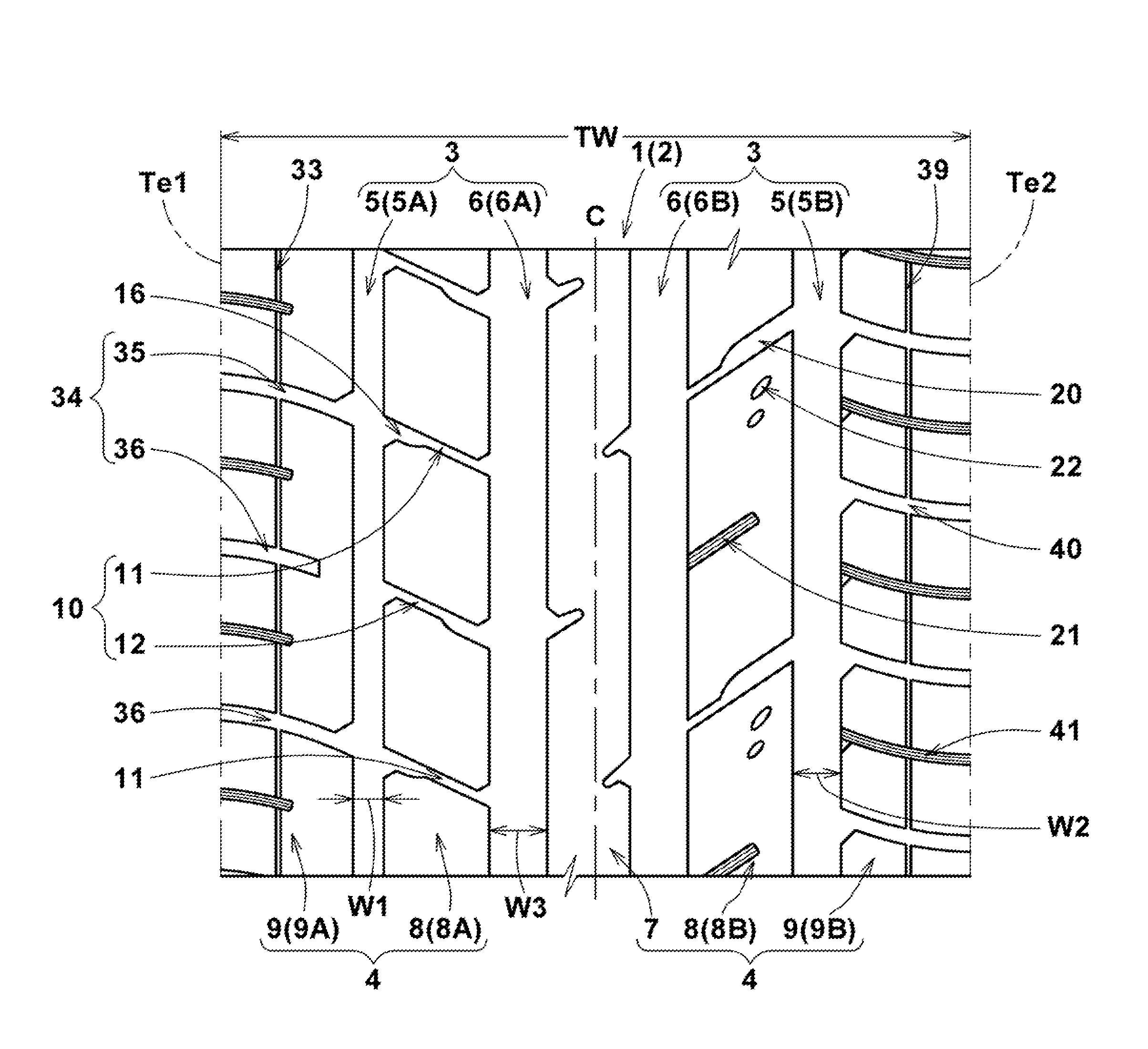

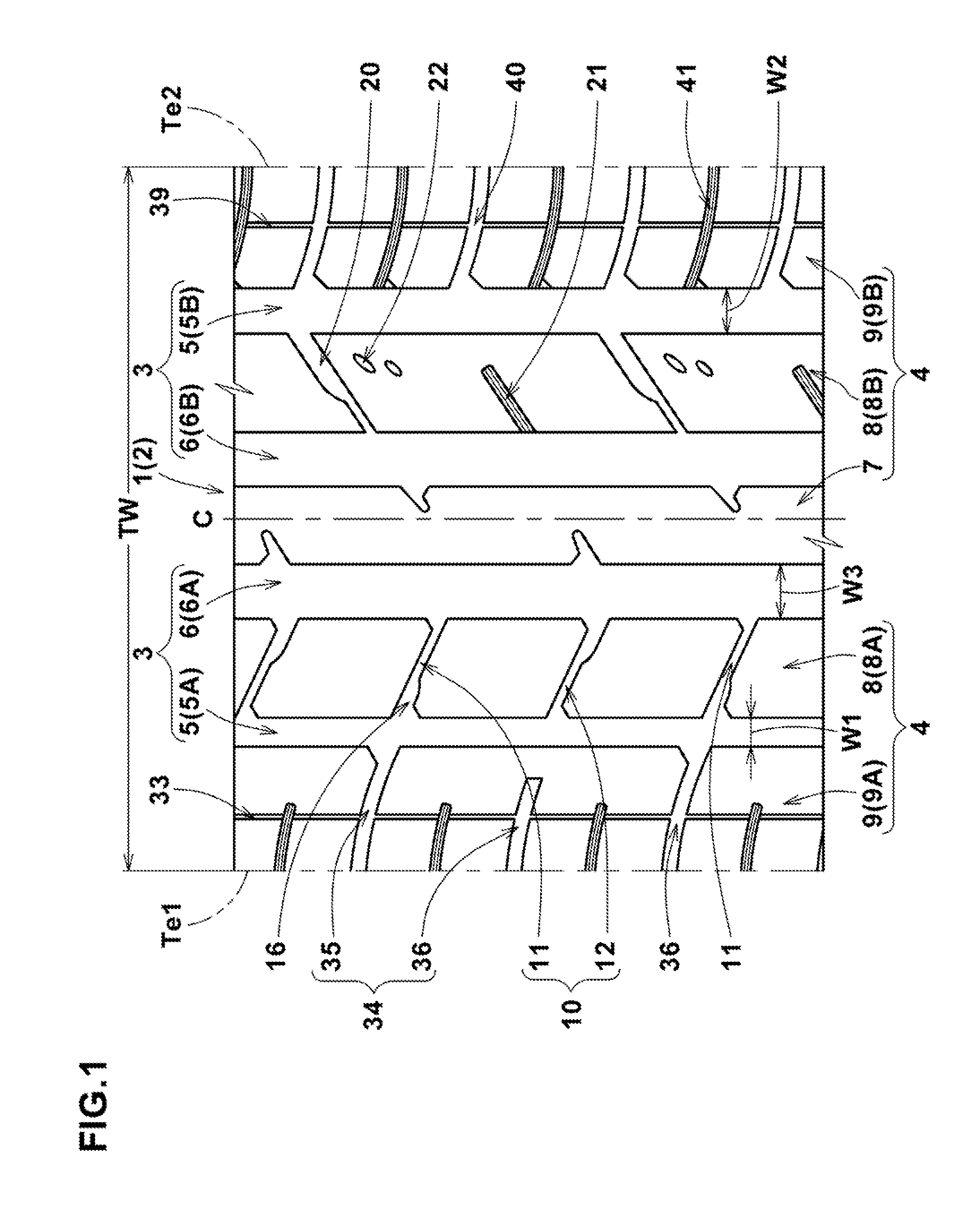

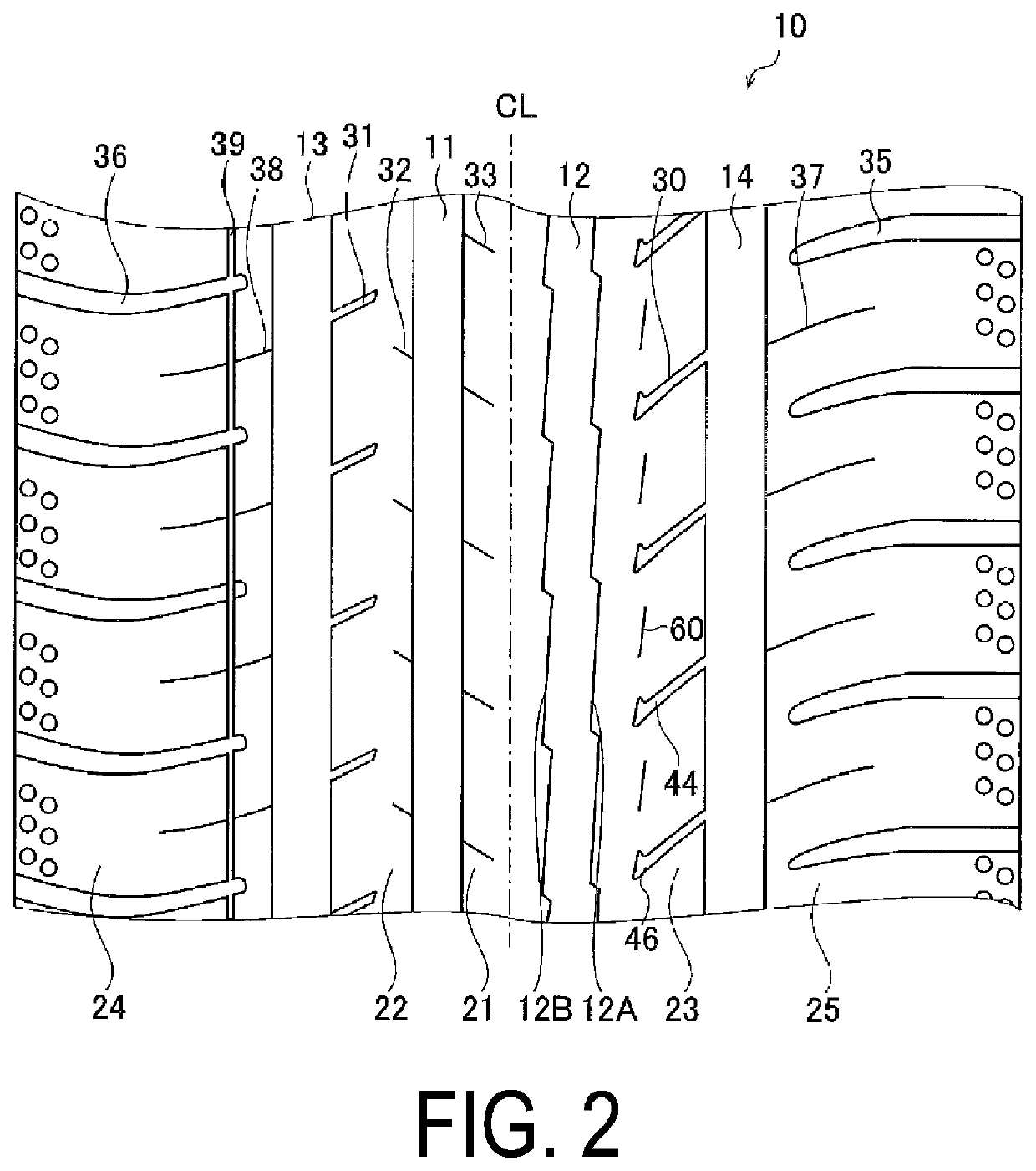

Pneumatic Tire

ActiveUS20200384810A1Improve performancePattern noise can be suppressedTyre tread bands/patternsEngineeringStructural engineering

A tread pattern of a pneumatic tire includes continuous lands provided in half treads on first and second sides, circumferential main grooves, and sipes having a chamfered configuration. The sipes extend inward in a lateral direction from the circumferential main grooves and are closed in the middle of regions of the continuous lands. An edge shape of each of sipes on the first side includes an extending portion extending inward in the lateral direction constantly in an extension direction and a bent portion that is provided to be joined to an end of the first extending portion and that has the edge shape bent from the extension direction of the first extending portion to a direction close to the circumferential direction. Every portion of the first extending portion and the bent portion of the sipes are provided with a main body portion and a sipe chamfered portion.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveUS10427467B2Steering stabilitySolve the small densityTyre tread bands/patternsAutomotive engineering

Owner:TOYO TIRE & RUBBER CO LTD

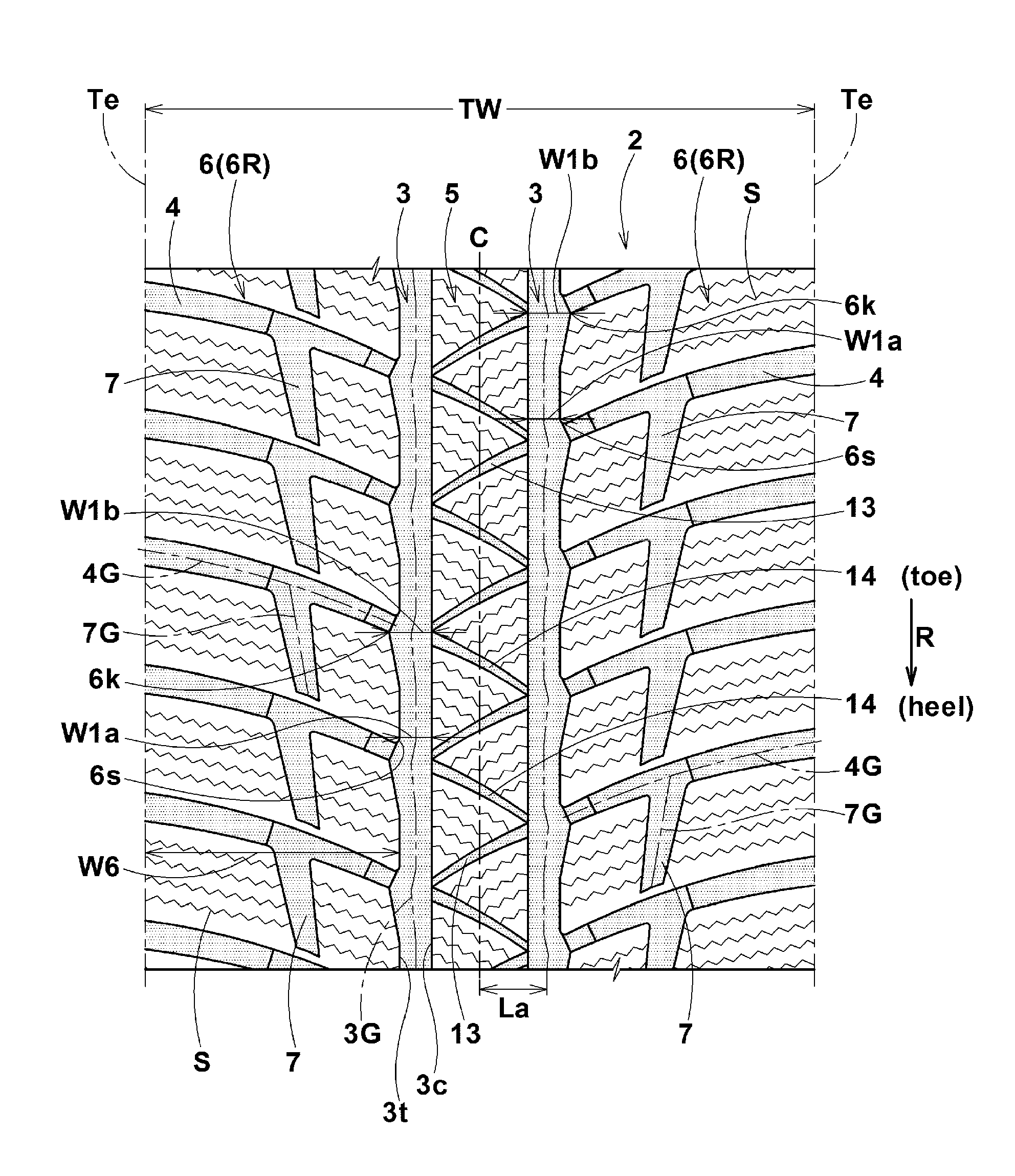

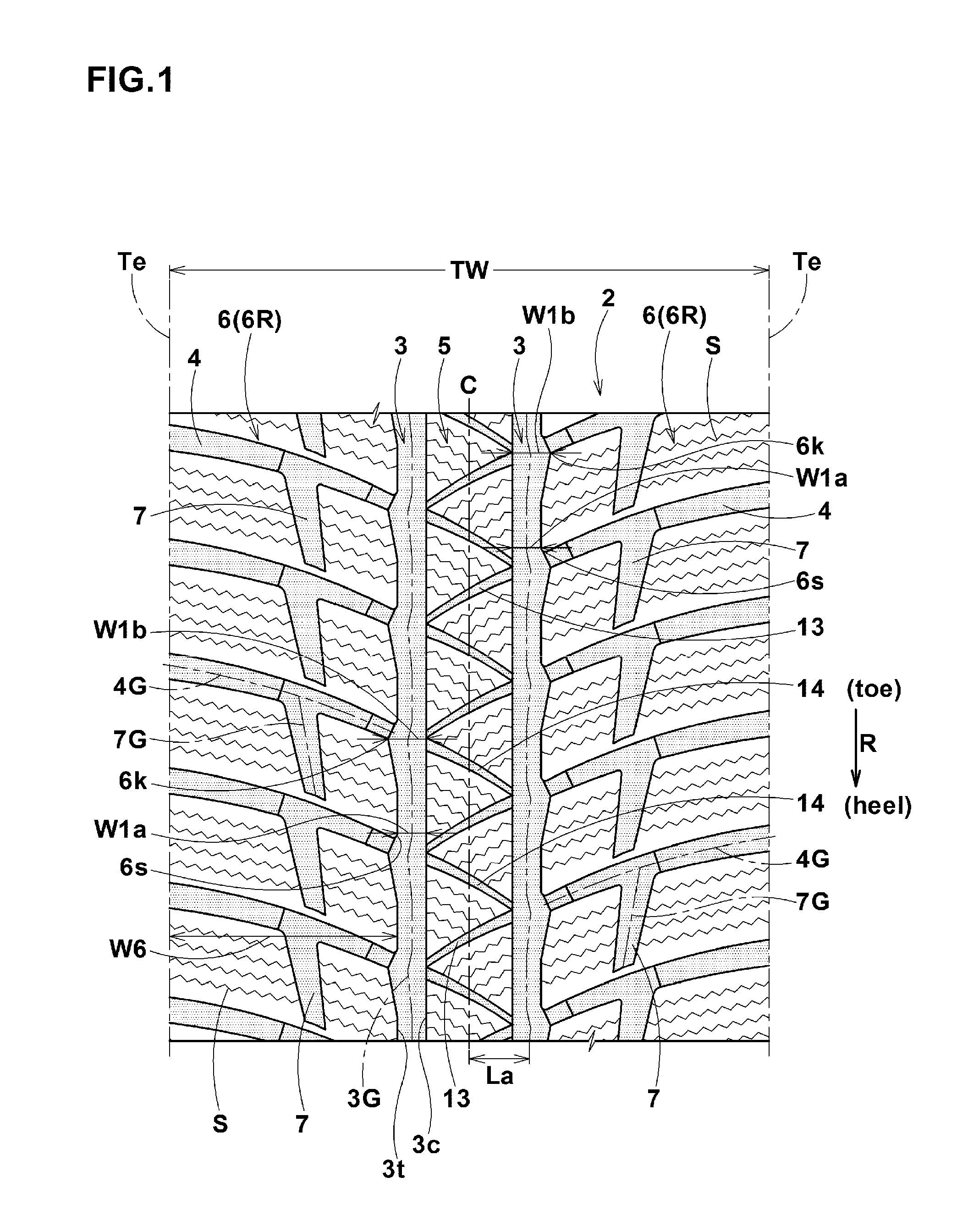

Tire

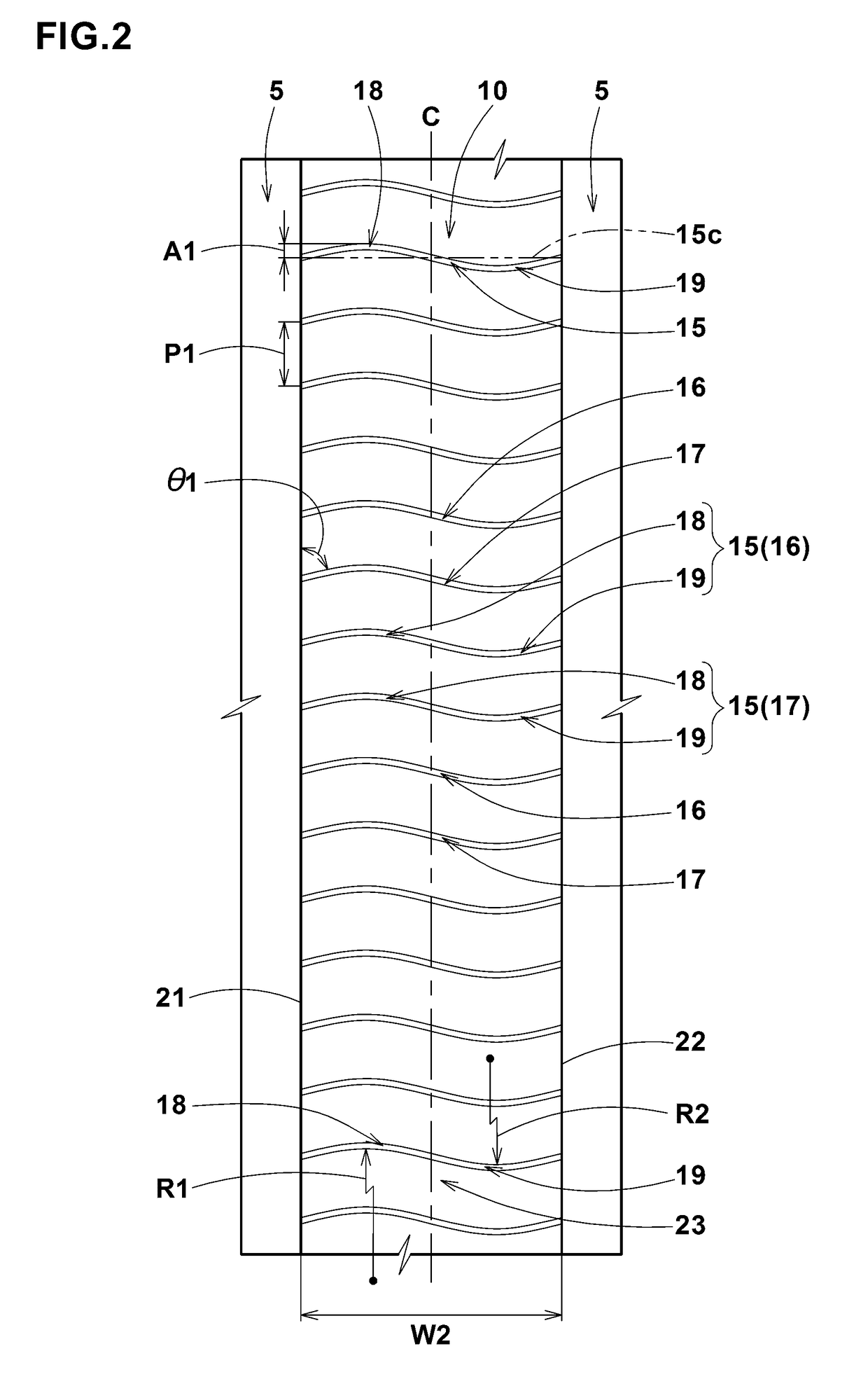

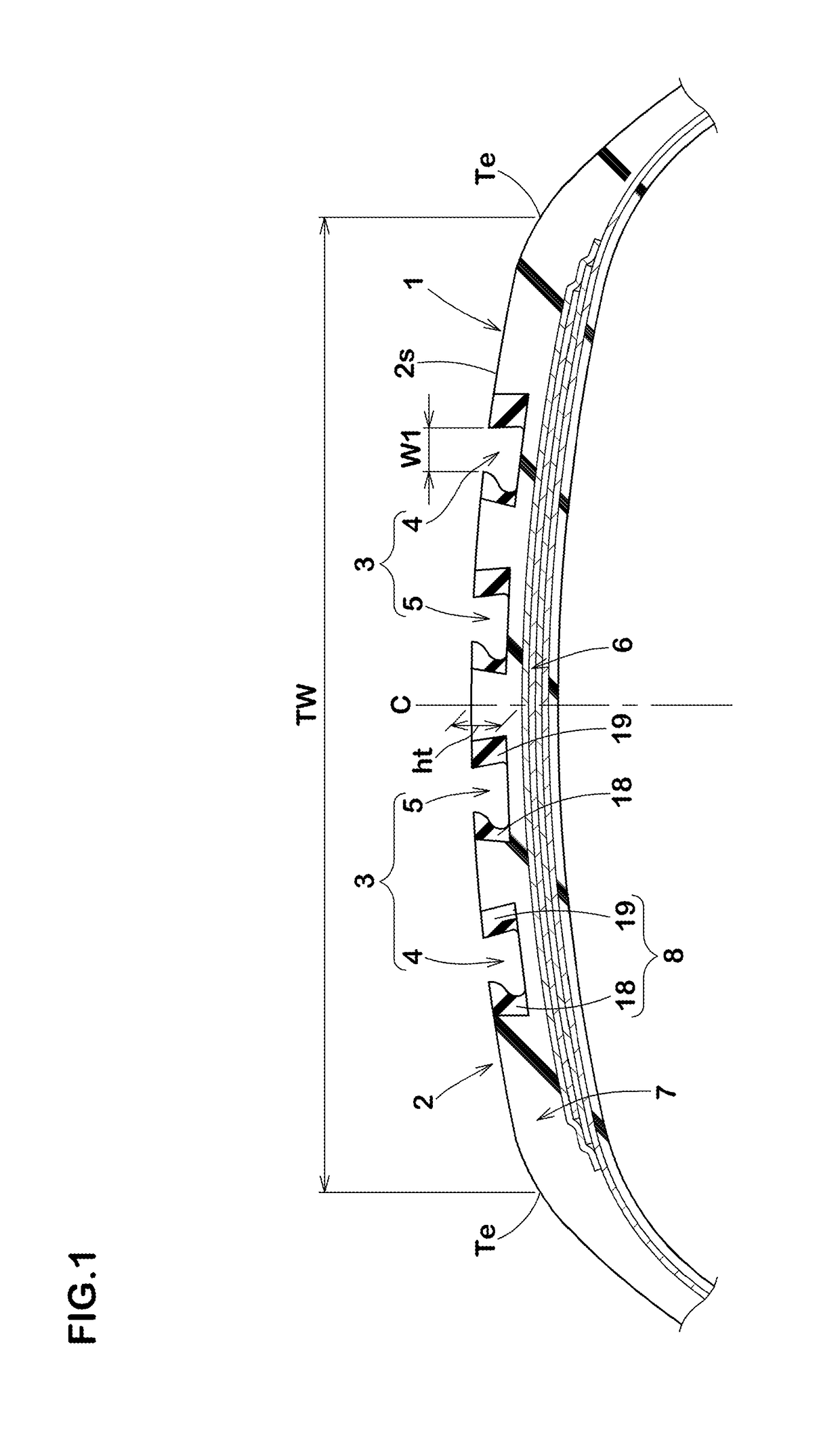

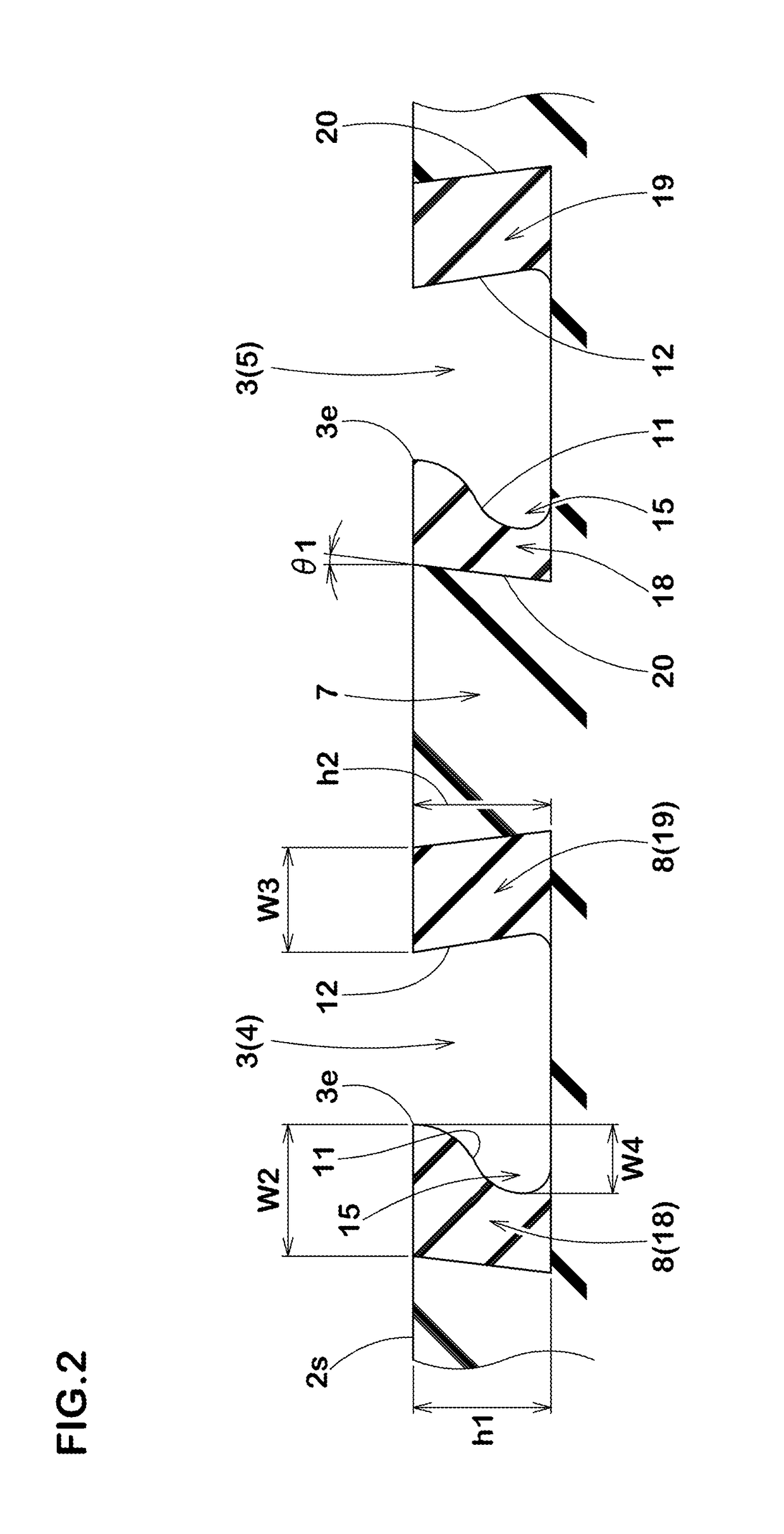

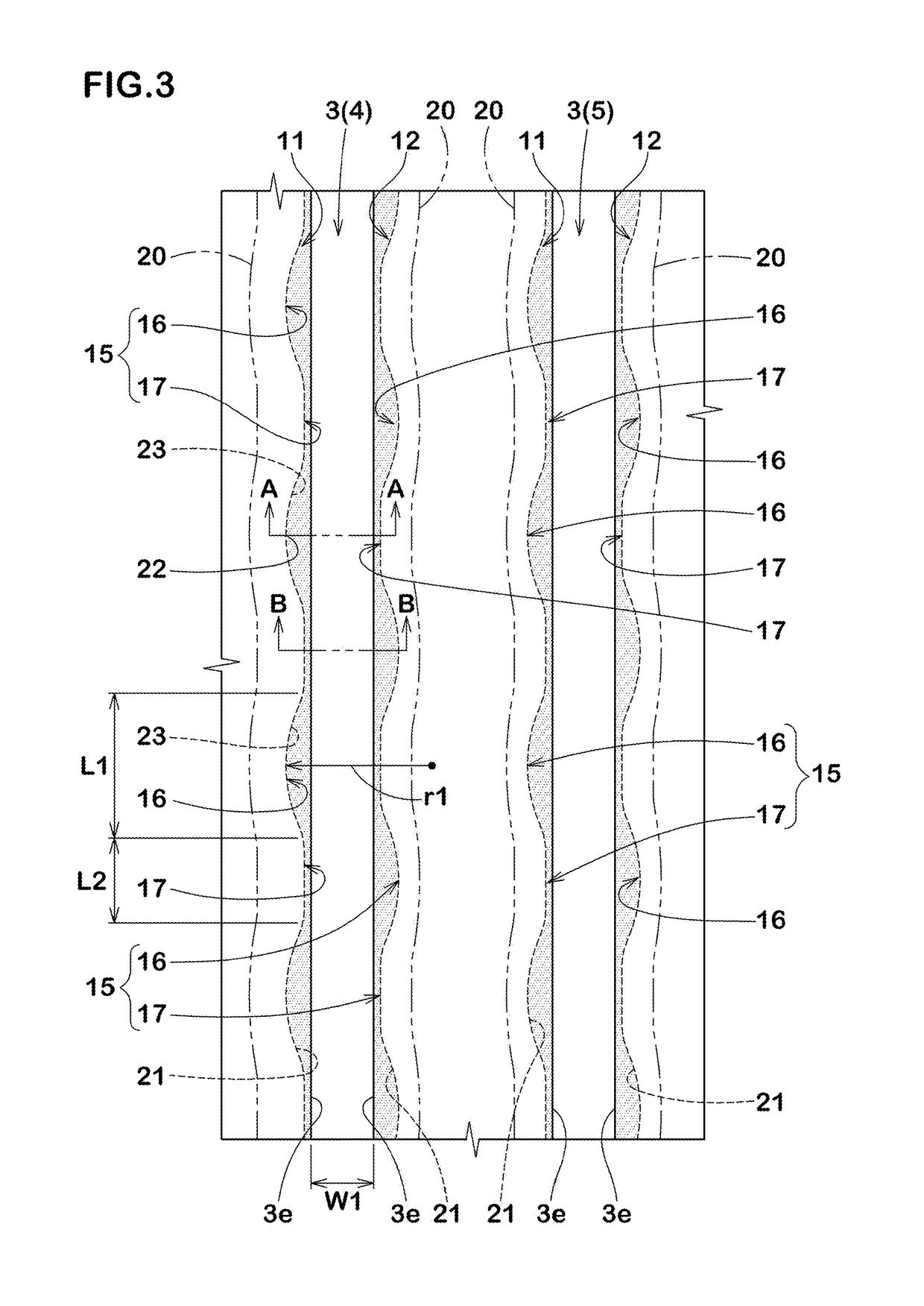

ActiveUS20190061435A1Improve wetting performanceSteering stabilityHeavy duty tyresHeavy duty vehicleGround contactGroove width

A tire comprises a tread portion 2. The tread portion 2 includes a tread ground contacting surface (2s) and at least one main groove 3 recessed from the tread ground contacting surface (2s) and extending continuously in a tire circumferential direction. The main groove 3 has a first groove wall 11. The first groove wall is provided with a recessed portion 15 recessed outwardly in a groove width direction from a groove edge of the main groove 3 on the tread ground contacting surface. The recessed portion 15 is formed of groove wall rubber 8 having a complex elastic modulus larger than that of base rubber 7 forming a main portion of the tread ground contacting surface (2s).

Owner:SUMITOMO RUBBER IND LTD

Pneumatic Tire

ActiveUS20200282776A1Improve steering stabilityImprove performanceTyre tread bands/patternsEngineeringStructural engineering

A tread pattern of a pneumatic tire includes one center continuous land portion and two intermediate continuous land portions that are divided by four circumferential main grooves and that are not provided with lug grooves. Edges on both sides of one center main groove include groove chamfered portions having a chamfered width changing in the circumferential direction in a zigzag shape. In the regions of the intermediate continuous land portions, first sipes extending inward in the lateral direction from shoulder main grooves of the main grooves, which are positioned on outer sides in the lateral direction, are provided. The first sipes each include a sipe main body portion having a constant distance between sipe wall surfaces on a sipe bottom side and a sipe chamfered portion inclined so that the sipe wall surfaces are open toward the tread surface.

Owner:THE YOKOHAMA RUBBER CO LTD

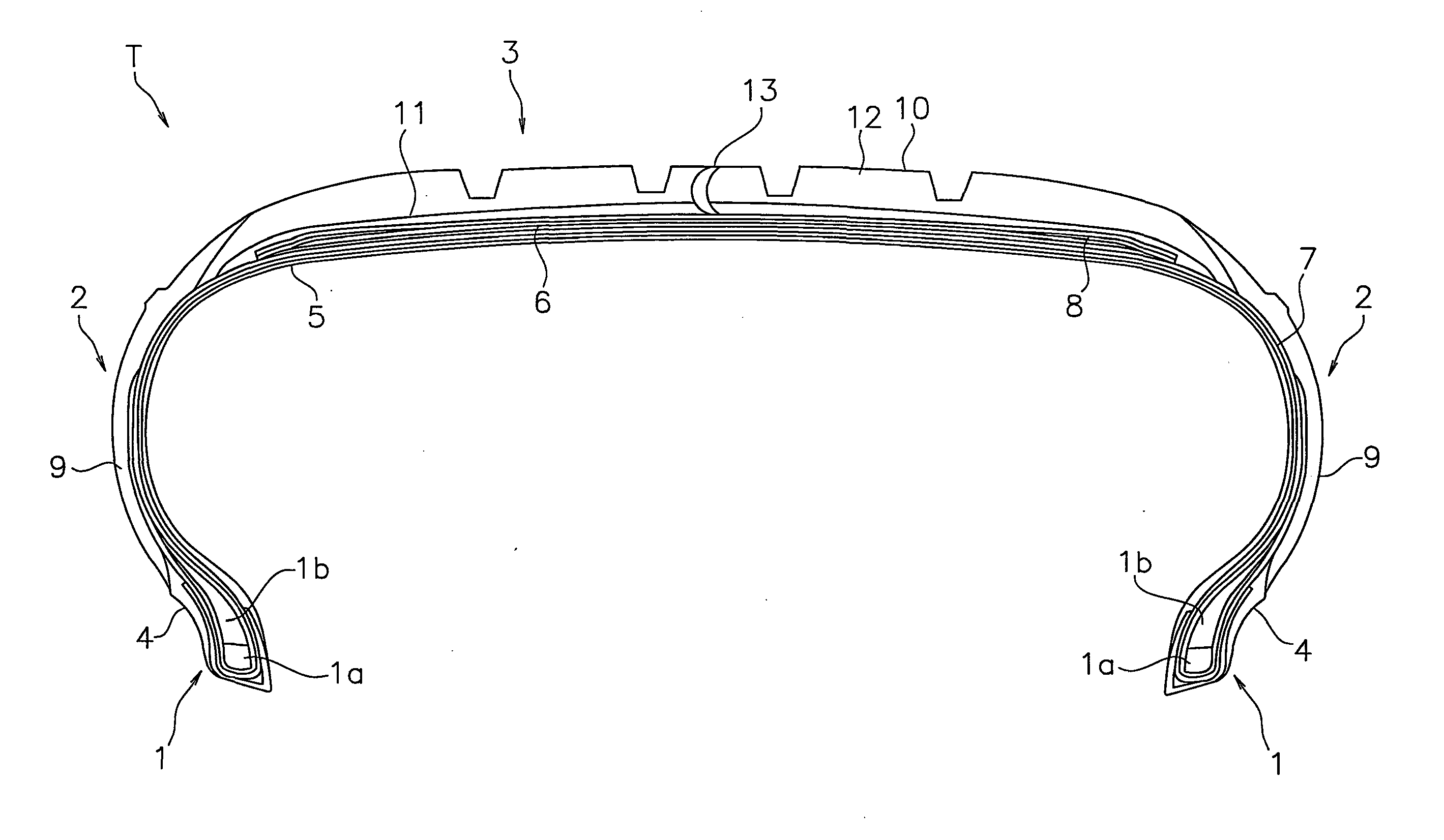

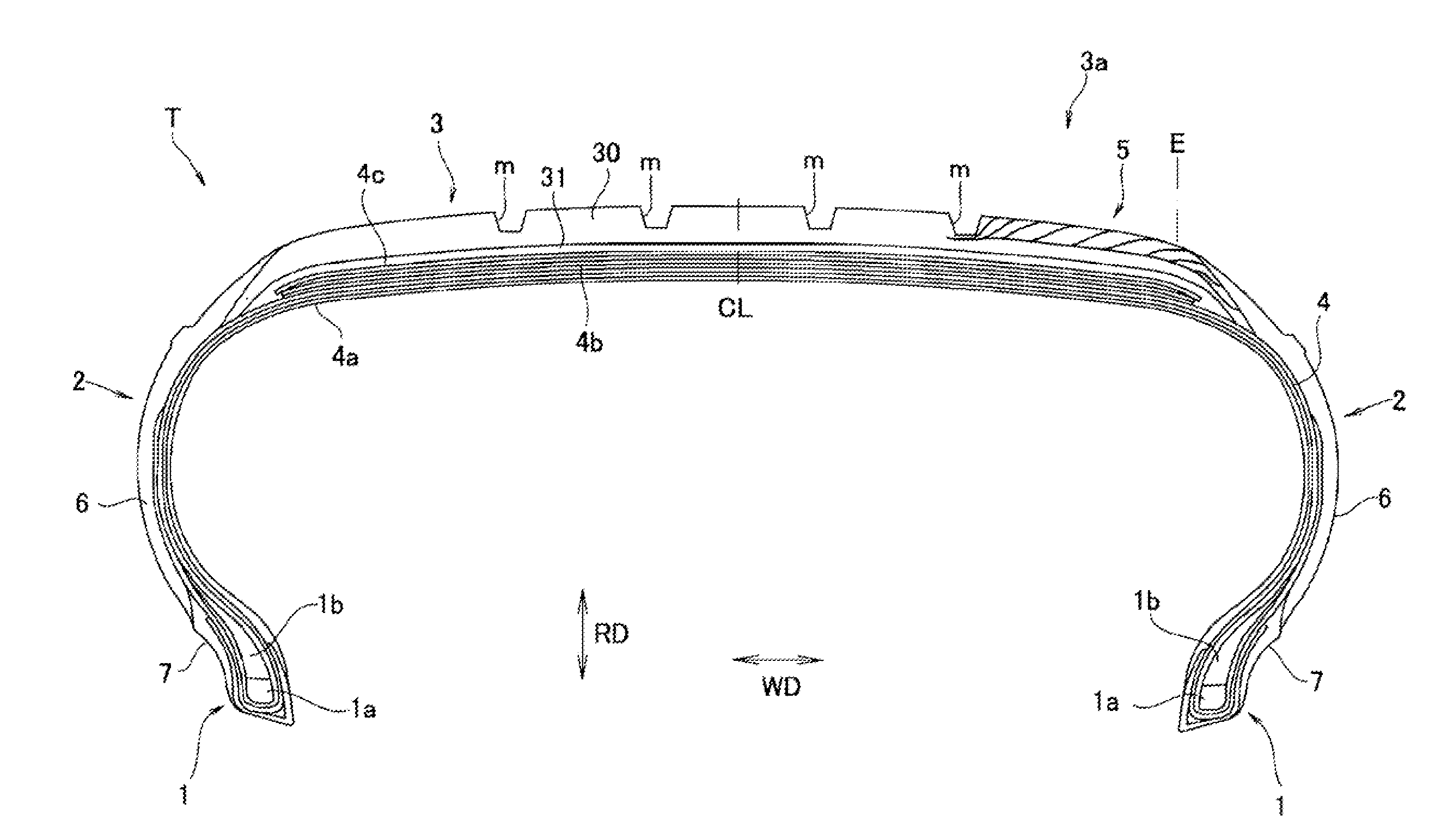

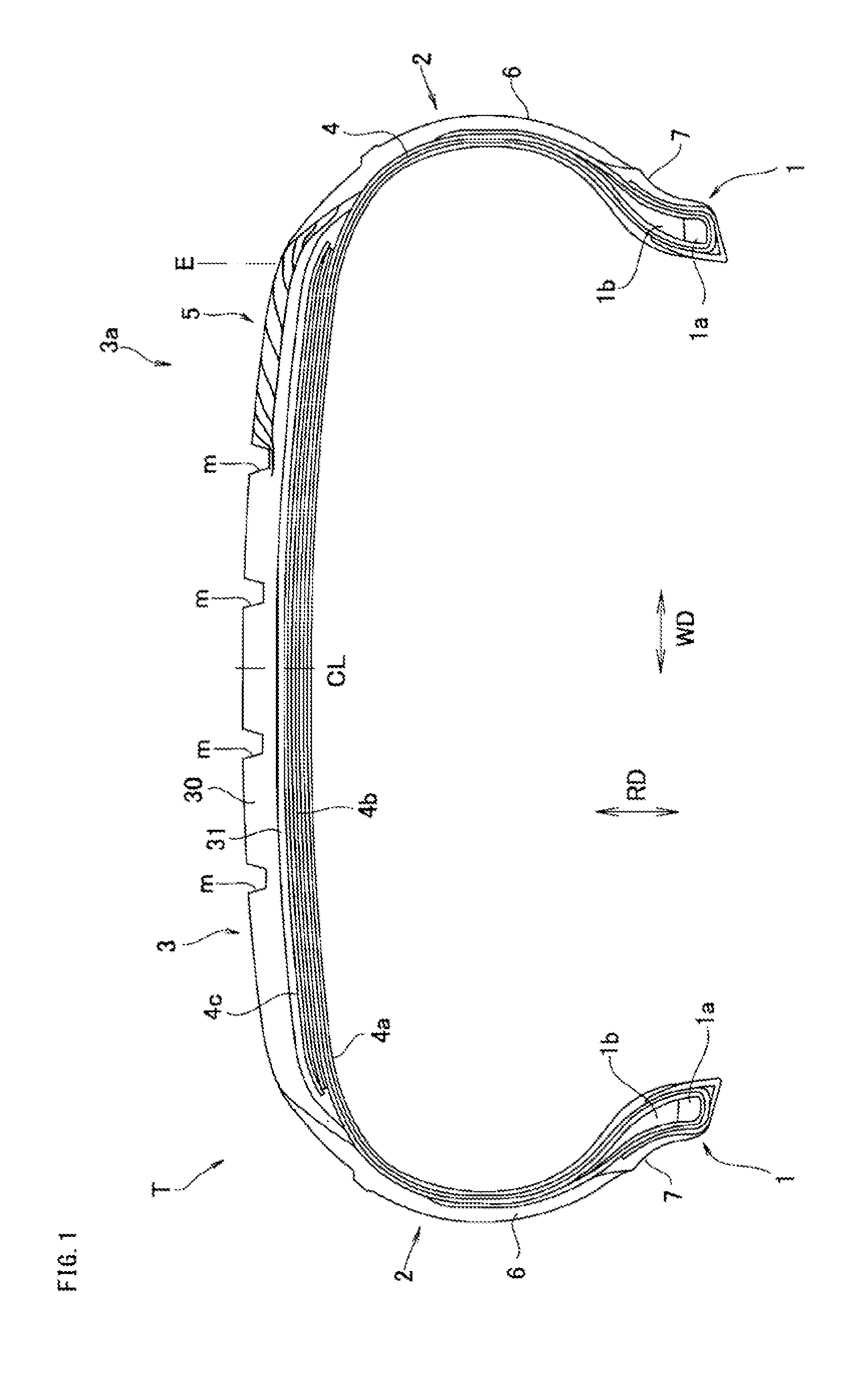

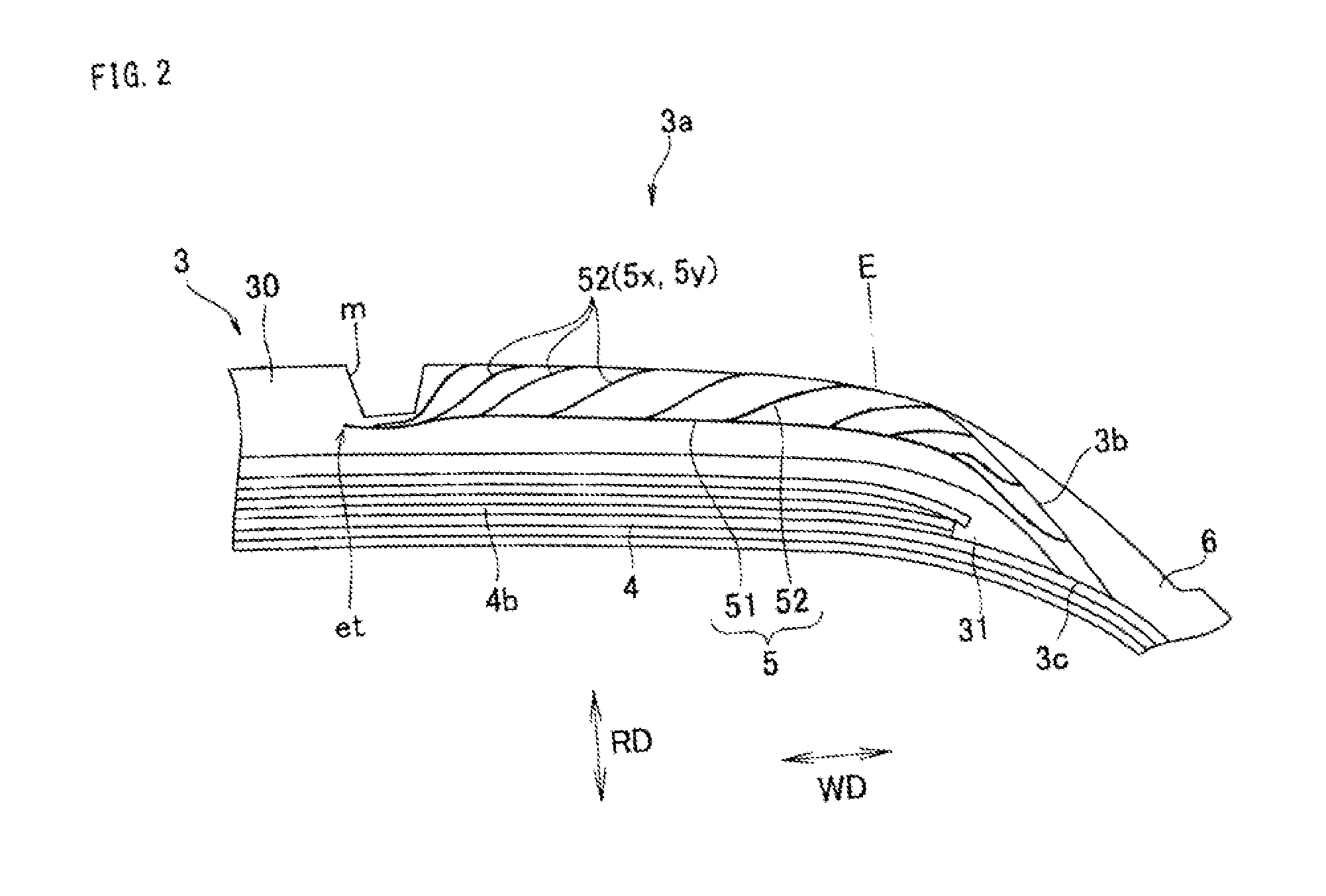

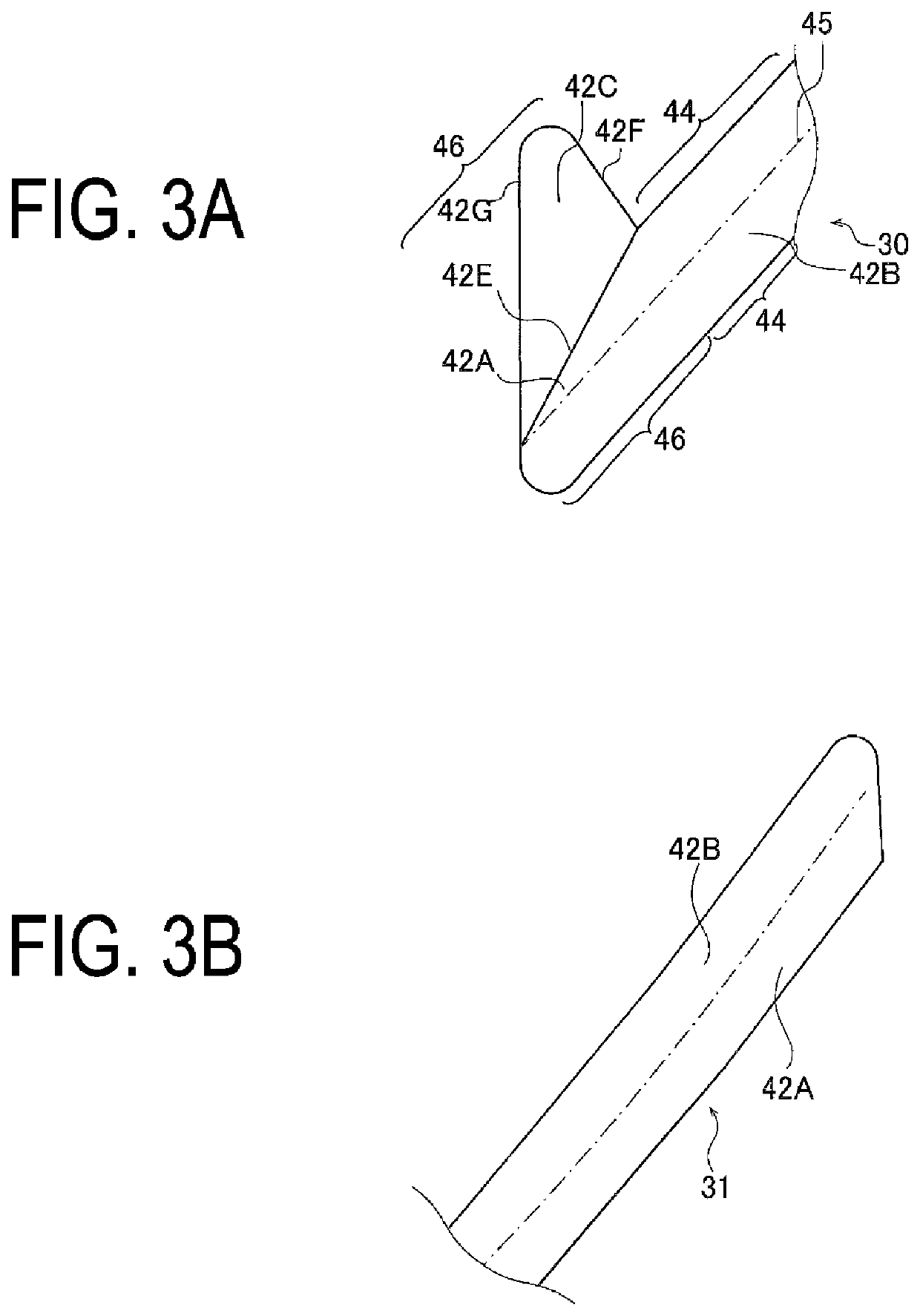

Pneumatic tire for a motorcycle

ActiveUS20180126788A1Increased durabilityImprove steering stabilityPneumatic tyre reinforcementsMotorcycle tyresGround contactEngineering

A pneumatic tire for a motorcycle includes a tread reinforcing cord layer and a tread rubber. The tread rubber includes a base rubber layer and a pair of shoulder rubber layers. The base rubber layer includes a cover portion covering at least the tread reinforcing cord layer over an entire width thereof and a convex portion protruding radially outwardly from the cover portion to form a crown ground contacting surface. The shoulder rubber layers are arranged radially outside the cover portion to form shoulder ground contacting surfaces. The base rubber layer is made of a first rubber composition having larger hardness than the shoulder rubber layers, and the shoulder rubber layers are made of a second rubber composition containing larger amount of oil component than the base rubber layer.

Owner:SUMITOMO RUBBER IND LTD

Shock absorber

ActiveUS20150159726A1Ensuring steering stabilitySteering stabilitySpringsShock absorbersSmall amplitudeEngineering

In a high-frequency mode (a small-amplitude mode), a shock absorber opens a guide member to reduce a damping force. In a low-frequency mode (a large-amplitude mode), the shock absorber prevents the guide member from being opened by increasing a pressure of a second pressure chamber formed between a second piston (lower piston) and a pilot valve through a groove (passage) formed in an outer periphery of a piston rod. A main damping force is generated through the second pressure chamber and a disk valve assembly. Therefore, it is possible to provide a round ride comfort having a damping feeling and ensure a steering stability through a linear vehicle control.

Owner:HL MANDO CORP

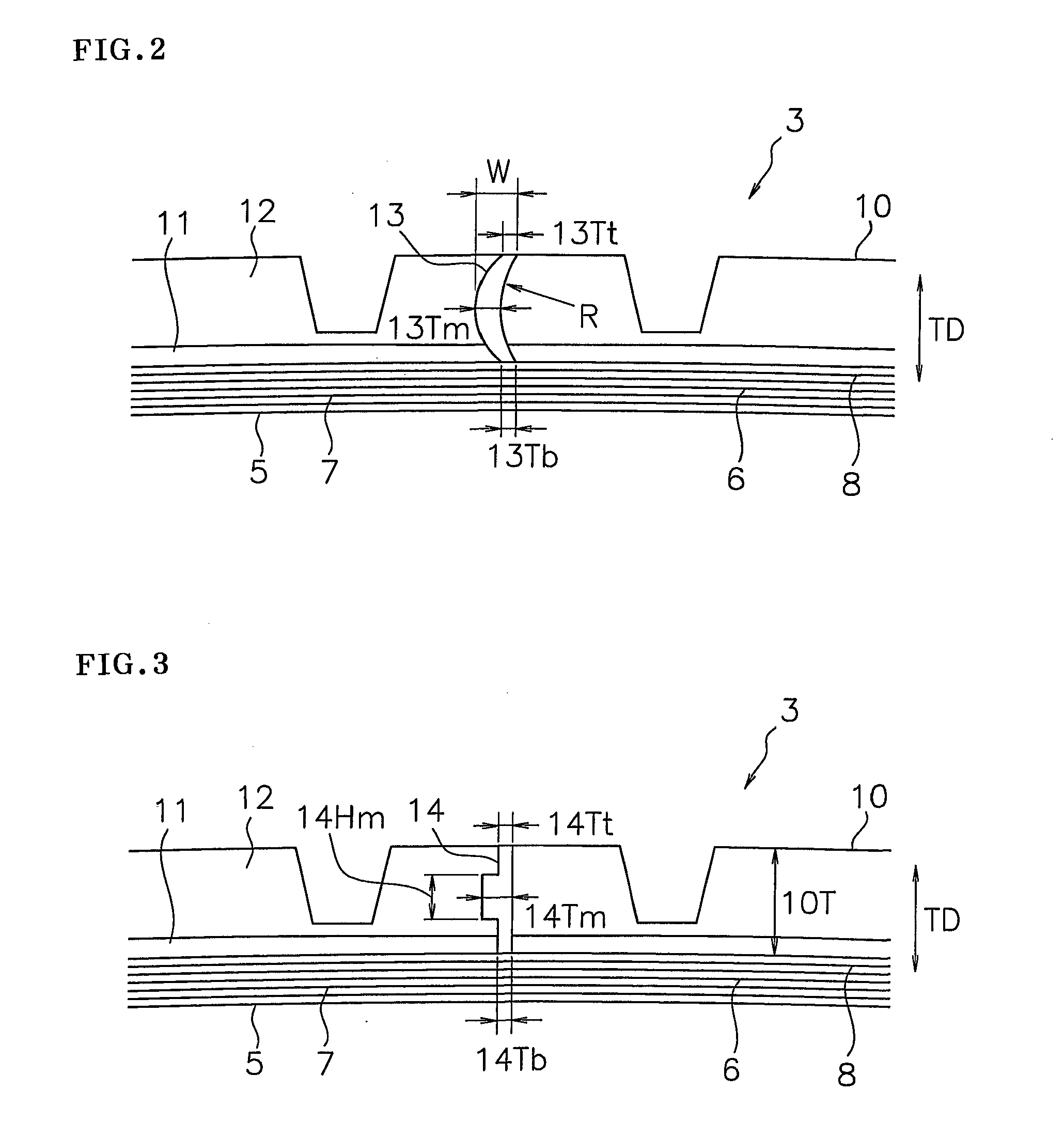

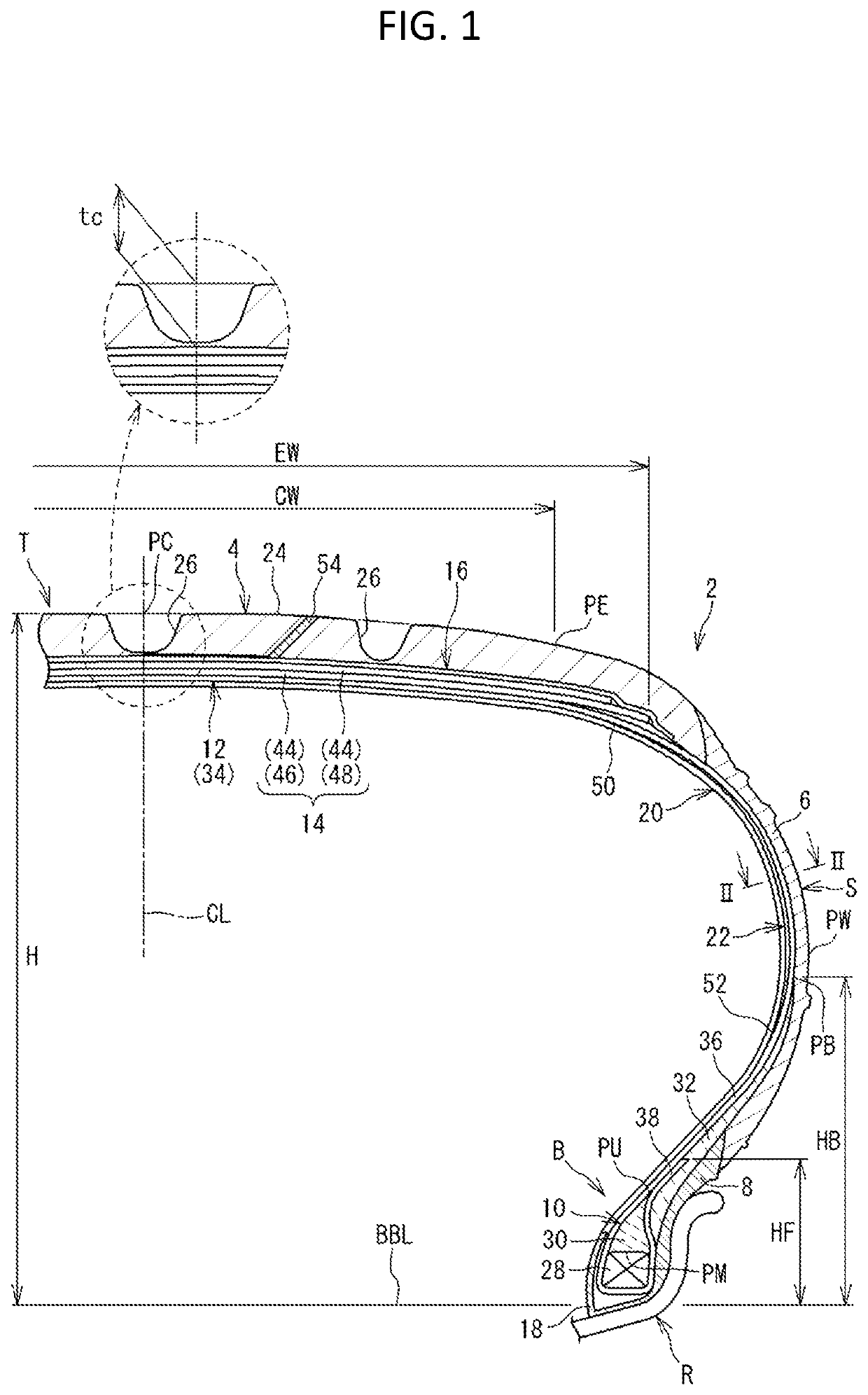

Tire

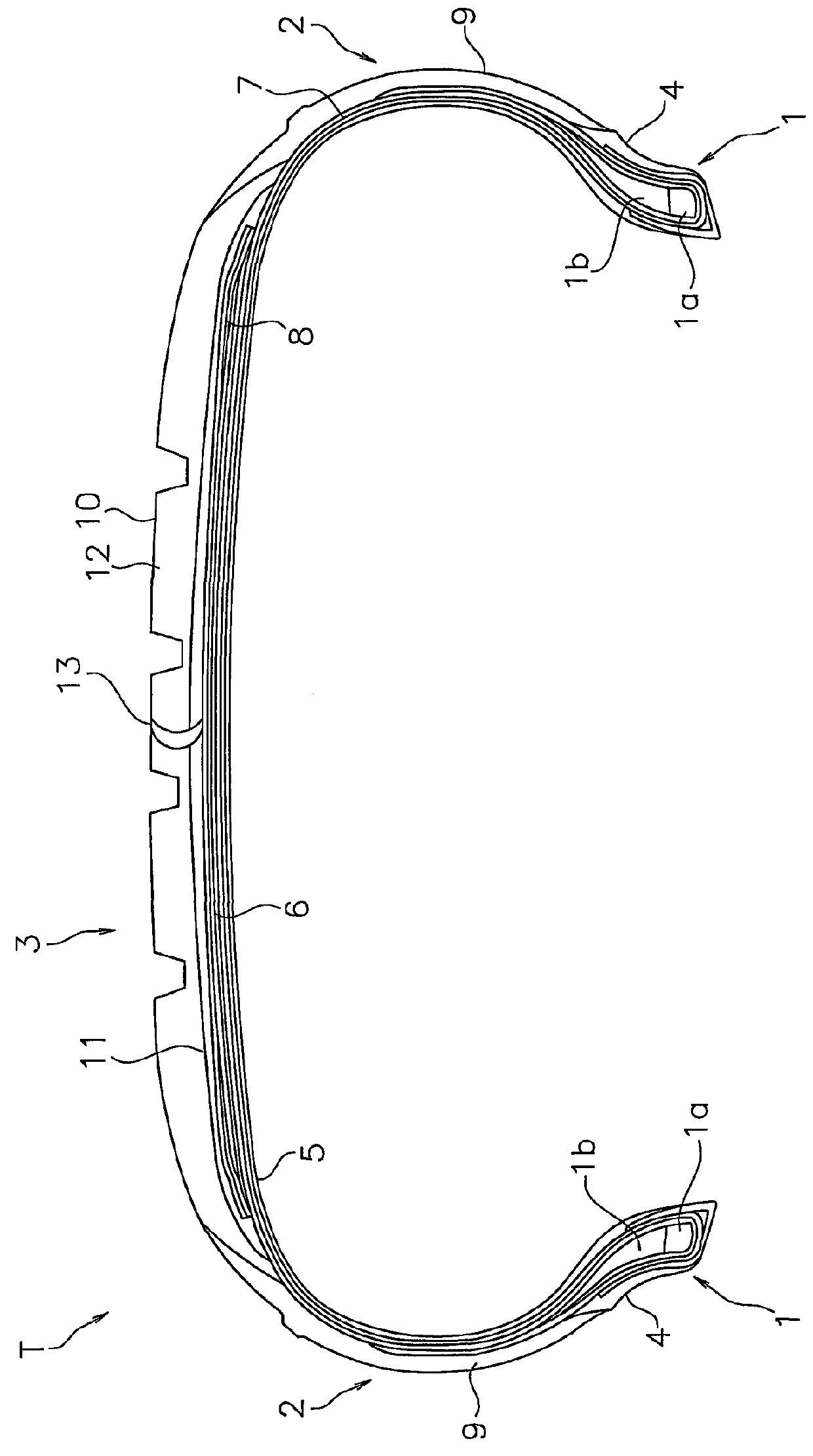

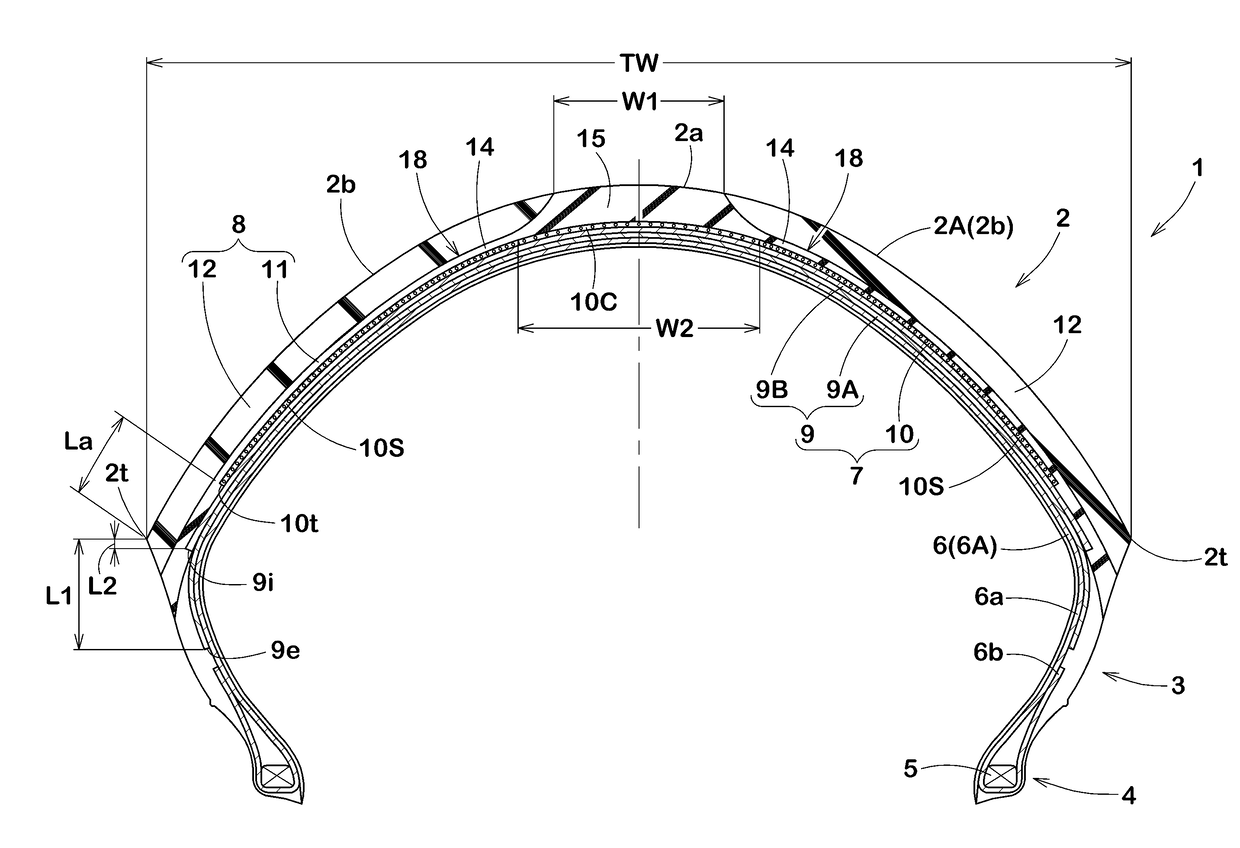

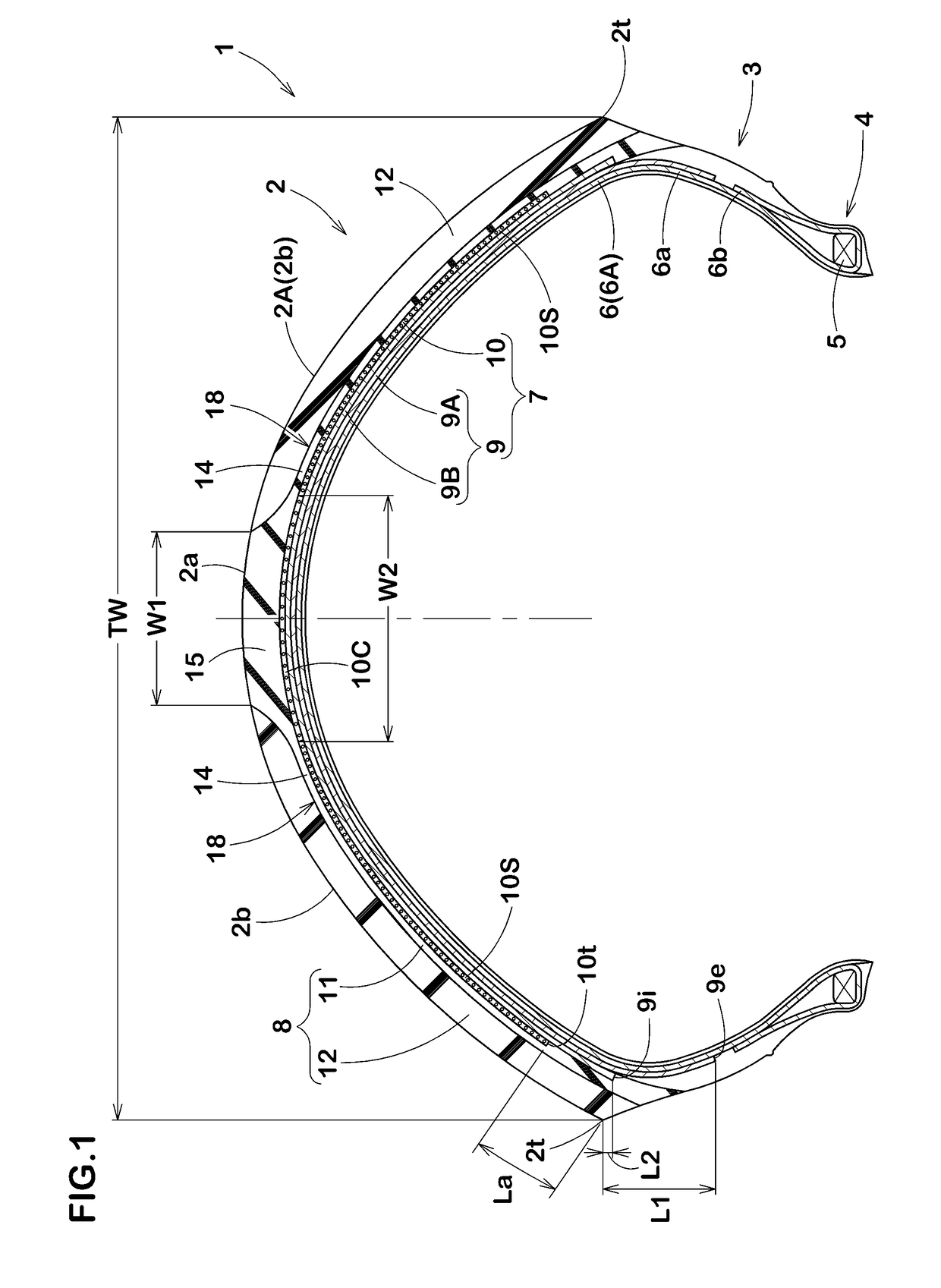

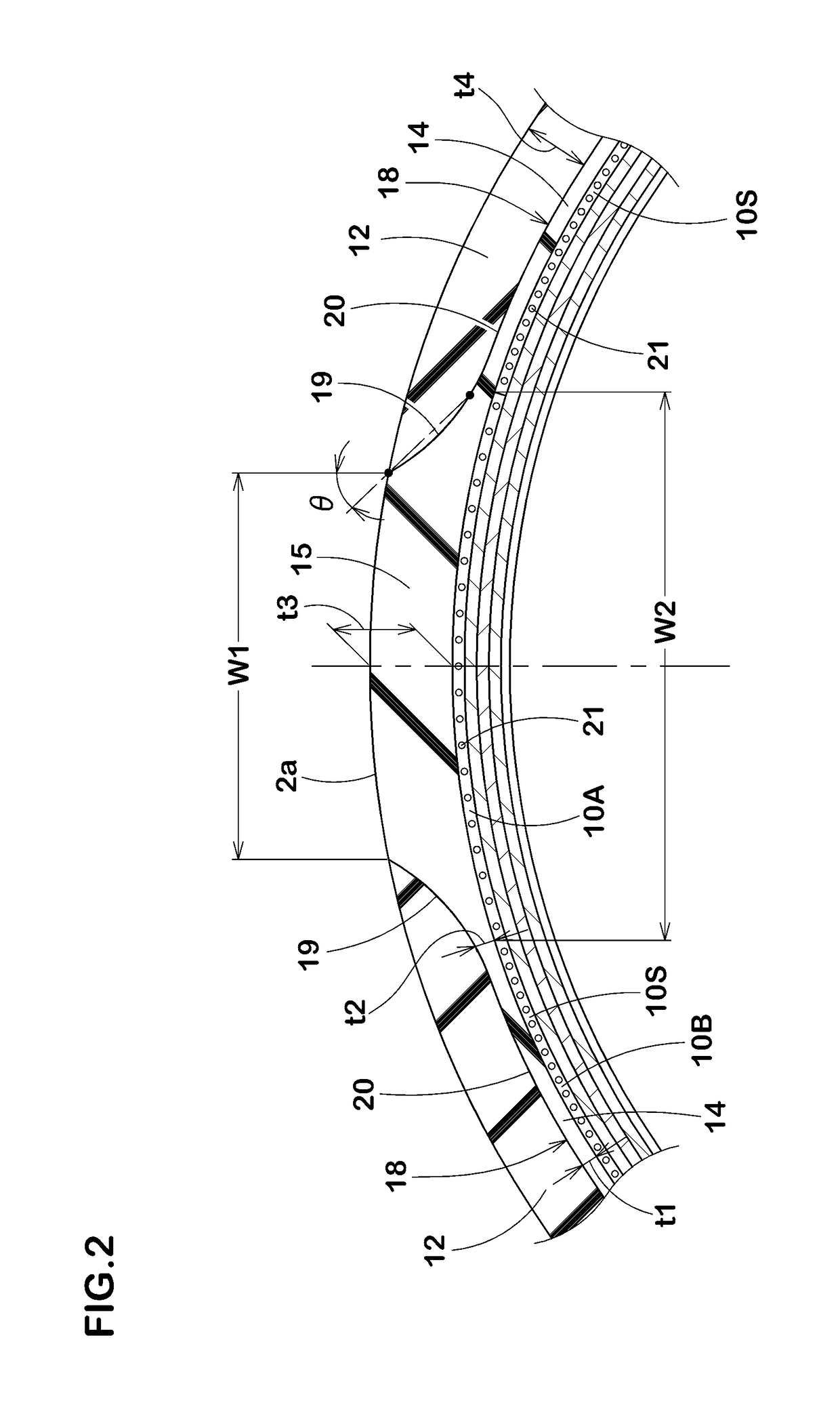

ActiveUS20210300128A1Reduce rolling resistanceReduce the impactRoad vehicle tyresPneumatic tyre reinforcementsEngineeringMechanical engineering

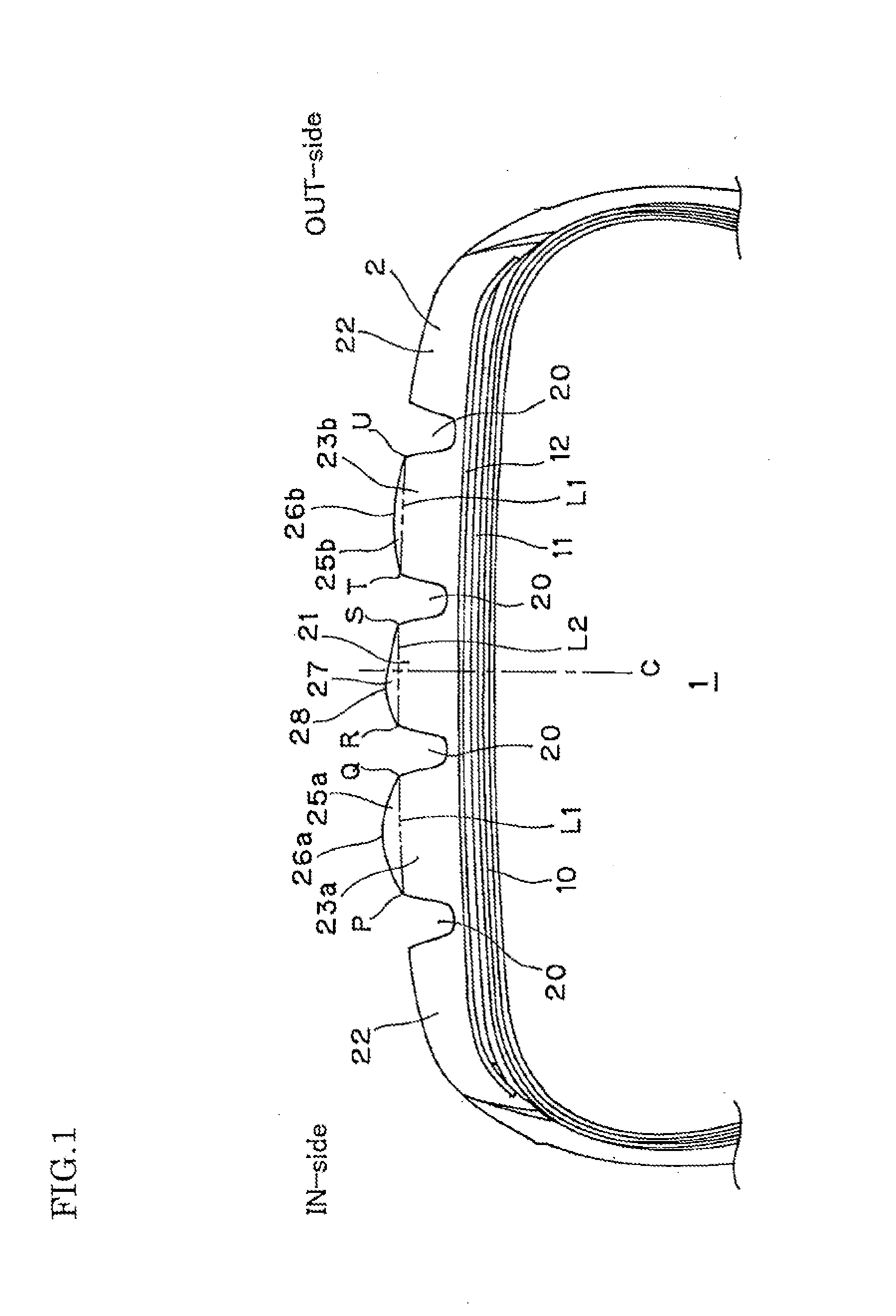

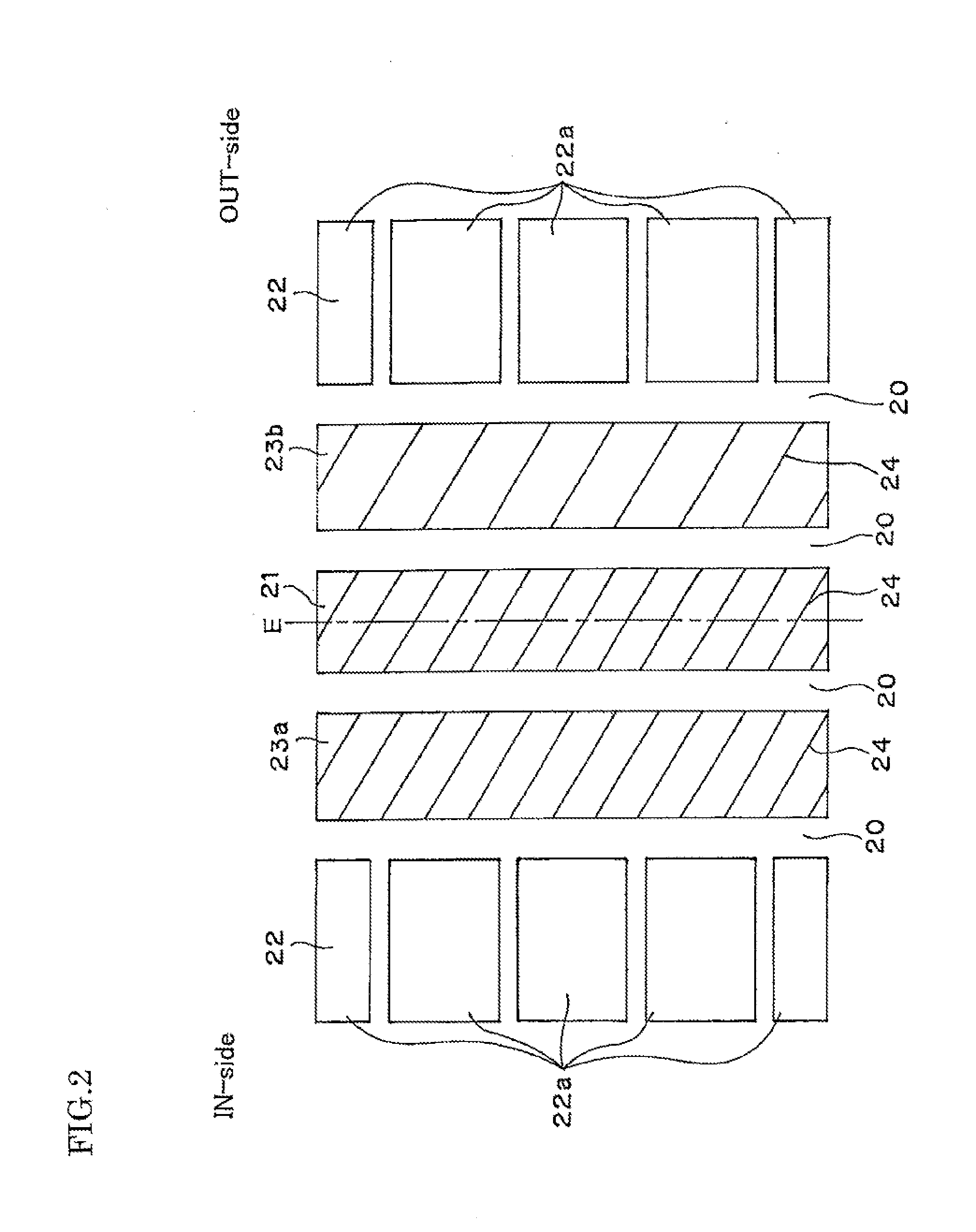

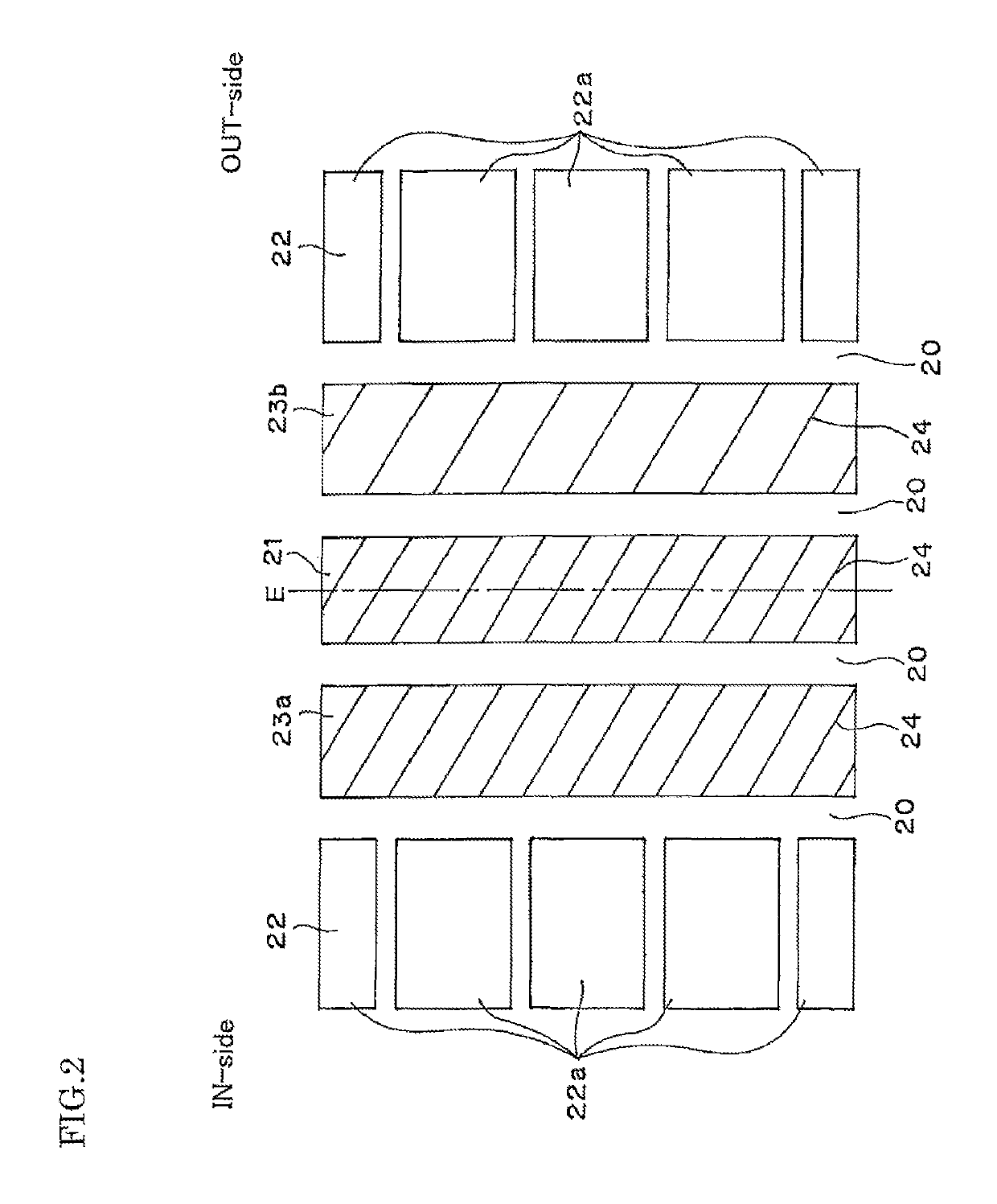

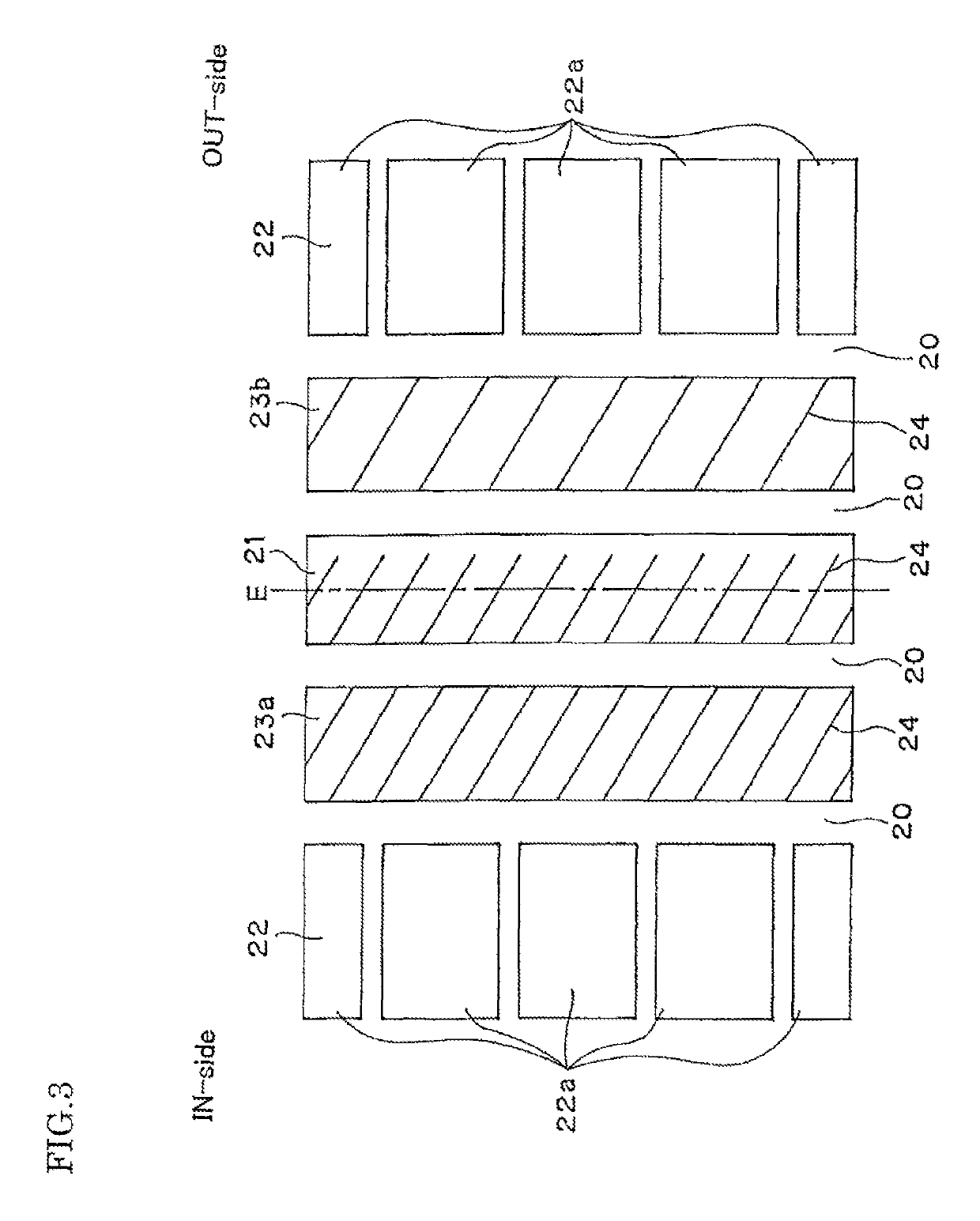

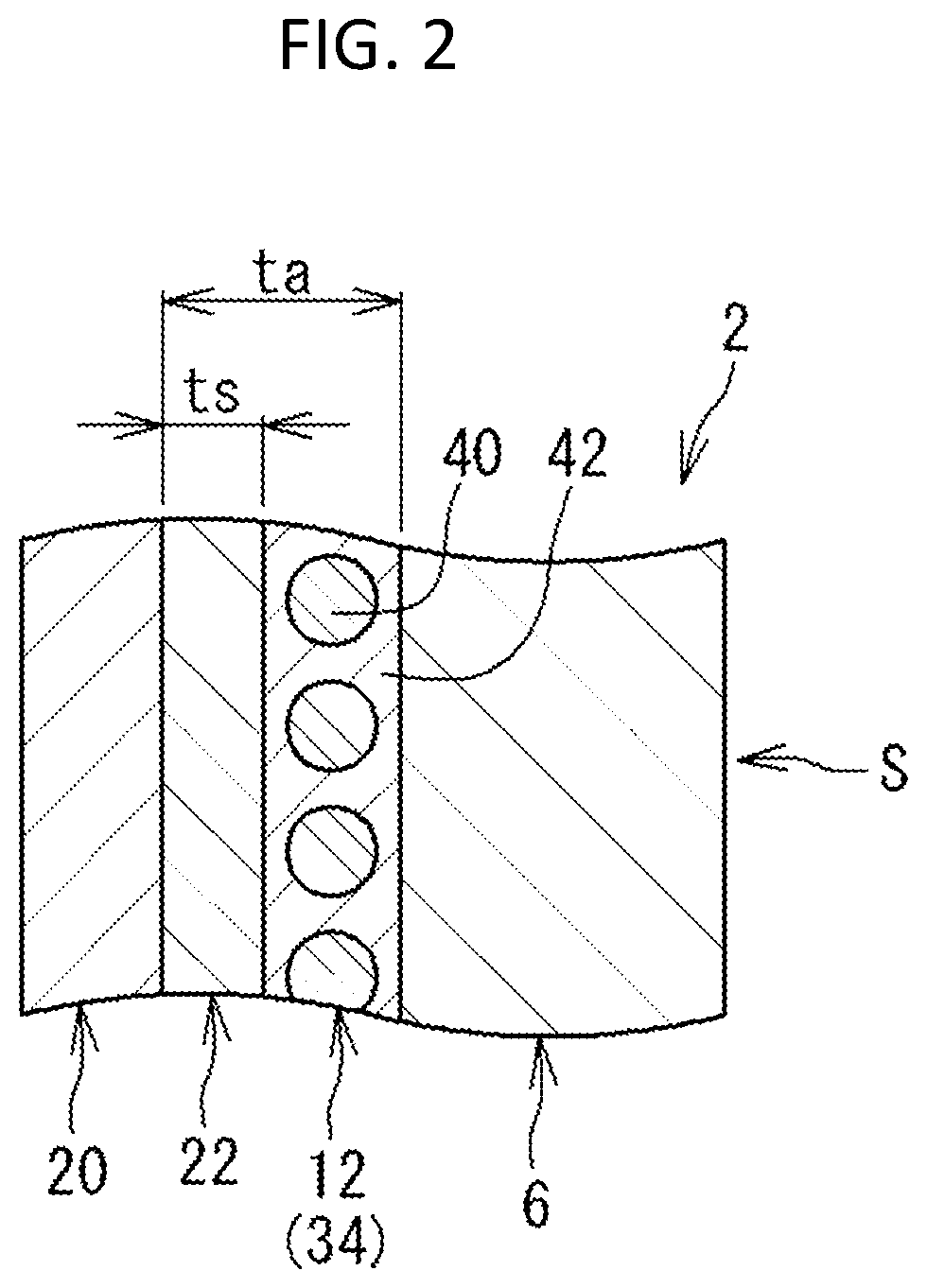

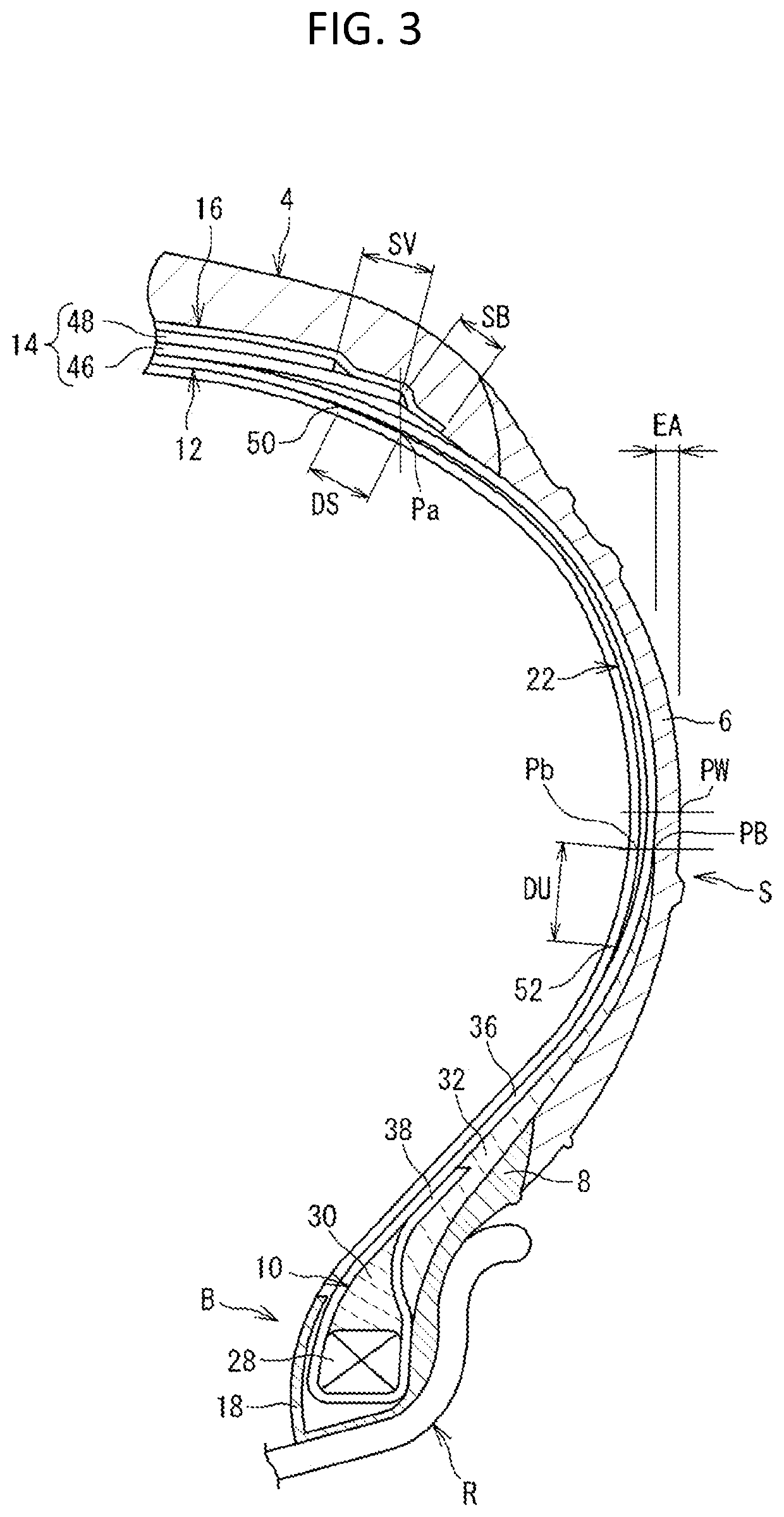

A tire 2 includes a tread 4, a pair of sidewalls 6, a pair of beads 10, a carcass 12, a belt 14, an inner liner 20, and a pair of insertion layers 22 disposed between the carcass 12 and the inner liner 20. Each insertion layer 22 is disposed between an end of the belt 14 and an end PB of the bead 10. Each insertion layer 22 has a volume resistivity of less than 108 Ω·cm. A complex elastic modulus of the insertion layer 22 is equivalent to or higher than a complex elastic modulus of the inner liner 20. A thickness of each sidewall 6 at a maximum width position PW is not greater than 5.0 mm.

Owner:SUMITOMO RUBBER IND LTD

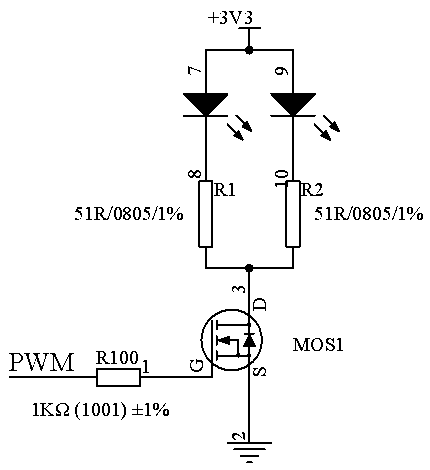

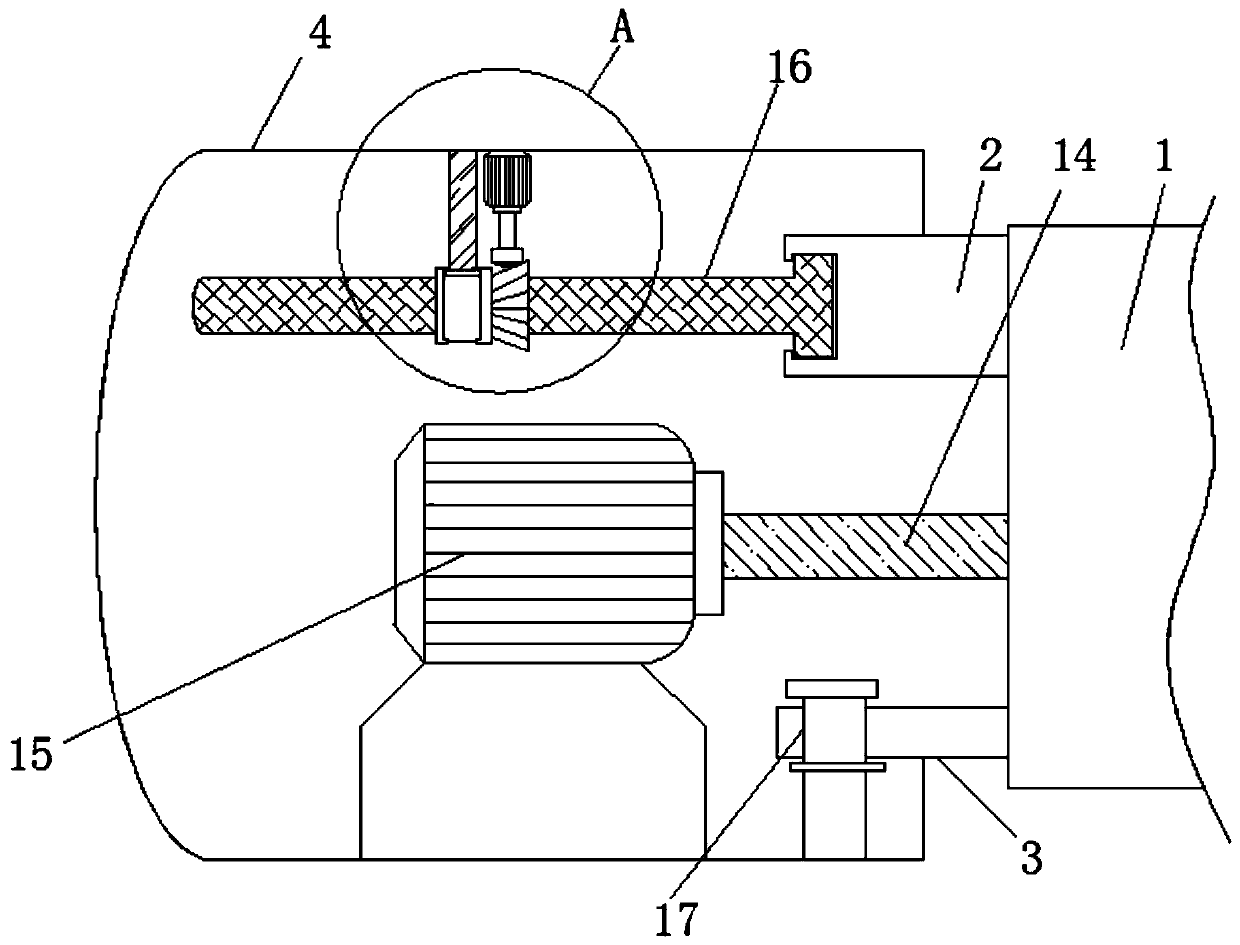

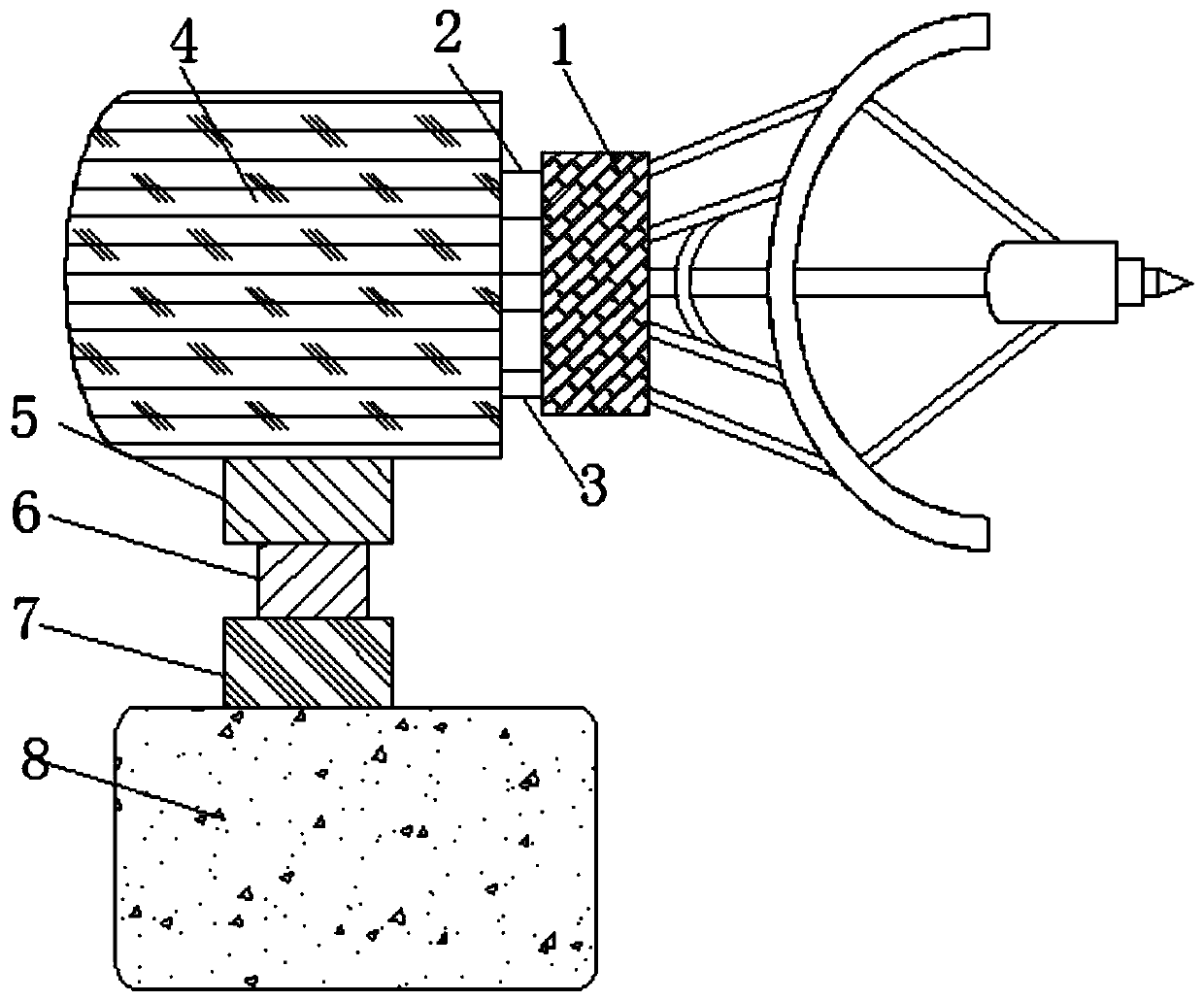

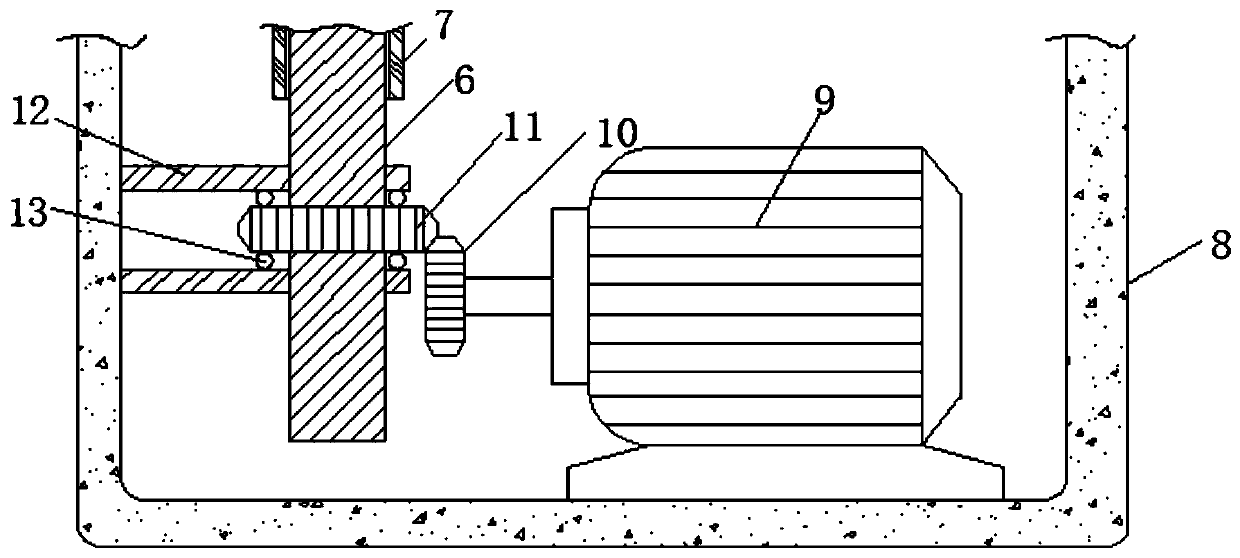

Cloth boundary recognition method for sewing machine and sensor and identification device thereof

PendingCN109056200AAutomatic adjustment of luminous intensitySteering stabilityWork-feeding meansIdentification deviceAnalog signal

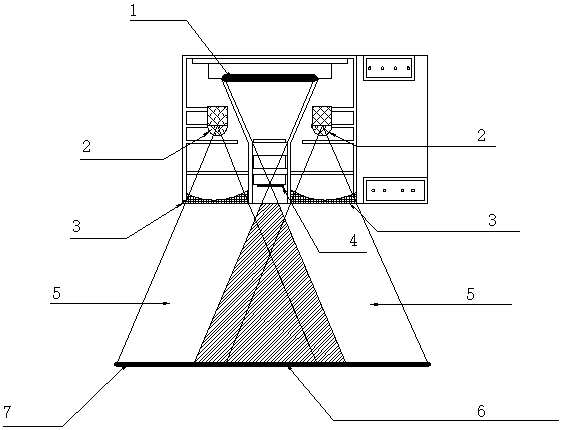

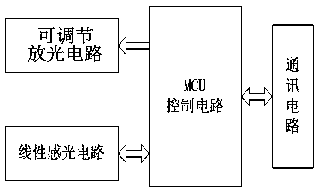

The invention relates to a cloth boundary recognition method for a sewing machine and a sensor and an identification device thereof, and belongs to the technical field of intelligent automatic sewingrobot control. A red light LDE light source is converted into a linear light source through a multiple layers of lens, the linear light source is reflected by a reflector to a lens group to be concentrated to form a point-distance linear beam, the point-distance linear beam is irradiated on a linear CCD sensor to form analog voltage output of a dot array, and the cloth boundary recognition sensoris constituted. The analog voltage of the dot array outputted by the cloth boundary recognition sensor is directly sent to an AD port of a MCU for calculation processing, and a digital quantity is transmitted outward through a communication circuit to constitute the cloth boundary identification device of the sewing machine. The cloth boundary recognition sensor adopts a linear CCD photosensitivechip, and the recognition precision is greatly improved; the MCU directly receives an analog voltage value, and the digital quantity is transmitted outward through the communication circuit after thecalculation processing, thereby avoiding interference on an analog signal transmitting over a long distance, and improving the stability of the cloth boundary identification sensor.

Owner:福恩达机器人(昆山)有限公司

Navigation radar antenna multi-angle rotating support

ActiveCN111584997AQuick and stable antenna heightAdjust the height of the antennaAntenna supports/mountingsMechanical engineeringControl theory

The invention relates to the technical field of navigation, and discloses a navigation radar antenna multi-angle rotating support comprising an antenna. The left side of the antenna is fixedly connected with an inclined support, and the left side of the antenna is fixedly connected with a fixed support. According to the multi-angle rotating support for the navigation radar antenna, a first motor is started to enable a first gear to drive a second gear to rotate, and the second gear is in threaded connection with a telescopic rod, so that the telescopic rod can move up and down to further enable the antenna to move up and down, and the effect of quickly and stably adjusting the height of the antenna is achieved; a third motor is started to enable a fourth gear to drive a third gear to rotate, at the moment, the third gear can drive a threaded rod to rotate, and the threaded rod moves left and right; the inclination angle of the antenna is further changed; a second motor is started to enable the antenna to rapidly and stably rotate, and therefore the effect that the radar antenna is more stable, faster and more convenient to steer is achieved.

Owner:合肥君百防务科技有限公司

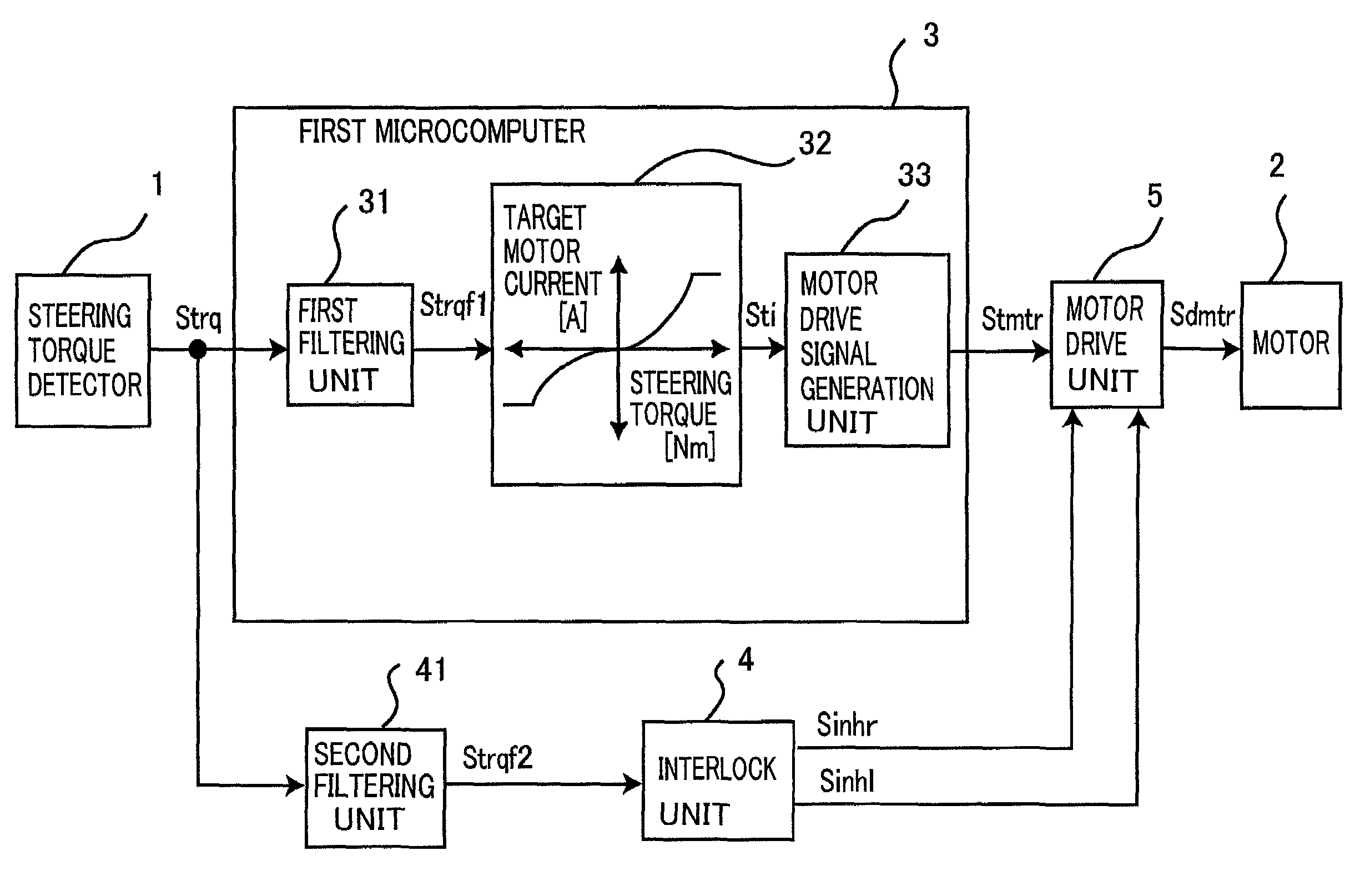

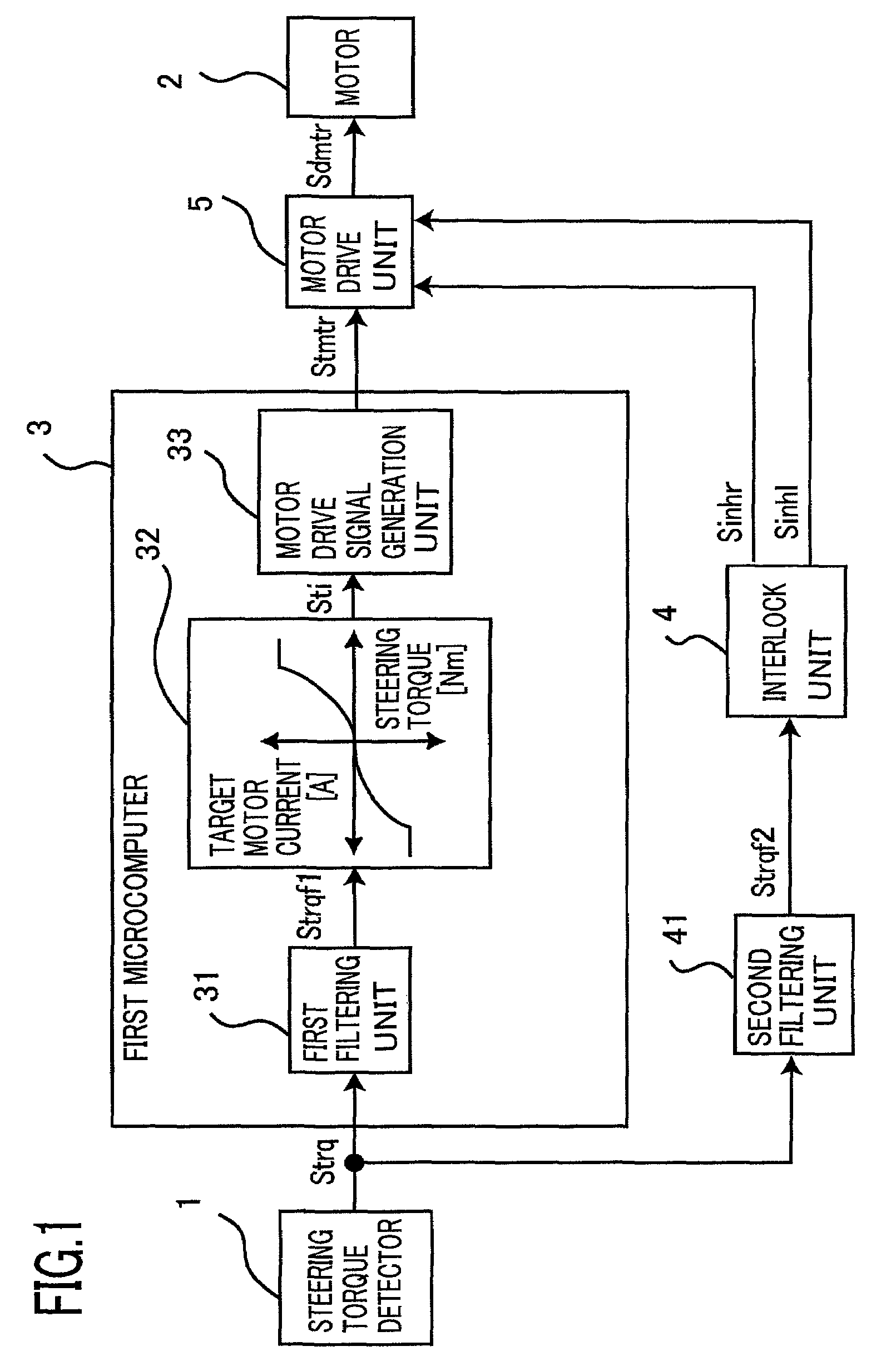

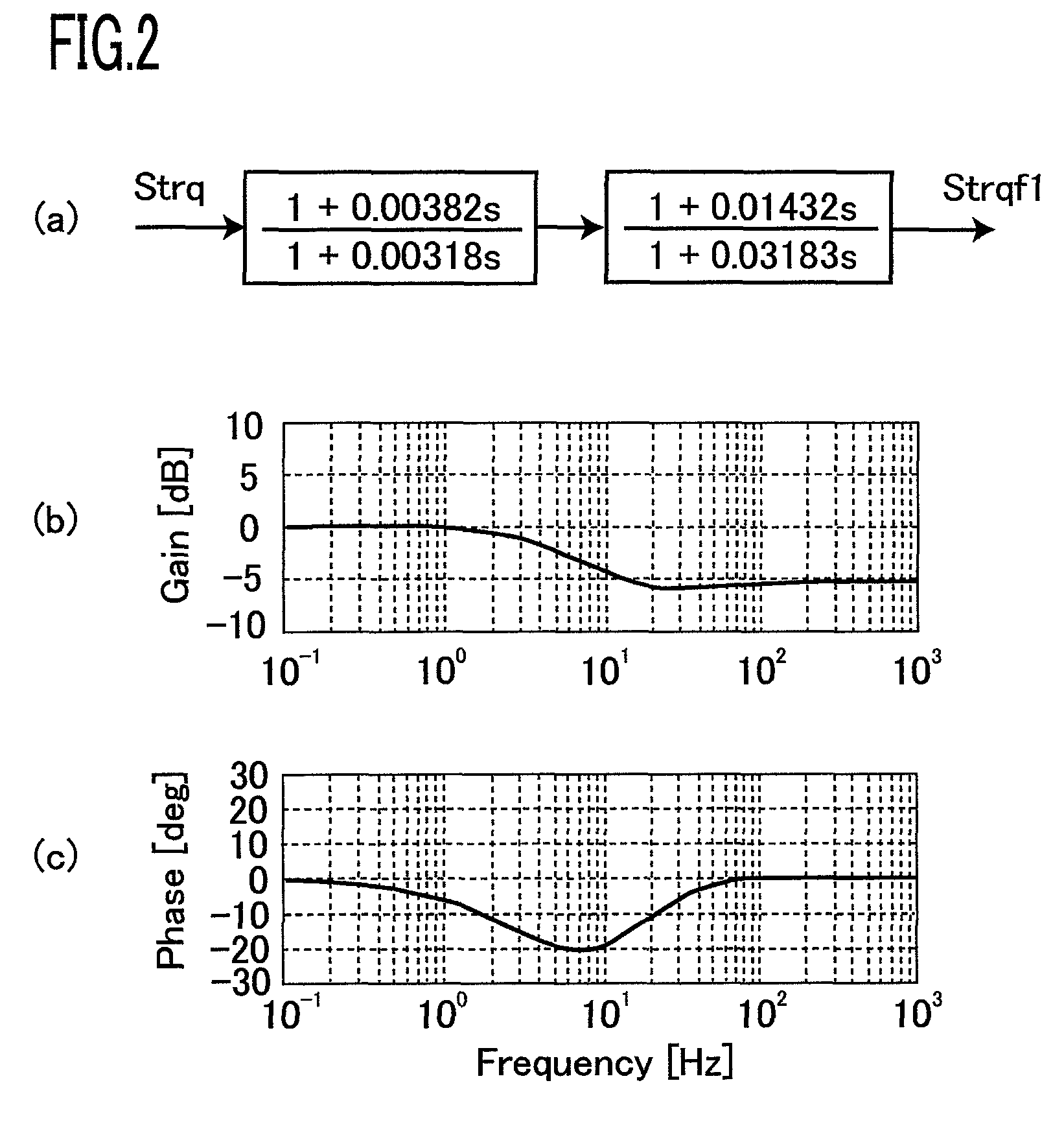

Electric power steering apparatus

InactiveUS8478485B2Steering stabilityReduce the differenceDigital data processing detailsSteering initiationsElectric power steeringMotor drive

An electric power steering apparatus is configured in such a way as to include a first filtering unit that applies filtering processing to the detected steering torque signal and outputs the processed torque signal; a control unit that generates and outputs a motor drive signal, based on a steering torque signal outputted from a first filtering unit; a second filtering unit that applies filtering processing to the detected steering torque signal and outputs the processed torque signal; and an interlock unit that generates and outputs a motor drive inhibition signal, based on the steering torque signal outputted from the second filtering unit. The second filtering unit performs filtering processing in such a way as to output a steering torque signal the same as or similar to the steering torque signal that is outputted from the first filtering unit at least when a vehicle is in a predetermined driving condition.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com