Portable heat preservation box

An incubator and portable technology, which is applied in the direction of insulated containers, lighting and heating equipment, containers, etc., can solve the problems of load waste, achieve the effects of preventing interference, reducing space occupation, and facilitating transportation and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

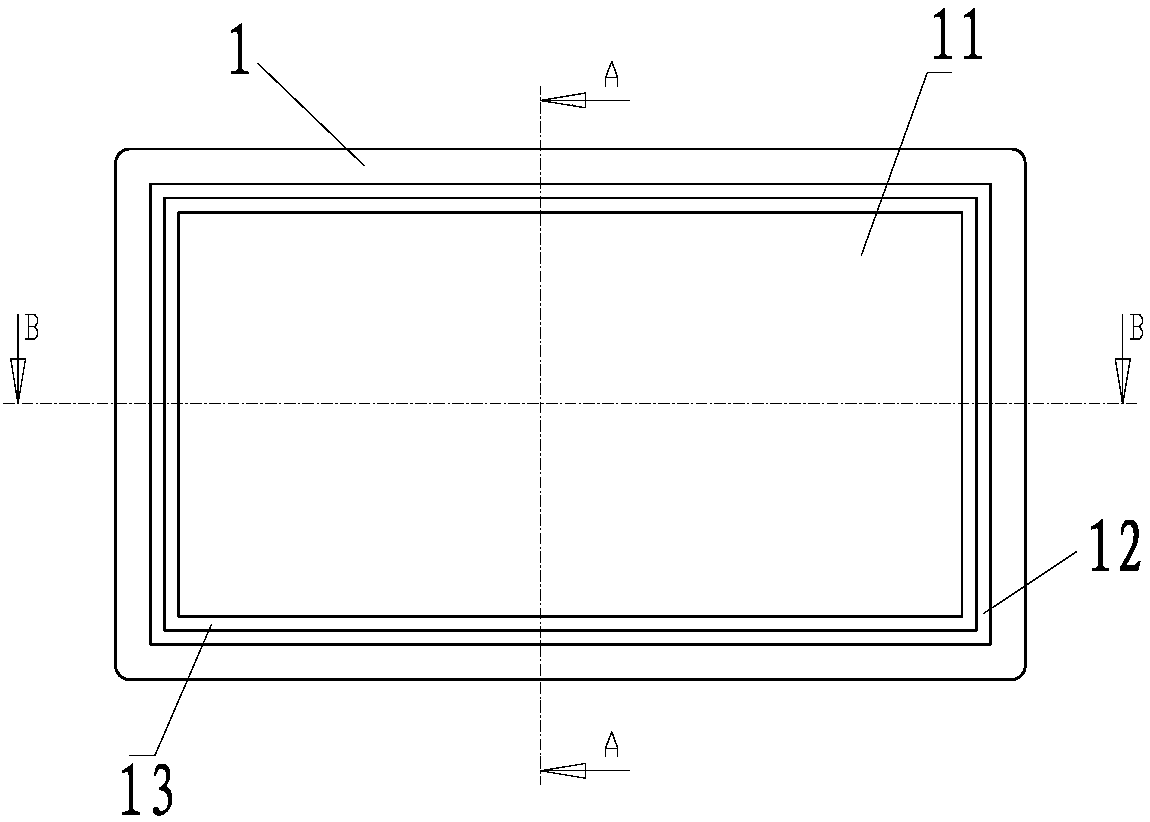

[0039] refer to Figure 1-11 , a detachable portable heat preservation box, comprising: an upper cover, a lower cover 1, front and rear side panels 2 and left and right side panels 3;

[0040] A first boss 11 protrudes outward from the opposite sides of the upper cover plate and the lower cover plate 1 , and a second boss 12 protrudes outward from the outer side of the first boss 11 ; the first boss A back-shaped groove 13 is formed between 11 and the second boss 12 .

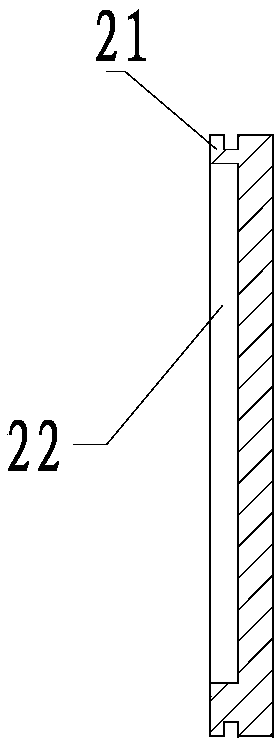

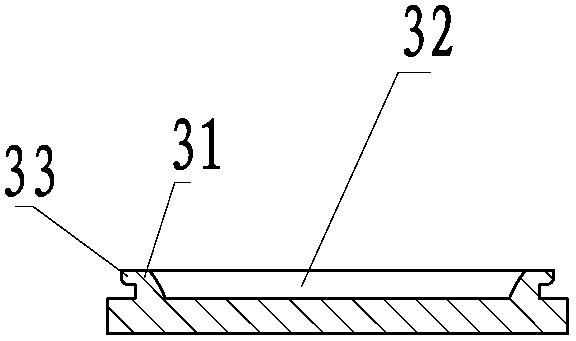

[0041] A third boss 21 protrudes outward from the opposite side of the front and rear side plates 2, and a part of the surface of the third boss 21 is concave inward to form a groove 22 toward the square away from the heat preservation accommodating cavity; the The upper and lower ends of the third boss are the same height as the front and rear side plates 2 , and the thickness thereof is equal to or slightly larger than the groove width of the return-shaped groove 13 , so as to form a static fit with the retu...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that in this embodiment, the upper cover, the lower cover, the front and rear side panels, and the left and right side panels are adhered by adhesives to form a non-removable incubator, although the disassembly is sacrificed. However, the sealing and thermal insulation performance of the incubator has been further improved.

Embodiment 3

[0053] refer to Figure 12 , the difference between the present embodiment and the embodiment 1 is: in the present embodiment, the front and back of the upper cover plate, the lower cover plate 1 and the front and rear side plates 2, the left and right side plates 3 are also respectively provided with a panel 4; the described The panel 4 is one of plastic parts, kraft paper, aluminum foil, stainless steel plate, color steel plate, and aluminum alloy plate. Wherein, the plastic part may be one of PVC / PET / PP / ABS / LDPE / LLDPE.

[0054] The panel 4 is adhered to the upper cover plate, the lower cover plate 1, the front and rear side plates 2, and the left and right side plates 3 through an adhesive layer; One; wherein the adhesive is one of polyurethane glue, epoxy resin, and silica gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com