A local heat treatment annealing device and method for blast furnace hot blast furnace shell

A local heat treatment and annealing device technology, applied in the field of heat treatment, can solve problems such as welding residual stress of the furnace shell, achieve the effect of preventing frequent cracking, eliminating residual stress, and ensuring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

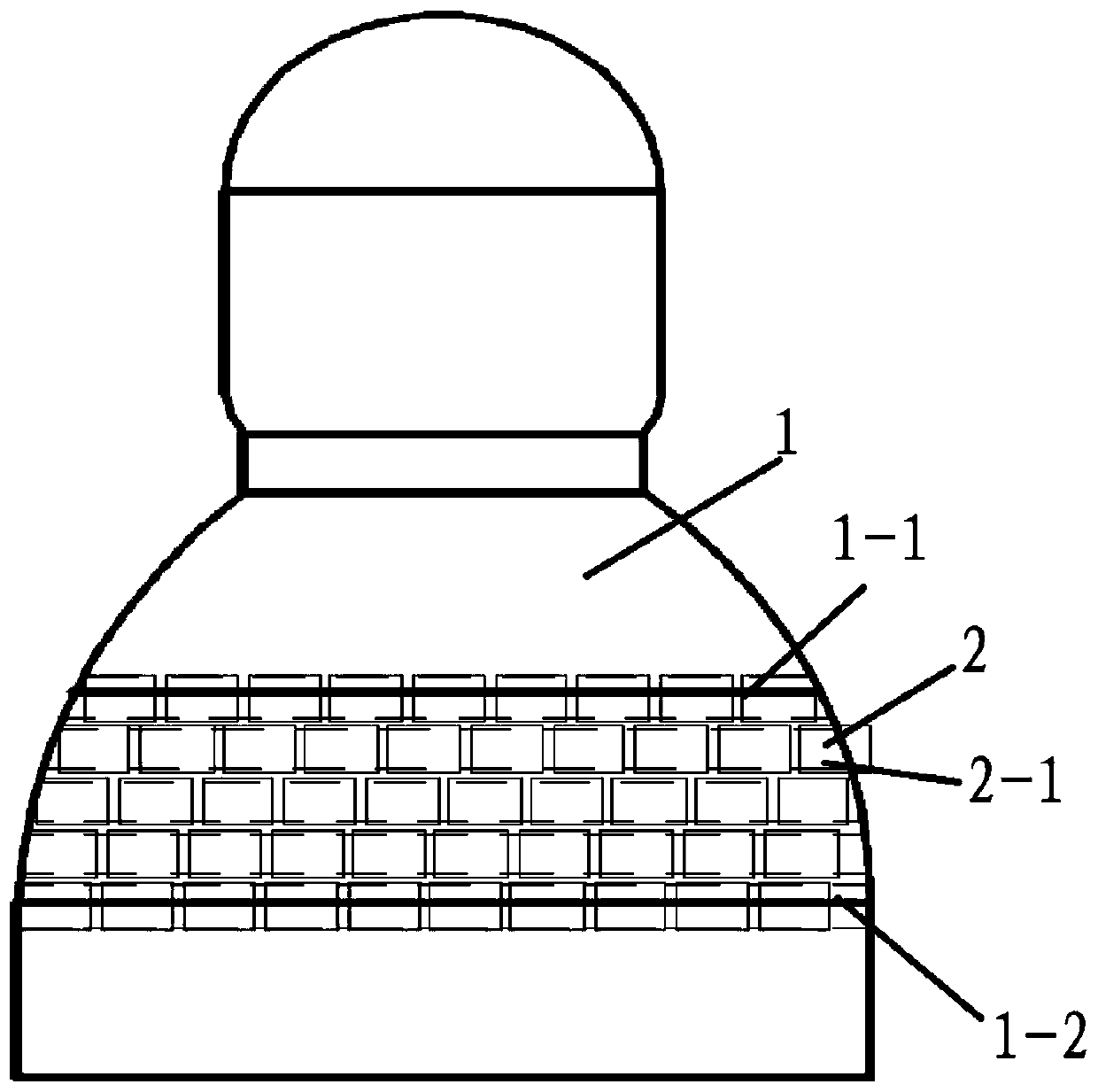

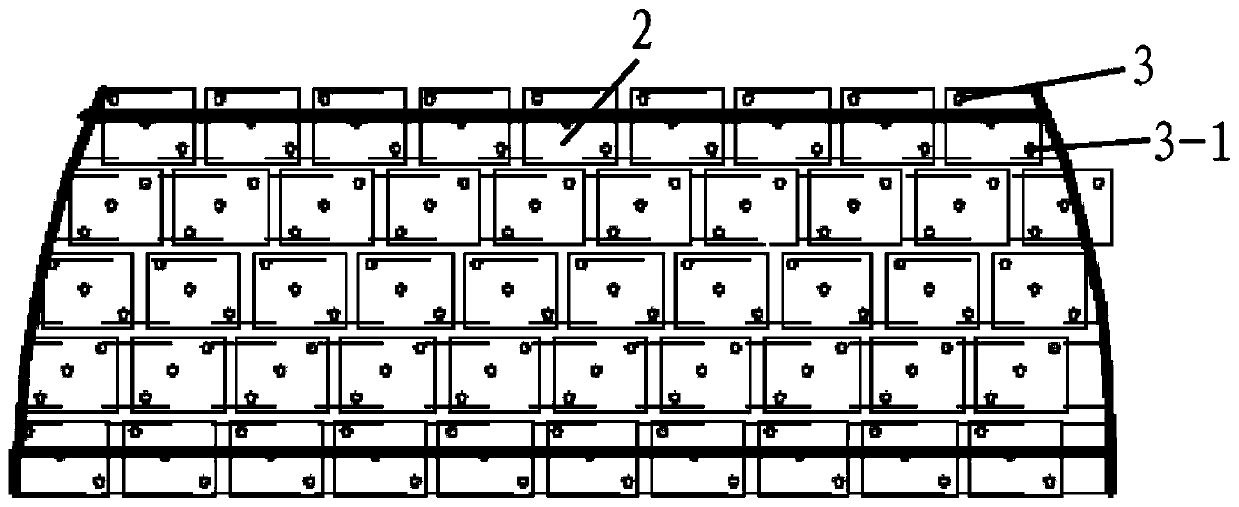

[0021] see Figure 1-2 , a local heat treatment annealing device for a blast furnace hot blast stove shell provided by an embodiment of the present invention, there are welds between the furnace shells 1, and the local heat treatment annealing device for a blast furnace hot blast stove shell includes: a temperature control mechanism, a heating mechanism 2 And temperature detection mechanism 3.

[0022] The heating mechanism 2 is connected with the temperature control mechanism, and the heating mechanism 2 is closely attached to the outer wall of the furnace shell.

[0023] The temperature detection mechanism 3 is connected with the temperature control mechanism, the temperature detection mechanism 3 is arranged between the heating mechanism 2 and the furnace shell 1, and the temperature detection mechanism 3 is arranged at the weld of the weld seam. In the groove opened on the road.

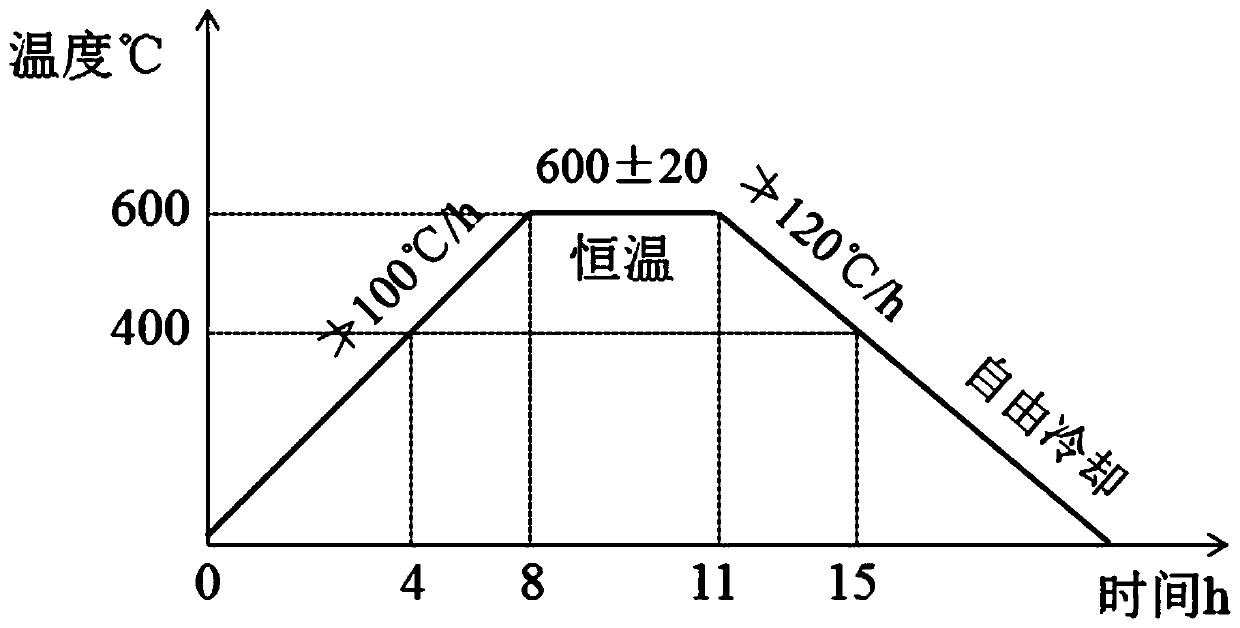

[0024] Wherein, the temperature control mechanism receives the temperature signal sent by t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap