Superconductive solar heat pump drying system

A technology of solar heat pump and drying system, applied in the field of solar drying system, can solve the problems of intermittent instability of light, low drying efficiency of equipment, large dispersion of solar radiation, etc., and achieve fast heat conversion speed, fast drying speed, and system work reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

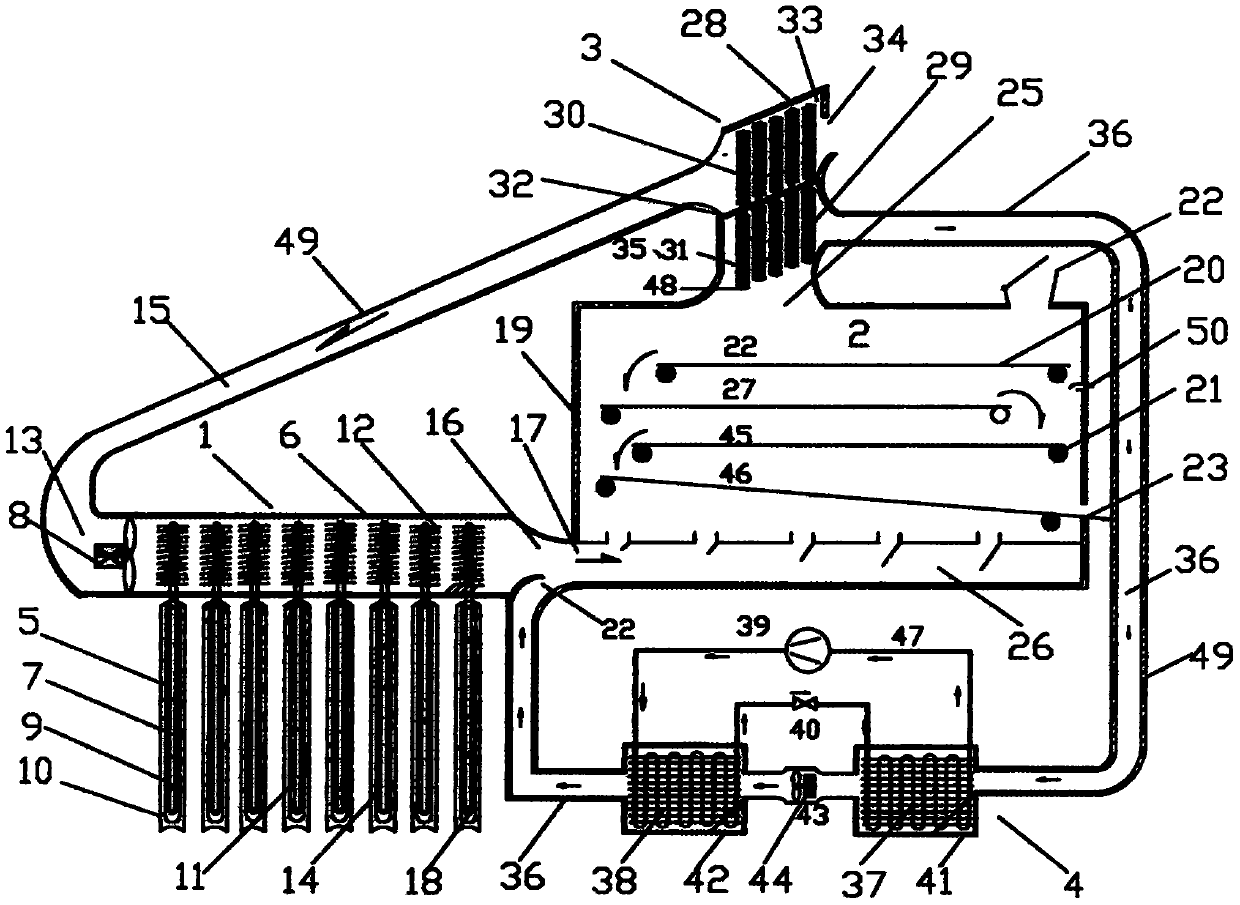

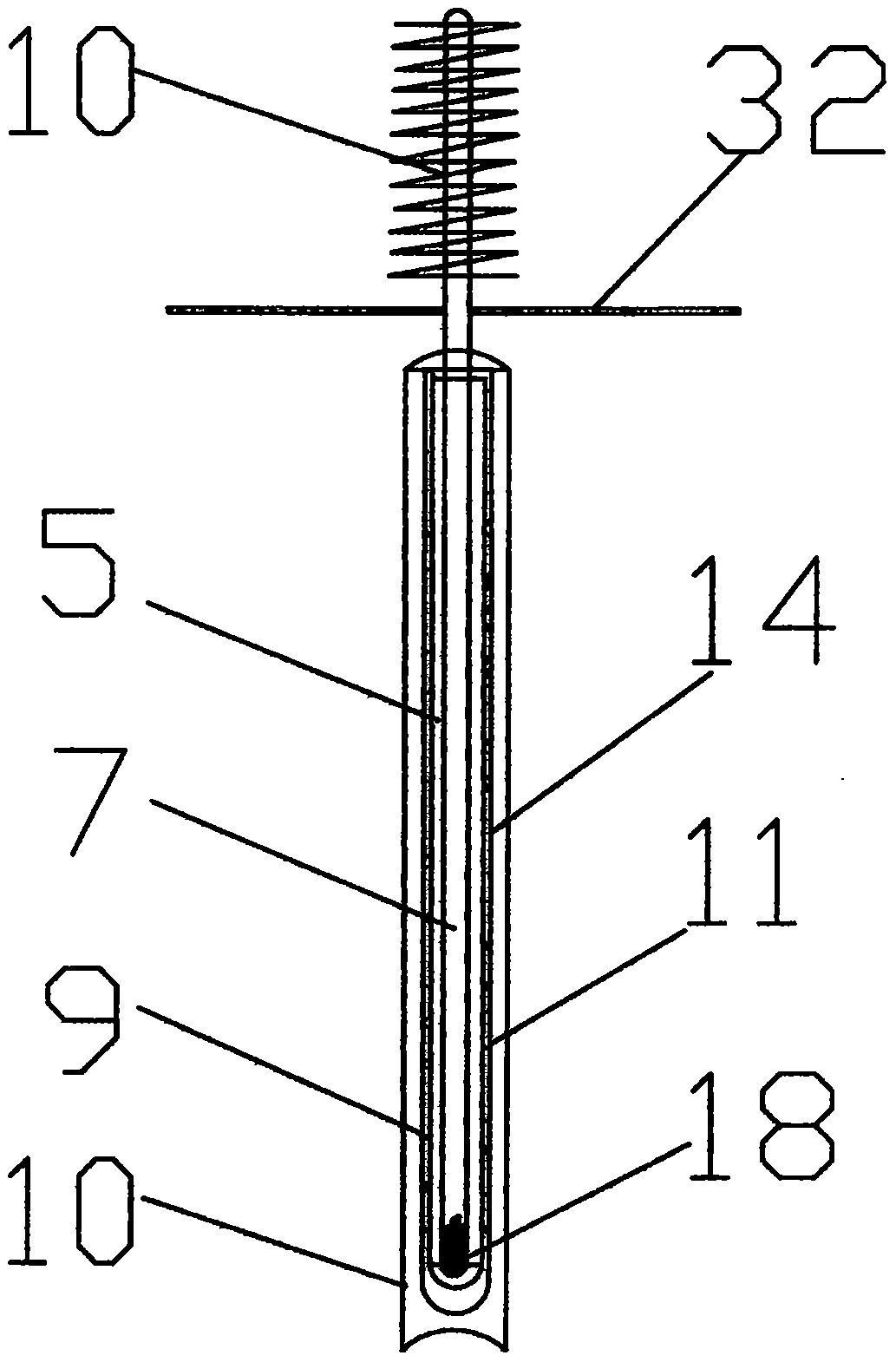

[0021] Attached below figure 1 , 2 The present invention is described further:

[0022] A superconducting solar heat pump drying system is composed of a superconducting solar heat collector 1, a drying oven 2, a superconducting waste heat recovery device 3, a waste heat source heat pump 4, and air ducts 15 and 36, and is characterized in that the superconducting solar heat collector 1 consists of a horizontal header 6, several superconducting heat transfer tubes 7 connected to the horizontal header 6, and an axial flow fan 8 installed in the horizontal header 6. Arc-shaped heat transfer fins 5 are welded below each superconducting heat transfer tube 7. The inner wall of the liner 14 is in close contact, and the back of the vacuum glass tube 9 is equipped with a groove-shaped flashlight plate 10. The groove-shaped concentrating plate 10 can focus the solar radiation light on the selective coating 11 on the outer wall of the inner liner 14 of the vacuum glass tube 9 in the for...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap