A manually controlled wind elevator

A manual control, elevator technology, applied to elevators, ventilation systems, space heating and ventilation in buildings, etc., can solve problems such as poor breathing of passengers, sultry car, shock, etc., to avoid finger slippage and improve comfort. degree, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

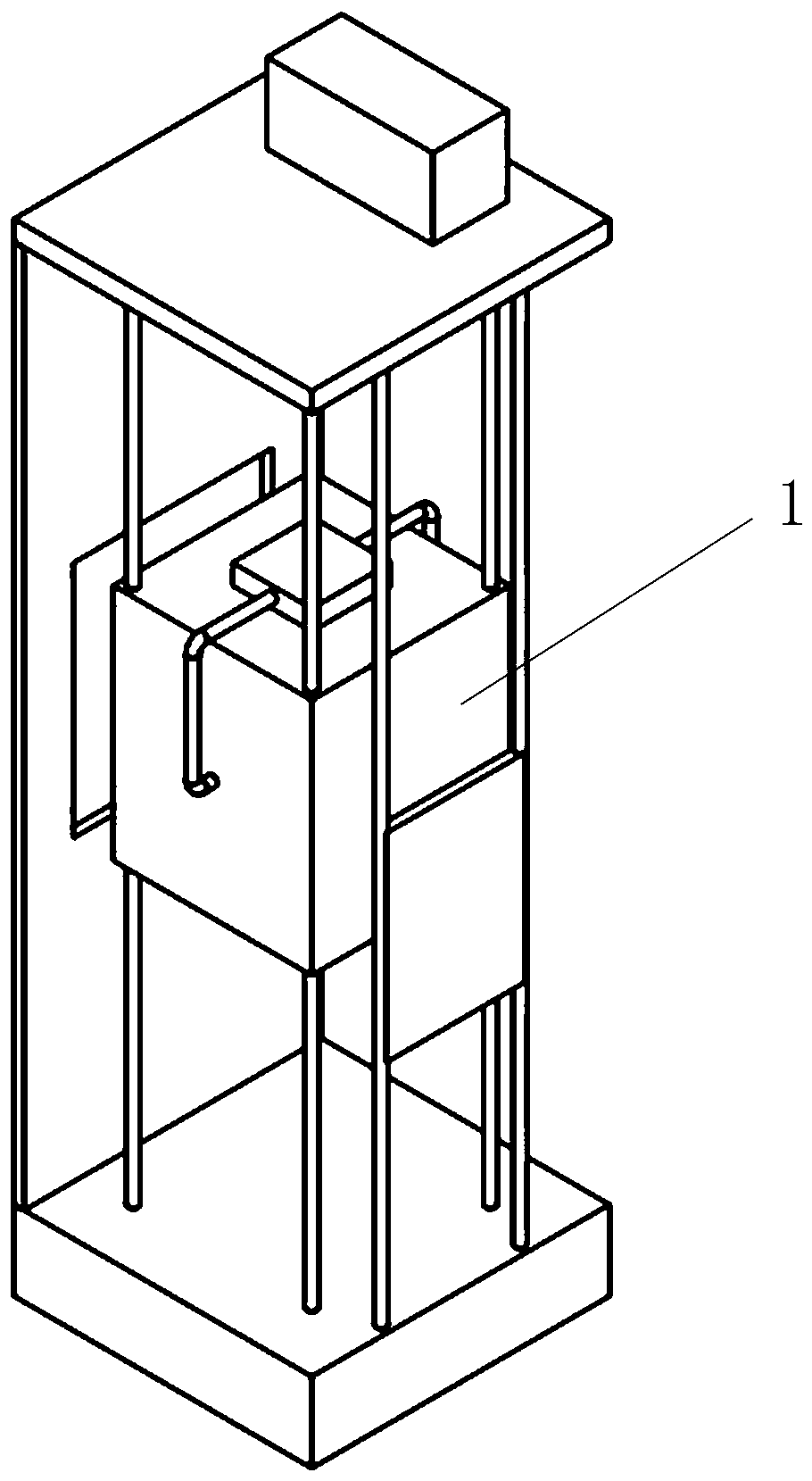

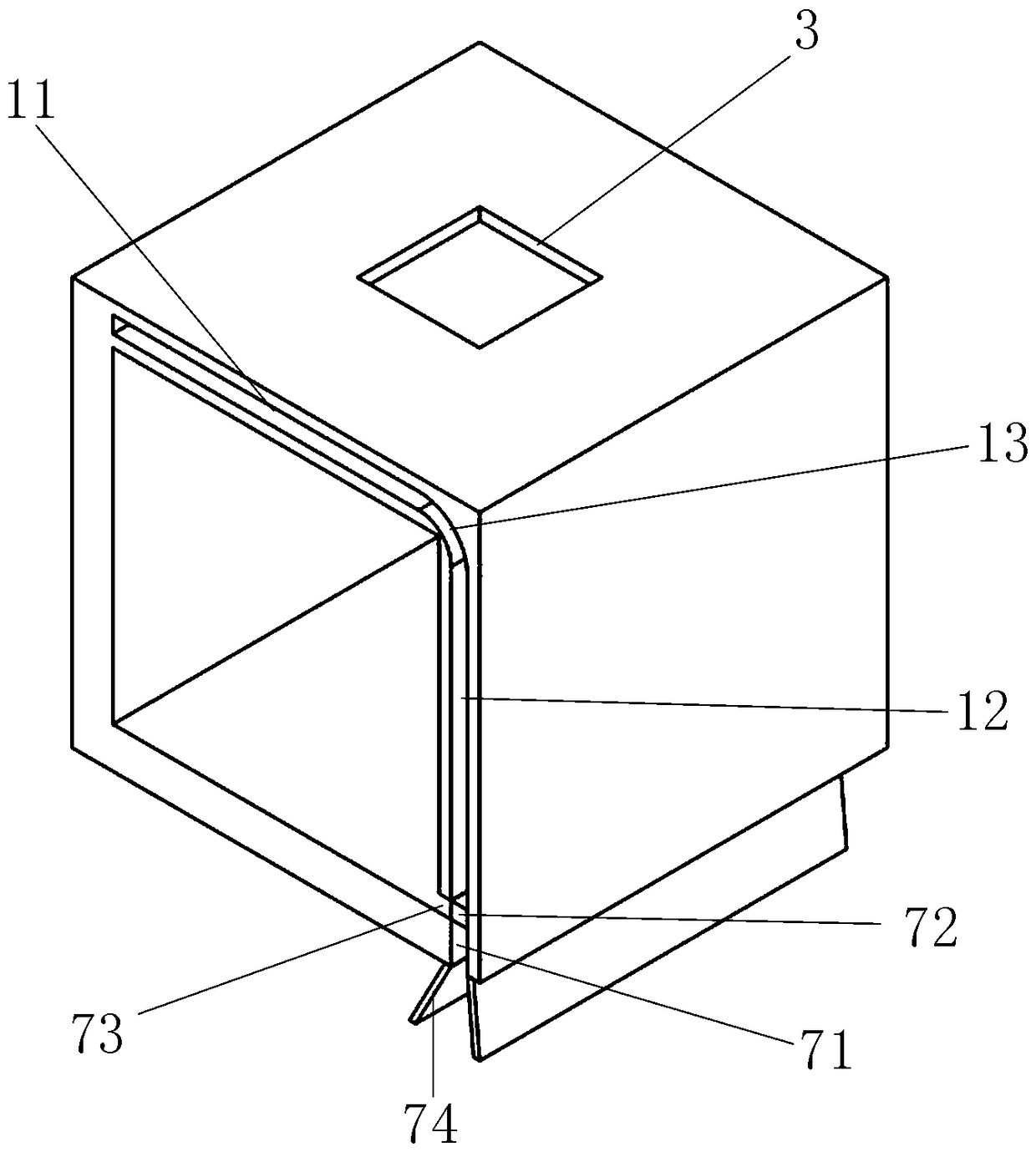

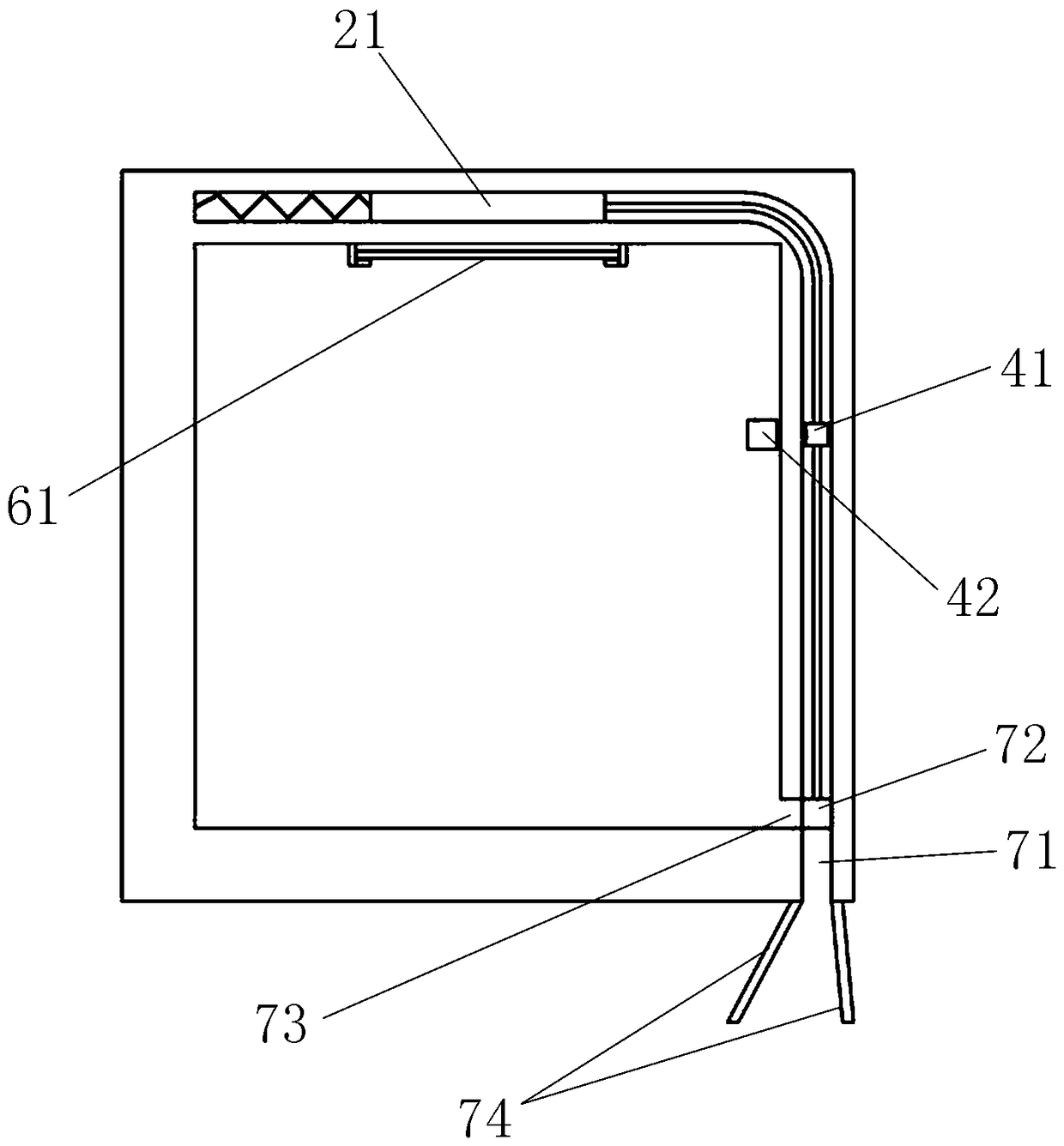

[0033] Example 1, such as figure 1 Shown is an overall schematic diagram of an elevator with manual wind control. A manually controlled wind elevator comprises a car 1, a wire rope, a counterweight and a traction machine, wherein, such as figure 2 As shown, the car 1 includes a car top surface, a car side surface and a car bottom surface. The car top surface includes a headspace groove 11. The headspace groove 11 is a rectangular parallelepiped hollow groove extending in the horizontal direction. The slot 12 is a rectangular parallelepiped hollow slot extending in the vertical direction. The headspace slot 11 and the side slot 12 are connected by a connecting slot 13. There is an opening and closing plate 21 in the headspace slot 11, and the opening and closing plate 21 is connected to the headspace slot through elastic connectors. 11 is connected to the end face away from the side of the connecting groove 13. There is a push part in the side cavity 12. The opening and closi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com