Technology for heating processing for car universal joint cross shaft

A cross shaft and automobile technology, applied in the field of heat treatment, can solve the problems of surface hardness and core hardness to be improved, high residual austenite content, etc., and achieve good shape and distribution, uniform refinement of martensite, and improved grade Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

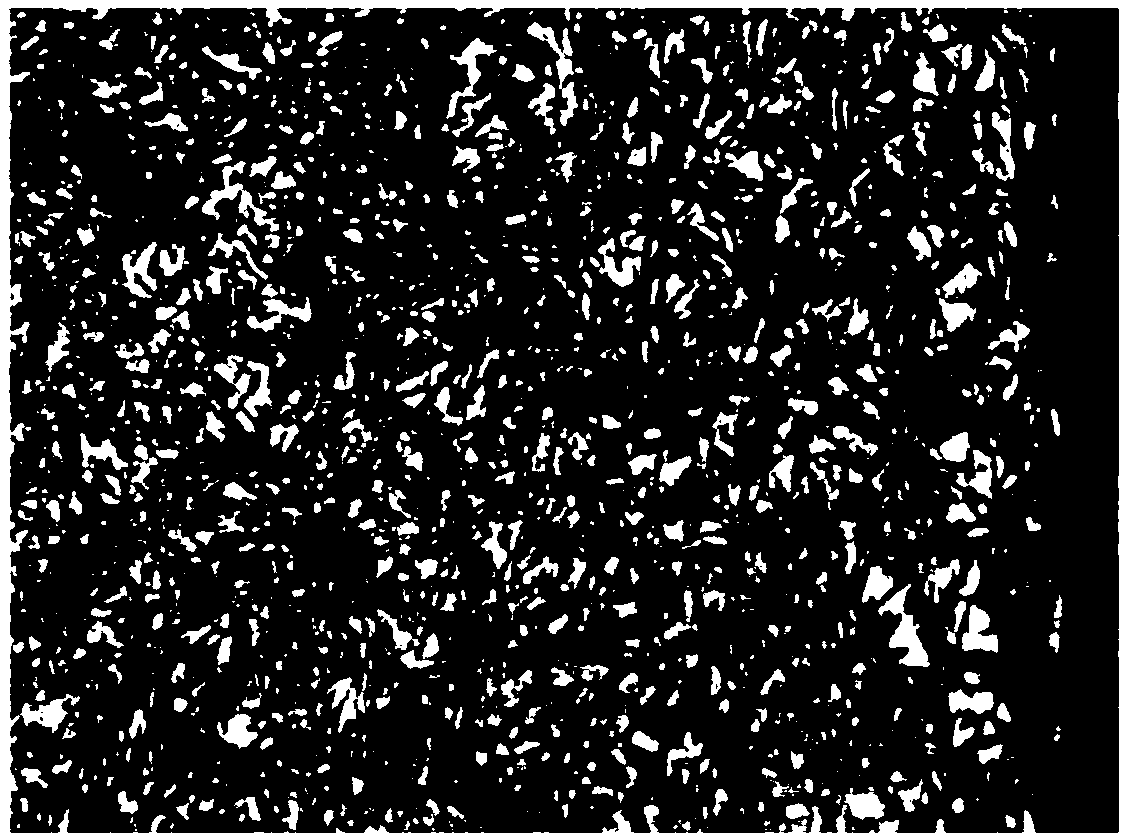

Image

Examples

Embodiment Construction

[0023] Please refer to figure 1 , a heat treatment process for a car universal joint cross shaft of the present invention, comprising:

[0024] Carburizing step

[0025] After raising the temperature of the sealed box-type multi-purpose furnace to 915°C±5°C, place the cross shaft of the universal joint in the furnace. Start carburizing, the carburizing temperature is 915°C±5°C, the carburizing carburizing potential is 1.15%, and the carburizing time is 160min;

[0026] Quenching step

[0027] Cool down the universal joint cross shaft after carburizing to 860°C, adjust the carbon potential to 0.95%, and feed ammonia gas at the same time. Quenching with quenching oil and stirring at medium speed;

[0028] tempering step

[0029] After quenching, the universal joint cross shaft is tempered in a tempering furnace at 180°C for 120min.

[0030] The cross shaft of the automobile universal joint is made of low-carbon alloy steel 20Cr steel. After heat treatment, the metallograph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com