Modularized wall for assembly integrated house

An integrated house and modular technology, applied in the direction of walls, floors, building components, etc., can solve the problems of large construction waste, large quality of components, dust pollution of the environment, etc., to increase thermal insulation, save the decoration process, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

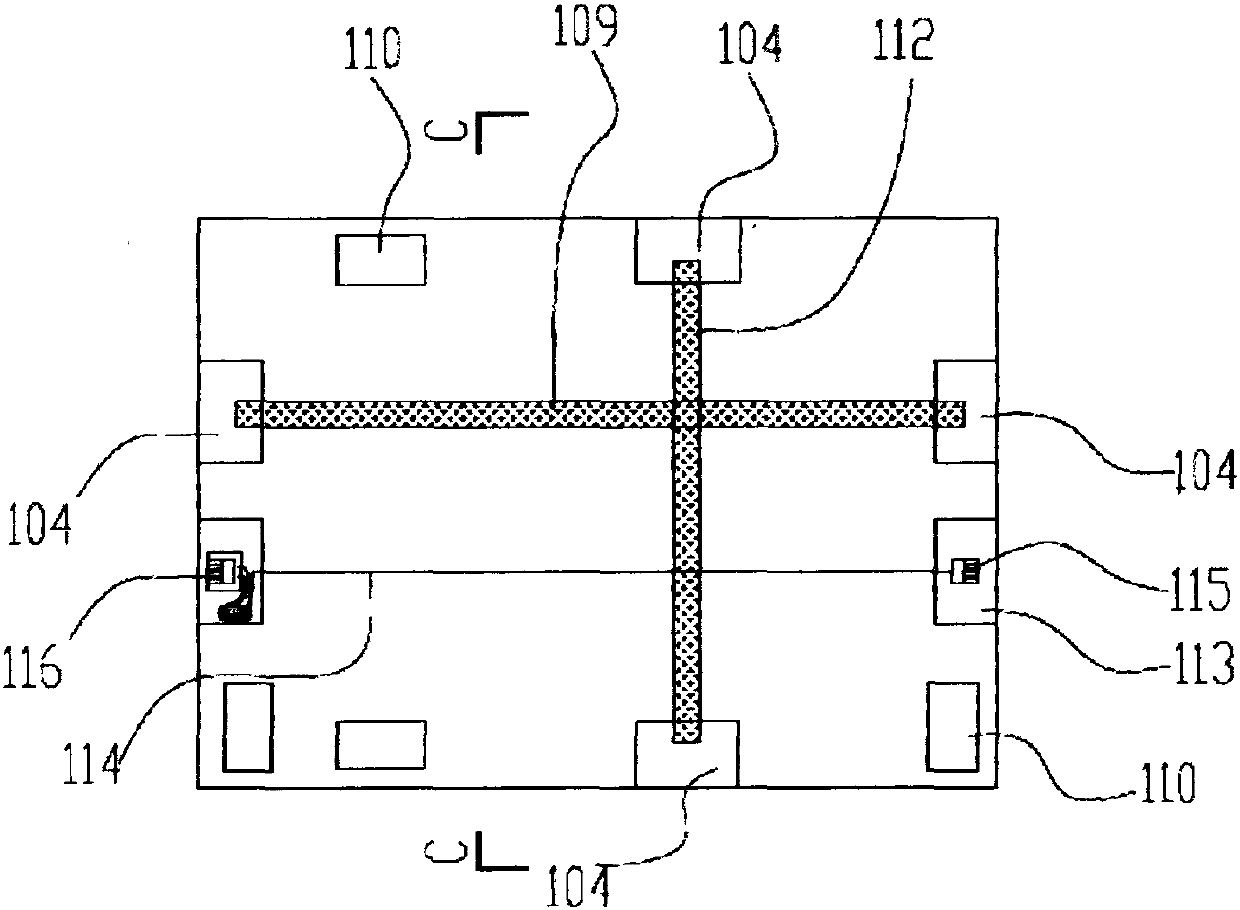

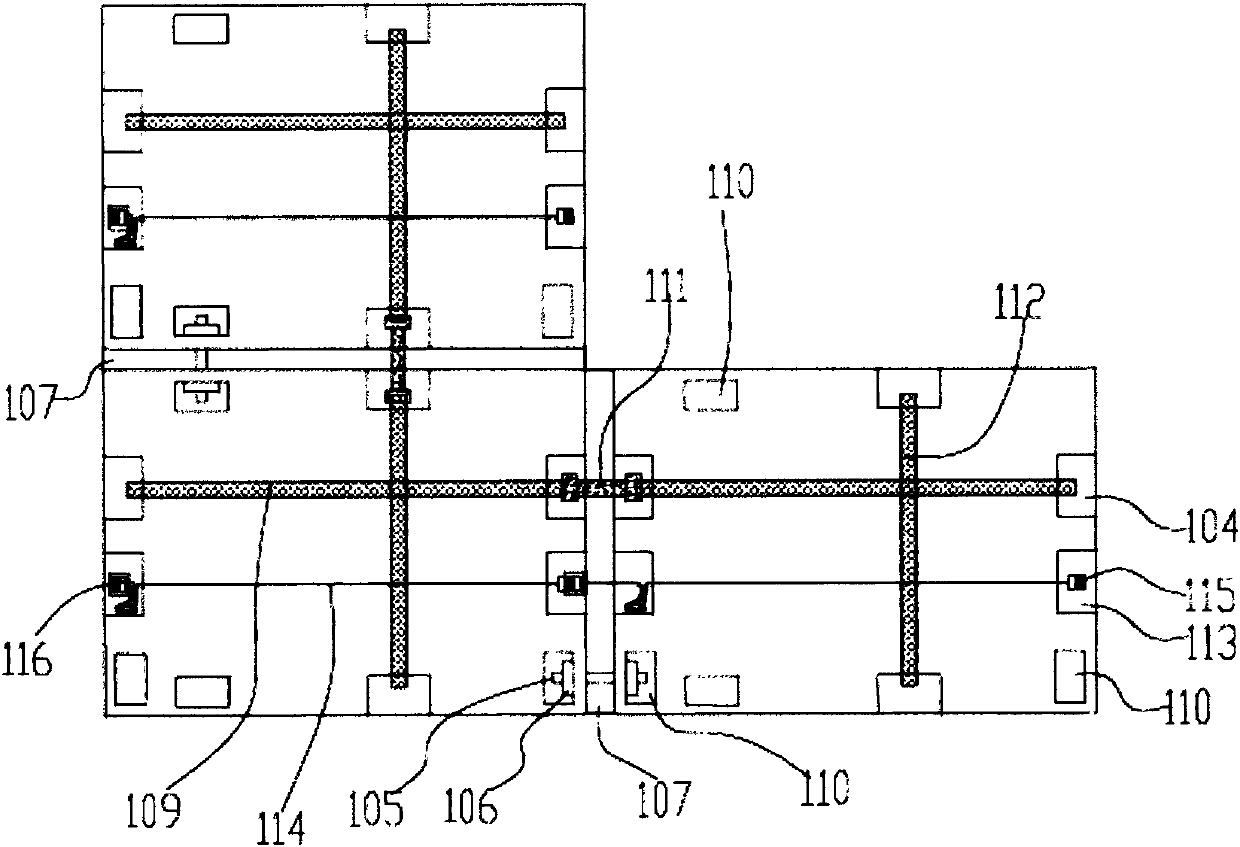

[0033] refer to Figure 1-6 , a modular wall for prefabricated integrated houses, including a steel structure frame and a filling layer 108 filled in the steel structure frame; the filling layer 108 is provided with a pair of water pipe operation holes 104, and a pair of water pipe operation holes 104 The holes 104 are respectively located on opposite sides of the filling layer 108 and are symmetrical about the axis. A first water conduit 109 is embedded in the filling layer, and the two ends of the first water conduit 109 are respectively located in a pair of water pipe operation holes 104; the filling layer 108 is provided with a pair of electric wire operation holes 113, and the pair of electric wire operation holes 113 are respectively located on the opposite sides of the filling layer 108 and are symmetrical about the axis. The filling layer 108 is embedded with electric wires 114, and the two ends of the electric wires 114 are respectively connected with mutually matching...

Embodiment 2

[0036] This embodiment is on the basis of embodiment 1:

[0037] The filling layer 108 is also buried with a second water pipe 112 , the second water pipe 112 vertically intersects with the first water pipe 109 and conducts, and the two ends of the second water pipe 112 are provided with water pipe operation holes 104 . The purpose is to facilitate the design of the water guiding system in the house. Adding the second water guiding pipe 112 provides more options for the design of the water guiding system. At the same time, when the first water guiding pipe 109 or the second water guiding pipe 112 is not included When using a water system, both ends need to be sealed. The size of all water pipe operation holes 104 is 200mm×200mm.

Embodiment 3

[0039] This embodiment is on the basis of embodiment 1:

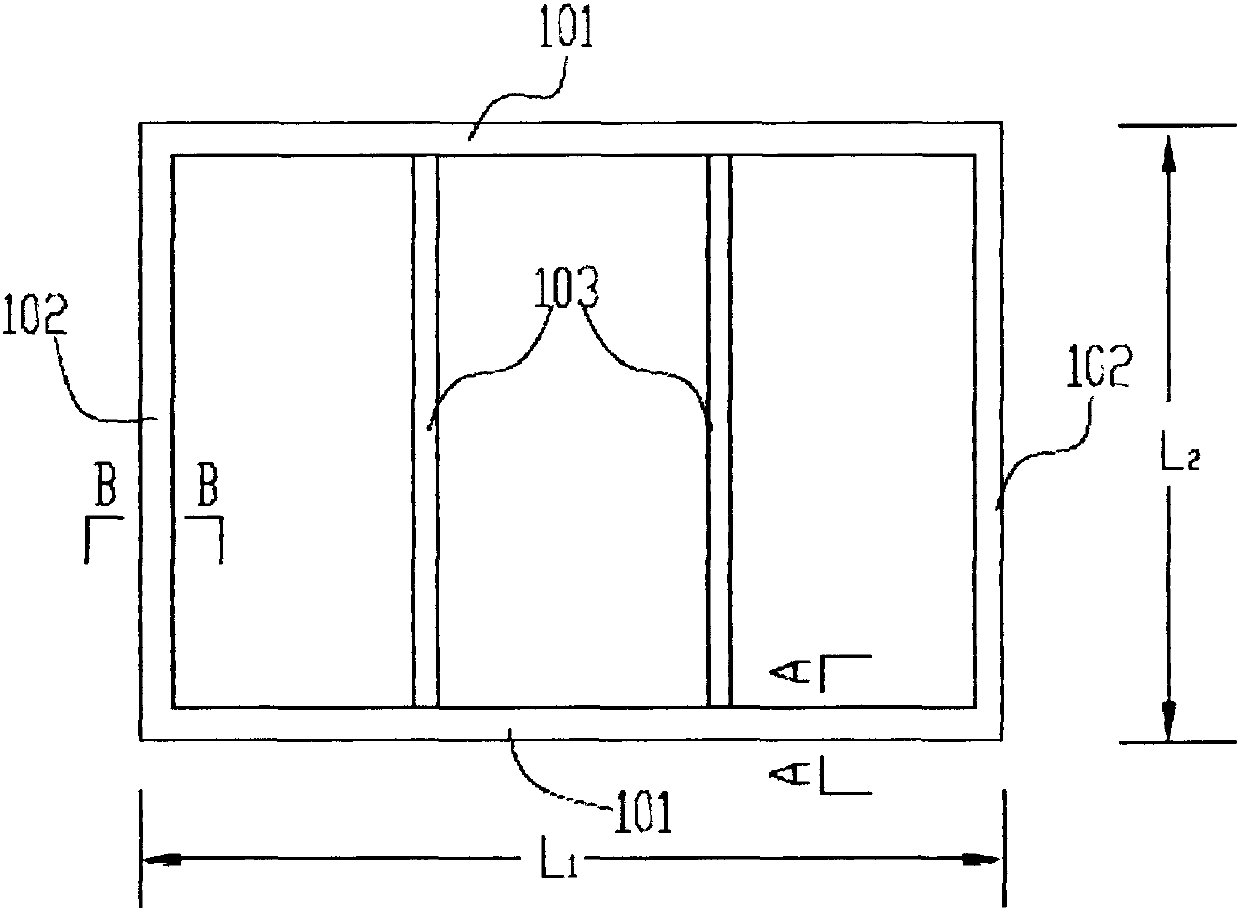

[0040] The steel structure frame includes a pair of first channel steel 101 and a pair of second channel steel 102, the first channel steel 101 and the second channel steel 102 form a rectangular frame structure, and the legs of a pair of first channel steel 101 Set opposite to each other, the legs of a pair of second channel steel 102 are set opposite to each other; two reinforcing ribs 103 are arranged along the width direction of the rectangular frame structure, and the reinforcing ribs 103 are evenly distributed in the length direction of the rectangular frame structure; The first channel steel 101 is provided with 6 threaded holes uniformly distributed along its length direction, and the threaded holes are located on the axis of symmetry of the first channel steel 101 along the length direction; the second channel steel 102 is provided with 5 A threaded hole uniformly distributed along its length direction, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thick waist | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com