High-power current converter low-temperature testing method

A low-temperature test and converter technology, applied in the field of converter test, can solve the problem of not examining the full power characteristics of the converter, and achieve the effects of verifying low-temperature start-up performance, improving thermal balance rate, saving test time and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A high-power converter low-temperature test method, the high-power converter low-temperature test method includes the following steps:

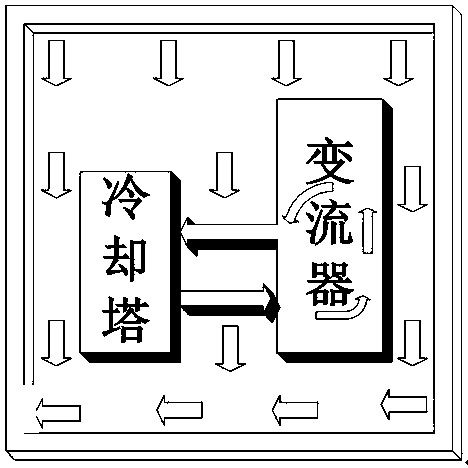

[0031] S1: Hoist the converter and cooling tower to the environmental chamber sample car; figure 1 As shown, in order to maintain the temperature uniformity of the environmental box, the air outlet of the cooling tower and the converter should be consistent with the forced air direction of the environmental box, and the air outlet should be aligned with the air return port of the environmental box.

[0032] S2: Set up the platform: under the network voltage of 25kV±0.5kV, connect the input terminal of the converter to the output terminal of the transformer, connect the output terminal of the converter to the resistive load, and connect the DC110V control circuit;

[0033] S3: Connect the cooling tower and the converter, add ethylene glycol as the cooling liquid;

[0034] S4: Converter test run: Connect the power supply to the DC110V c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com