Photosensitive resin composition and color filter comprising same

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve the problems of limited degree of freedom, color purity of color filter, limited brightness and contrast, and achieve improved brightness, reduced sensitivity, and excellent solvent resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0199] Examples 1-4 and Comparative Examples 1-3 were produced according to the ratio shown in the following Table 1. The feeding unit of each composition is gram (g).

[0200] [Table 1]

[0201]

experiment example 1

[0202] Experimental example 1. Measurement of film reduction

[0203] The said photosensitive resin composition was spin-coated (spincoated) on glass (5cm*5cm), and it prebaked (prebake) at 110 degreeC for 70 second, and formed the film. Irradiate 30mJ / cm to the entire surface of the substrate 2 exposure. After removing the film layer at the center of the substrate, check the level difference using a surface level difference measuring device.

[0204] Thereafter, the exposed substrate was developed at 0.1 mPa for 55 seconds with a developing solution (KOH, 0.04%), and the level difference was confirmed using a surface level difference measuring device.

[0205] The height difference before and after image development was confirmed, and the degree of film reduction was calculated|required, and it shows in following Table 2.

experiment example 2

[0206] Experimental example 2. Evaluation of peeling

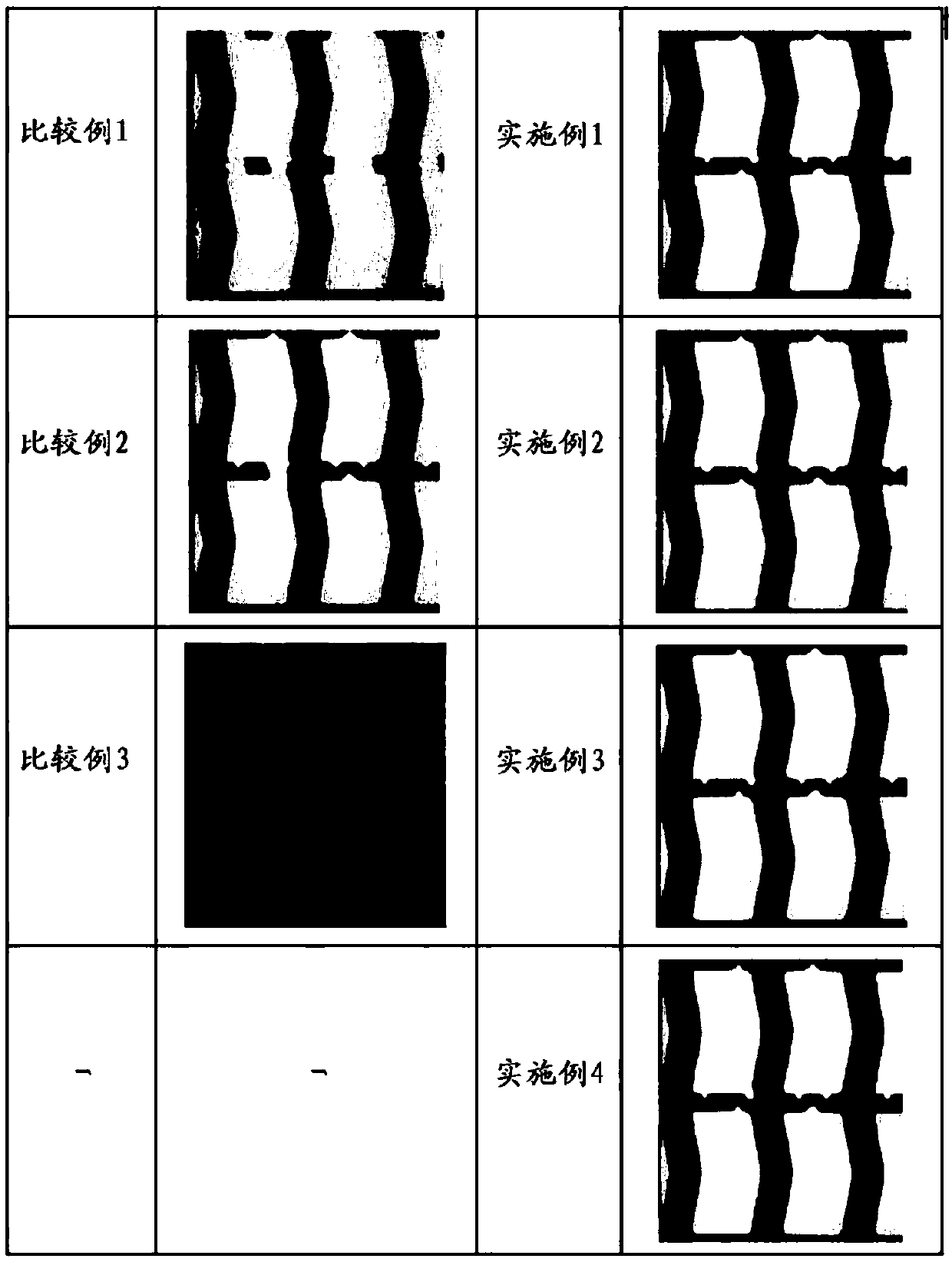

[0207] The said photosensitive resin composition was spin-coated (spincoated) on glass (5cm*5cm), and it prebaked (prebake) at 110 degreeC for 70 second, and formed the film. The distance between the substrate on which the film is formed and the photo-mask (photo-mask) is set to 600um, and the entire surface of the substrate is irradiated with 30mJ / cm 2 exposure. Thereafter, after developing the exposed substrate at 0.2 mPa for 300 seconds with a developing solution (KOH, 0.04%), the pattern was observed with an Olympus optical microscope to confirm the degree of pattern peeling. The degree of stripping is shown in the attached figure 1 .

[0208] [Table 2]

[0209]

[0210] As above Table 2 and attached figure 1 As shown, it can be seen that when color filters are manufactured using the photosensitive resin compositions of Examples 1 to 4 containing both the compound represented by Chemical Formula 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com