Transformer sealing terminal and installation fabrication process thereof

A technology of sealing terminals and manufacturing process, which is applied in the direction of inductor/transformer/magnet manufacturing, transformer/inductor casing, transformer/inductor parts, etc., to achieve the effects of saving economic costs, high installation efficiency, and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

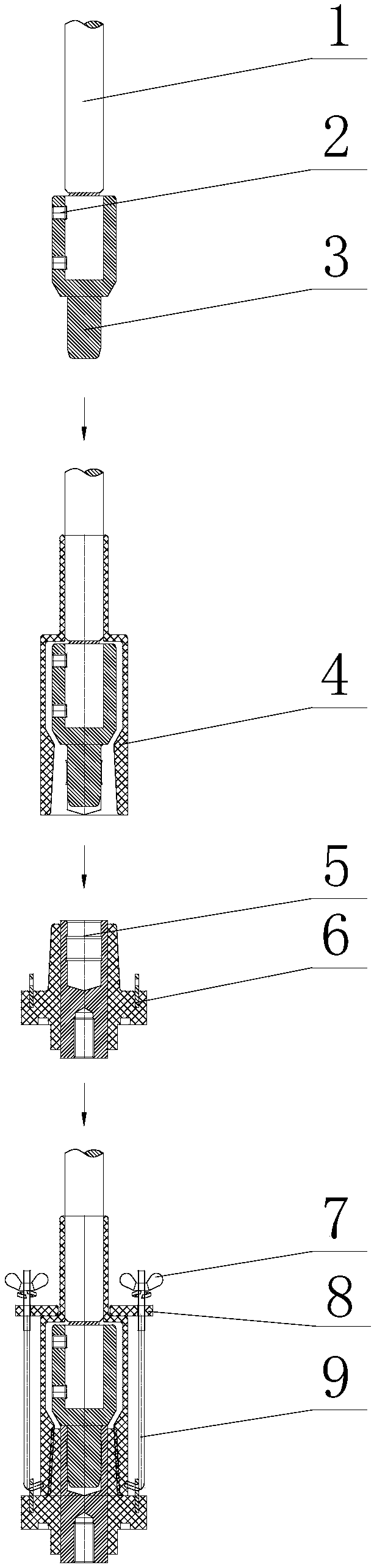

[0024] Such as figure 1 As shown, the transformer sealing terminal of the present invention includes an integrated sleeve installed on the transformer body and a silicone sleeve sleeved on the integrated sleeve. The silicone sleeve is sleeved on the power cable and the stress cone. The integrated A steel support is provided on the casing base, and two arc-shaped stainless steel sheets are provided on the large end surface of the silicone sleeve, and the silicone sleeve is tightened on the integrated casing by a pull hook and a butterfly nut.

[0025] In the present invention, a copper spring is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com