Automatic film coating machine of battery electrode group

A battery pole group, coating machine technology, applied in the direction of lead-acid battery, lead-acid battery construction, packaging, etc., can solve the problems of physical health damage of staff, slow coating of PVC film, etc., to achieve ingenious structure, avoid scattered, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

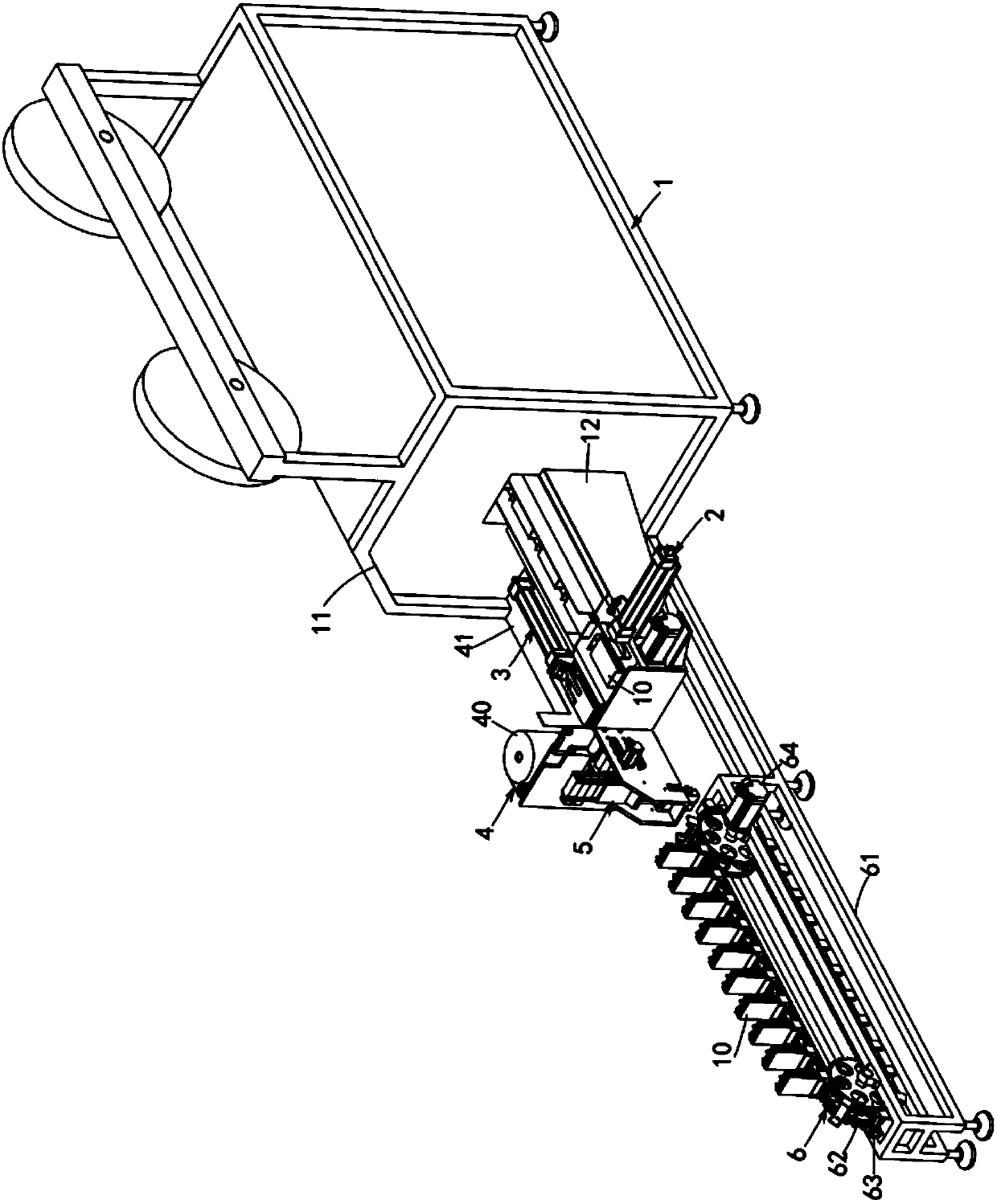

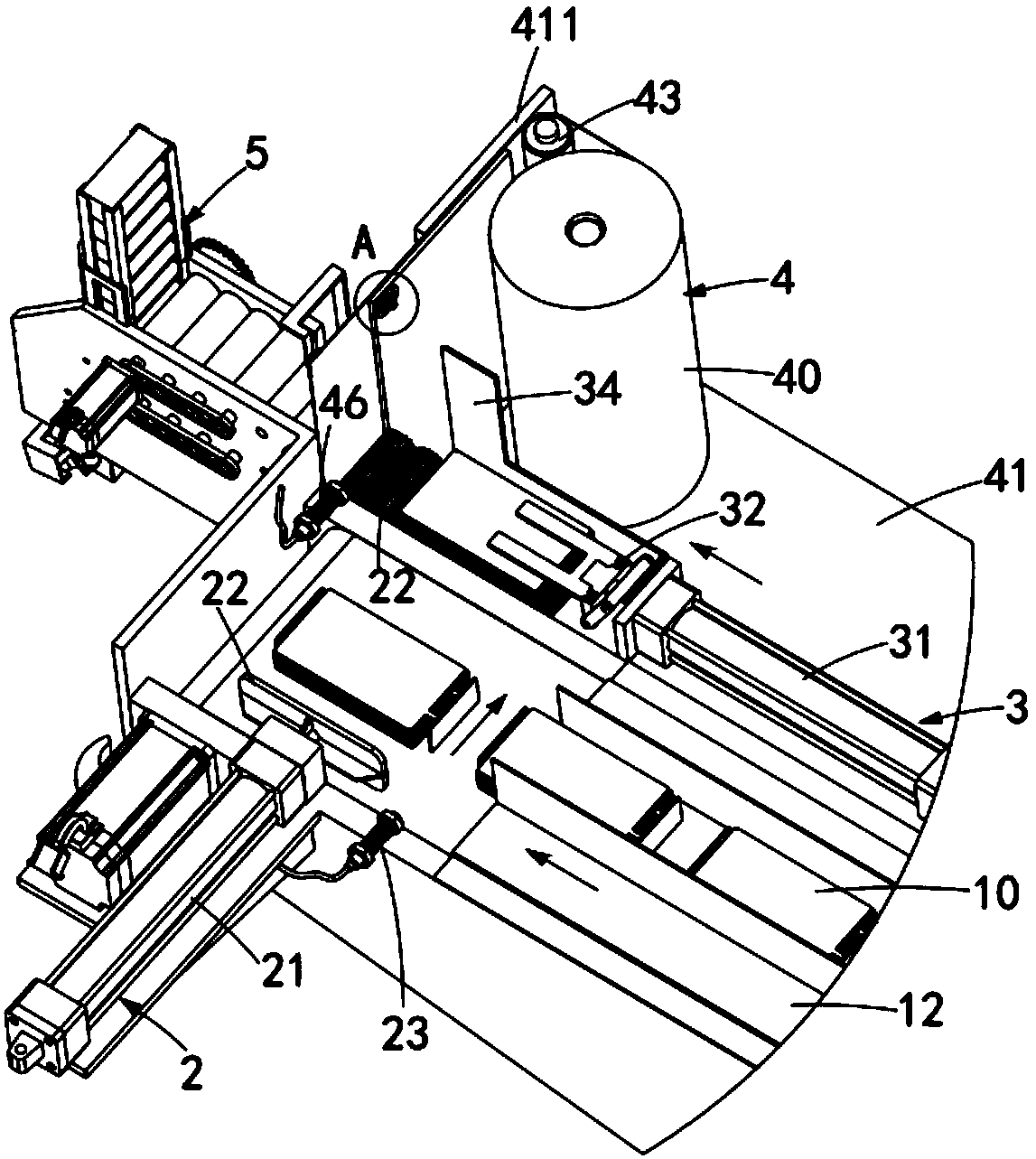

[0076] Such as figure 1 and figure 2 As shown, an automatic coating machine for battery pole groups includes a wrapping machine 1. The wrapping machine 1 includes a body 11 and a conveying channel 12, and a plurality of pole groups 10 are transported on the conveying channel 12, and also includes:

[0077] The first pushing mechanism 2, the first pushing mechanism 2 is arranged on one side at the end of the delivery channel 12, it is vertically arranged with the delivery channel 12, and it pushes the pole group output by the delivery channel 12;

[0078] The second pushing mechanism 3, the second pushing mechanism 3 is arranged on the other side of the conveying channel 12 relative to the first pushing mechanism 2, it is arranged in parallel with the conveying channel 12, and it pushes the pole group 10 Complete the coating work;

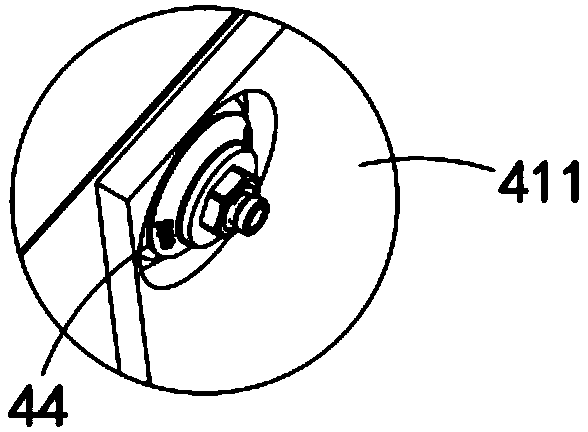

[0079] The film delivery mechanism 4, the film delivery mechanism 4 is arranged on the rear side of the second pushing mechanism 3, and it trans...

Embodiment 2

[0136] Figure 11 It is a schematic structural view of Embodiment 2 of a battery electrode group automatic coating machine of the present invention; as Figure 11 As shown, the same or corresponding parts as in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 are described below, and this Embodiment 2 is different from Embodiment 1. figure 1 Example 1 shown differs in that:

[0137] Such as Figure 11 As shown, a rod-shaped electric heating rod 351 can also be arranged inside the coating roller of the described coating roller group 35, and the heating of the electric heating rod 351 makes the coating roller have a certain amount of heat, and the PVC is driven in the pole group 10. When the film 40 passes through the film-coated roller group 35, the film-coated roller rolls the PVC film, so that the effect of the PVC film on the pole group 10 is better.

[0138] The working process is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com