Fiber reinforced composite material anti-vibration hammer

A composite material and fiber-reinforced technology, applied in the direction of mechanical vibration attenuation devices, can solve problems such as weak ability to absorb vibration energy, easy oxidation, and poor corrosion resistance, and achieve low cost, improved life, strong oxidation resistance and The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

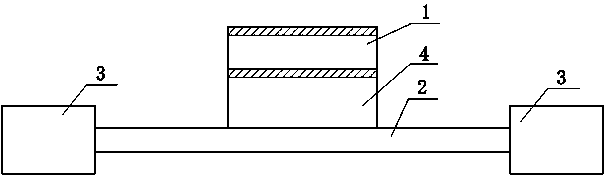

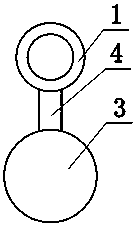

[0016] Example: see figure 1 with figure 2 , in the figure, 1-line card, 2-elastic rod, 3-hammer, 4-connecting plate.

[0017] The anti-vibration hammer made of fiber reinforced composite material includes a line card 1 and a hammer head 3. There are two hammer heads 3, which are arranged at both ends of the elastic rod 2. The middle part of the elastic rod 2 is provided with a connection with the line card 1. The plate 4 and the connecting plate 4 are composite pultruded plates, the elastic rod 2 is a composite pultruded rod, and the hammer head 3 is a composite body of structural steel and composite material.

[0018] The connection part between the hammer head 3 and the elastic rod 2 is composite material. The connecting part between the hammer head 3 and the elastic rod 2 is structural steel. The hammer head 3 is a structural steel wrapped with a composite material. The composite material is a fiber reinforced composite material.

[0019] When in use, due to the rigi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com