Harvester assorted auger compression straw bundling machine

A harvester and screw technology, applied in the field of screw compression straw breaker, can solve the problems of high economic cost, environmental pollution, no direct recycling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiment is further described in detail below in conjunction with accompanying drawing:

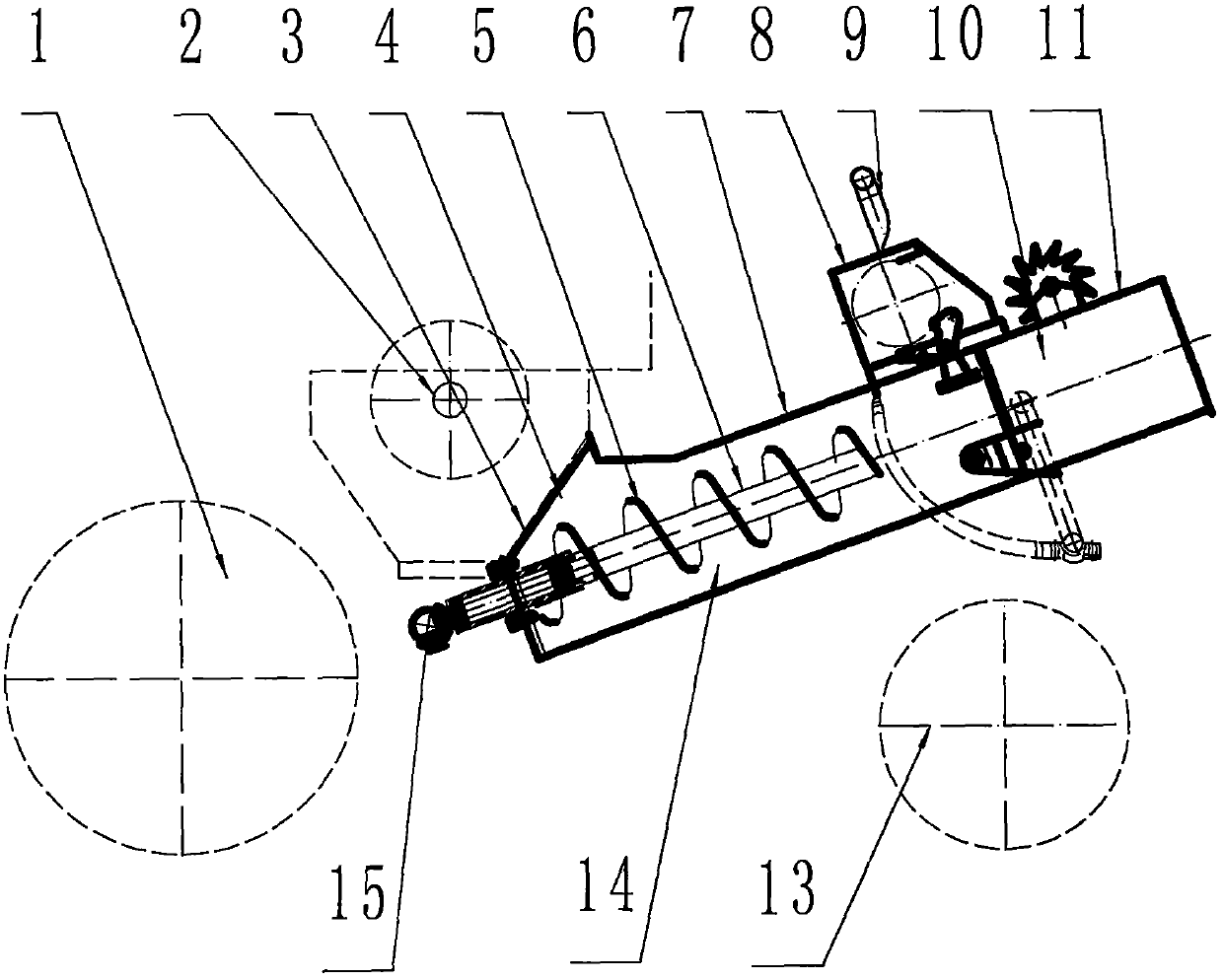

[0009] refer to figure 1 : 1-Front wheel of harvester, 2-Roller shaft of harvester, 3-Grass outlet of harvester, 4-Grass inlet of pruning machine, 5-Screw blade, 6-Spindle, 7-Material barrel, 8-Knot device, 9- air duct, 10- punching device, 11- punching box, 13- rear wheel of harvester, 14- screw compression device, 15- mechanical transmission parts, the whole baler only has screw compression device 14, punching The punching device 10 and the power transmission device are composed of three parts. The punching device 10 includes a knotting device 8 and a punching box 11. The screw compression device 14 includes a screw and a barrel 7. The screw is installed in the barrel 7, and the barrel 7 It is the same channel as the punching box 11. The screw rod includes a helical blade 5 and a main shaft 6. The helical blade 5 is fastened on the main shaft 6. The main shaft 6 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com