Regulating type mining machinery gear heat treatment device

A heat treatment device and adjustable technology, applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve problems such as inability to adjust, damage to gears and rotating parts, and blocking of rotating parts, so as to achieve good stability in use and reasonable structure settings , fast fix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

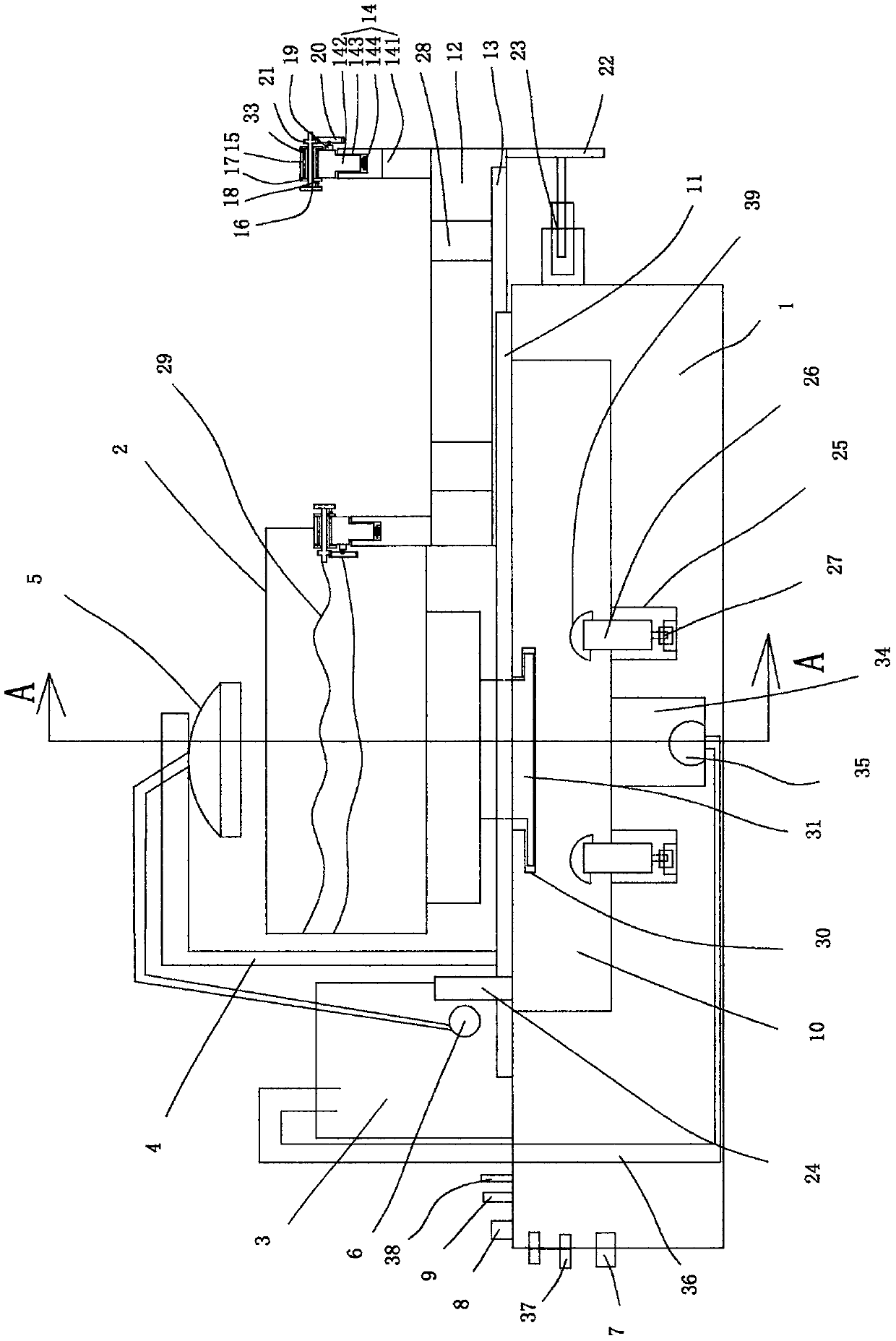

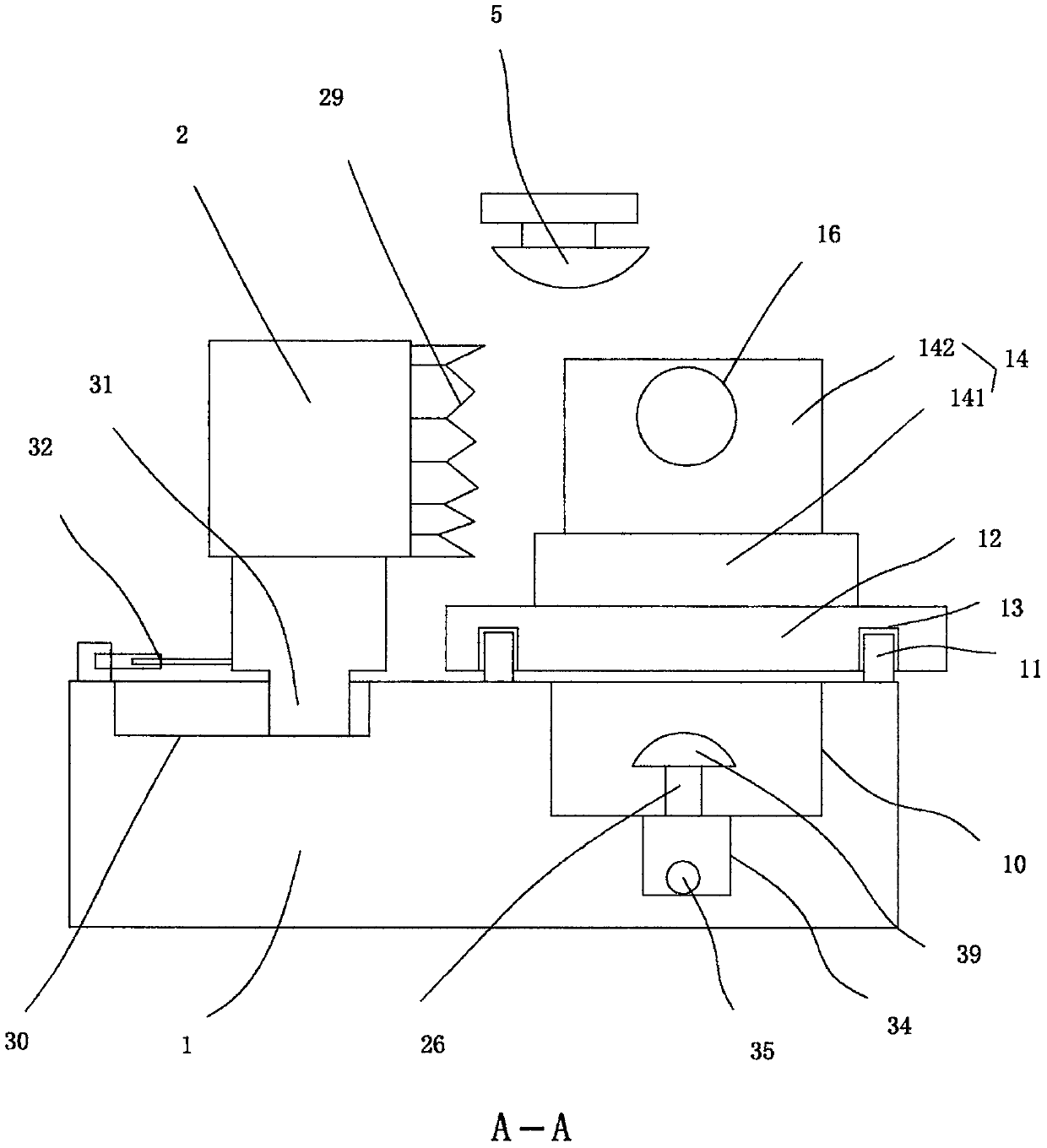

[0018] figure 1 with figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 for figure 1 Middle A-A sectional view.

[0019] See figure 1 with figure 2 , an adjustable gear heat treatment device for mining machinery, comprising a base 1, an all-solid induction heater 2 and a water storage tank 3 arranged on the base 1, the all-solid induction heater and the water storage tank are structures of the prior art, It is also a conventional use structure in this technical field, so it is not described in detail. A cooling bracket 4 is fixed on the base 1, a shower head 5 is fixed on the cooling bracket 4, and a shower head 5 is fixed on the cooling bracket 4. A shower pipe and a shower pump 6 connecting the shower head 5 and the water storage tank 3 are fixed, and a power socket 7 and a control switch 8 connected to the solid state induction heater 2 are arranged on the base 1 and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com