A method for measuring shape parameters of cylindrical rods

A measurement method and technology of shape parameters, applied in the field of measurement, can solve problems such as inability to calculate cylindricity, pipe end straightness, etc., and achieve the effect of improving labor efficiency and simplifying work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1: Calculating the straightness and coaxiality of the end of the oil well pipe

[0075] In view of the requirement of measuring the straightness and coaxiality of the end of the oil well pipe by using the saddle gauge measurement method manually, the method proposed by this method can be applied to measure in a non-contact, efficient and accurate manner.

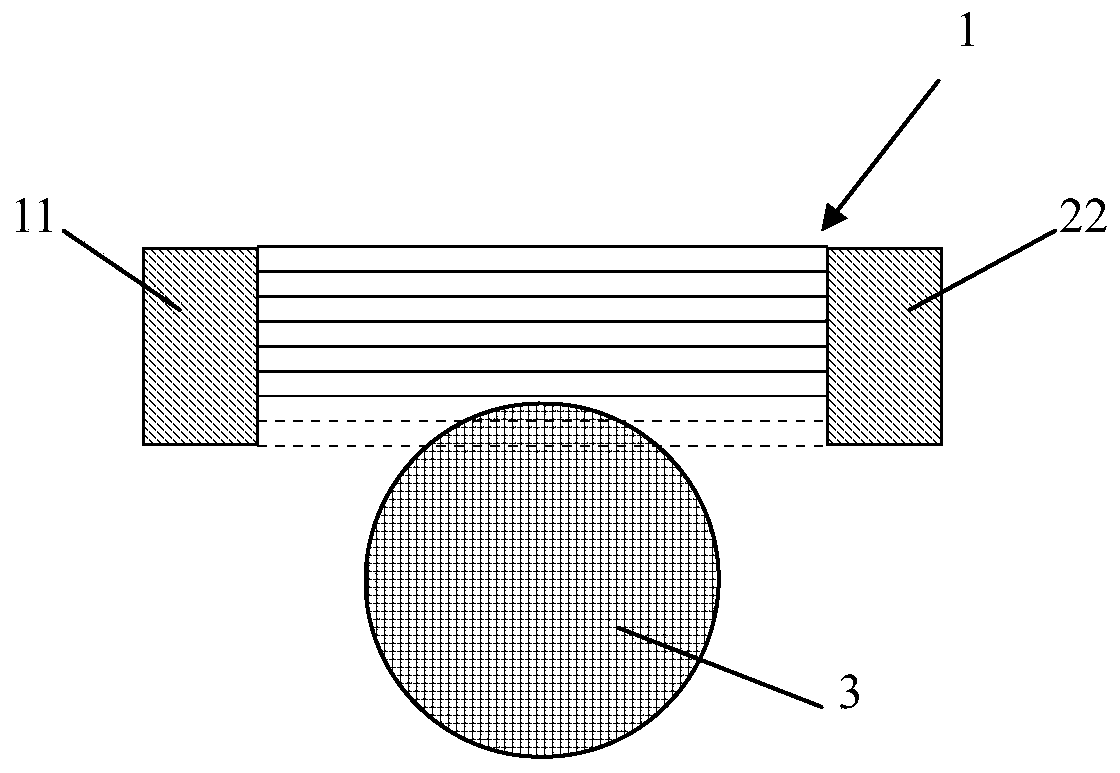

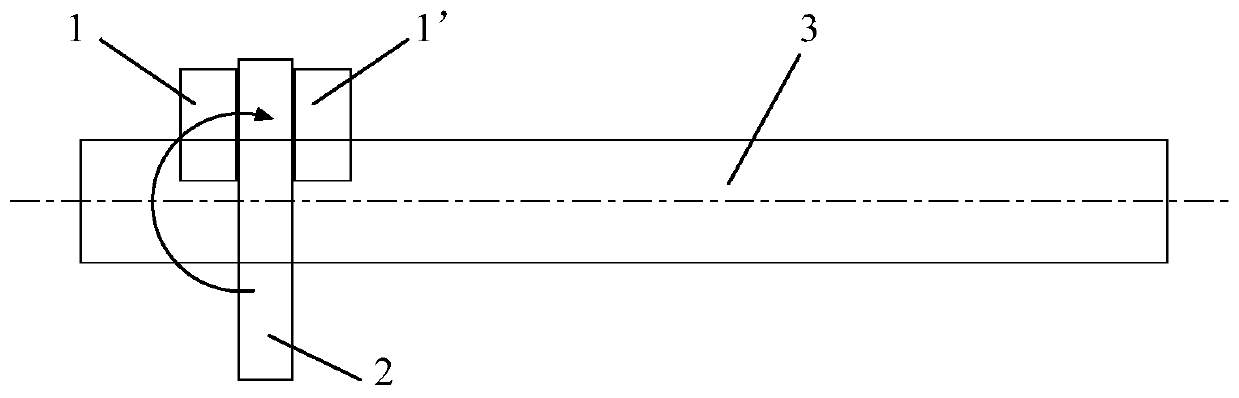

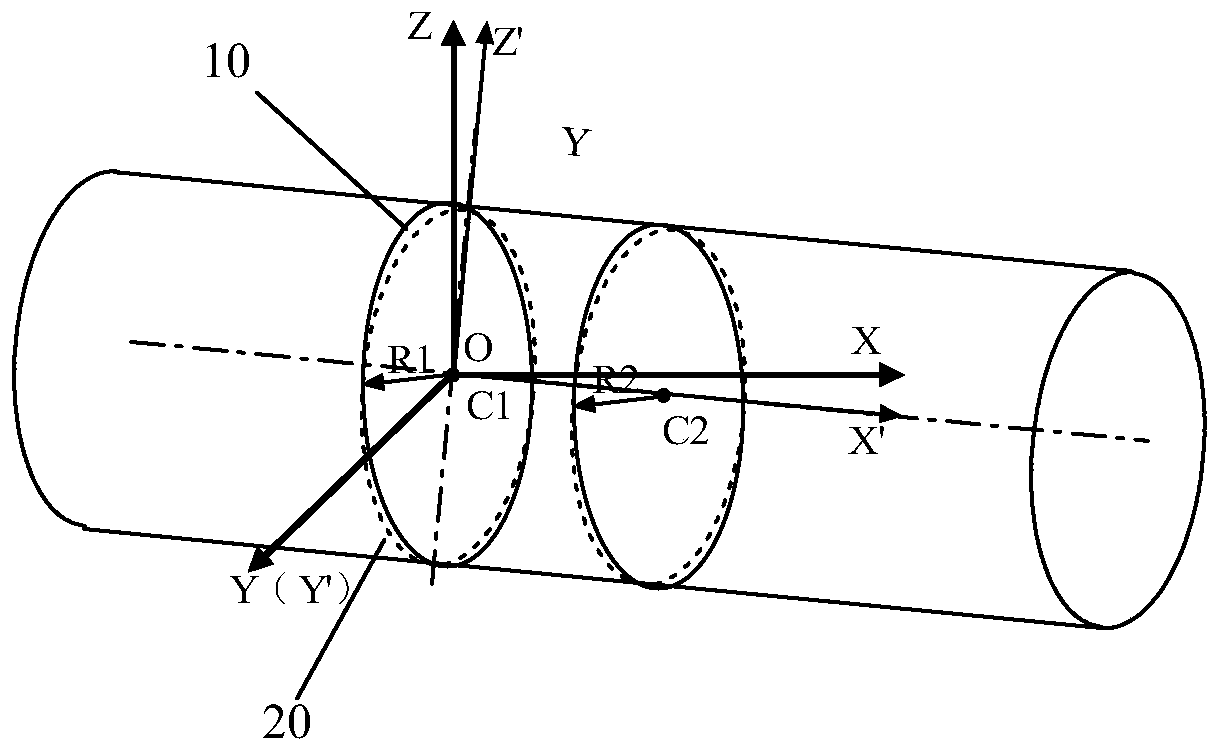

[0076] Such as Figure 5 As shown in Fig. 1, a set of measuring sensors are respectively arranged at the end and inside of the oil well pipe, and the positions between the sensors are fixed. Rotate the two sets of sensors, measure two sections at the end and inside of the oil well pipe respectively, calculate the centers C1~C4 of these four sections and connect them, so that the diameter of the pipe end and the centerline C1C2, internal Diameter and centerline C3C4, calculate the angle θ and distance d between two straight lines in the three-dimensional space coordinate system, and characterize the straightne...

Embodiment 2

[0077] Embodiment 2: Calculate steel pipe diameter, roundness and straightness

[0078] Such as Image 6 As shown, multiple groups of sensors are arranged in the length direction of the steel pipe, and the positions between the sensors are fixed and can rotate around the steel pipe on a fixed track. During the measurement, multiple sets of sensors rotate around the steel pipe synchronously to obtain the contour data of multiple sections, and calculate the center C1~C4, circle radius R1~R4, and roundness of each contour circle respectively; connect the circle centers C1~C4 to calculate the The straightness of the connecting line is used to characterize the straightness of the steel pipe.

[0079] The present invention has broad prospects for popularization and application, and can be applied to the parameter measurement of all round rods, pipes and rollers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com