Acidic gas absorbent and composition for absorbing acidic gas comprising same

A technology of acid gas and absorbent, applied in reagents, educts, climate sustainability, etc., can solve the problems of high energy consumption, low economic benefits, difficult to handle chemical reaction products, etc., to achieve low energy consumption and good economic benefits , The effect of reducing electricity costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

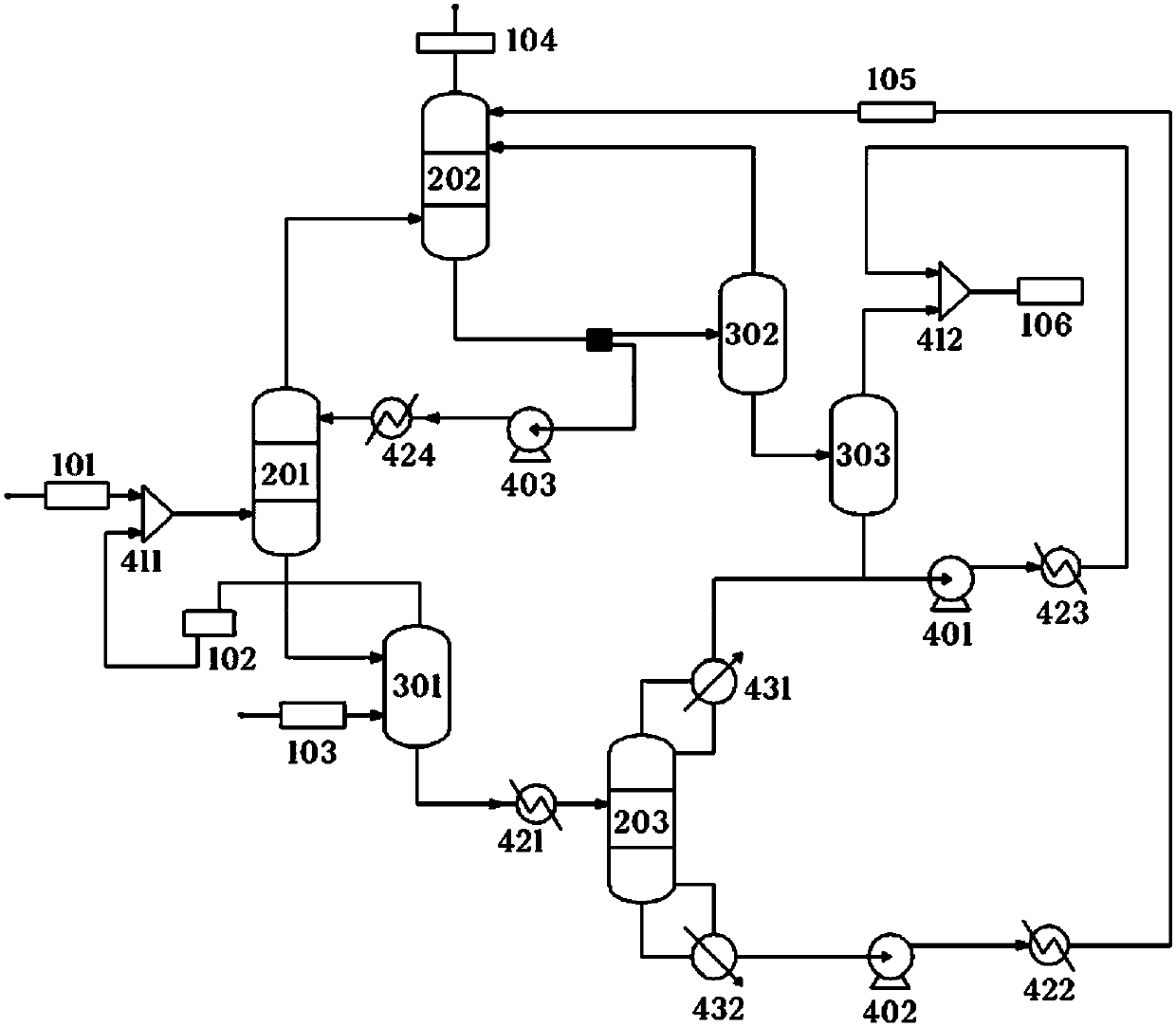

Method used

Image

Examples

example 6

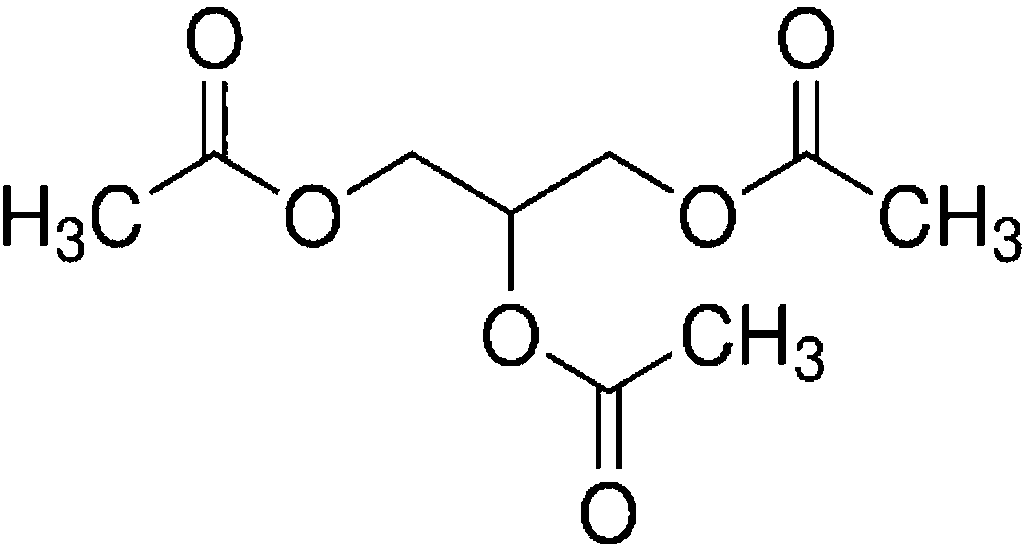

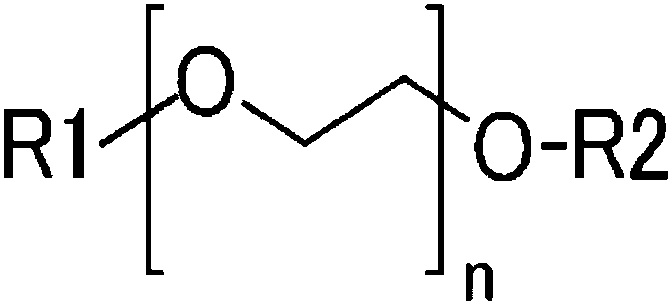

[0093] According to the ingredients listed in Table 1 below, a composition for absorbing acid gas was prepared in the same manner as in Example 1, except that polyethylene glycol of formula 2 having a weight average molecular weight of 250 g / mol was changed to a weight average molecular weight The polyethylene glycol of formula 2 is 280 g / mol.

example 7

[0095] According to the ingredients listed in Table 1 below, a composition for absorbing acid gas was prepared in the same manner as in Example 1, except that polyethylene glycol of formula 2 having a weight average molecular weight of 250 g / mol was changed to a weight average molecular weight 350 g / mol of polyethylene glycol of formula 2.

example 8

[0097] According to the ingredients listed in Table 1 below, a composition for absorbing acid gas was prepared in the same manner as in Example 1, except that polyethylene glycol of formula 2 having a weight average molecular weight of 250 g / mol was changed to a weight average molecular weight 400 g / mol of polyethylene glycol of formula 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com