Robot welding workstation for aluminum alloy heat radiator

A robot welding and radiator technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of low welding efficiency, troublesome positioning, troublesome welding, etc., and achieve the effect of improving welding efficiency, fast and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

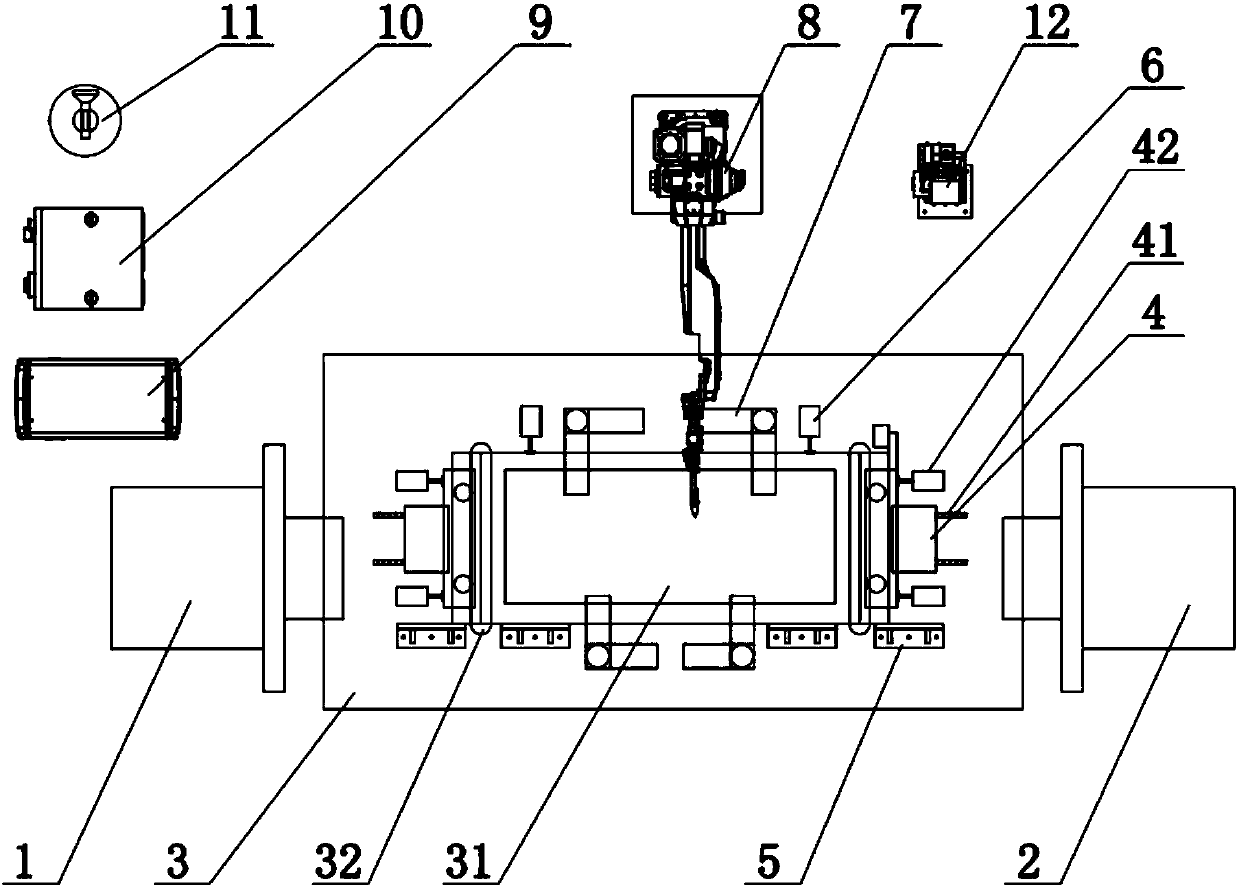

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the aluminum alloy radiator robot welding workstation of this embodiment includes a welding robot system and a fixed overturning mechanism, the fixed overturning mechanism includes an active positioner 1 and a driven positioner 2, the active and driven positioner 1, 2 is connected with a fixed frame 3, and the fixed frame 3 is provided with a rectangular relief hole 31 in the middle of the welding radiator and a waist-shaped relief hole 32 at both ends of the welding radiator, and the left and right sides of the fixed frame 3 are provided with a sliding top tightening mechanism 4 , the sliding clamping mechanism 4 is arranged on the guide rail 41, and the sliding clamping mechanism 4 is connected to the driving cylinder 42, the fixed positioning block 5 is arranged on the front side of the fixed frame 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com