Chamfer processing method for cylindrical roller

A technology of cylindrical rollers and processing methods, which is applied to metal processing equipment, manufacturing tools, and parts of grinding machine tools. Deviation and other problems, to achieve the effect of improving dynamic unbalance, chamfering symmetry control, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

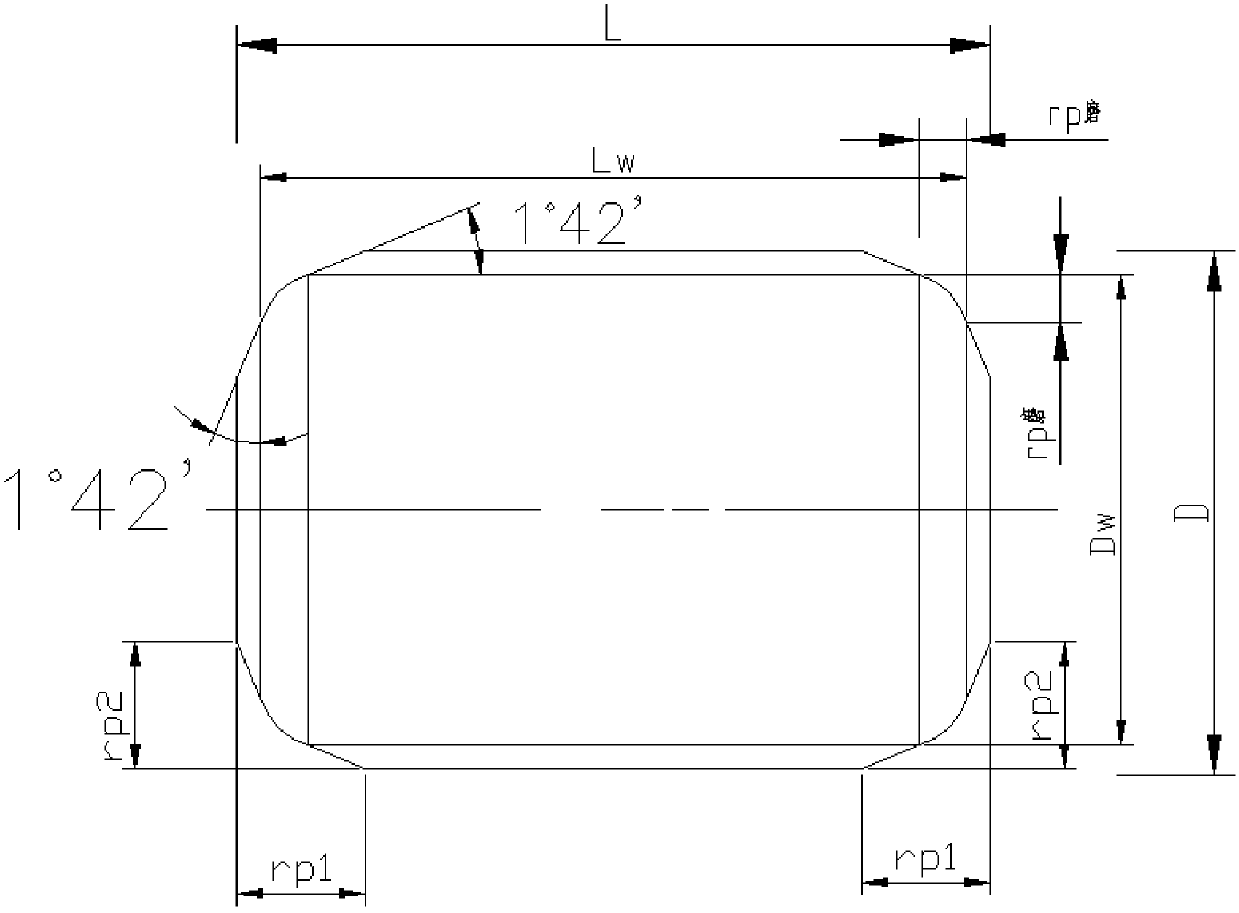

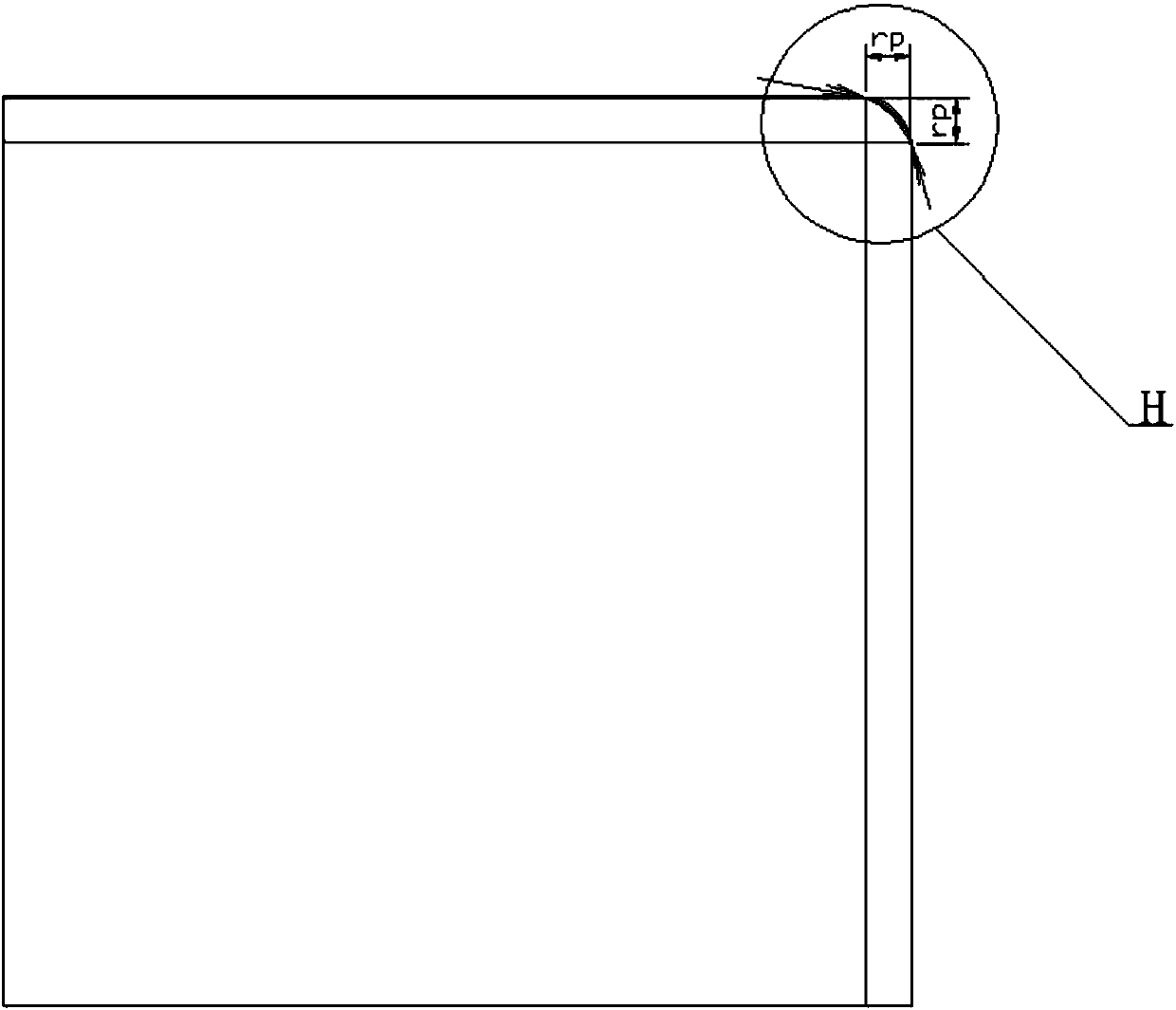

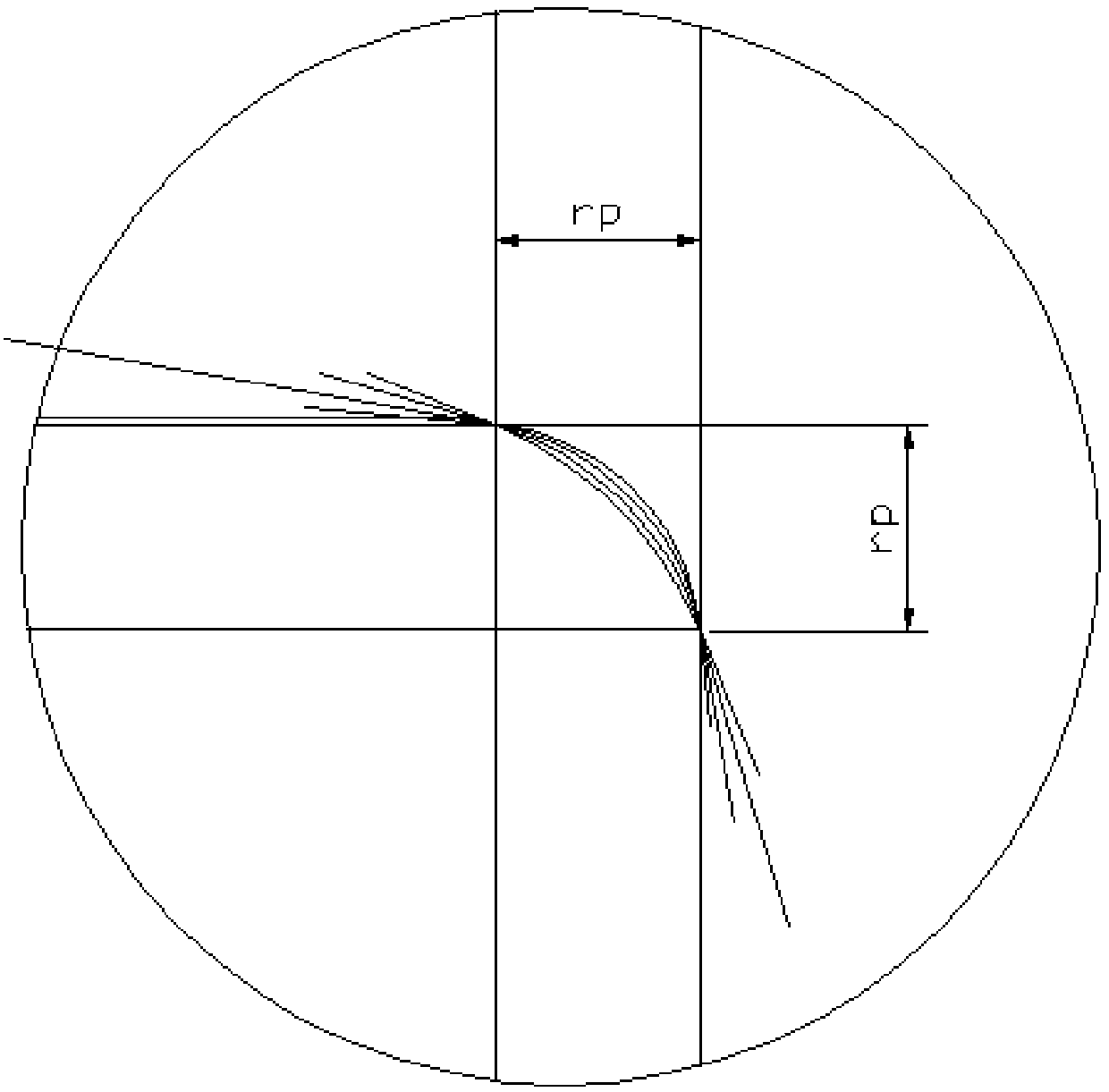

[0027] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, the chamfering processing method of a kind of cylindrical roller of this embodiment, it comprises the following processing steps:

[0028] Step 1: cut off;

[0029] Cut the bar according to the size required by the process on the CNC lathe, with an outer diameter of 0.5mm and a length of 0.5mm;

[0030] Step 2: Softly grind the outer diameter and end face of the cut bar;

[0031] Carry out soft grinding to the bar after cutting, the outer diameter removal amount of soft grinding is 0.2mm, and the end face removal amount of soft grinding is 0.18mm;

[0032] Step 3: Chamfering at both ends of the car;

[0033] On the basis of step 2, the chamfering of the cylindrical roller is carried out on the lathe, and the cutting parameters are the chamfering coordinate allowance before chamfering grinding plus the allowance of the outer diameter and the end face;

[0034] Step four: heat tr...

specific Embodiment approach 2

[0049] Specific implementation mode two: combination Figure 1 to Figure 5 To describe this embodiment, the outer contour shape of the diamond roller used in step six of this embodiment is consistent with the chamfer shape of the cylindrical roller to be ground. Such setting can make the chamfering shape reach the ideal state, ensure the consistency of the chamfering shape of the rollers in the processing process, improve the accuracy of the runout of the outer diameter of the chamfering of the rollers, and improve the dynamic unbalance of the rollers during operation. Other contents are the same as those in the first embodiment.

specific Embodiment approach 3

[0050] Specific implementation mode three: combination Figure 1 to Figure 5 To illustrate this embodiment, the processing steps after heat treatment in Step 5 of this embodiment are a rough outer diameter grinding process, an end face grinding process, a fine outer diameter grinding process, a fine end face grinding process, and a fine grinding outer diameter process. With such setting, the machining precision of the roller can meet the final precision requirement. Because the outer diameter and end surface processing of the roller need to be positioned with each other during the processing of the roller, the principle is to process the outer diameter first, and then the end surface; since the outer diameter is the main working surface, the processing accuracy is high and the busbar shape is required. Therefore, the final machining process is also outer diameter machining. Other contents are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com