A sandblasting heat treatment device

A heat treatment device and sandblasting technology, which is applied in heat treatment furnaces, heat treatment equipment, abrasive jet machine tools, etc., can solve the problems of increasing the labor load of workers and wasting energy, so as to improve the treatment effect, reduce the labor load, and improve various performances. Effect

Active Publication Date: 2020-08-04

马鞍山祥源机械厂

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to solve the shortcomings in the prior art, such as: the traditional heat treatment and sand blasting are carried out separately, and the metal material needs to be heated twice, which greatly wastes energy and increases the labor of workers , and proposed a sandblasting heat treatment device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

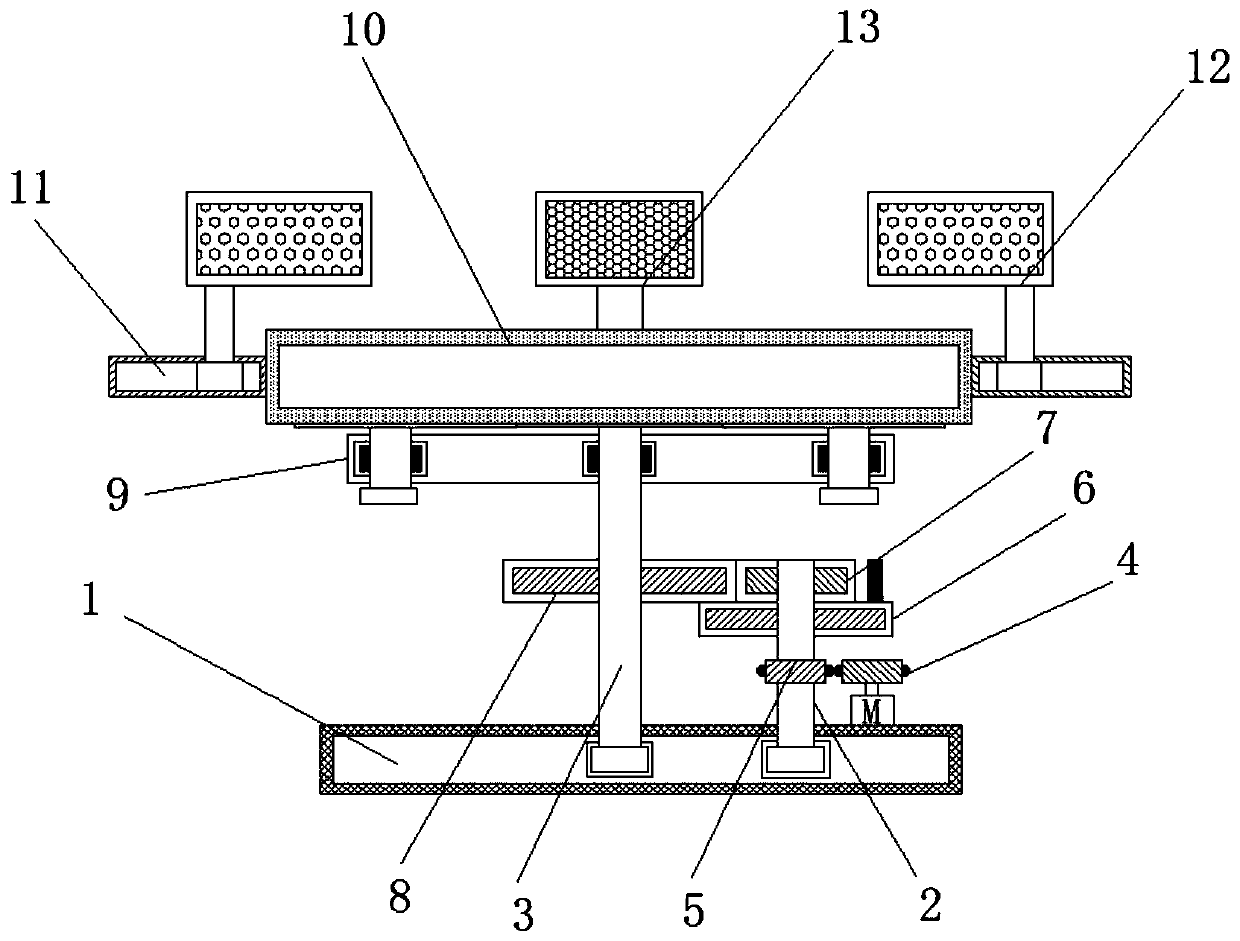

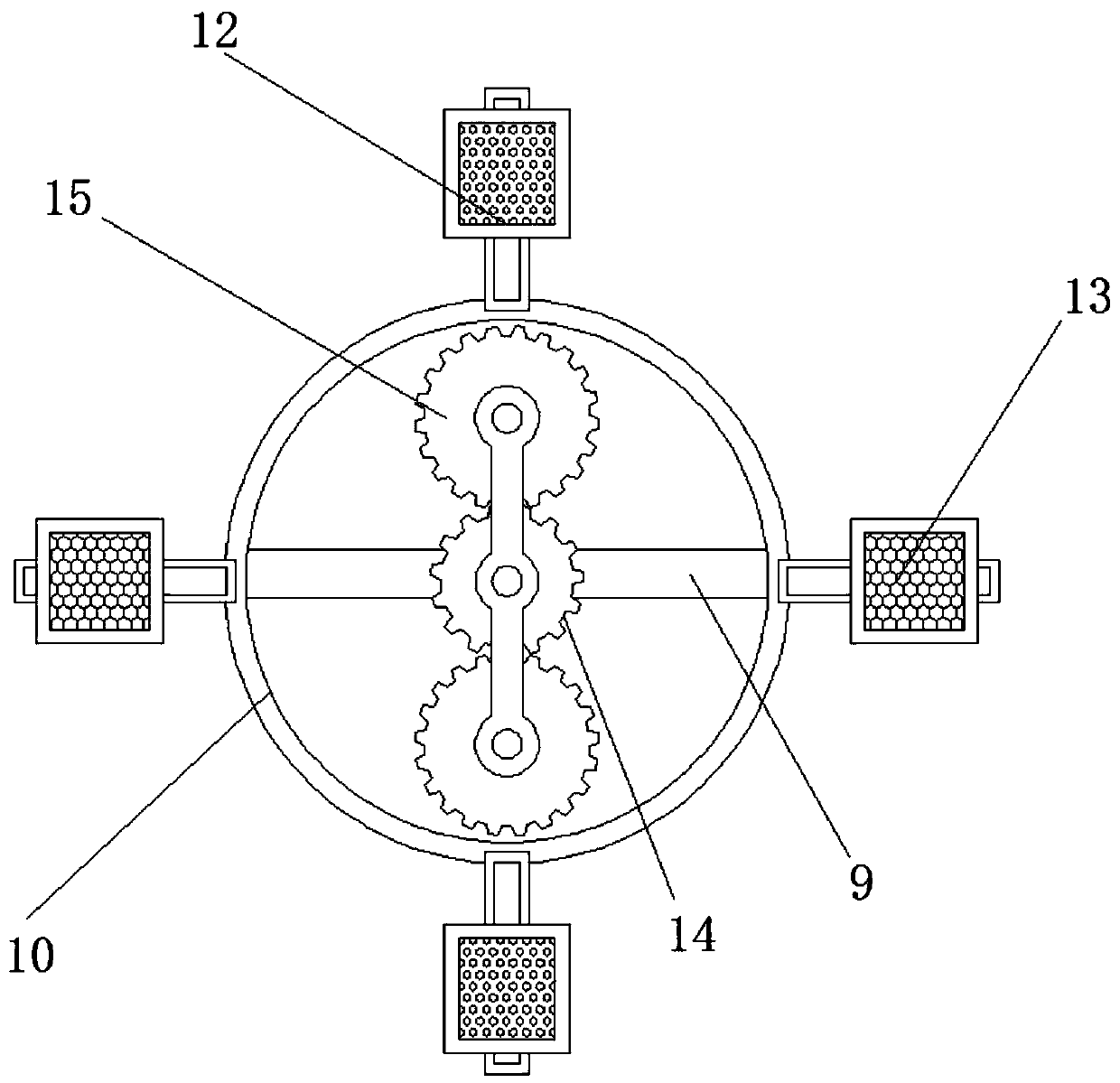

The invention discloses a sand blasting type heat treatment device. The sand blasting type heat treatment device comprises a bottom plate, wherein a first rotating groove and a second rotating grooveare arranged in the upper side of the bottom plate; a first rotating shaft in rotating connection with the first rotating groove is inserted into the first rotating groove; a first rotating disc and aconnecting disc are arranged on the first rotating shaft; the connecting disc is located at the upper side of the first rotating disc; a second rotating shaft in rotating connection with the second rotating groove is inserted into the second rotating groove; a second rotating disc is arranged on the second rotating shaft; the second rotating disc is in sliding connection with the connecting disc;a connecting plate in rotating connection with the second rotating shaft is arranged on the second rotating shaft; and the connecting plate is located at the upper side of the second rotating disc. The sand blasting type heat treatment device has the advantages that heat treatment and sand blasting procedures are combined by the device, so that energy is greatly saved, and at the same time, the workload of workers is reduced; and as the two procedures are set together, the treatment effect is also improved, and the multiple properties of metal are improved.

Description

technical field [0001] The invention relates to the technical field of metal processing devices, in particular to a sandblasting heat treatment device. Background technique [0002] Heat treatment is a metal thermal processing process in which metal materials are heated, kept warm, and cooled in a certain medium, and their properties are controlled by changing the crystal phase structure on the surface or inside of the material. Heat treatment has an excellent effect on solving the surface properties of metal materials, so in actual production, people often perform heat treatment on the surface of metal parts after the parts are produced. Sand blasting is also a processing technology that can clean and roughen the surface of the substrate by the impact of high-speed sand flow. However, the traditional heat treatment and sandblasting are carried out separately, and the metal material needs to be heated twice, which greatly wastes energy and increases the workload of workers....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24C3/02C21D9/00

CPCB24C3/02C21D9/0018

Inventor 查德祥

Owner 马鞍山祥源机械厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com