Municipal engineering transport vehicle for road greening

A transportation vehicle and municipal technology, applied in the direction of freight vehicles, goods transportation vehicles, transportation objects, etc., can solve the problems of low tree branch transportation efficiency and inconvenient urban road greening projects, so as to improve transportation efficiency and increase transportation volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

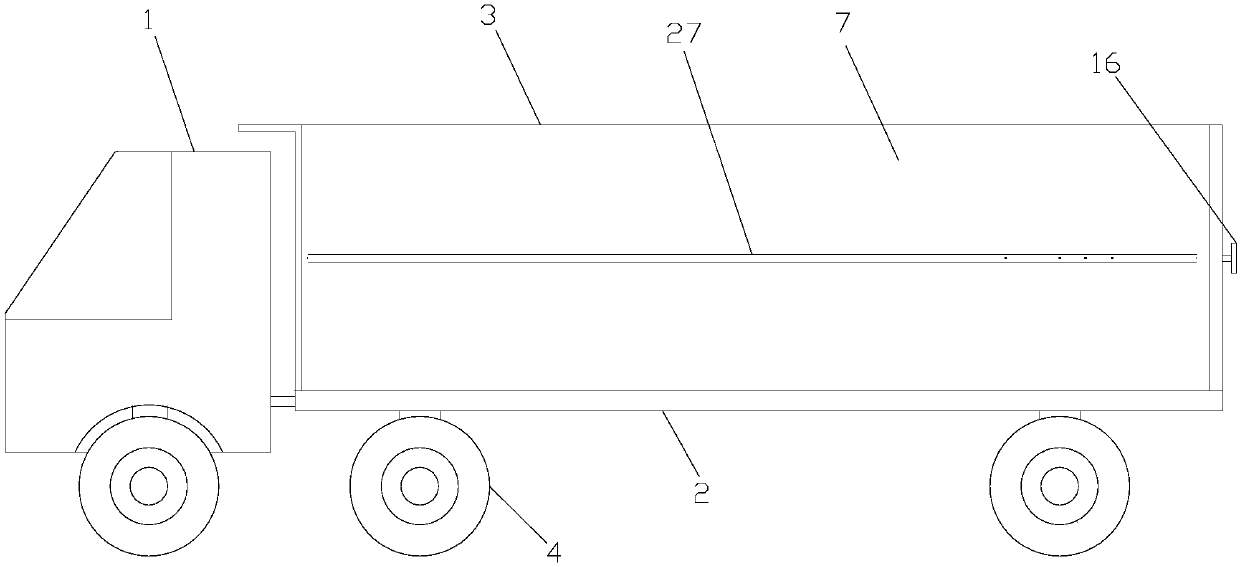

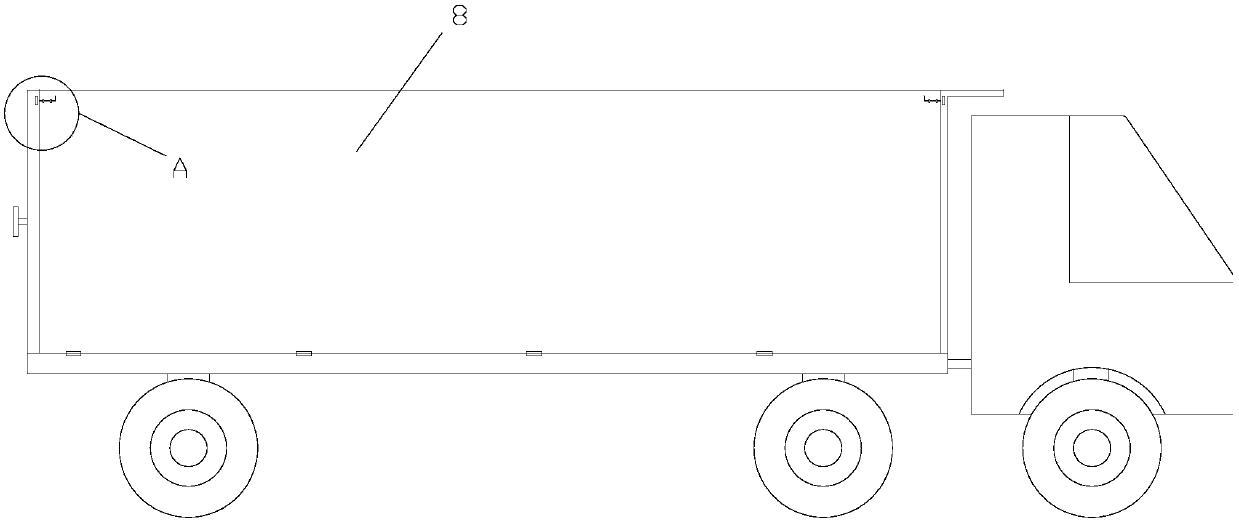

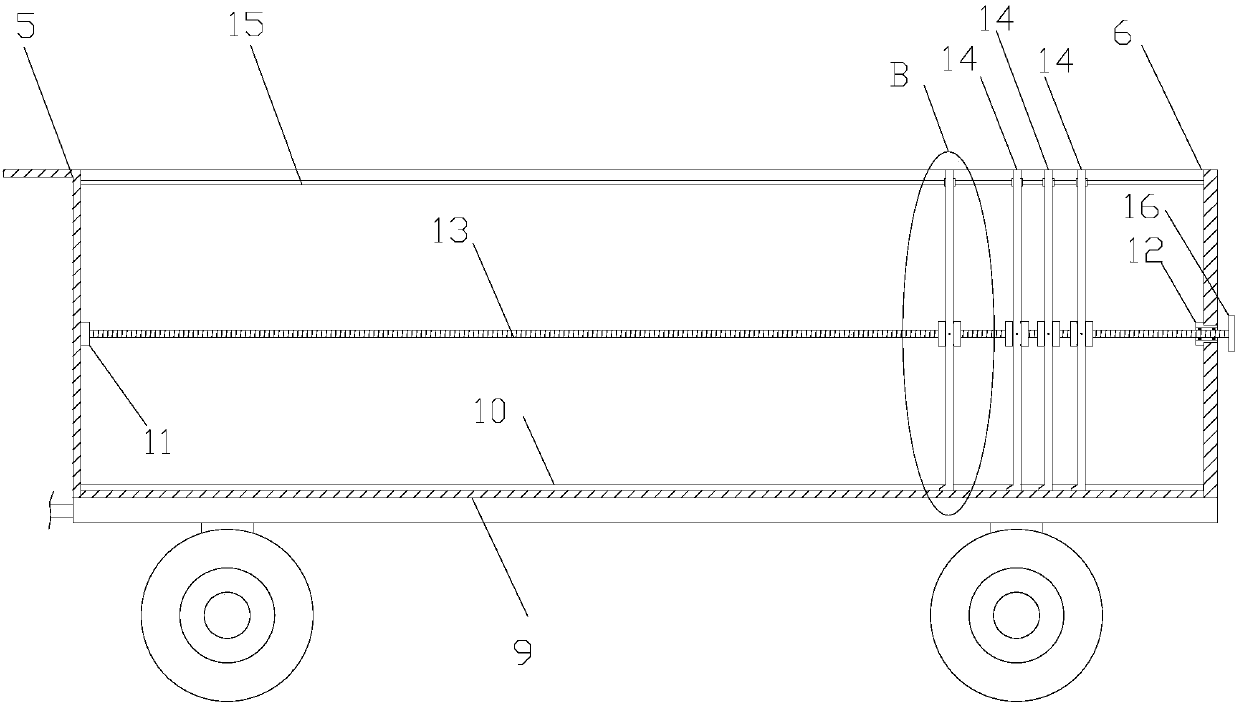

[0029] Such as figure 1 As shown, the municipal engineering transport vehicle described in this embodiment for road greening includes a headstock 1, a vehicle frame 2 and a carriage 3, the headstock 1 and the carriage 2 are connected and wheels 4 are provided below them, and the carriage 3 Set on the vehicle frame 2; It is characterized in that: as image 3 As shown, the compartment 3 is composed of a left baffle 5, a right baffle 6, a front baffle 7, a rear baffle 8 and a base plate 9, and the center of the base plate 9 is provided with a guide groove 10 arranged transversely; The baffle plate 5 is provided with a left bearing seat 11, and the right baffle plate 6 is provided with a right bearing seat 12, as Figure 9 As shown, a screw rod 13, a plurality of moving plates 14 and two guide rods 15 are also provided in the compartment 3, and the two guide rods 15 are located at both sides of the upper part of the compartment 3 and the two ends of the guide rods 15 are respecti...

Embodiment 2

[0035] Such as Figure 10 , 11 As shown, the municipal engineering transport vehicle for road greening described in this embodiment is different from Embodiment 1 in that: the front end of the moving plate 14 is provided with a hollow seat 30, and the hollow seat 30 is located in the transverse channel 27 Inside, the front end of the telescoping rod 25 passes through the hollow seat body 30, and the telescopic rod 25 is provided with a first limiting rod 31 and a second limiting rod 32, the first limiting rod 31 is located in the hollow seat body 30 and the second A spring 33 is provided between a limit rod 31 and the hollow seat body 30; the second limit rod 32 is located in front of the hollow seat body 30 and a removable spring is provided between the second limit rod 32 and the hollow seat body 30 U-shaped clamping block 34; U-shaped clamping block 34 is usually stuck in the specified position, so that the telescopic rod 25 is pulled out, and when a certain moving plate 1...

Embodiment 3

[0037] Such as Figure 12 As shown, the municipal engineering transport vehicle for road greening described in this embodiment is different from Embodiment 1 in that: the left end face of the left ring body 22 and the right end face of the right ring body 23 are provided with protruding Tube body 35, the screw rod 13 passes through the tube body 35; the effect of the tube body 35 is that when the moving plate 14 moves, the tube body 35 pushes away the branches that may exist in the moving direction, preventing the screw thread from being involved in the gear ring 21 Cooperate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com