Railway wagon body

A railway freight car and car body technology, applied in railway car body, railway car body parts, freight car and other directions, can solve problems such as low production efficiency, mismatch between side wall deflection and chassis deflection, etc., to improve impact resistance, improve The effect of material utilization and reducing assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

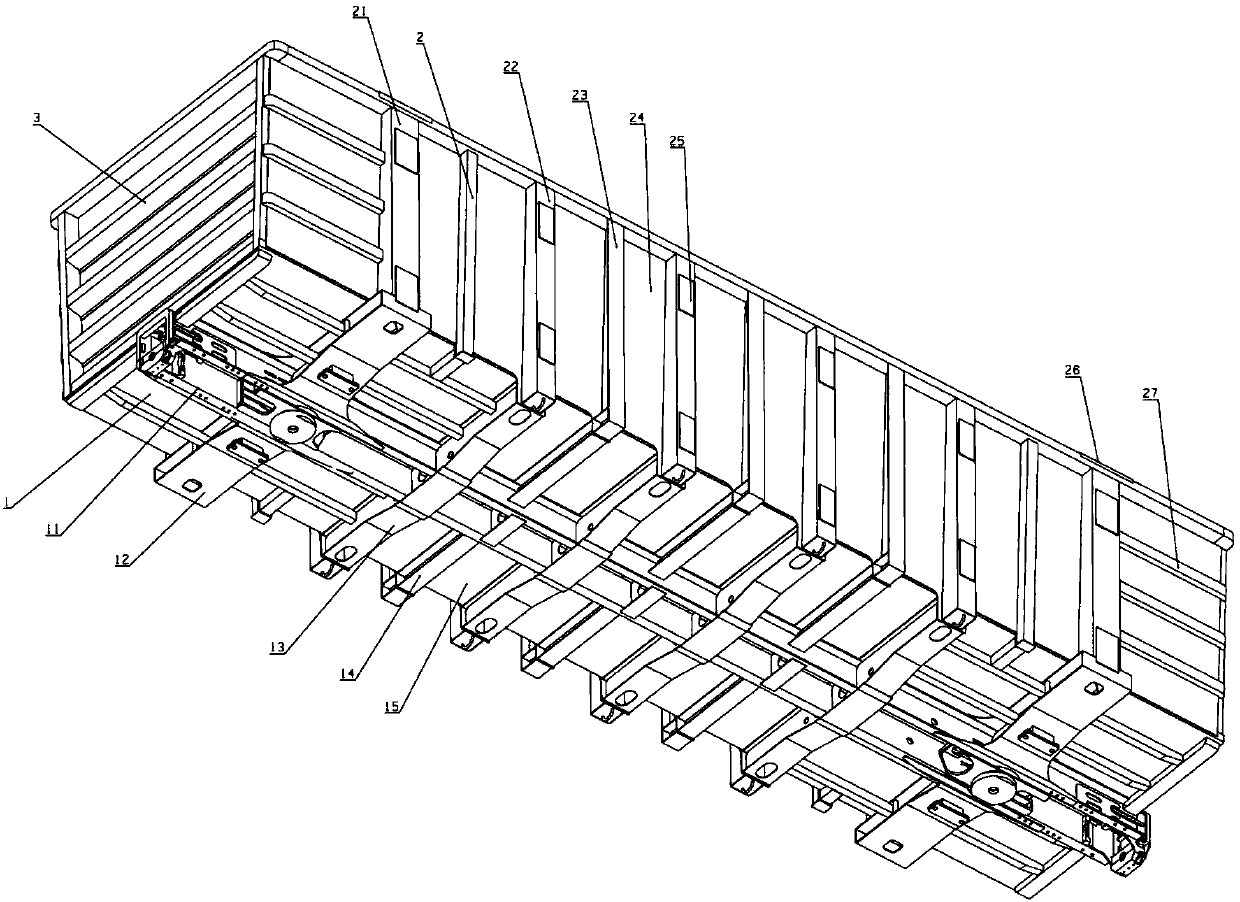

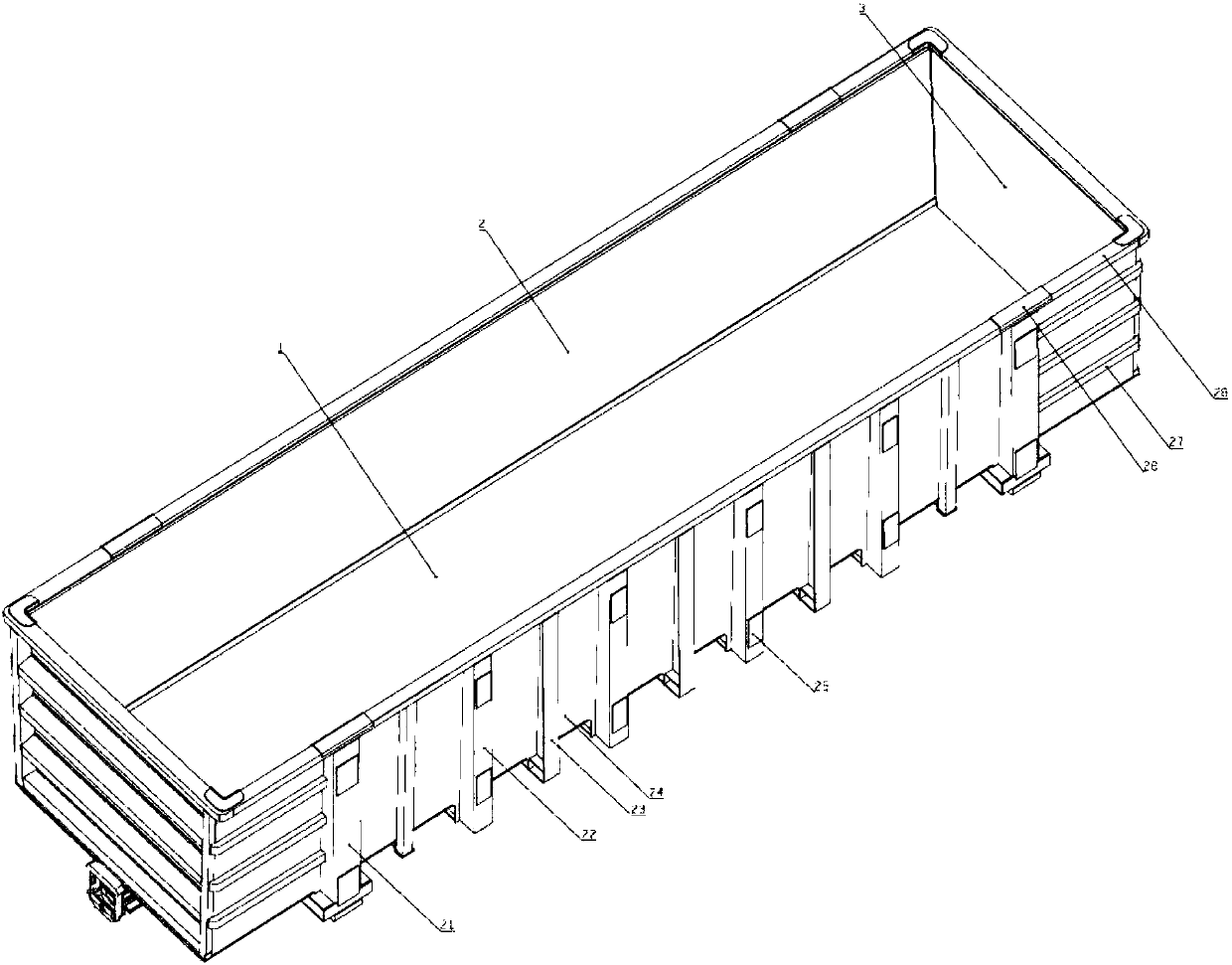

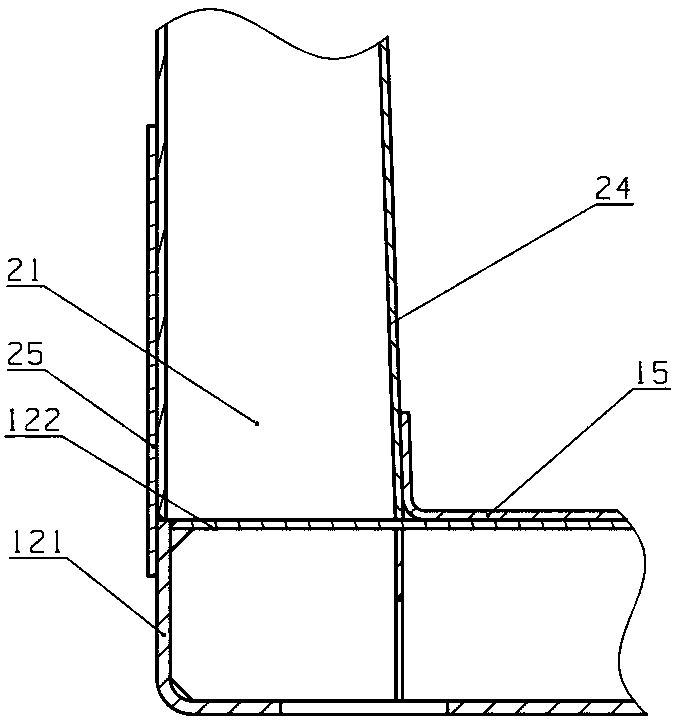

[0036] combine Figure 1 to Figure 5 .

[0037] The invention provides a railway wagon body with large volume, smooth interior, high unloading rate, high unloading efficiency and reinforced structure.

[0038] The car body is an integral load-bearing car body, all-steel welded structure, and a skeleton structure composed of an underframe 1, an end wall 3, and a side wall 2. Among them, the underframe 1 adopts a structure without side beams, which is composed of a welding center beam 11, a variable cross-section box-shaped corbel 12, a variable cross-section box-shaped cross-beam 13 with an enlarged cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com